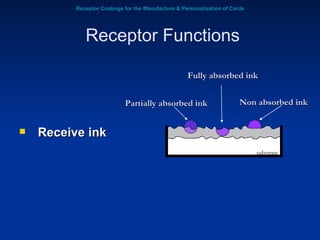

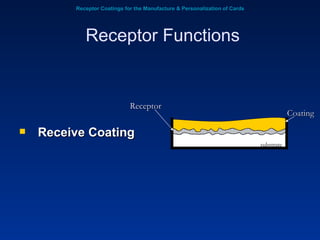

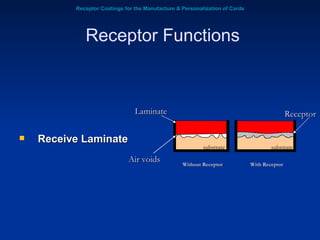

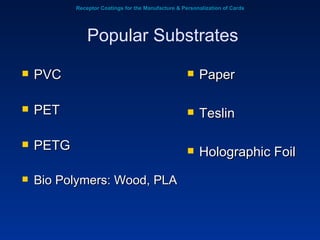

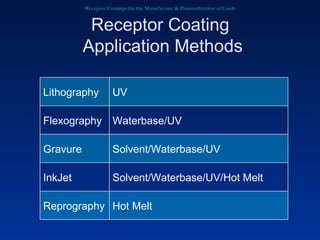

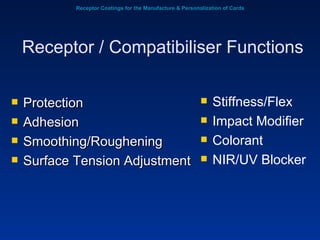

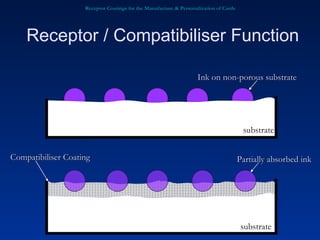

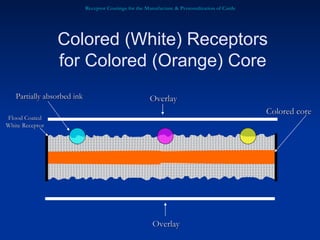

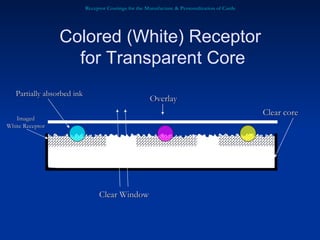

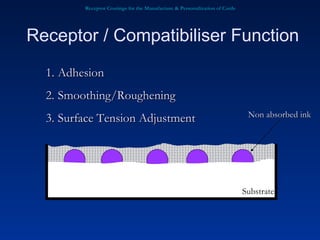

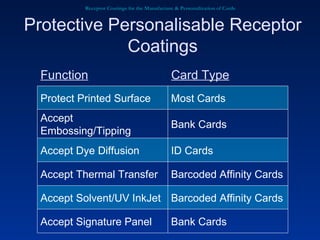

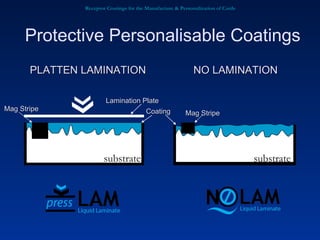

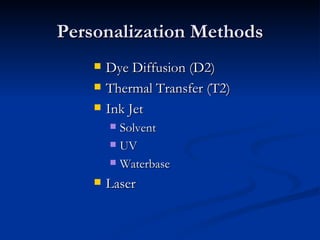

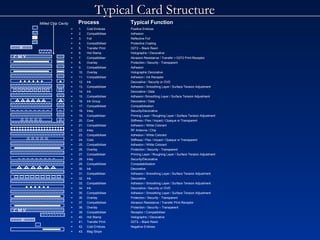

The document discusses receptor coatings used for card manufacturing and personalization. It describes how receptor coatings receive ink and laminates, and their functions like adhesion, protection, and making surfaces compatible with printing and coating methods. It also lists common substrate materials, coating application techniques, and how receptor coatings are used for different card types and personalization methods.

![Contact Information Josef Feldman Functional Materials Inc. 100 Wells Ave. Congers, NY 10920, USA +1-845-753-6000 – Office +1-845-753-6222 – Fax [email_address] www.FunctionalMaterials.com](https://image.slidesharecdn.com/2011setuppresentationv2diffcolourwhiteprintprintv4-110415094132-phpapp01/85/2011-setup-presentation_v2_diff_colour_white_printprint_v4-20-320.jpg)