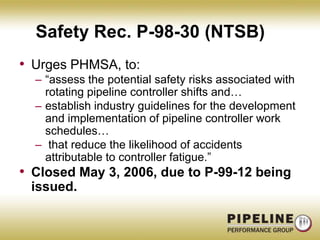

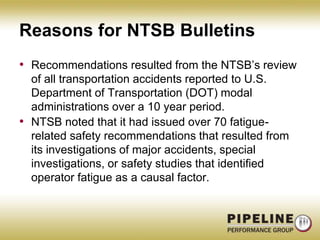

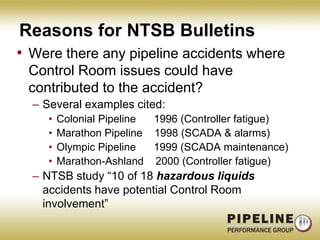

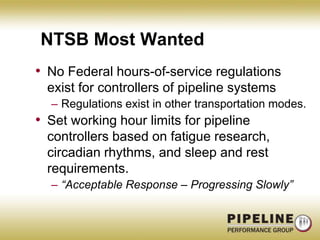

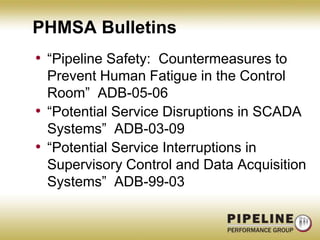

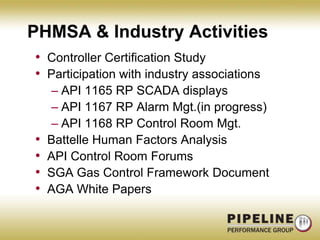

The document provides background on the development of a new control room management rule by the Pipeline and Hazardous Materials Safety Administration (PHMSA). It summarizes National Transportation Safety Board recommendations that prompted the rule relating to control room operations, fatigue, alarms, and training. The final rule requires pipeline operators to implement a control room management plan to define roles and responsibilities, provide necessary information to controllers, manage alarms and fatigue, and review incidents and operating experience. It aims to formalize best practices for control room oversight, but gives operators flexibility in how to comply with more general requirements.