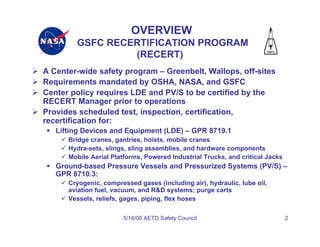

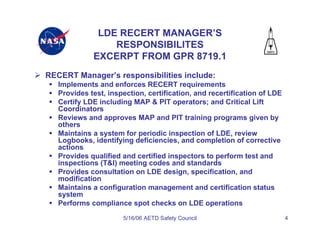

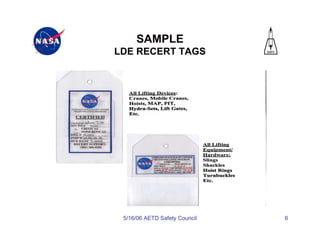

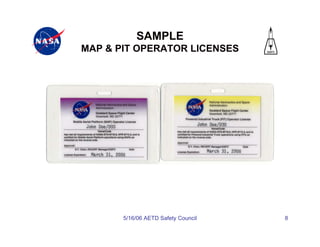

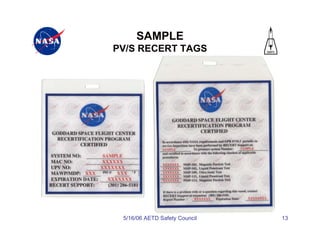

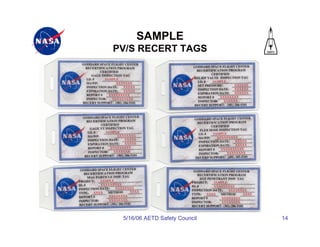

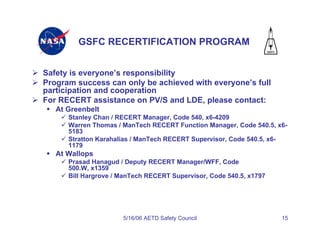

The document summarizes the Goddard Space Flight Center (GSFC) Recertification Program (RECERT) which provides scheduled testing, inspection, certification and recertification of lifting devices and equipment (LDE) and ground-based pressure vessels and pressurized systems (PV/S). It outlines the roles and responsibilities of the RECERT Manager and equipment owners to ensure safety compliance. Key aspects of the program include certification of equipment and operators, conducting inspections, and maintaining certification records and tags.