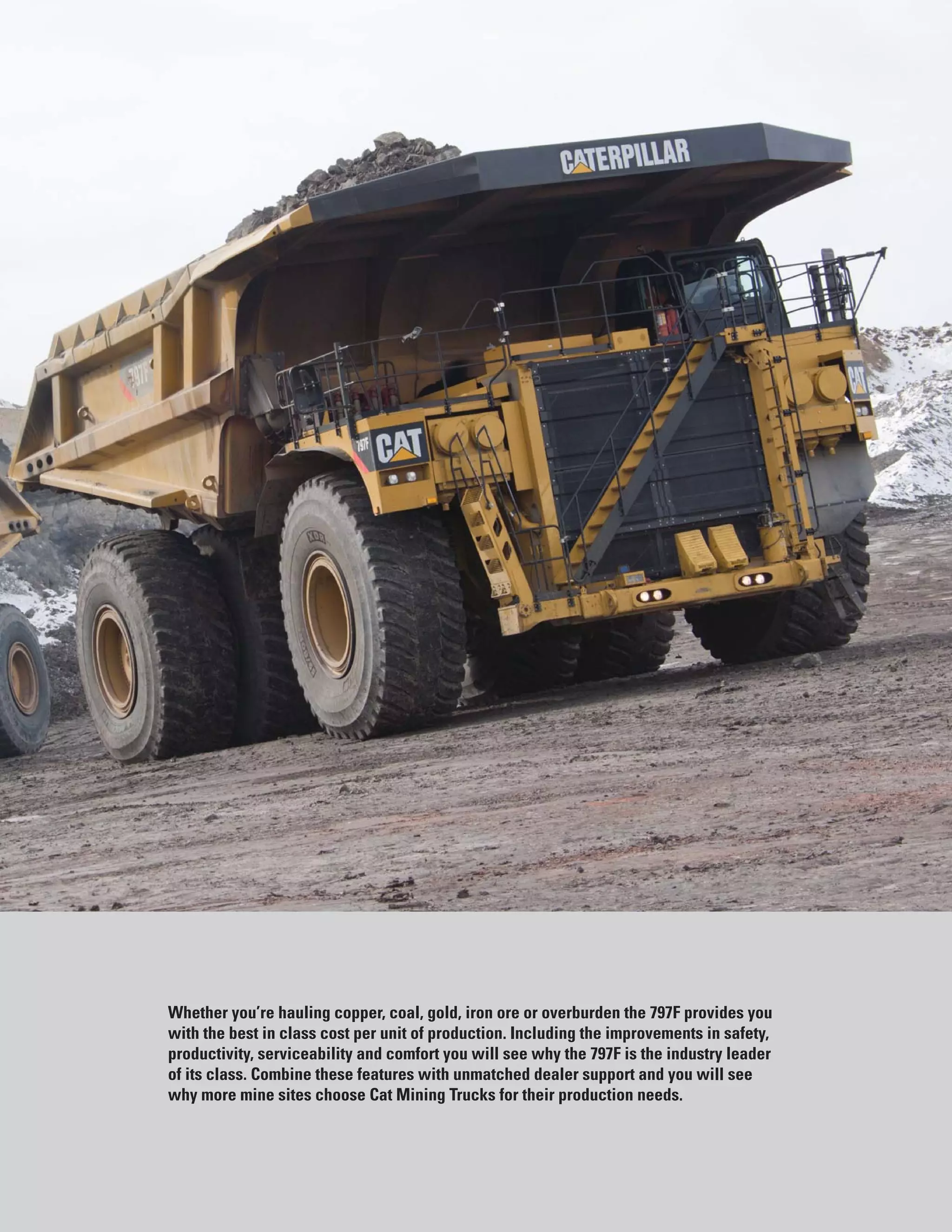

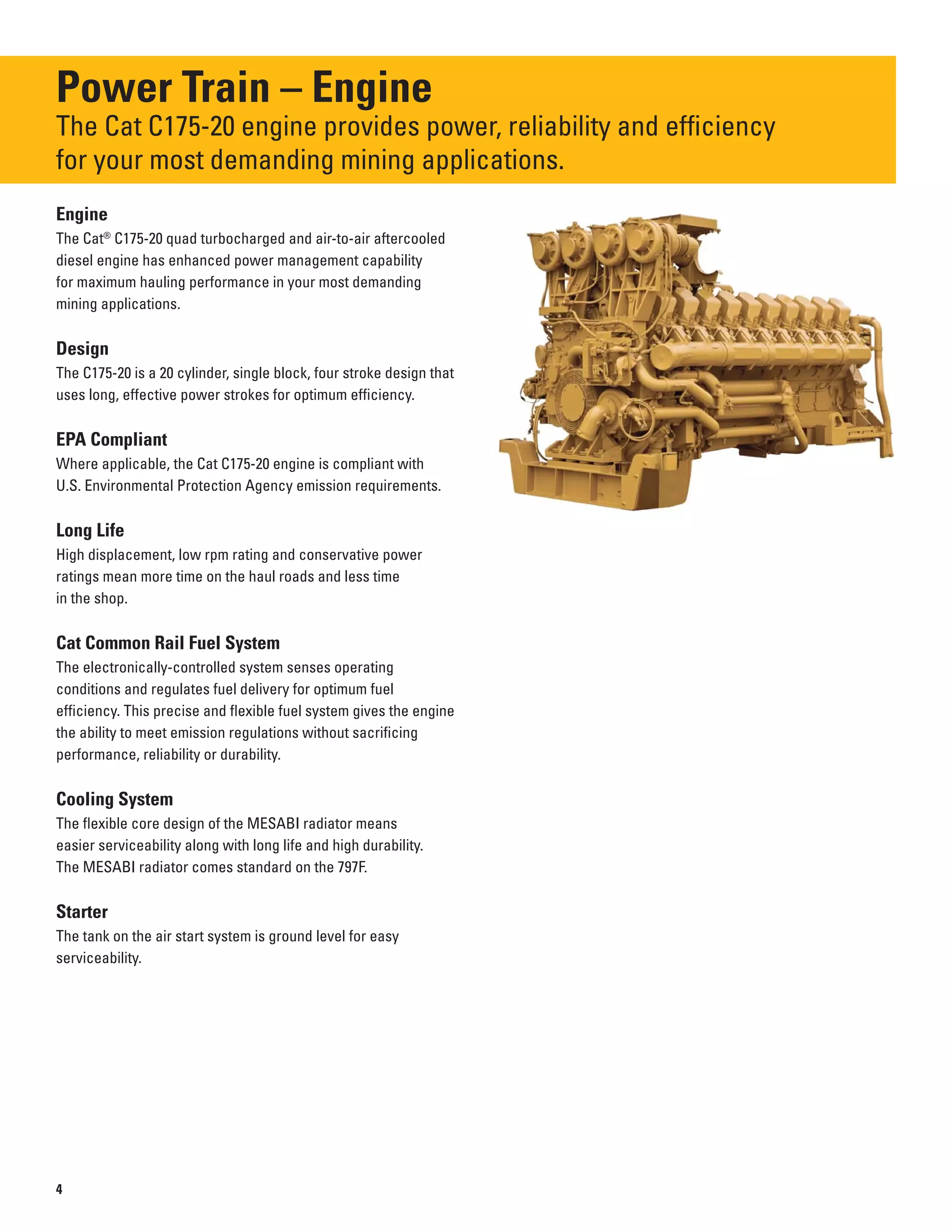

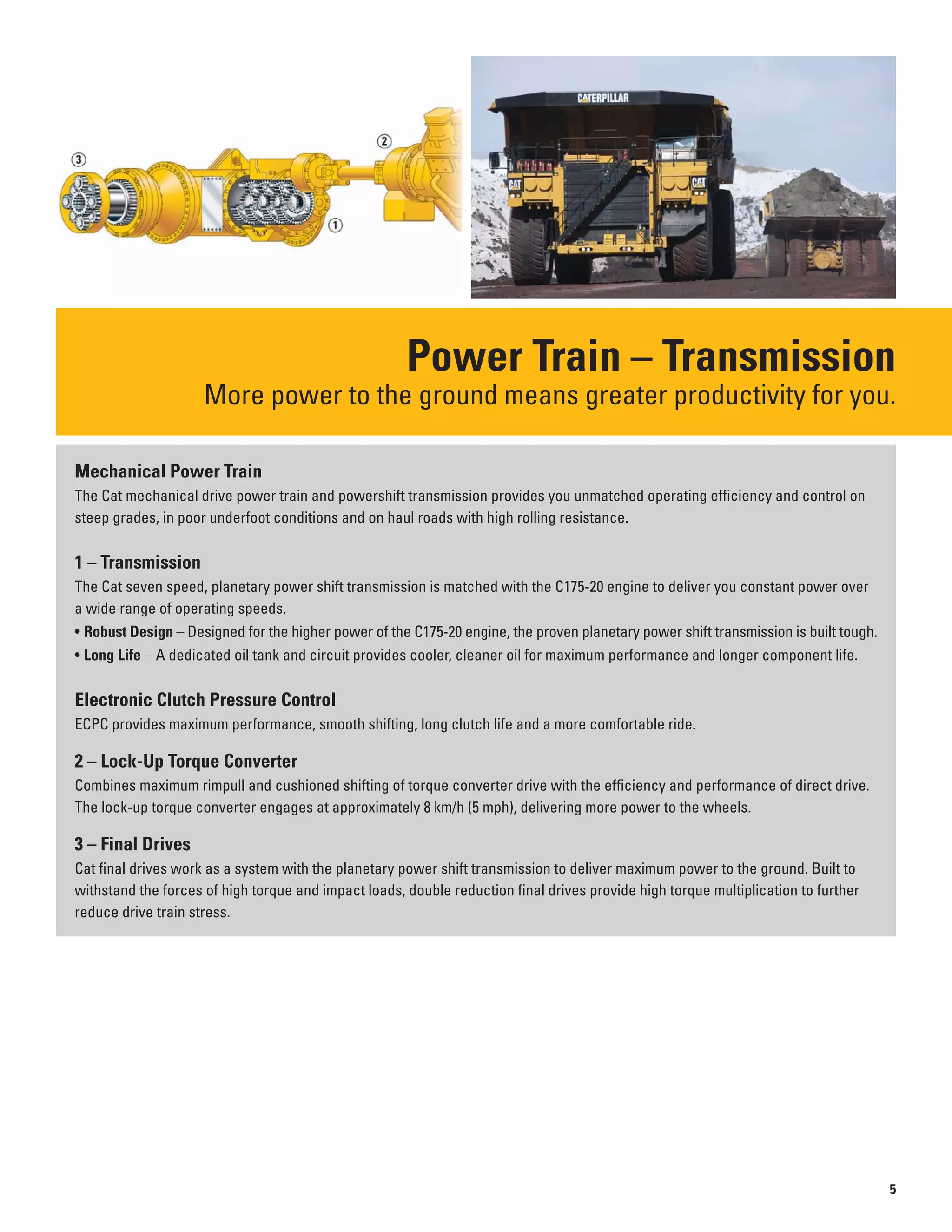

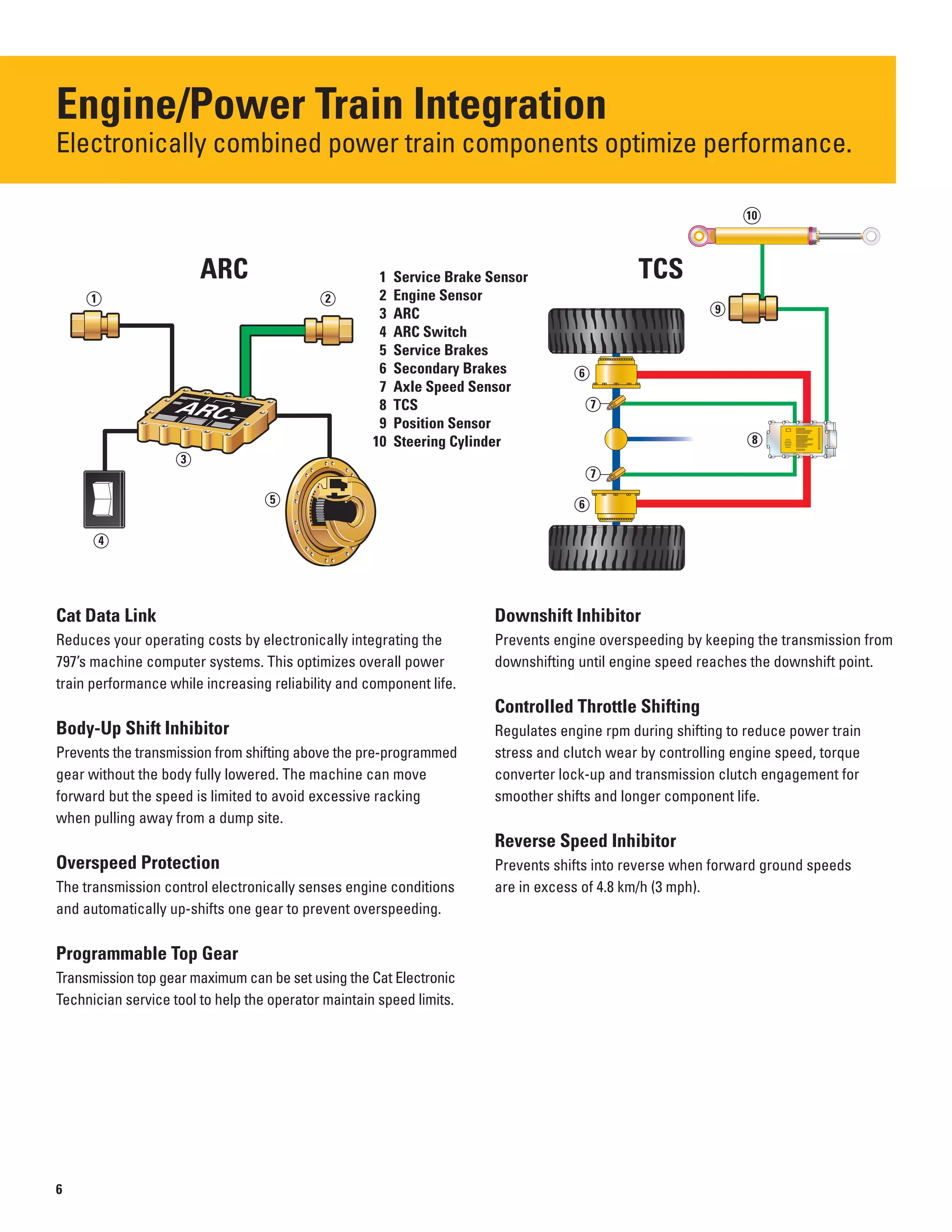

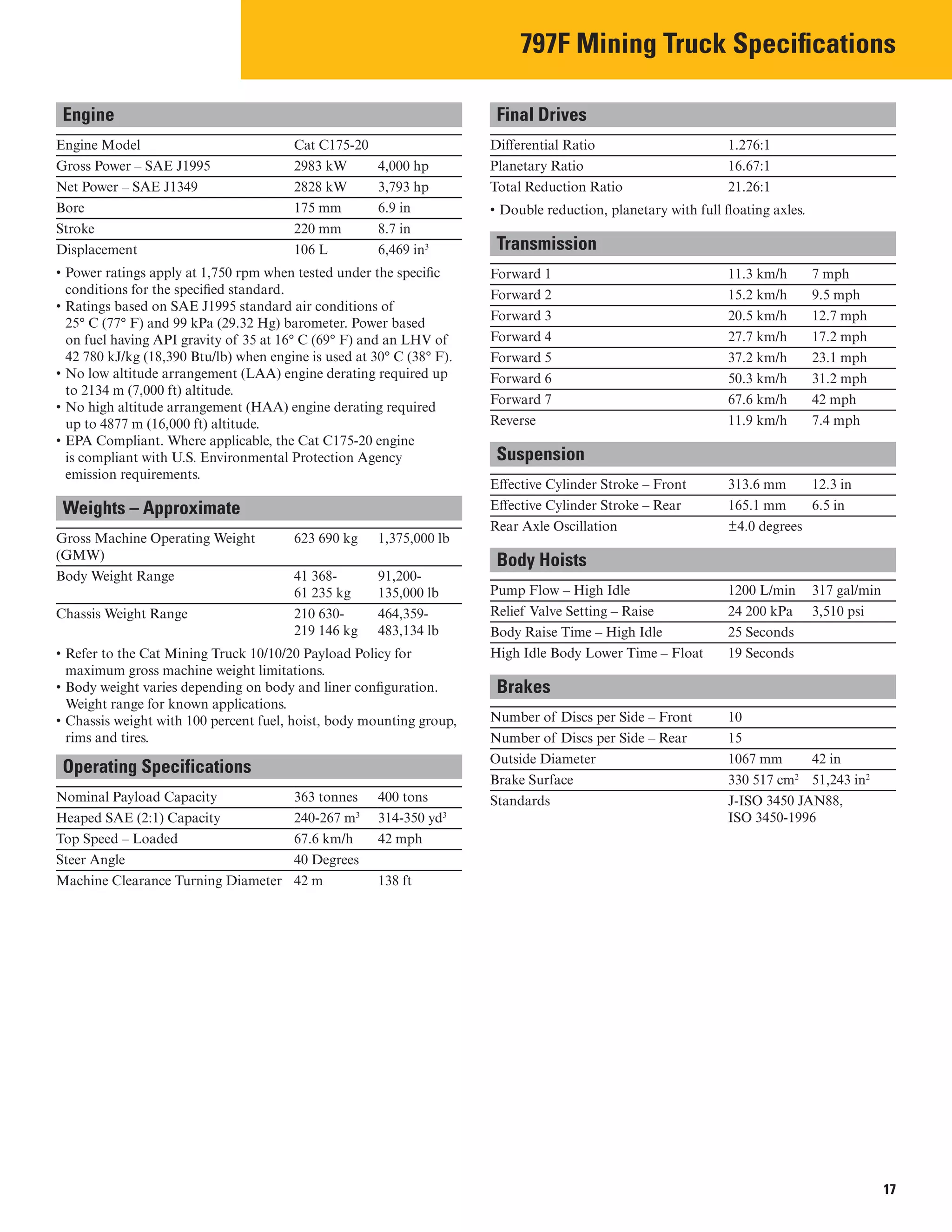

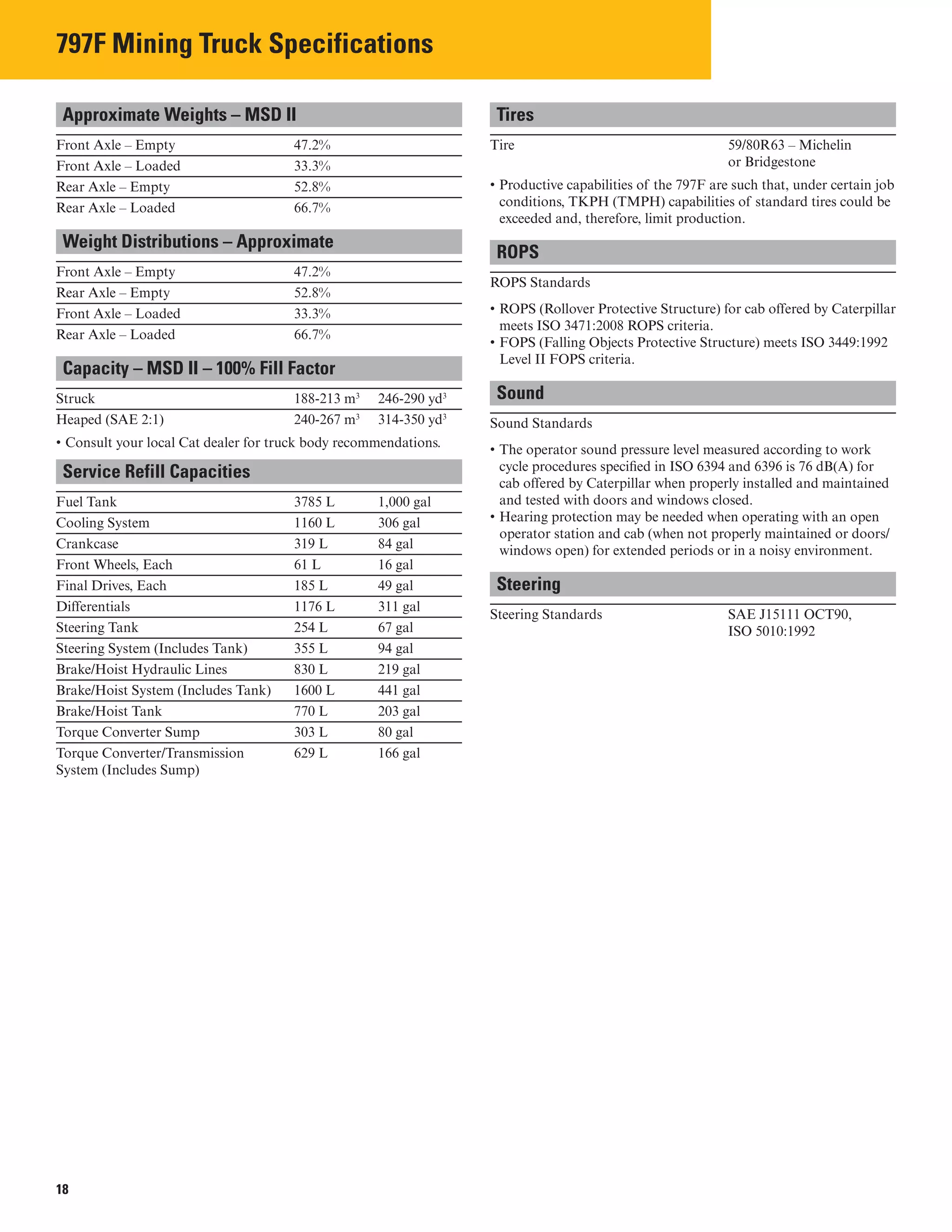

The 797F mining truck has a C175-20 engine producing 2983 kW of gross power. It has a gross machine weight of 623,690 kg and a nominal payload capacity of 363 tonnes. The 797F features a robust powertrain, braking, and suspension system to provide exceptional performance and reliability in mining applications. It offers various options for bodies, monitoring, and other systems to optimize efficiency.