This document discusses garment marker making. It defines marker making as drawing pattern pieces on thin marker paper to minimize fabric waste when cutting. There are two main methods: manual and computerized.

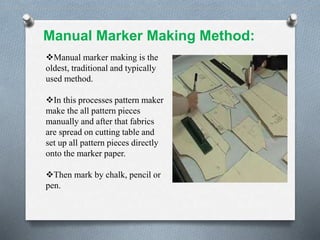

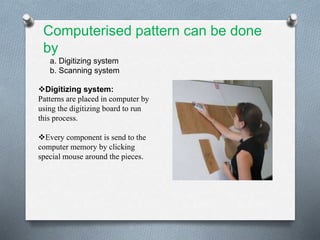

Manual marker making is the oldest method where a pattern maker draws pieces directly onto marker paper laid over fabric. Computerized uses CAD systems to digitally place minimized patterns and automatically generate markers, allowing for higher efficiency but requiring more investment and skilled labor. The document outlines the process, advantages, and types of each marker making method.