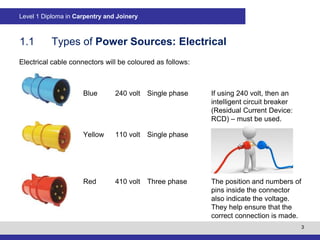

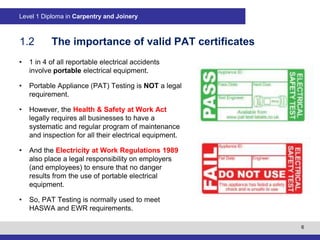

The document outlines safety, maintenance, and storage practices for portable power tools as part of a Level 1 Diploma in Carpentry and Joinery. It emphasizes the importance of valid PAT certificates, proper personal protective equipment (PPE), and adherence to current legislation to mitigate risks associated with power tools. Additionally, it highlights the potential hazards and necessary precautions to ensure safe operation and maintenance of these tools.