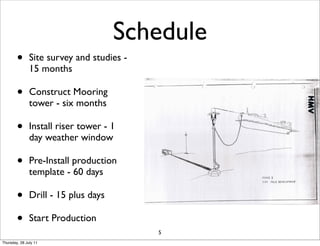

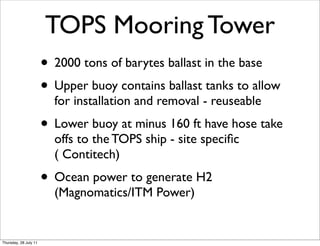

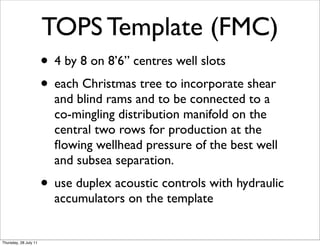

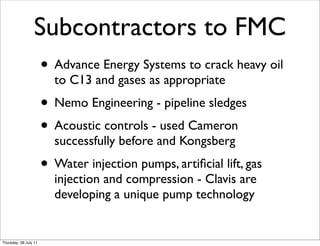

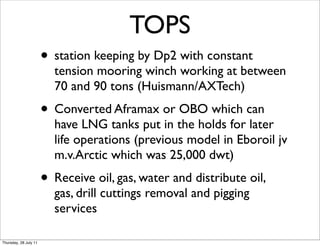

This document describes the TOPS (TOPS Offshore Production Systems) concept for offshore oil and gas production. TOPS aims to eliminate conventional rigs and platforms by using a ship-based system for continuous exploration, production, processing, and transport. The system would include a mooring tower, subsea well template, and a converted tanker ship equipped for drilling, production, and initial processing directly at the offshore location. The goal is to significantly reduce costs and risks compared to traditional offshore infrastructure.