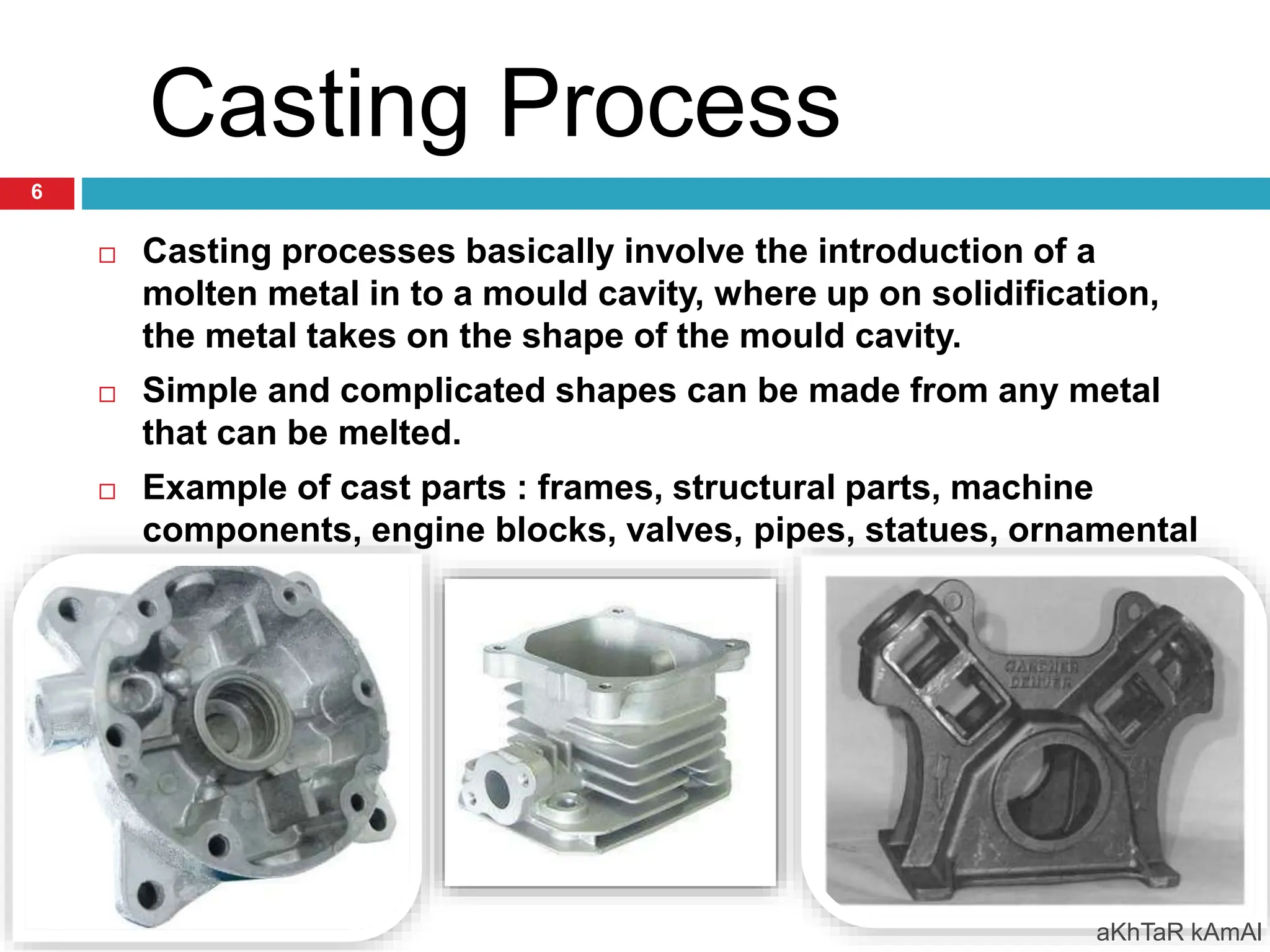

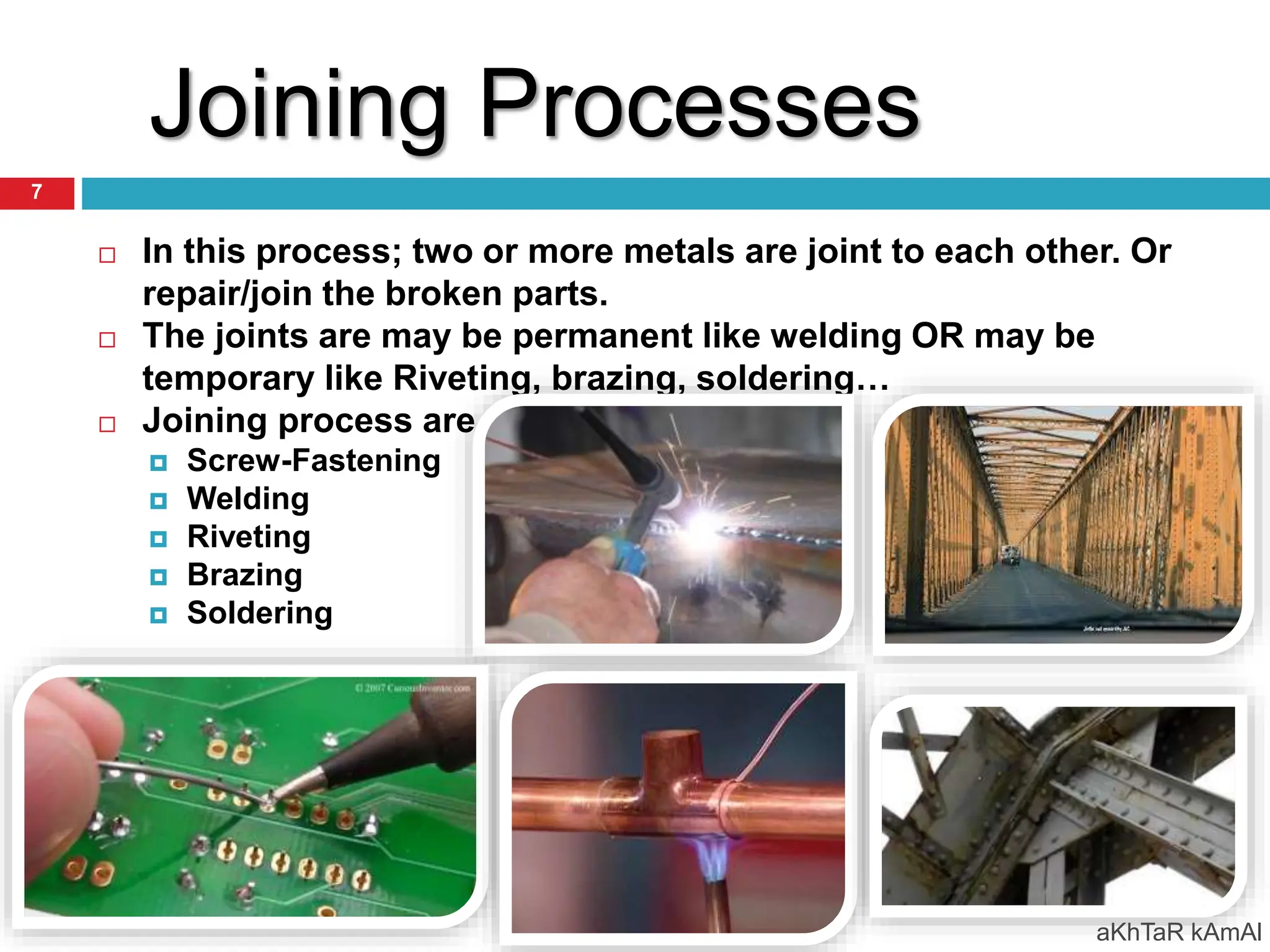

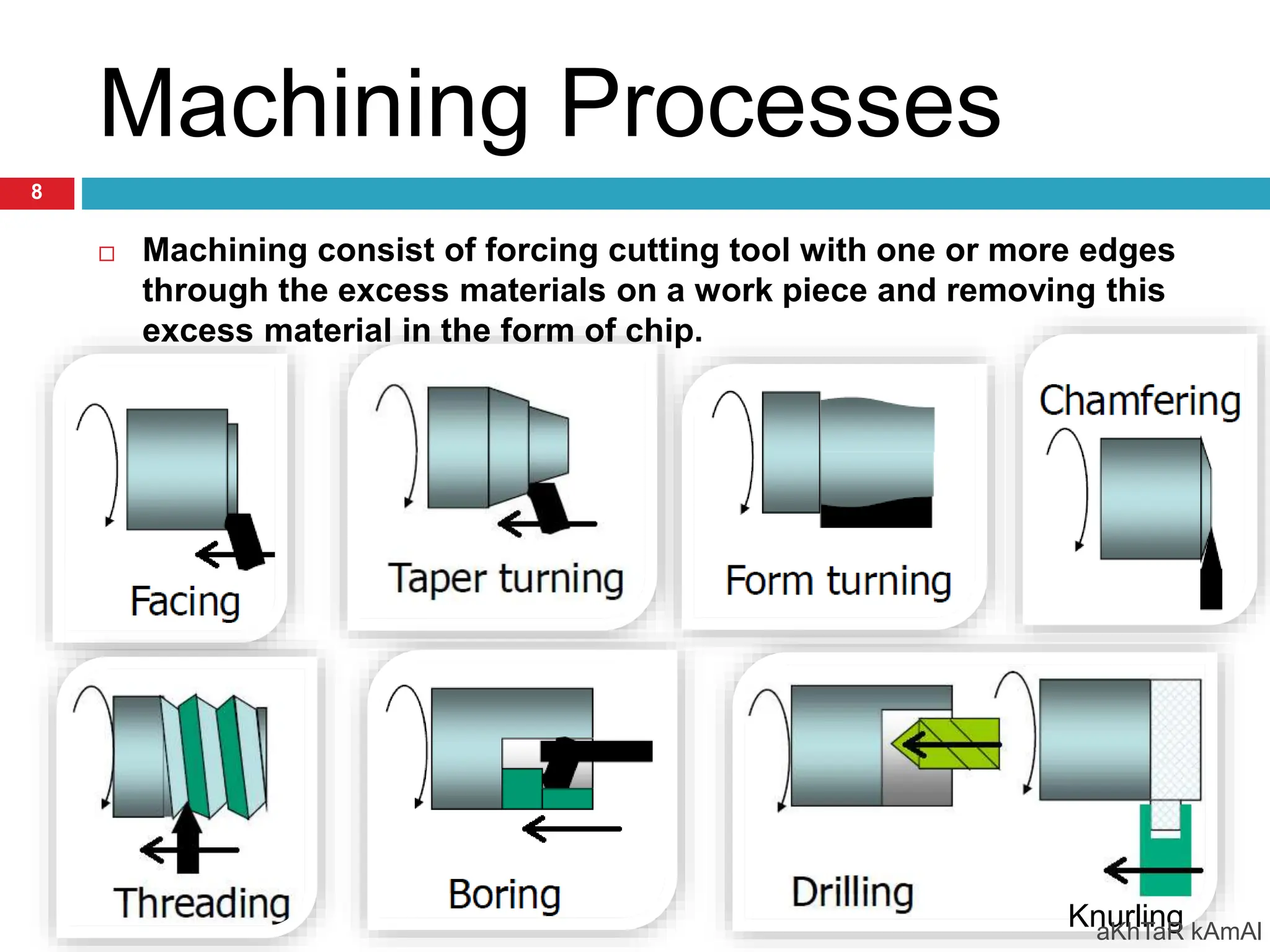

This document classifies manufacturing processes based on their function and level of production. It discusses several key classifications: processes that change physical properties like heat treating; casting processes that introduce molten metal into molds; joining processes that connect two materials like welding; machining processes that cut excess material like turning; and surface finishing processes that smooth surfaces like polishing. The document provides examples within each classification and briefly outlines some of the main processes within each category to transform, shape, join, cut, or finish workpieces in manufacturing.