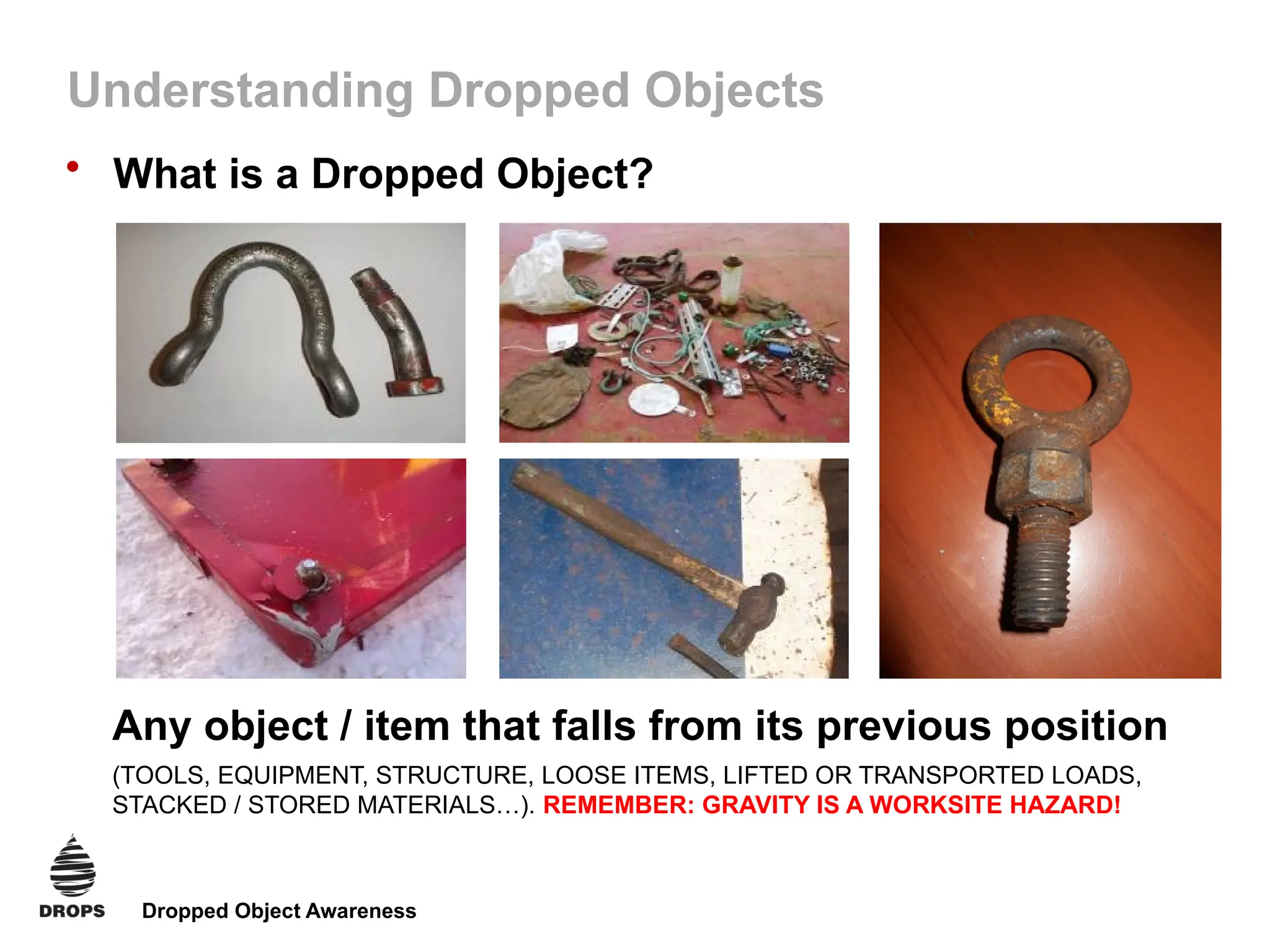

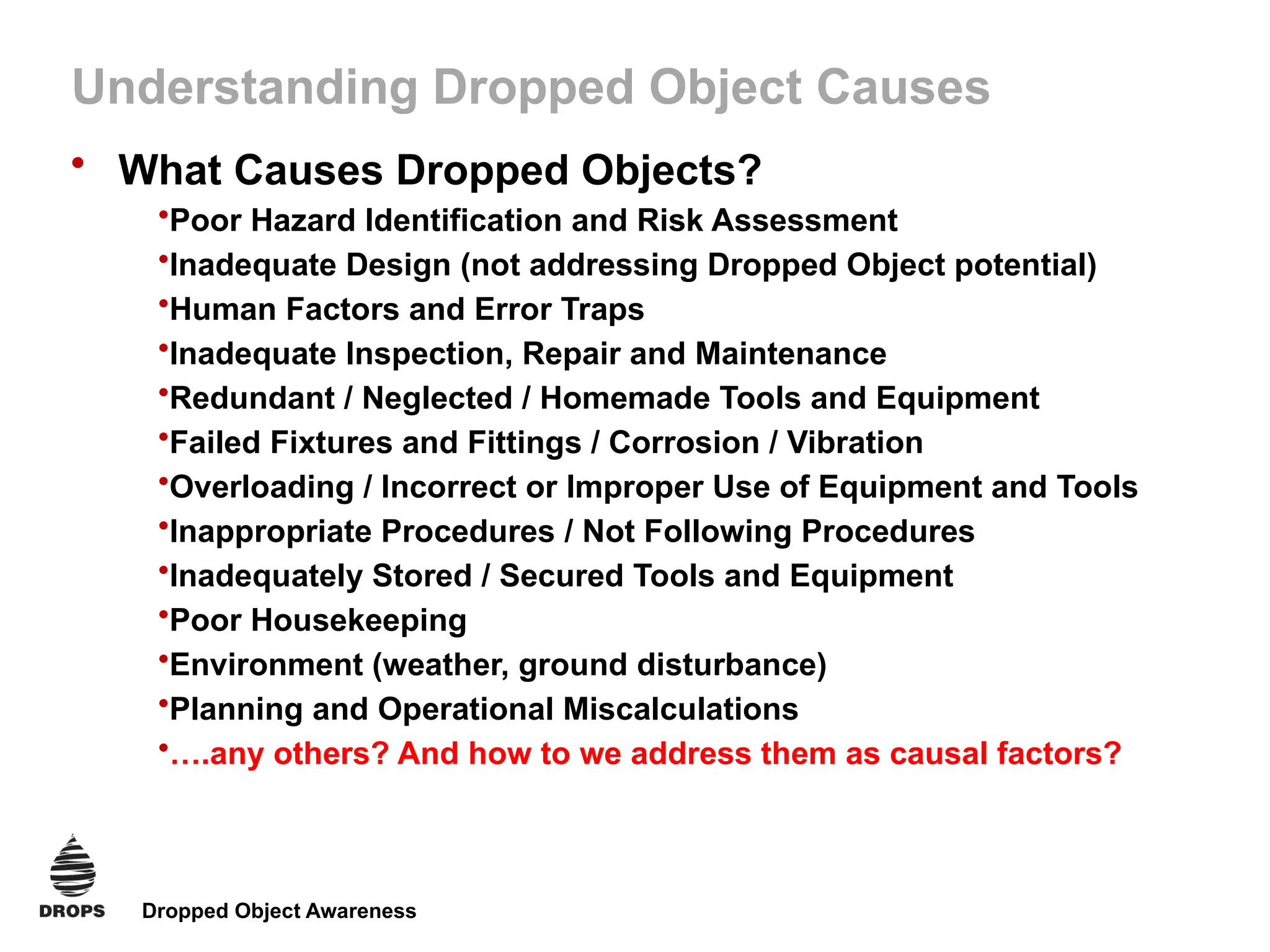

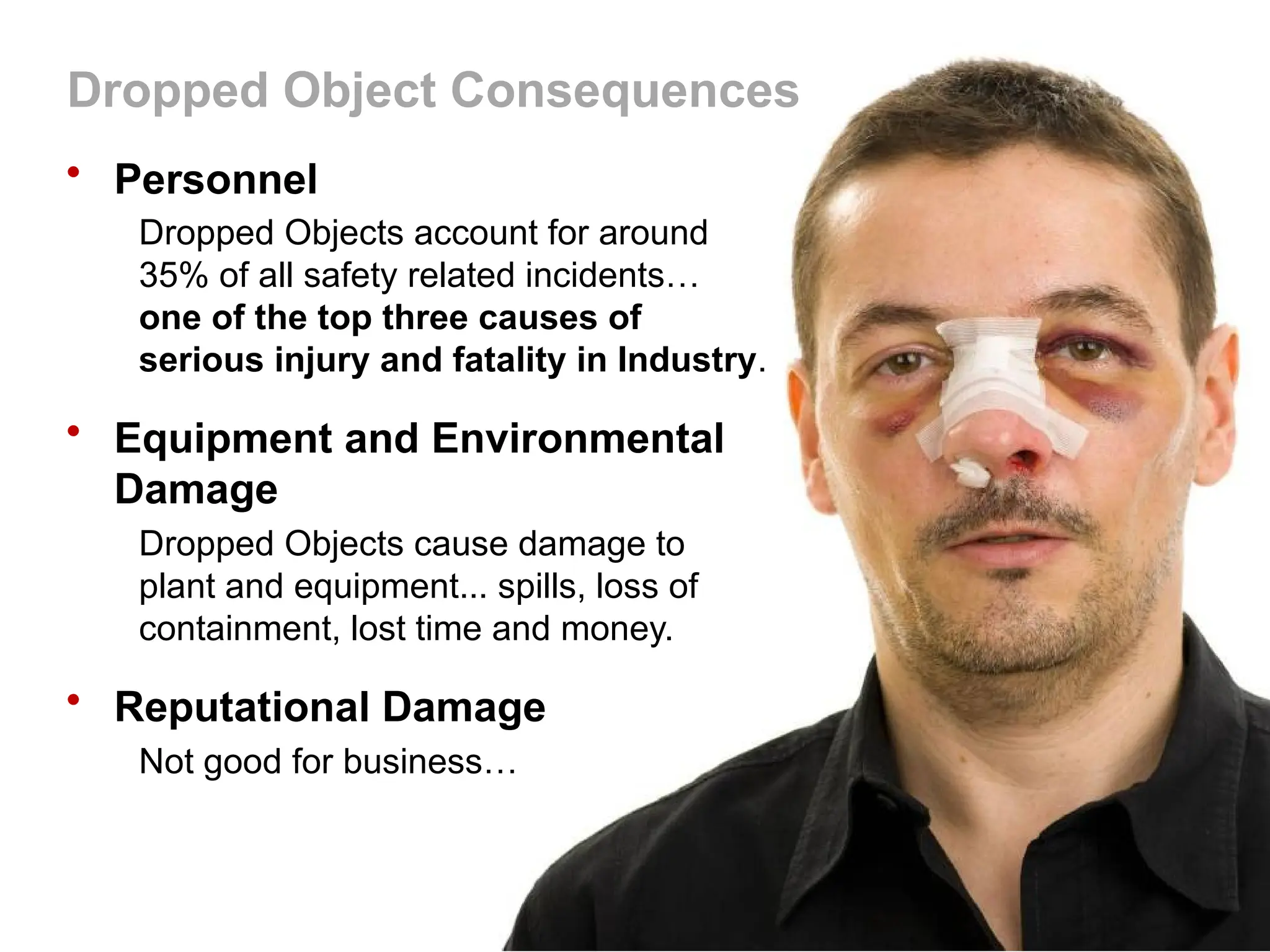

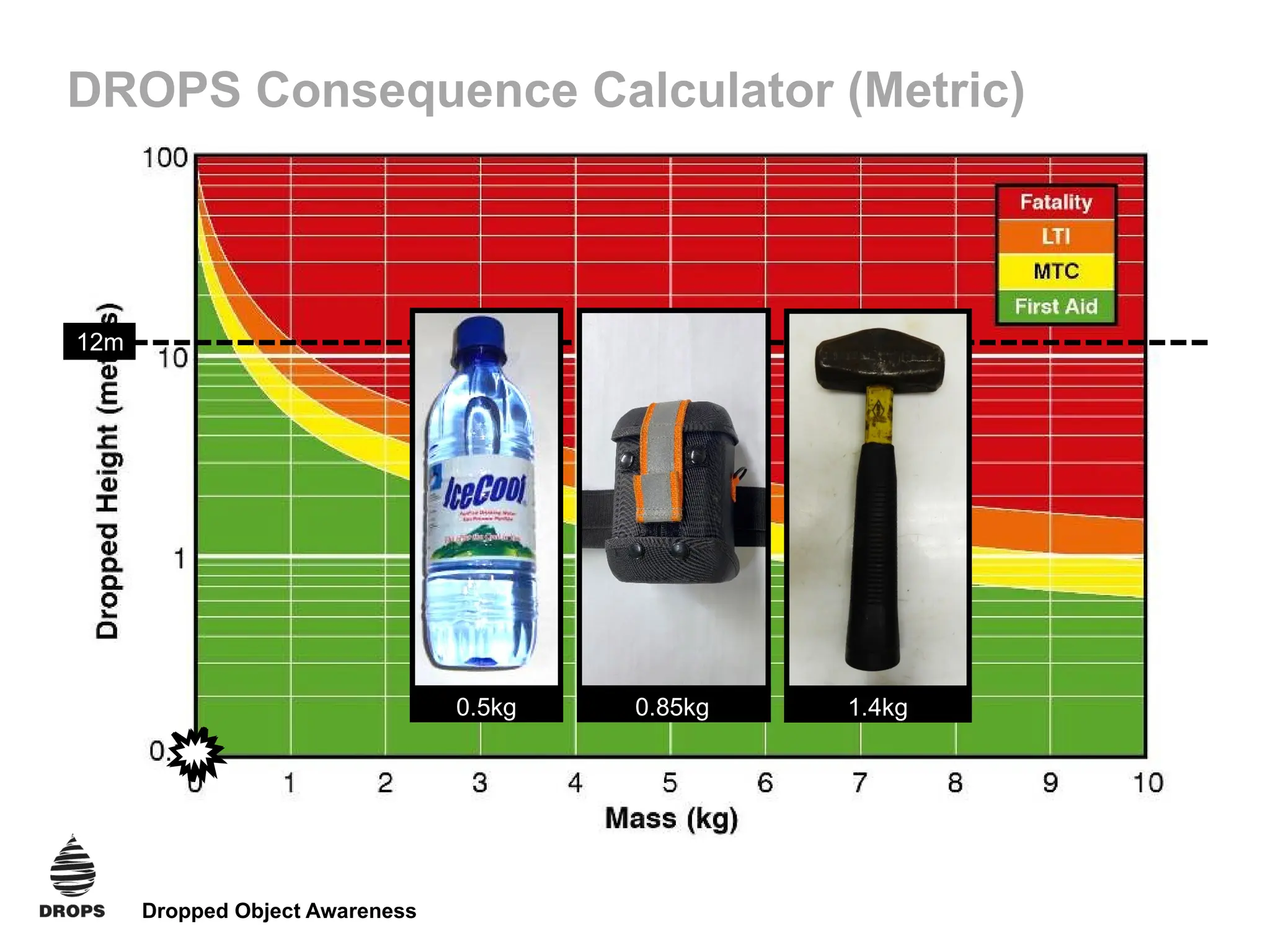

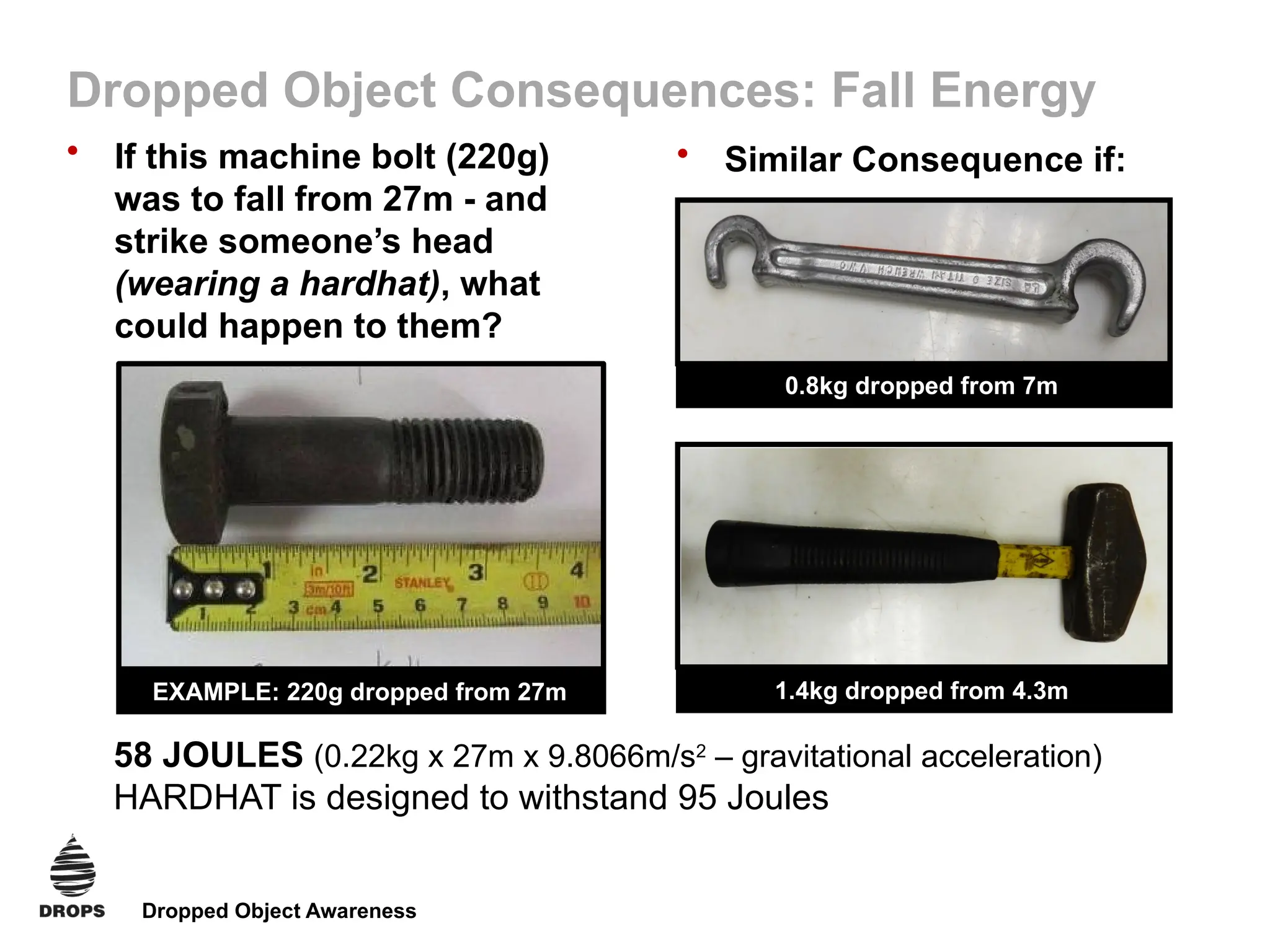

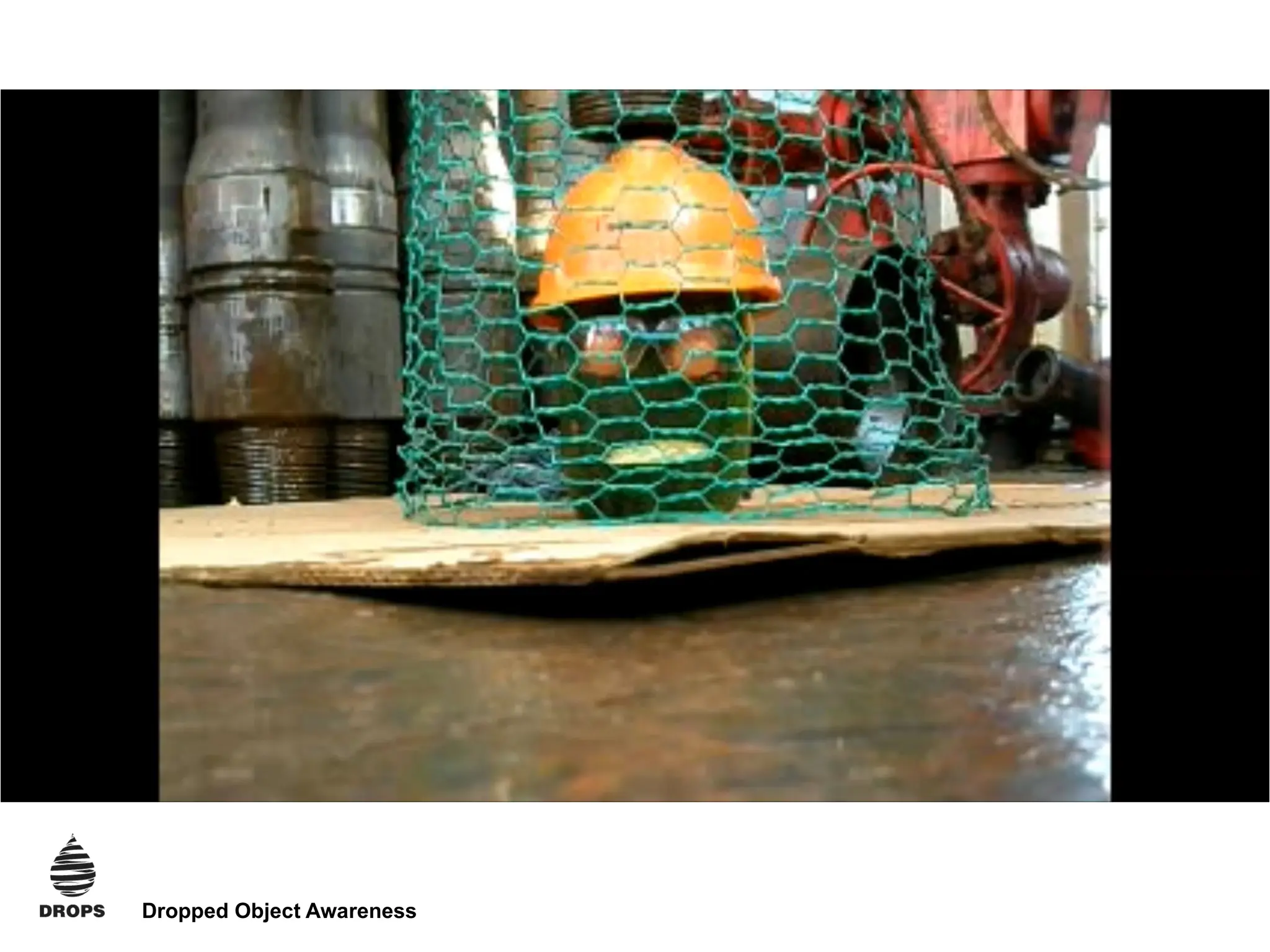

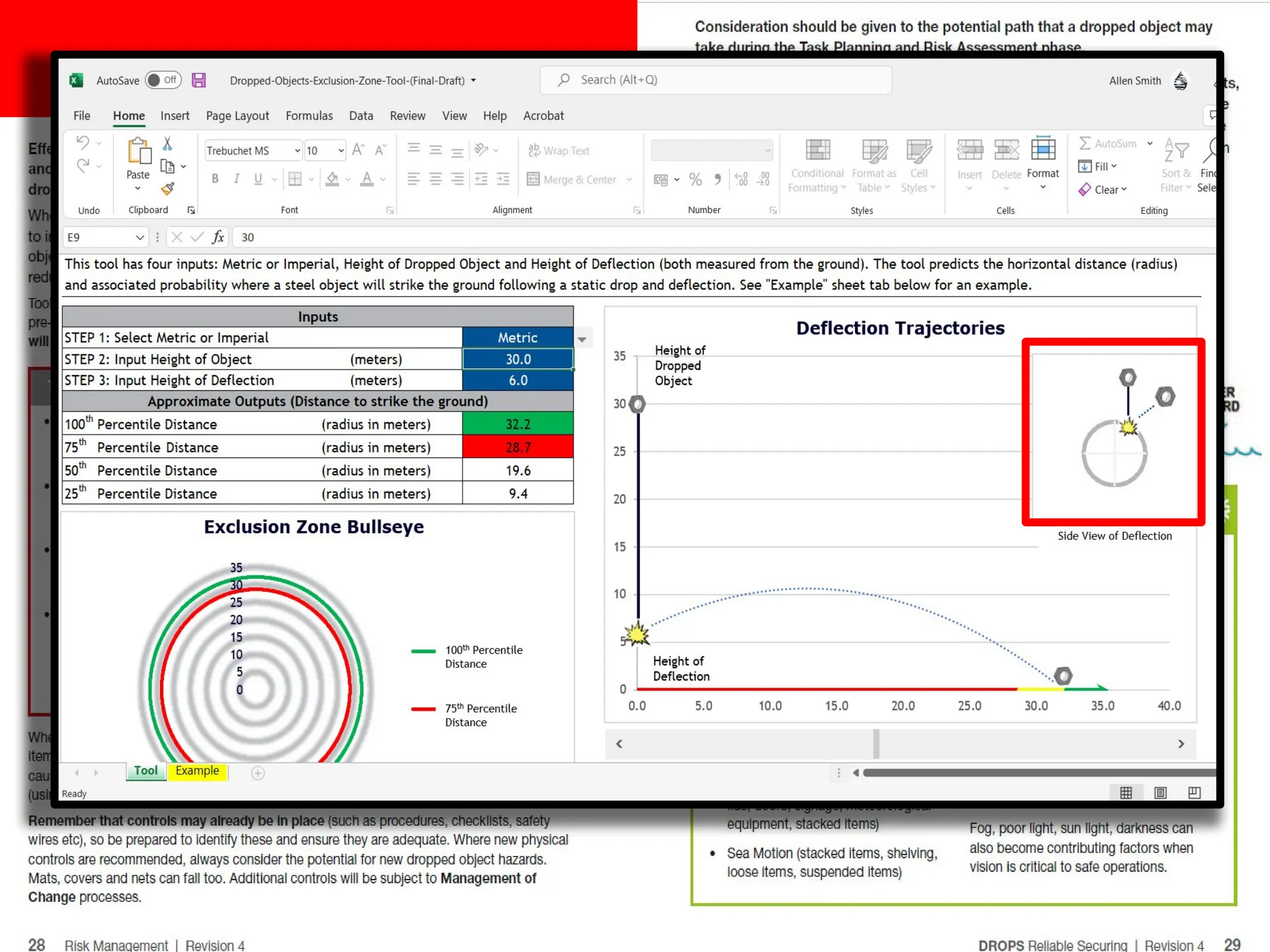

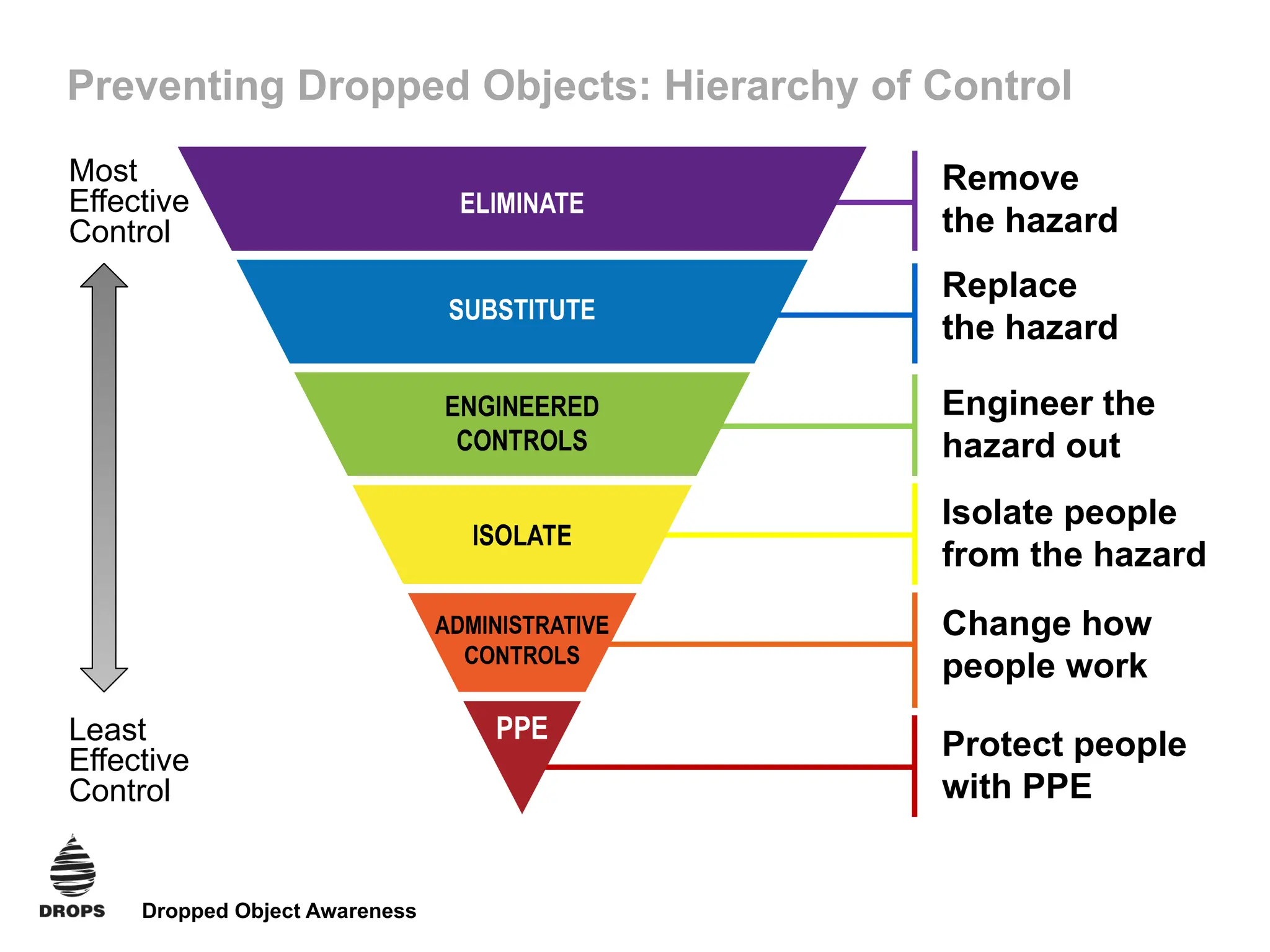

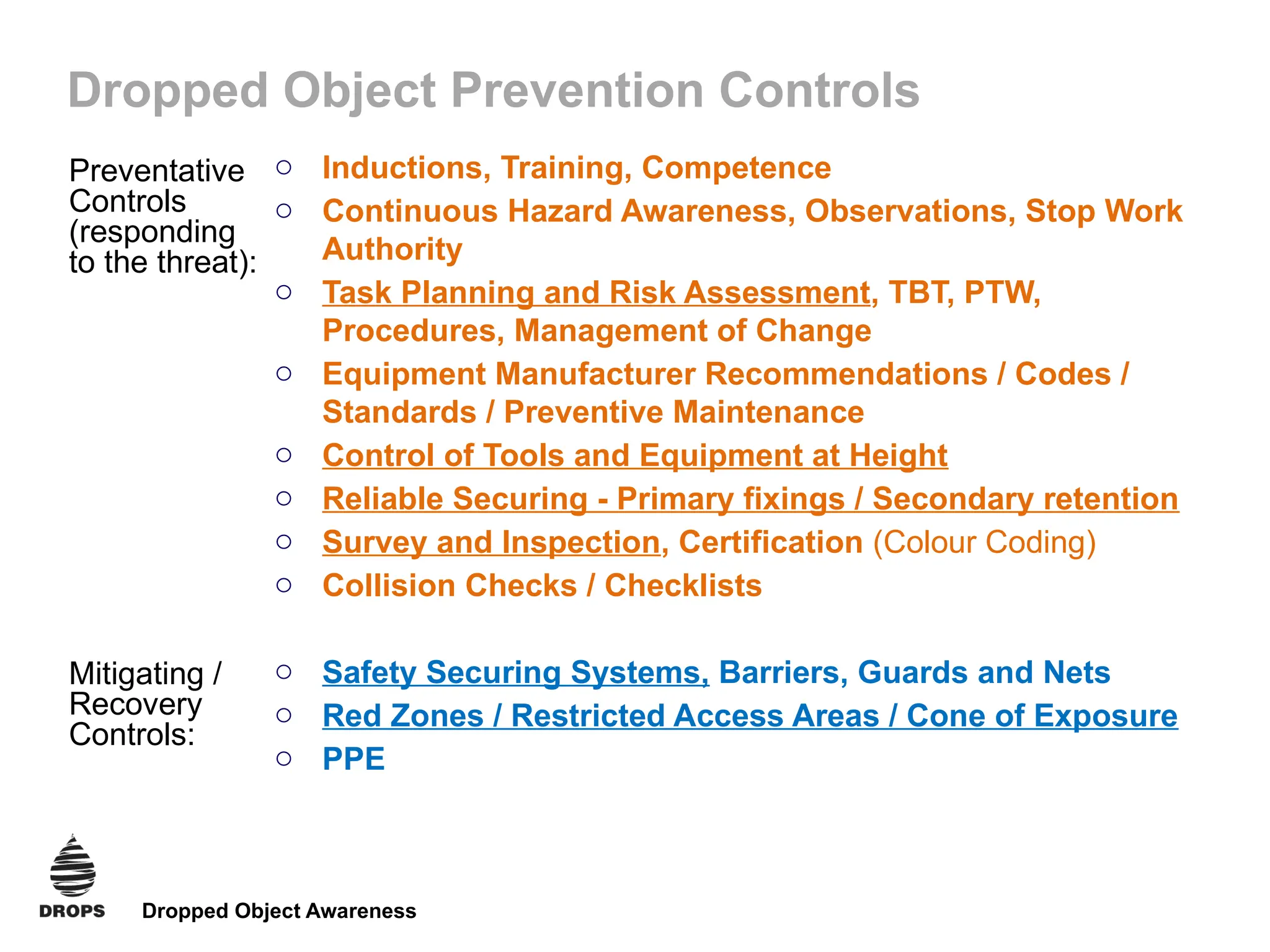

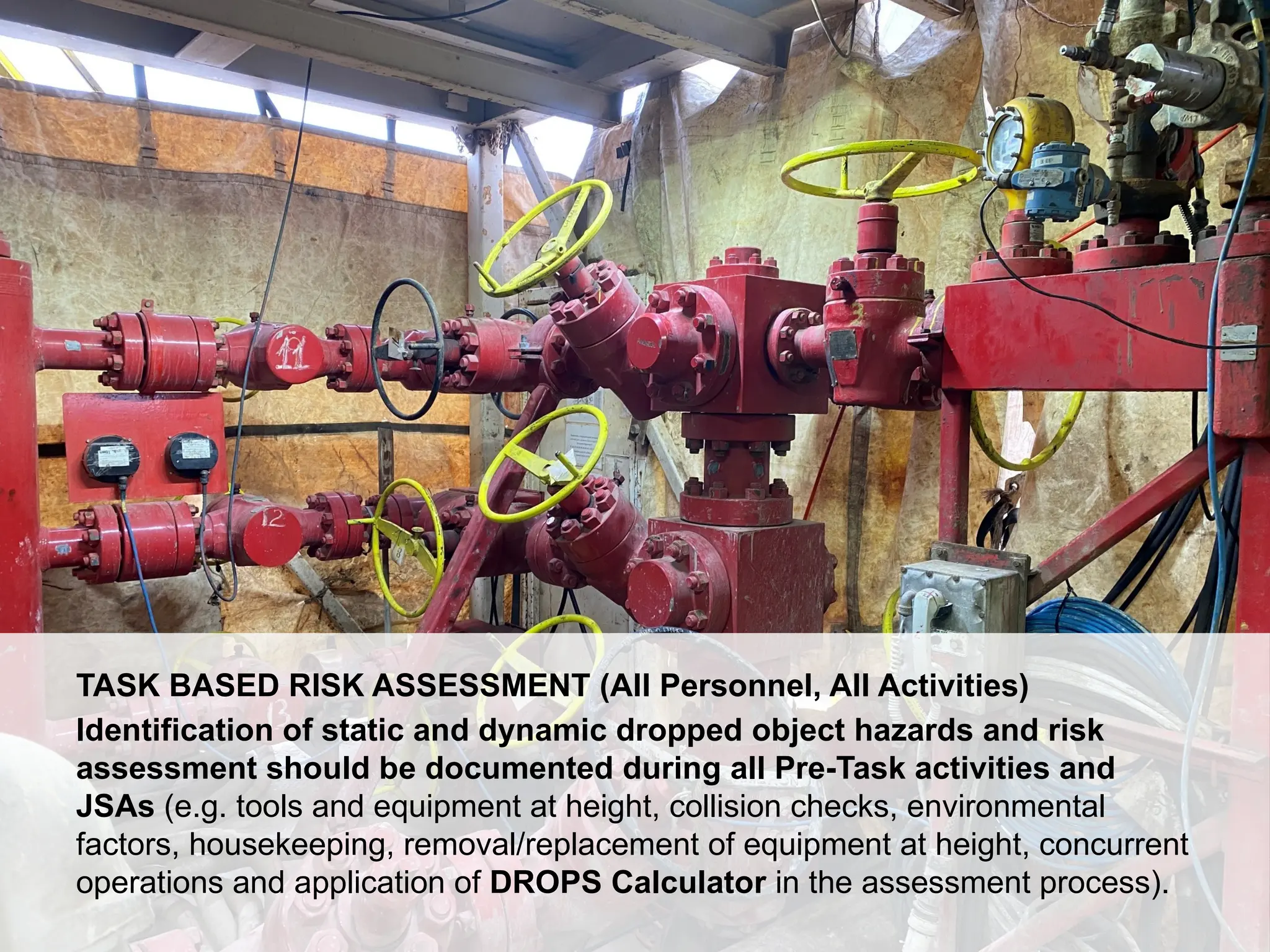

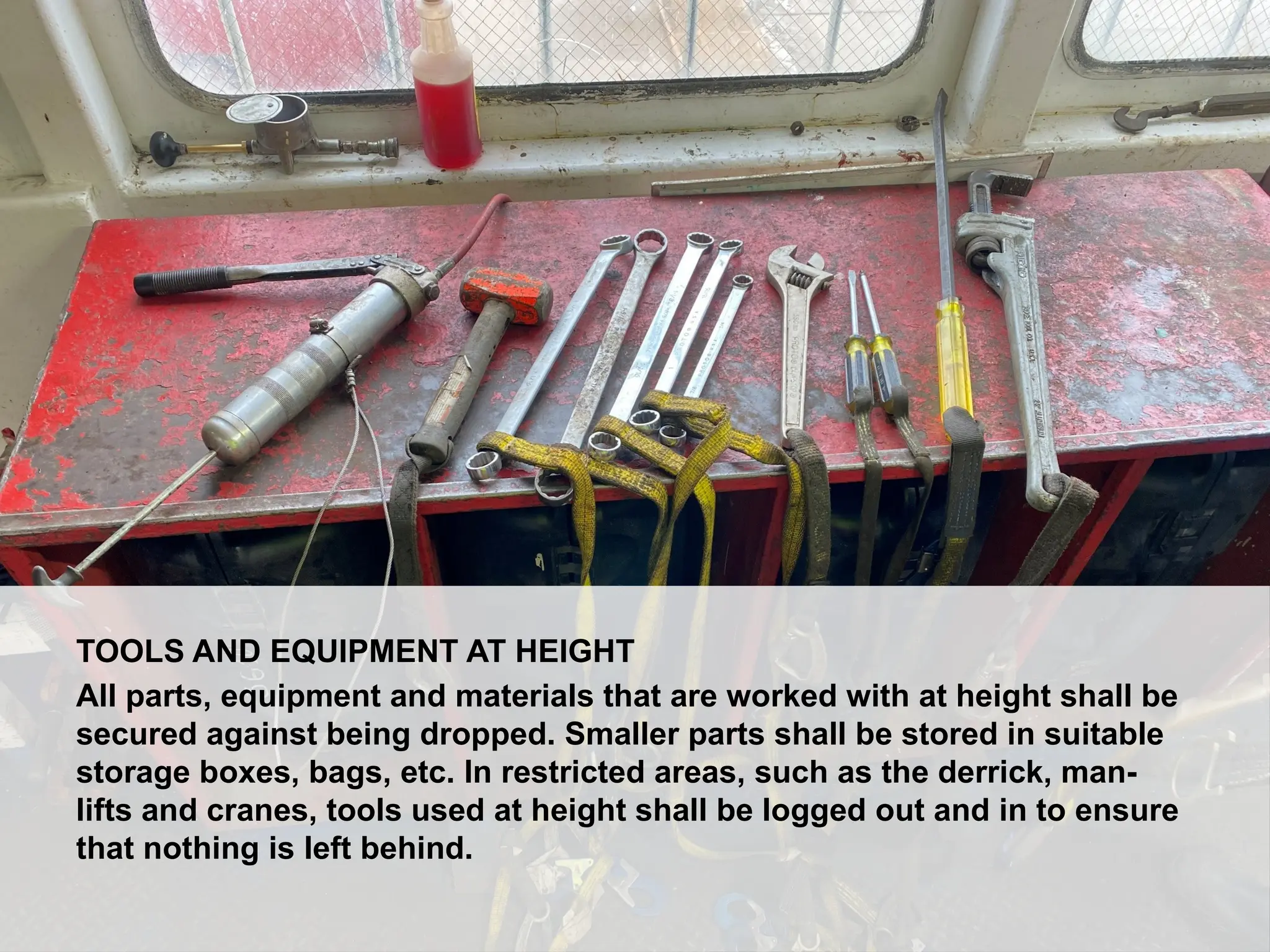

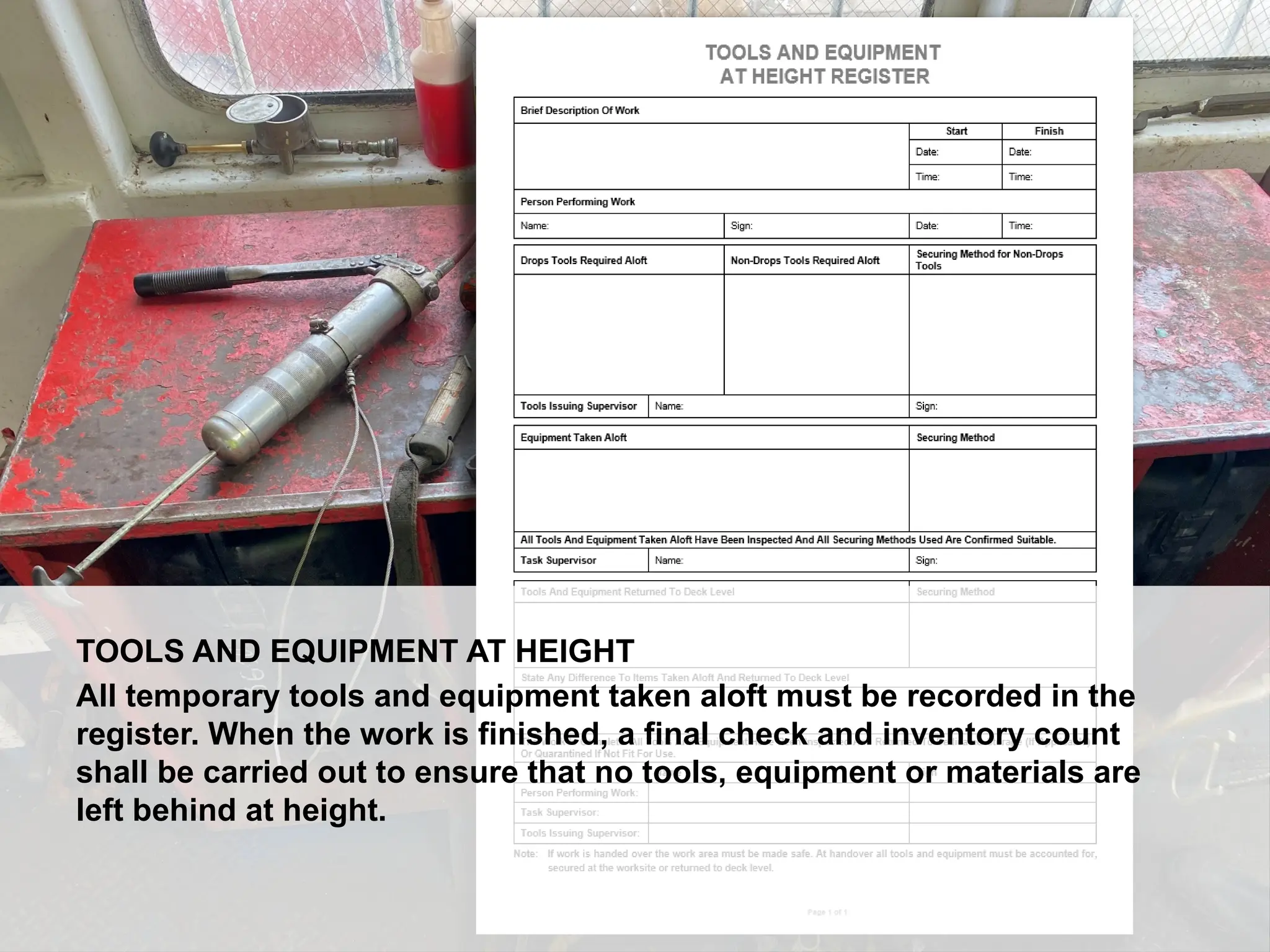

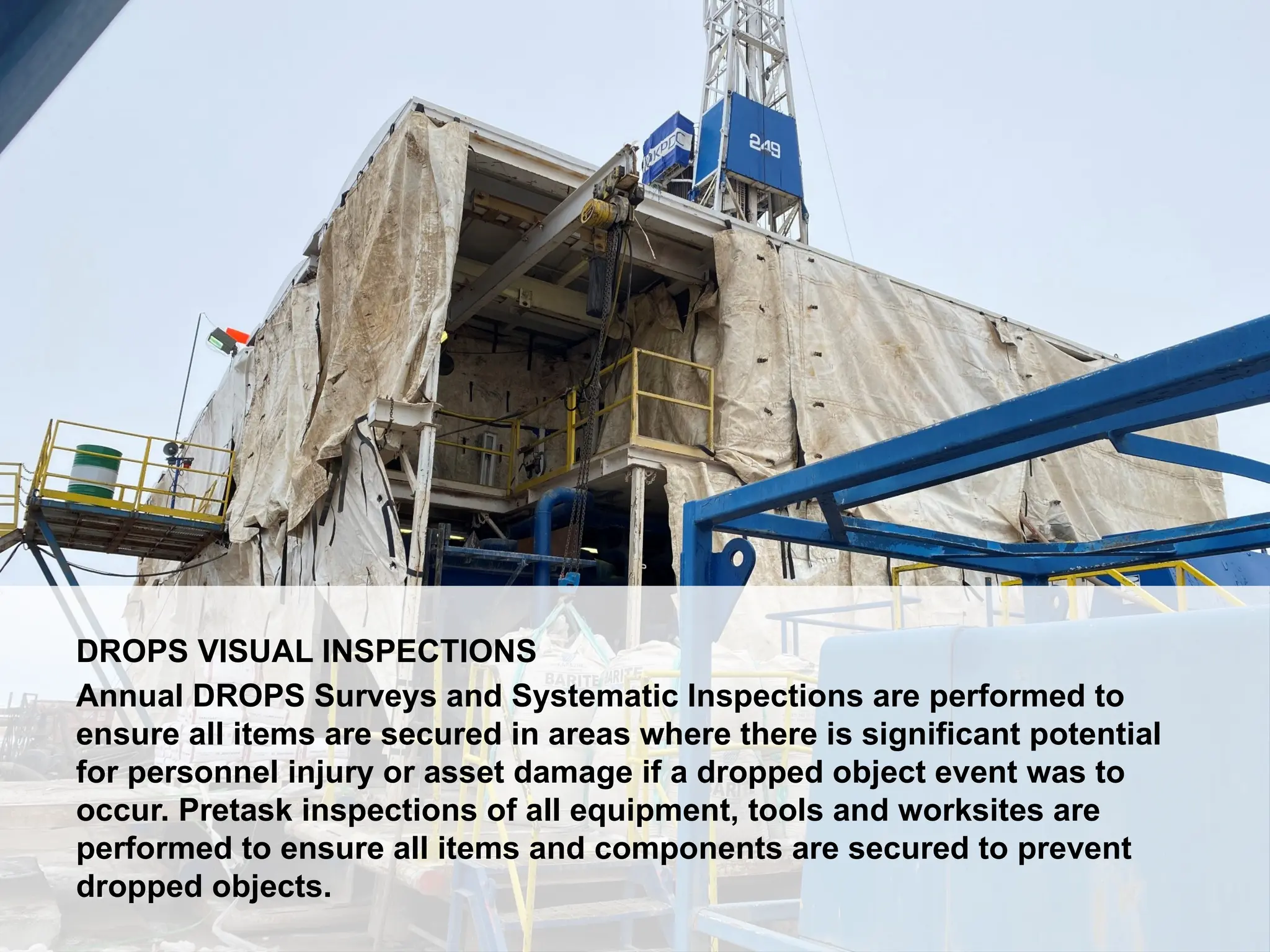

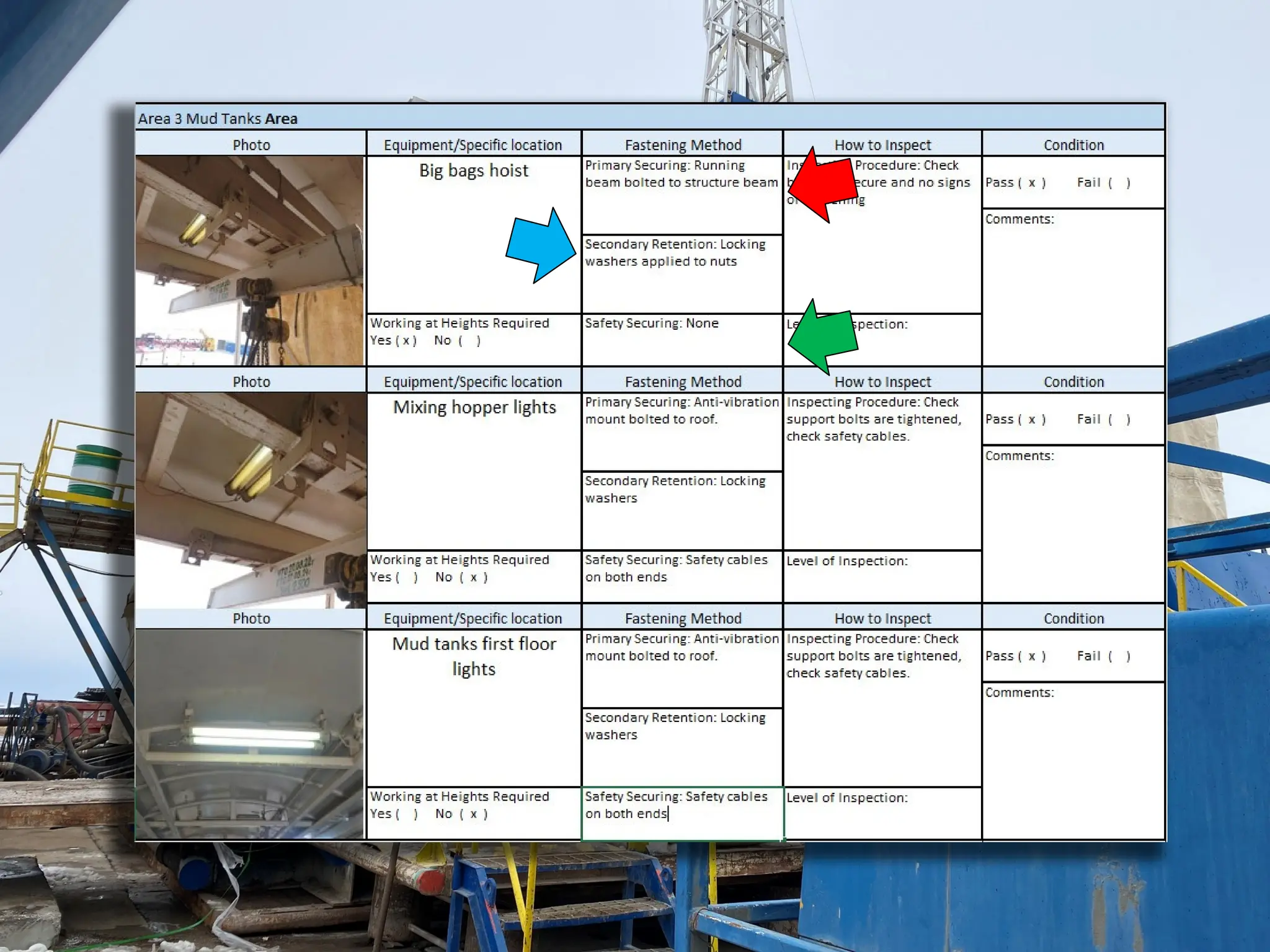

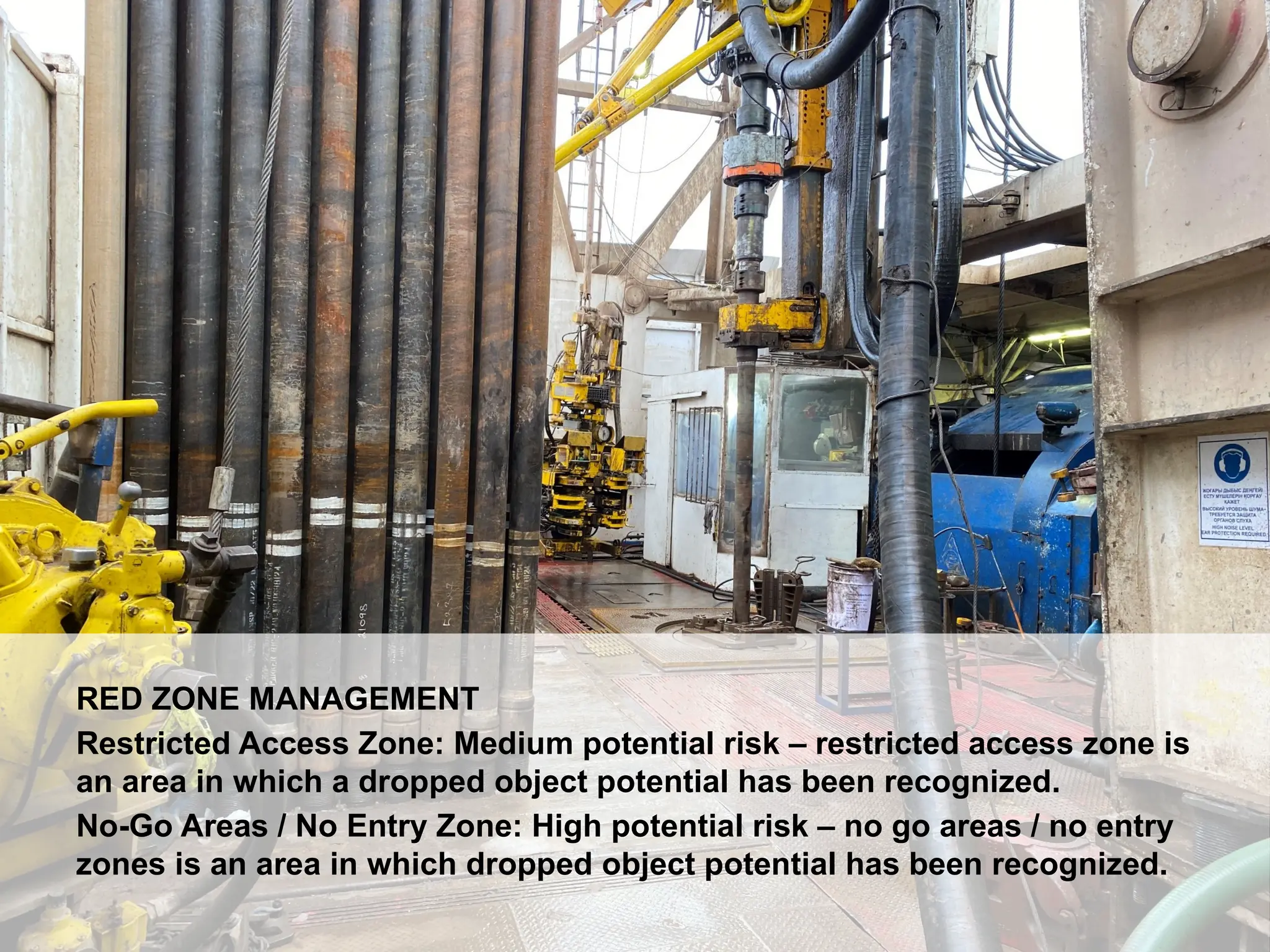

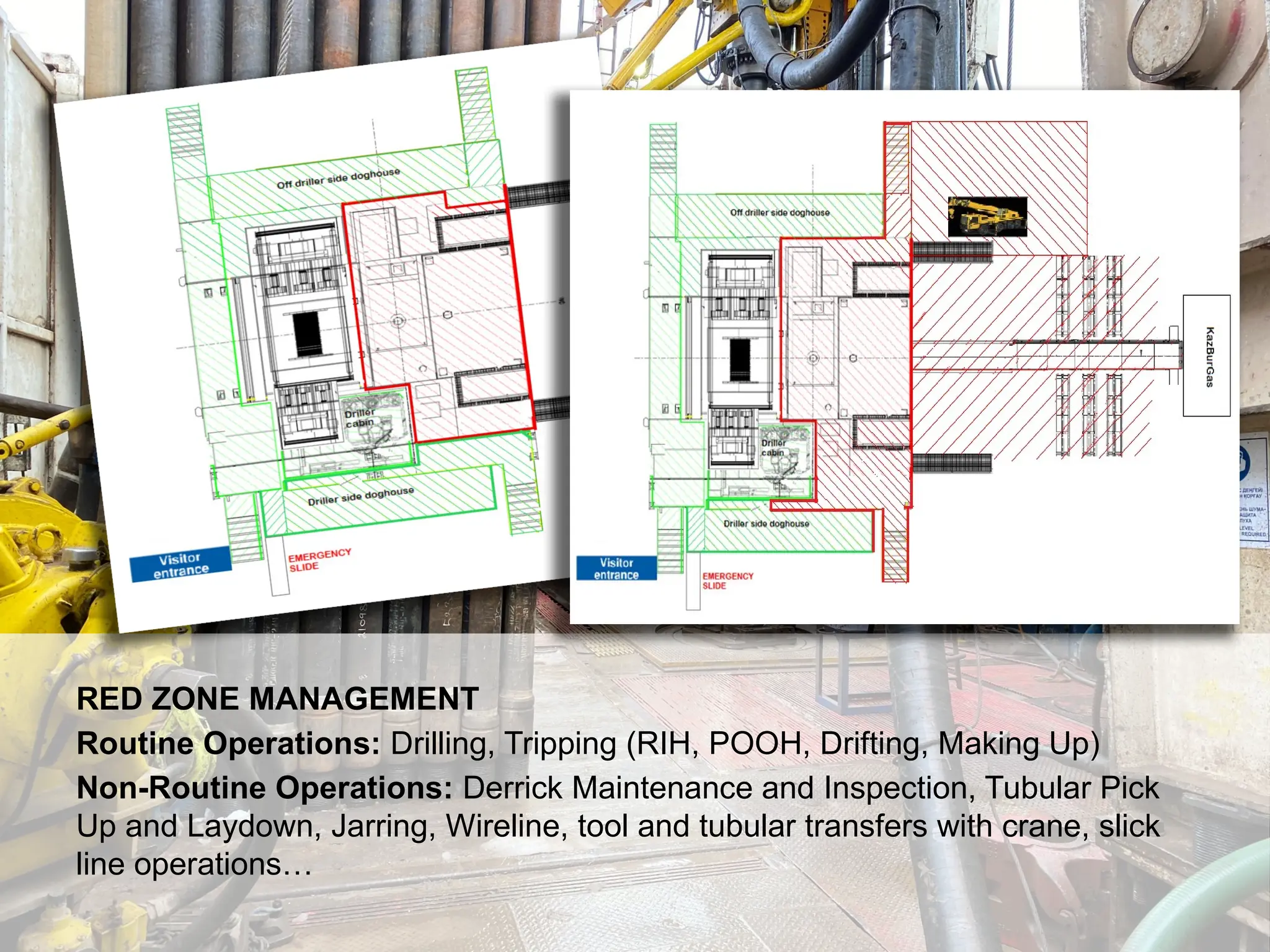

The document outlines the importance of dropped object awareness and prevention, emphasizing that dropped objects account for significant safety incidents in various industries. It details definitions, causes, and consequences of dropped objects, and introduces a hierarchy of control strategies for prevention, including proper securing of tools and equipment at height. Additionally, it stresses the need for effective task planning, risk assessment, and continuous awareness to mitigate the risks associated with dropped objects.