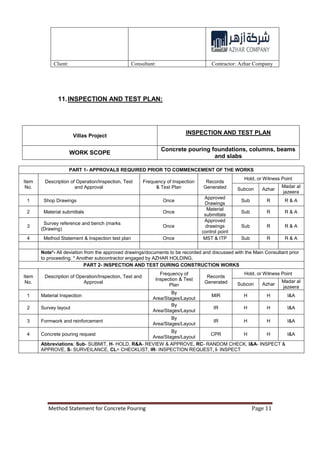

This document presents a method statement for concrete pouring for the Palm Al-Ahsa project, detailing the procedures, materials, tools, and responsibilities involved. It emphasizes the importance of proper preparation, quality assurance, health and safety measures, and supervision throughout the concrete pouring process. The method statement also includes guidelines for inspections and tests during construction to ensure compliance with project specifications.