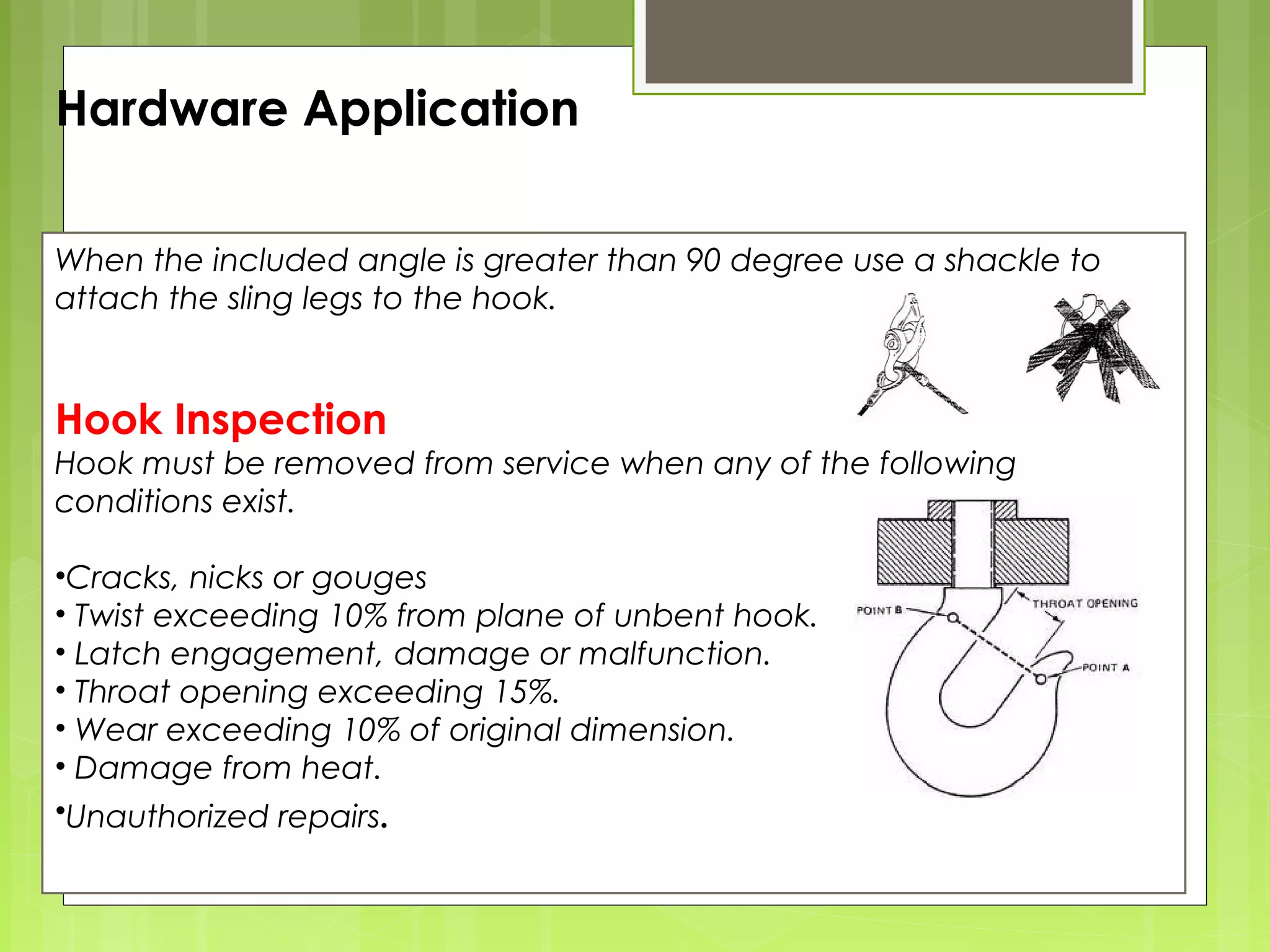

The document provides guidelines for riggers on safely lifting loads. It outlines the responsibilities of riggers, which include being physically fit, trained in lifting equipment, able to properly signal crane operators, and understand load placement for safety. Riggers must understand lifting tackle certification and color coding. They must also inspect lifting gear, like slings and shackles, and ensure equipment markings are present and legible. Proper hitches and safety precautions during lifts are also covered.