ANTEC 2011 - Penn State Behrend College

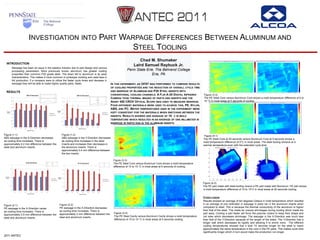

- 1. SCHOOL DESIGNATION SHOULD FIT WITHIN CONFINES OF TEXT BOX INVESTIGATION INTO PART WARPAGE DIFFERENCES BETWEEN ALUMINUM AND STEEL TOOLING Chad M. Shumaker INTRODUCTION Laird Samuel Raybuck Jr. Warpage has been an issue in the plastics industry due to part design and various processing parameters. More previously known aluminum has greater cooling Penn State Erie, The Behrend College properties than common P20 grade steel. The down fall to aluminum is its wear Erie, PA characteristics. This makes it more common in prototype molding and used less in full production. If a company were to utilize the faster cycle times and decease in warpage they will be able to make higher quality parts, faster. IN THIS EXPERIMENT, AN OFAT WAS PERFORMED TO COMPARE RESULTS OF COOLING PROPERTIES AND THE REDUCTION OF OVERALL CYCLE TIME RESULTS AND WARPAGE OF ALUMINUM AND P20 STEEL INSERTS WITH ABS (X-Direction) ABS (Y-Direction) CONVENTIONAL COOLING CHANNELS. A FLIR A-20 DIGITAL INFRARED Figure (3-3) 0.9 1.4 CAMERA TOOK THERMAL IMAGES OF PARTS AND INSERTS AND THE The PE Steel Core versus Aluminum Core shows a mold temperature difference of 5 to 0.8 1.2 AVANT 400 CROV OPTICAL SCOPE WAS USED TO MEASURE WARPAGE. 10 °C in most areas at 5 seconds of cooling. 0.7 1 FOUR DIFFERENT MATERIALS WERE USED TO ACHIEVE THIS, PE, NYLON, 0.6 0.5 0.8 ABS, AND PC. WATER TEMPERATURES USED IN THE EXPERIMENT WERE Warpage Warpage (mm.) 0.4 Warpage-AL (mm.) 0.6 Warpage-AL KEPT CONSISTENT FOR THE MATERIALS WHEN SWITCHING BETWEEN THE Warpage-Steel INSERTS. RESULTS SHOWED AND AVERAGE OF 10 Warpage-Steel 0.3 0.4 C IN MOLD 0.2 TEMPERATURE WHICH RESULTED IN AN AVERAGE OF ONE MILLIMETER IN 0.2 0.1 WARPAGE IN PARTS RAN IN THE ALUMINUM INSERTS. 0 0 10 15 20 25 30 45 60 10 15 20 25 30 45 60 Cooling Time (sec.) Cooling Time (sec.) Figure (1-1) Figure (1-2) Figure (4-1) ABS warpage in the X-Direction decreases ABS warpage in the Y-Direction decreases The PE Steel Core at 20 seconds versus Aluminum Core at 5 seconds shows a as cooling time increases. There is as cooling time increases in the steel mold temperature difference of 5°C in most areas. The steel tooling remains at a approximately 0.2 mm difference between the Inserts and increases then decreases in warmer temperature even with the extended cycle time. steel and aluminum inserts. the aluminum inserts. There is approximately 0.4 mm difference between the two inserts. Figure (3-3) . PE (X-Direction) 3 PE (Y-Direction) The PE Steel Core versus Aluminum Core shows a mold temperature 3 difference of 10 to 15 °C in most areas at 5 seconds of cooling. 2.5 2.5 2 2 Warpage 1.5 Warpage (mm.) 1.5 Warpage-AL (mm.) Warpage-AL Warpage-Steel Warpage-Steel 1 1 Figure (4-2) 0.5 0.5 The PE part made with steel tooling versus a PE part made with Aluminum PE part shows 0 0 a mold temperature difference of 10 to 15°C in most areas at 20 seconds cooling. 10 15 20 25 30 45 60 10 15 20 25 30 45 60 Cooling Time (sec.) Cooling Time (sec.) CONCLUSION Results showed an average of ten degrees Celsius in mold temperature which resulted Figure (2-2) in an average of one millimeter in warpage in parts ran in the aluminum inserts when Figure (2-1) PE warpage in the X-Direction decreases compared to steel. This is because the thermal conductivity of the aluminum is higher PE warpage in the X-Direction varies as cooling time increases. There is than that of the steel. This made for uneven shrinkages during cooling which made the as cooling time increases. There is approximately 2 mm difference between the Figure (3-2) part warp. Cooling a part faster will force the polymer chains to keep their shape and approximately 0.5 mm difference between the steel and aluminum inserts. The PE Steel Cavity versus Aluminum Cavity shows a mold temperature not relax which decreases shrinkage. The warpage in the X-Direction was much less steel and aluminum inserts. difference of 10 to 15 °C in most areas at 5 seconds cooling. than that of the Y-Direction because of the length of the sides. The Y-Direction has a longer wall which decreases its rigidity and allowing it to shrink more. The different cooling temperatures showed that it took 15 seconds longer for the steel to reach approximately the same temperature in the core in the PE parts. This makes cycle time significantly longer which in turn would make the production run longer. 2011 ANTEC