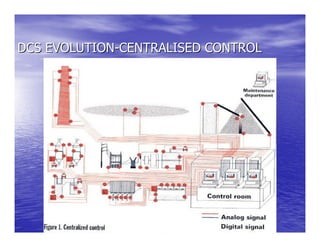

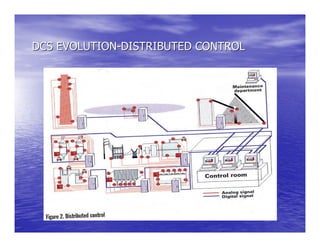

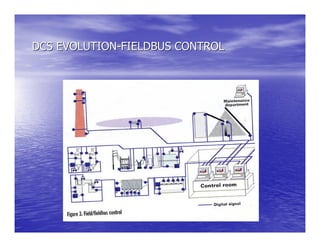

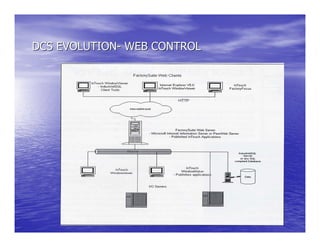

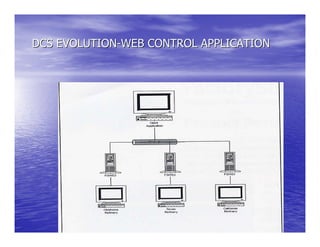

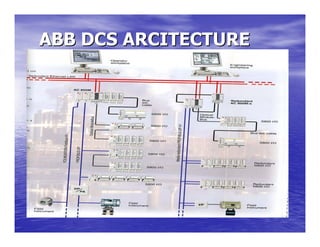

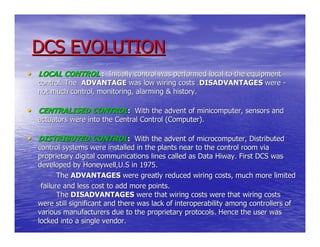

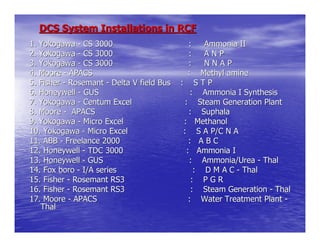

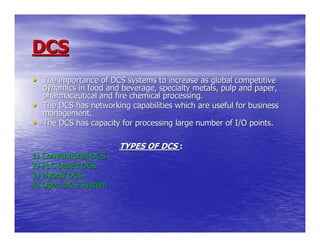

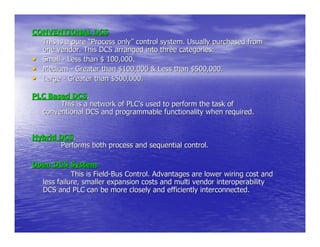

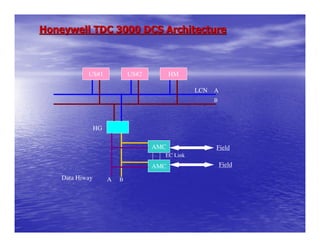

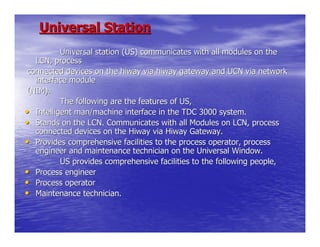

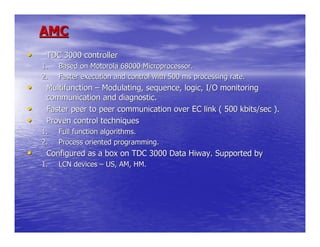

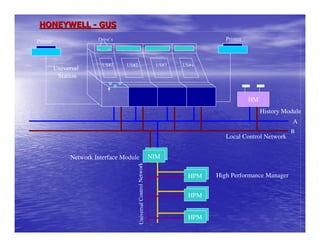

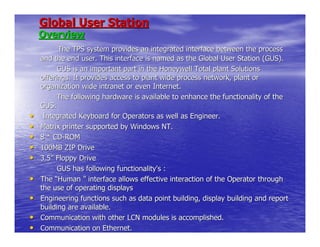

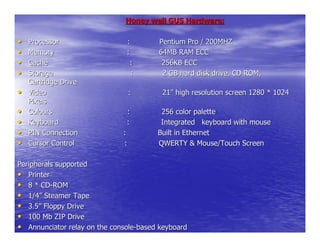

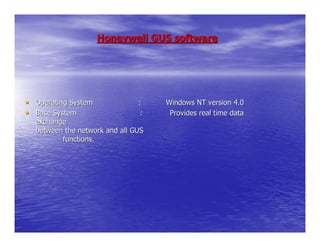

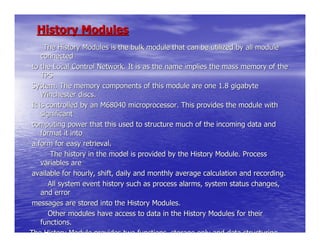

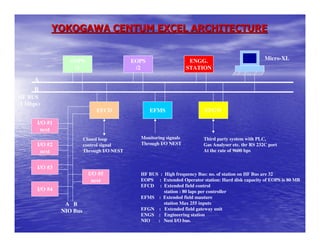

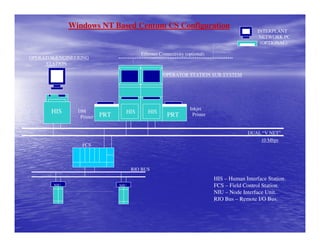

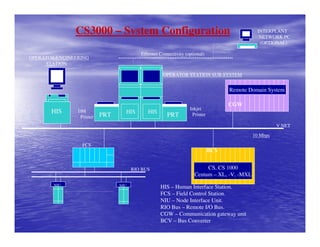

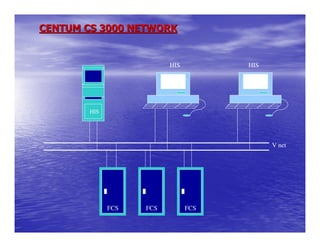

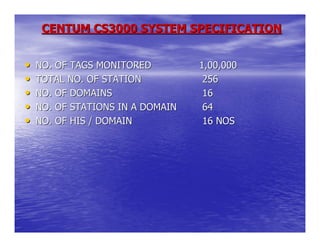

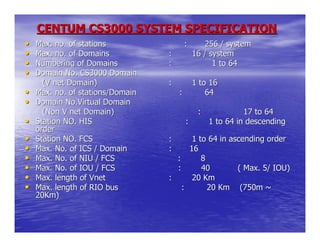

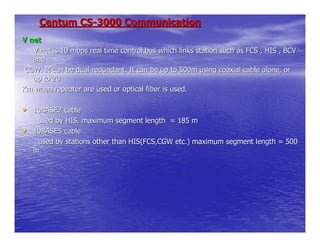

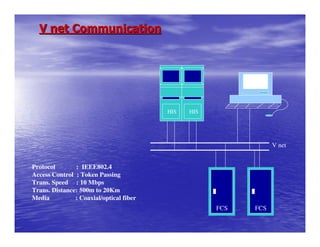

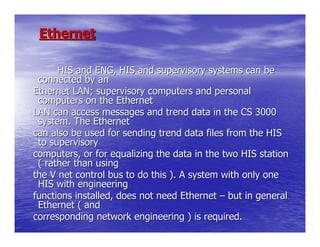

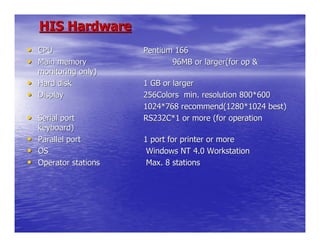

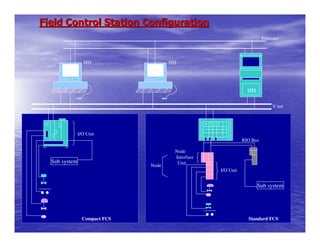

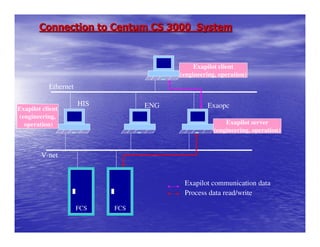

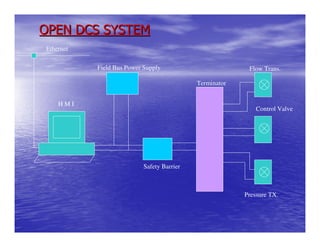

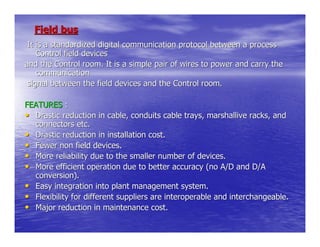

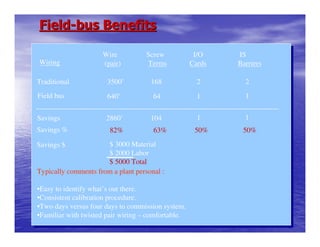

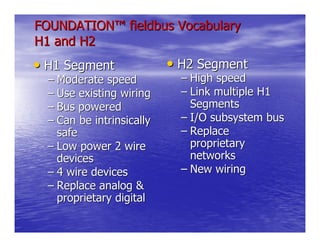

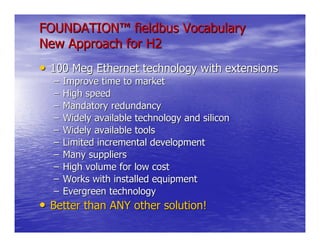

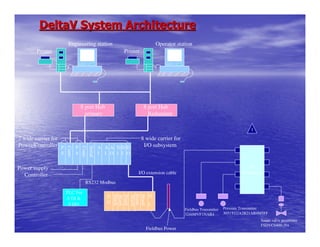

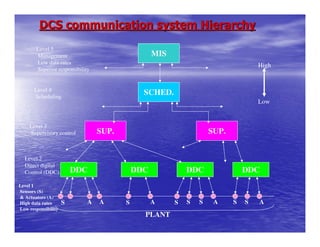

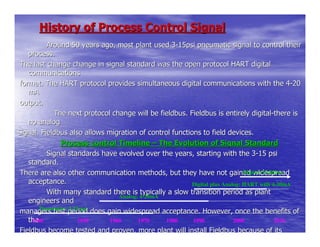

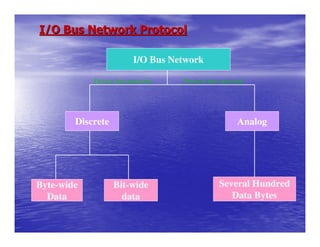

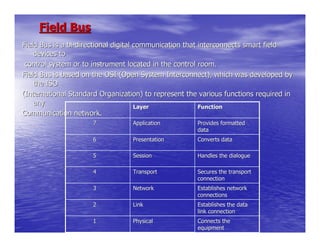

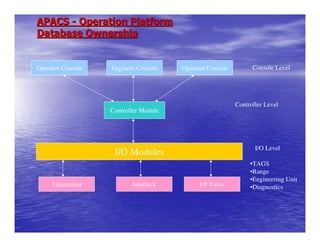

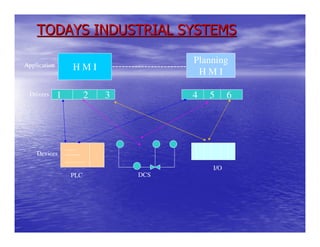

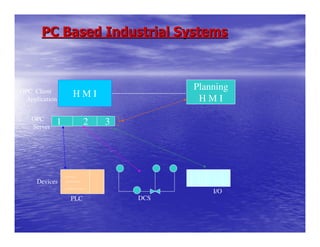

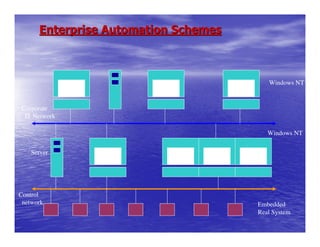

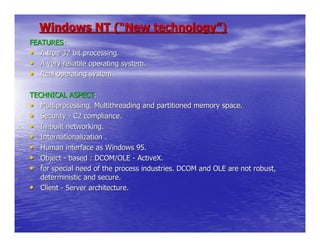

The document discusses control system trends and different distributed control system (DCS) architectures. It describes the evolution of DCS from centralized to distributed control with fieldbus connectivity. It provides examples of DCS installations and components of DCS systems from manufacturers like Honeywell, Yokogawa, and ABB. These include control stations, input/output modules, networks, and the use of Windows-based control.