This document discusses cleaner production and waste reduction in industry. It addresses the following key points:

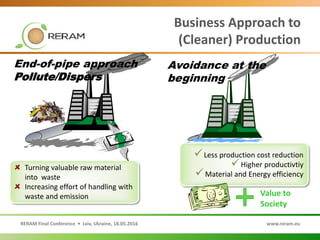

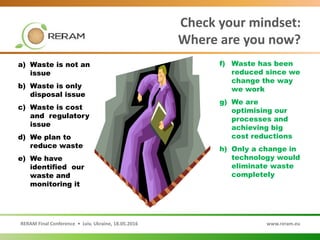

1) Cleaner production focuses on avoiding waste at the beginning by increasing material and energy efficiency, rather than end-of-pipe waste handling. This reduces costs and increases productivity.

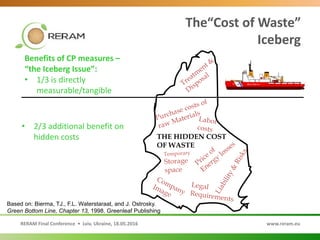

2) Only about 1/3 of the benefits of cleaner production measures are directly measurable, while 2/3 are additional "hidden costs" of waste.

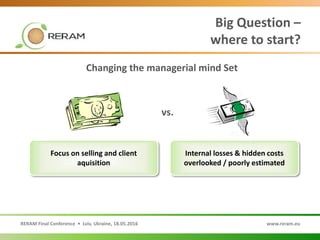

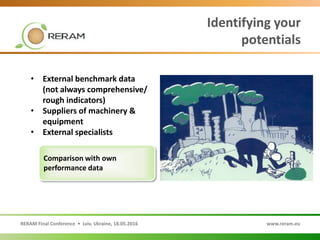

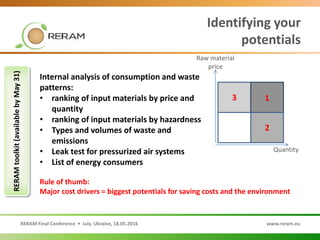

3) Companies should start by analyzing their largest material and energy inputs to identify biggest waste reduction potentials and costs savings. Internal benchmarks and specialist guidance are recommended.

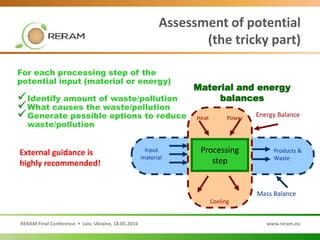

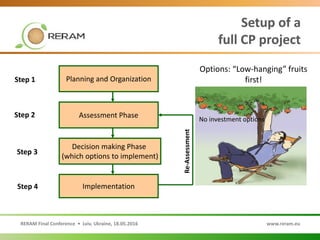

4) A full cleaner production project involves planning, assessment of each process step to identify waste causes and solutions,