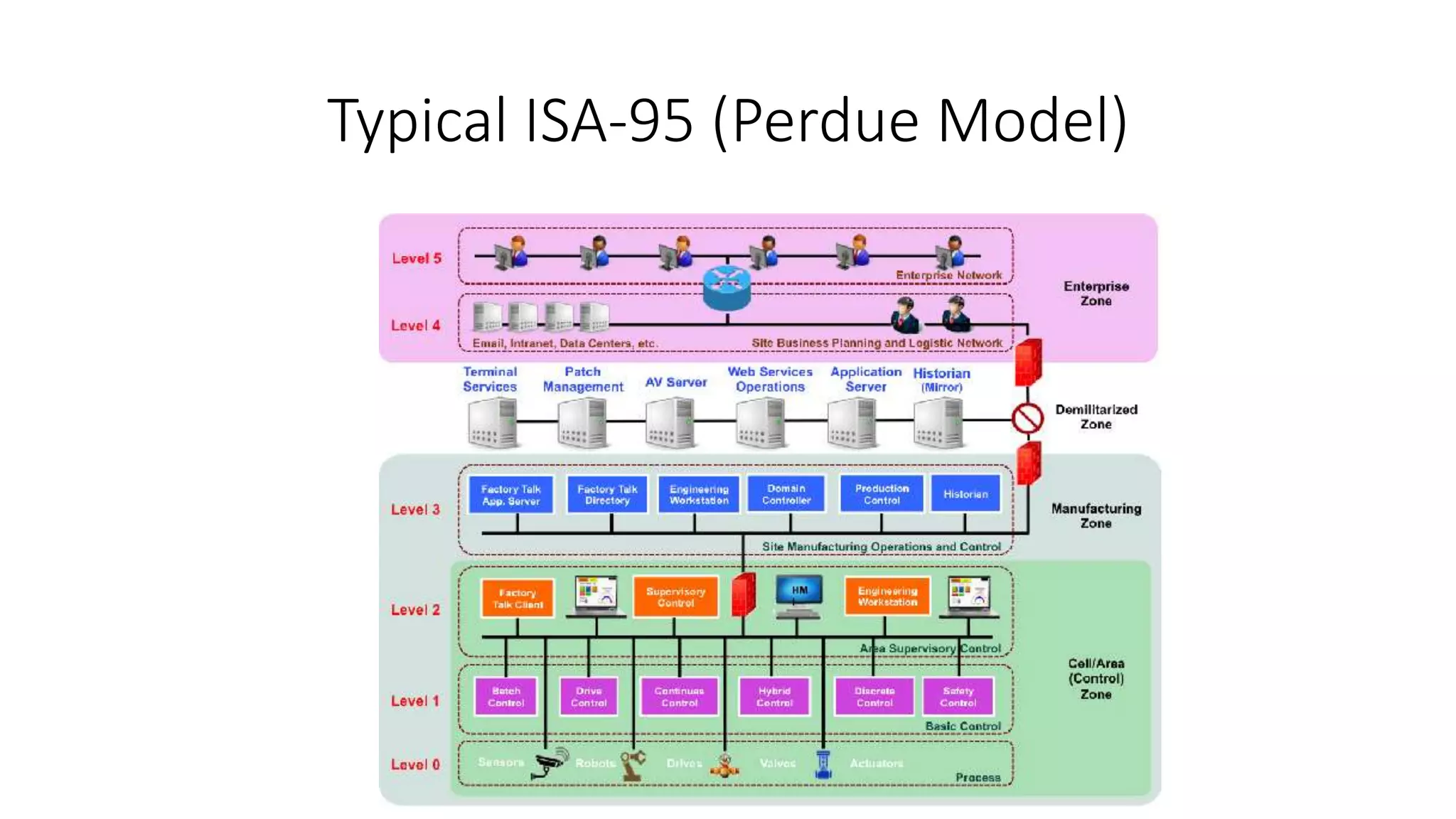

ISA-95 is a set of standards for integrating enterprise and control systems to allow them to communicate and exchange data seamlessly. It defines a framework and common terminology for discussing manufacturing operations. However, ISA-95 was developed before modern technologies like IoT, cloud computing, and AI. As a result, the traditional ISA-95 model may not be sufficient to address the challenges of modern networks, which have new requirements for flexibility, scalability, and real-time data processing. New standards are needed to ensure the safe integration of enterprise and control systems in an era with more complex, dynamic IoT systems.