Workshop on fabrics manufacturing technology

•Download as PPTX, PDF•

6 likes•3,328 views

Report

Share

Report

Share

Recommended

presentationProject on spirality SUPERVISING TEACHER Md. Emdad Sarker Lecturer, Departme...

Project on spirality SUPERVISING TEACHER Md. Emdad Sarker Lecturer, Departme...Bangladesh University of Textiles (BUTEX)

Recommended

presentationProject on spirality SUPERVISING TEACHER Md. Emdad Sarker Lecturer, Departme...

Project on spirality SUPERVISING TEACHER Md. Emdad Sarker Lecturer, Departme...Bangladesh University of Textiles (BUTEX)

This thesis deals with a major problem of production loss of a knitting industry. The knitting machine has to stop when defects occurred and then faults are corrected, which results in time loss and efficiency loss. Not only that the knitted fabric may be rejected if quality requirements are not met. An effective monitoring is required to avoid defects and to avoid productivity and quality losses. The study identifies two main categories of defects (average time required for correcting defects and machine down time) are responsible for reducing productivity. The thesis reflects that due to yarn breakage machine stopped for seen minutes per days, for maintaining machine stopped for two hours per month, for needle breakage six minutes per day and for technical problem machine stopped for several times.Efficiency losses calculation and identify causes of losses of circular knitt...

Efficiency losses calculation and identify causes of losses of circular knitt...Elias Khalil (ইলিয়াস খলিল)

This paper deals with the results of an investigation of various gauges of circular knitting machines with a view to producing same single jersey fabric with different parameters. All parameters including machine diameter, stitch length, yarn count, yarn lot, yarn tension etc. but gauges are used for this work is different. Even dyeing has been done at the same time on the same machine by stitching one with other, finishing parameters and processes are also same and done at same time as well to minimize the effects of other variable which can be responsible for changing the physical and mechanical properties like finished width of the fabric, finished GSM (Grams per Square Meter), shrinkage, spirality, bursting strength etc. This is done for finding only the effects which actually affects the fabric properties. Finally the findings or results are as expected with some variations with the results that are thought theoretically.Effect of gauge variation of circular knitting machine on physical and mechan...

Effect of gauge variation of circular knitting machine on physical and mechan...Elias Khalil (ইলিয়াস খলিল)

More Related Content

What's hot

This thesis deals with a major problem of production loss of a knitting industry. The knitting machine has to stop when defects occurred and then faults are corrected, which results in time loss and efficiency loss. Not only that the knitted fabric may be rejected if quality requirements are not met. An effective monitoring is required to avoid defects and to avoid productivity and quality losses. The study identifies two main categories of defects (average time required for correcting defects and machine down time) are responsible for reducing productivity. The thesis reflects that due to yarn breakage machine stopped for seen minutes per days, for maintaining machine stopped for two hours per month, for needle breakage six minutes per day and for technical problem machine stopped for several times.Efficiency losses calculation and identify causes of losses of circular knitt...

Efficiency losses calculation and identify causes of losses of circular knitt...Elias Khalil (ইলিয়াস খলিল)

This paper deals with the results of an investigation of various gauges of circular knitting machines with a view to producing same single jersey fabric with different parameters. All parameters including machine diameter, stitch length, yarn count, yarn lot, yarn tension etc. but gauges are used for this work is different. Even dyeing has been done at the same time on the same machine by stitching one with other, finishing parameters and processes are also same and done at same time as well to minimize the effects of other variable which can be responsible for changing the physical and mechanical properties like finished width of the fabric, finished GSM (Grams per Square Meter), shrinkage, spirality, bursting strength etc. This is done for finding only the effects which actually affects the fabric properties. Finally the findings or results are as expected with some variations with the results that are thought theoretically.Effect of gauge variation of circular knitting machine on physical and mechan...

Effect of gauge variation of circular knitting machine on physical and mechan...Elias Khalil (ইলিয়াস খলিল)

What's hot (20)

Efficiency losses calculation and identify causes of losses of circular knitt...

Efficiency losses calculation and identify causes of losses of circular knitt...

Weft knitting machine & parameters of weft knitted fabric

Weft knitting machine & parameters of weft knitted fabric

Effect of gauge variation of circular knitting machine on physical and mechan...

Effect of gauge variation of circular knitting machine on physical and mechan...

2 the effectsof tightness factor on spirality and seams displacement of tubul...

2 the effectsof tightness factor on spirality and seams displacement of tubul...

Viewers also liked

Chemicals Used Textile Wet Processing (Desizing To Finishing) & Their importance.Chemicals used in textile wet processing & their function assignment work

Chemicals used in textile wet processing & their function assignment workDaffodil International University

Viewers also liked (19)

Institute of professional textile technology IPTT Panipat

Institute of professional textile technology IPTT Panipat

Industrial Internship Report on Opex Sinha Textile Group

Industrial Internship Report on Opex Sinha Textile Group

Chemicals used in textile wet processing & their function assignment work

Chemicals used in textile wet processing & their function assignment work

Similar to Workshop on fabrics manufacturing technology

This slide is for the student of Textile Engineering of initial stage of knitting of fabric formation. prepared by Matiur,Mesbah, Amzad, Shakil, Rifat & tuhinIntroduction of knitting, prepared by students of Daffodil International Univ...

Introduction of knitting, prepared by students of Daffodil International Univ...Matiur Rahman khan Babu

Similar to Workshop on fabrics manufacturing technology (20)

A compressive study on rib circular knitting machine

A compressive study on rib circular knitting machine

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Weft Knitting Machine (Single Jersey, Rib & Interlock)

Weft Knitting Machine (Single Jersey, Rib & Interlock)

Introduction of knitting, prepared by students of Daffodil International Univ...

Introduction of knitting, prepared by students of Daffodil International Univ...

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

Recently uploaded

Recently uploaded (20)

Ensure the security of your HCL environment by applying the Zero Trust princi...

Ensure the security of your HCL environment by applying the Zero Trust princi...

Call Girls Kengeri Satellite Town Just Call 👗 7737669865 👗 Top Class Call Gir...

Call Girls Kengeri Satellite Town Just Call 👗 7737669865 👗 Top Class Call Gir...

Call Girls Navi Mumbai Just Call 9907093804 Top Class Call Girl Service Avail...

Call Girls Navi Mumbai Just Call 9907093804 Top Class Call Girl Service Avail...

Call Girls Hebbal Just Call 👗 7737669865 👗 Top Class Call Girl Service Bangalore

Call Girls Hebbal Just Call 👗 7737669865 👗 Top Class Call Girl Service Bangalore

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

Enhancing and Restoring Safety & Quality Cultures - Dave Litwiller - May 2024...

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

0183760ssssssssssssssssssssssssssss00101011 (27).pdf

Business Model Canvas (BMC)- A new venture concept

Business Model Canvas (BMC)- A new venture concept

MONA 98765-12871 CALL GIRLS IN LUDHIANA LUDHIANA CALL GIRL

MONA 98765-12871 CALL GIRLS IN LUDHIANA LUDHIANA CALL GIRL

RSA Conference Exhibitor List 2024 - Exhibitors Data

RSA Conference Exhibitor List 2024 - Exhibitors Data

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

How to Get Started in Social Media for Art League City

How to Get Started in Social Media for Art League City

BAGALUR CALL GIRL IN 98274*61493 ❤CALL GIRLS IN ESCORT SERVICE❤CALL GIRL

BAGALUR CALL GIRL IN 98274*61493 ❤CALL GIRLS IN ESCORT SERVICE❤CALL GIRL

Call Girls Service In Old Town Dubai ((0551707352)) Old Town Dubai Call Girl ...

Call Girls Service In Old Town Dubai ((0551707352)) Old Town Dubai Call Girl ...

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Pune Just Call 9907093804 Top Class Call Girl Service Available

Workshop on fabrics manufacturing technology

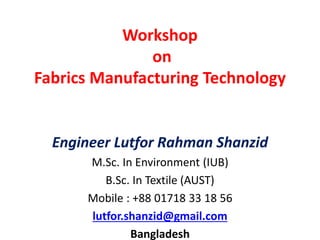

- 1. Workshop on Fabrics Manufacturing Technology Engineer Lutfor Rahman Shanzid M.Sc. In Environment (IUB) B.Sc. In Textile (AUST) Mobile : +88 01718 33 18 56 lutfor.shanzid@gmail.com Bangladesh

- 2. Contents • Definition of different terms of Textile • Weaving sequences • Weaving motions • Weaving calculation • Knitting machines • Knit products • Knitting elements • Knit structures • Knitting calculation Sunday, June 15, 2014 2

- 3. Definition • Textile • Fabric • Woven • Knit • Common error Sunday, June 15, 2014 3

- 4. FLOW CHART OF WEAVING Yarn (In the form of spinner’s package) Warp Preparation Weft Preparation Winding (cone, cheese) Winding (Cop, Pirn, Cone, Cheese) Warping (Pre beam/ Warper’s beam/ back beam) Weaving (Fabric) Sizing (weavers beam) Drafting, Drawing, Pinning Denting, Looming Weaving (Fabric) Sunday, June 15, 2014 4

- 5. Sunday, June 15, 2014 5

- 6. yarn package Cone Flange bobbin Cheese Sunday, June 15, 2014 6

- 7. WARPING a) Direct/ high speed warping b) Sectional warping Sunday, June 15, 2014 7

- 8. Sunday, June 15, 2014 8

- 9. Sectional warping Sunday, June 15, 2014 9

- 10. LOOM MOTION Primary Motion Secondary Motion Tertiary Motion Primary motion 1Shedding: (Tappet (Dobby. (Jacquard. 2Picking: (Over pick (Under pick. (Modern pick. 3Beating: (Single (Multiple (Variable. Secondary Motion 1. Take up a) Positive b) Negative. 2. Let off a) Positive b) Negative. (5 wheel, 7 wheel) Tertiary Motion 1 Warp stop motion 2 Weft stop motion (Centre, side) 3 Reed stop motion (Loose, fast) 4 Temple motion (Roller, reed) 5 Weft replenish Sunday, June 15, 2014 10

- 11. Knitting warp weft Sunday, June 15, 2014 11

- 12. • Wale: Vertical column of needle loop. • Course: Horizontal row of needle loop. Stitch Density: Wales per Inch × Course per Inch. Stitch length: Needle loop + Sinker loop •Extended sinker loop Face loop • Back loop Independent Needle Needle: United Needle Knitting M/C: there are three types of knitting M/C – 1. Warp knitting: Gives vertical movement of yarn. 2. Weft knitting: Gives horizontal movement of yarn. 3. Other loop forming and combined M/C: Tri-axial. Sunday, June 15, 2014 12

- 13. Needle Carrier: Which carries needle. Number of Feed System: The number of feeder by course. Working Diameter: In circular knitting m/c, the distance from one needle exact to the other needle is known as working dia. Working Width: In flat knitting m/c, the distance from first needle to the last needle is known as working width. Gauge: Number of needle per inch. Pitch: The distance the center from one needle to the center of another needle is known as pitch. There Are Three Types Of Knitted Fabric 1. Selvage fabric 2. Cut edge fabric 3. Tubular fabric Sunday, June 15, 2014 13

- 14. MECHANICAL PRINCIPAL OF KNITTING TECHNOLOGY Basic Elements of Knitting 1. Needle 2. Sinker 3. Cam 1. NEEDLE: There are various types of needle are available in market which can be divided in the following group. a. Spring Bearded Needle b. Latch Needle c. Compound Needle Sunday, June 15, 2014 14

- 15. Sunday, June 15, 2014 15

- 16. Sunday, June 15, 2014 16

- 17. SINKER Sunday, June 15, 2014 17

- 18. FUNCTION OF SINKER There are three function of sinker. 1. Loop formation 2. Holding down 3. Knocking over 1. Loop Formation: On bearded needle weft knitting machines of straight bar frame and sinker wheel type, the loop forming action is performed. The purpose of a sinker is to kink the newly laid yarn into loop as its forward edge of advance between two adjoining needle. 2. Holding down Sinker: The second function is hold down the old loop a lower level on the needle stem, then the new loop which are being formed and prevent to old loops from being lifted as the needles rise to clear from their hooks. 3. Knocking Over Sinker: The third function of the sinker is to knock over the old loops on the neck of the new loops. Sunday, June 15, 2014 18

- 19. CAM The knitting cams are hardened steels and they are the assembly of different cam plates so that a track for butt can be arranged. Each needle movement is obtained by means of cams acting on the needle butts. The knitting cams are divided in to three groups. Such as 1. Knit cam 2. Tuck cam 3. Miss cam Sunday, June 15, 2014 19

- 20. PRIMARY BASIC STRUCTURES Knitting Fabric Structure 1.Plain structure 2.Rib structure 3.Interlock structure 4.Purl structure Sunday, June 15, 2014 20

- 21. Knit calculation • A Single jersey Circular knitting machine, having dia of 30 “, 24 Gauge, 30 RPM, 3 Feeder/inch and yarn count is 26s. Efficiency is 90%. Calculate the production per day in kg? • • Solution: • Here, • Total no. of Feeder = Feeder per inch × Machine Dia • Total no. of needle= 𝜋DG • SL=2.2 mm • So, • = Sunday, June 15, 2014 21

- 22. Thanks to all Sunday, June 15, 2014 22