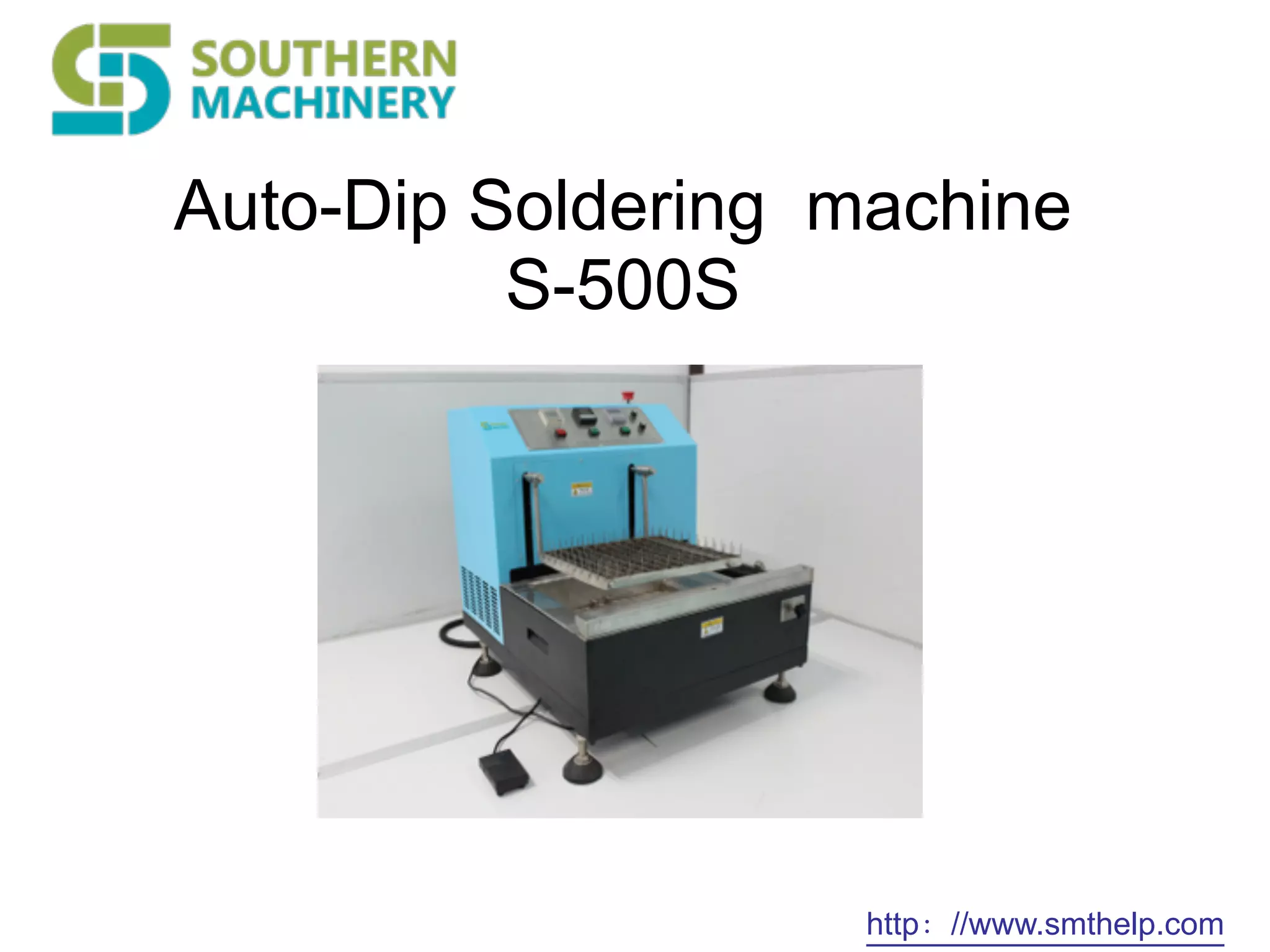

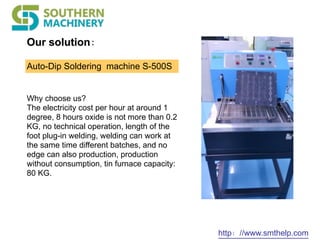

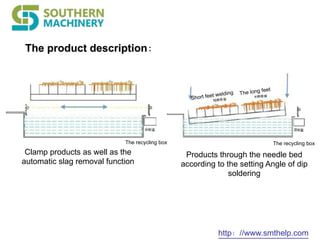

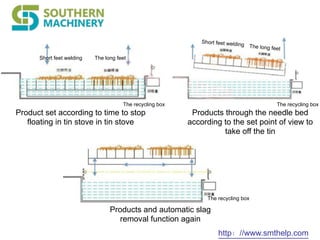

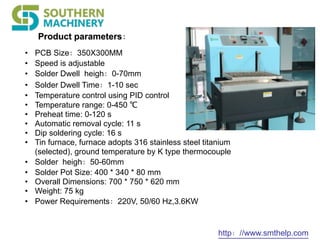

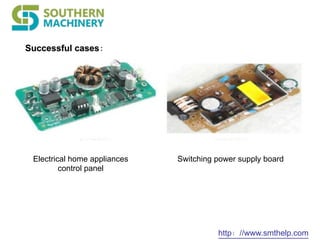

The document describes an auto-dip soldering machine called the S-500S. It has automatic slag removal, allows soldering of multiple batches at once, and improves efficiency over manual soldering. The machine parameters include a 350x300mm PCB size, adjustable speed and solder dwell time, PID temperature control from 0-450 degrees Celsius, and a 75kg weight. It is suitable for circuit boards, LEDs, toys, transformers and can save nearly 40% energy compared to other models.