METAL CASTING AND JOINING PROCESSES

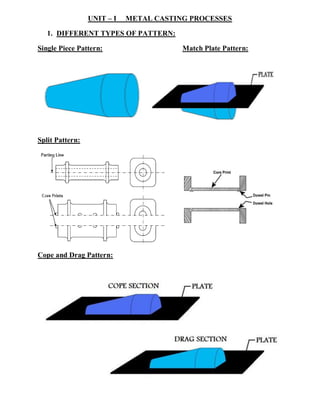

- 1. UNIT – I METAL CASTING PROCESSES 1. DIFFERENT TYPES OF PATTERN: Single Piece Pattern: Match Plate Pattern: Split Pattern: Cope and Drag Pattern:

- 2. Sweep Pattern: Gated Pattern Skeleton Pattern Loose Piece Pattern:

- 3. 2. DIFFERENT TYPES OF ALLOWANCES: Drift or Taper Allowance: Distortion or Camber Allowance: Machining Allowance:

- 4. Figure (a) Core held in place in the mold cavity by chaplets, (b) possible chaplet design, (c) casting with internal cavity. SQUEEZING MACHINES

- 6. SAND SLINGERS Direct Arc Electric Furnace

- 7. Indirect Arc Electric Furnace Induction Furnace

- 9. CRUCIBLE FURNACES (a) lift-out crucible, (b) stationary pot, from which molten metal must be ladled, and (c) tilting-pot furnace. Shell Molding Process

- 10. Investment casting process STEP 1: Pattern creation STEP 2: Mold creation STEP 3: Pouring STEP 4: Cooling & Casting removal

- 11. Ceramic Mold casting Process The Basic Permanent Mold Process (OR) GRAVITY DIE CASTING

- 12. Hot-Chamber Die Casting Cold-Chamber Die Casting Machine

- 13. True Centrifugal Casting Semicentrifugal Casting

- 14. Centrifuge Casting Defects in casting

- 16. Stir casting BALANCED CORE AND HANGING CORE HORIZONTAL CORE AND VERTICAL CORE

- 17. 11/20/2014ManufacturingTechnology I1 (a) Neutral flame (b) Oxidising flame (c) Carburising flame OXY ACETYLENE GAS WELDING UNIT-2 METAL JOINING PROCESSES 11/20/2014ManufacturingTechnology I2 OXY ACETYLENE GAS WELDING 11/20/2014ManufacturingTechnology I3 MANUAL METAL ARC WELDING 11/20/2014ManufacturingTechnology I4 METAL INERT GAS WELDING

- 18. 11/20/2014ManufacturingTechnology I5 TUNGSTEN INERT GAS WELDING 11/20/2014ManufacturingTechnology I6 SUBMERGED ARC WELDING 11/20/2014ManufacturingTechnology I7 ELECTRO SLAG WELDING 11/20/2014ManufacturingTechnology I8 PLASMA ARC WELDING

- 19. 11/20/2014ManufacturingTechnology I9 RESISTANCE SPOT WELDING 11/20/2014ManufacturingTechnology I10 RESISTANCE PROJECTION WELDING 11/20/2014ManufacturingTechnology I11 RESISTANCE SEAM WELDING 11/20/2014ManufacturingTechnology I12 RESISTANCE BUTT WELDING

- 20. 11/20/2014ManufacturingTechnology I13 RESISTANCE PRECUSSION WELDING 11/20/2014ManufacturingTechnology I14 ELECTRON BEAM WELDING 11/20/2014ManufacturingTechnology I15 THERMIT WELDING Thermit welding:(1)Thermit ignited;(2) crucible tapped,superheated metal flows into mold; (3) metal solidifies to produce weld joint. 16 ManufacturingTechnology I 11/20/2014 Friction welding (FRW):(1) rotating part, no contact;(2) parts brought into contact to generate friction heat;(3) rotation stopped and axial pressure applied;and (4) weld created. FRICTION WELDING

- 21. 11/20/2014ManufacturingTechnology I17 FRICTION WELDING 11/20/2014ManufacturingTechnology I18 FRICTION STIR WELDING 11/20/2014ManufacturingTechnology I19 BRAZING 11/20/2014ManufacturingTechnology I20 SOLDERING

- 22. Welding Defects Cont., Cracks cont., 21 ManufacturingTechnology I 11/20/2014 Welding Defects Cont., Incomplete Fusion A weld bead in which fusion has not occurred throughout entire cross section of joint Several forms of incomplete fusion are shown below 22 ManufacturingTechnology I 11/20/2014 Welding Defects Cont., Miscellaneous defects (a) Desired profile for single V-groove weld joint, (b) undercut - portion of base metal melted away, (c) underfill - depression in weld below adjacent base metal surface, and (d) overlap - weld metal spills beyond joint onto part surface but no fusion occurs 23 ManufacturingTechnology I 11/20/2014

- 23. 11/20/2014 1 (a) open-die forging 1Manufacturing Technology I Three types of forging UNIT-3 METAL FORMINGPROCESS 2Manufacturing Technology I Three types of forging (b) impression-die forging (c 3Manufacturing Technology I Three types of forging (c) Flashless or Closed forging FORMING LIMIT DIAGRAM

- 24. 11/20/2014 2 Forging Hammers (Drop Hammers) Drop forging hammer, fed by conveyor and heating units at the right of the scene (photo courtesy of Chambersburg Engineering Company) 5Manufacturing Technology I Manufacturing Technology I 6 BOARD HAMMER BELT AND CHAIN TYPE HAMMER Manufacturing Technology I 7 SPRING HAMMER Manufacturing Technology I 8

- 25. 11/20/2014 3 PNEUMATIC HAMMER Manufacturing Technology I 9 Manufacturing Technology I 10 STEAM HAMMER Forging Presses - Mechanical Presses 11Manufacturing Technology I • Mechanical presses transform the rotational force of a motor into a translational force vector. Therefore the energy in a mechanical press comes from the motor. Mechanical presses are generally faster than hydraulic or screw presses. 1. Crank Presses 2. Knuckle Joint Presses 3. EccentricPresses 4. Rack and Pinion Presses 5. ScrewPresses Mechanical Forging Presses – Crank Presses 12Manufacturing Technology I

- 26. 11/20/2014 4 MechanicalForging Presses– Knuckle Joint Presses 13Manufacturing Technology I • The knuckle joint press translates the energy of a motor through a powerful linkage design, and is capable of delivering a tremendous amount of force. The drive shaft crank rotates completely. The links are well grounded to support such pressure. Mechanical Forging Presses – Eccentric Presses 14Manufacturing Technology I Mechanical Forging Presses – Rack and Pinion Presses 15Manufacturing Technology I Mechanical Forging Presses – Screw Presses 16Manufacturing Technology I

- 27. 11/20/2014 5 Forging Presses - Hydraulic Presses 17Manufacturing Technology I • Hydraulic presses derive the energy they deliver through hydraulic pressure. Fluid pressure, in a particular chamber, can be increased or decreased by the use of pumps, and valves. Sometimes devices and systems may be used to increase the capacity of the pumps in more powerful presses. FORGING OPERATIONS 18Manufacturing Technology I Manufacturing Technology I 19 UPSETTING Manufacturing Technology I 20

- 28. 11/20/2014 6 Manufacturing Technology I 21 SWAGING Manufacturing Technology I 22 Direct extrusion 11/20/2014 23Manufacturing Technology I EXTRUSION Indirect extrusion to produce (a) a solid cross-section and (b) a hollow cross-section 11/20/2014 24Manufacturing Technology I INDIRECT EXTRUSION

- 29. 11/20/2014 7 Manufacturing Technology I 25 TUBE EXTRUSION Manufacturing Technology I 26 HYDROSTATICEXTRUSION Manufacturing Technology I 27 HOT EXTRUSION Impact Extrusion 11/20/2014 28Manufacturing Technology I

- 30. 11/20/2014 8 11/20/2014 29Manufacturing Technology I Drawing of bar, rod, or wire 11/20/2014 30Manufacturing Technology I Continuous drawing of wire 11/20/2014 31Manufacturing Technology I Wire Drawing 11/20/2014 32Manufacturing Technology I

- 31. 11/20/2014 9 Draw die for drawing of round rod or wire 11/20/2014 33Manufacturing Technology I Tube Drawing cont., 11/20/2014 34Manufacturing Technology I Without Mandrel (Tube Sinking) With Fixed Mandrel With Floating Mandrel • Deformation process in which work thickness is reduced by compressive forces exerted by two opposing rolls The rolling process (specifically, flat rolling) ROLLING 11/20/2014 35Manufacturing Technology I Rolling Mills OR FLAT STRIP ROLLING • Rollingmill consists basically of rolls, bearings, housing for containing these parts and a drive for applyingpower to the rolls and control their speed. • Equipmentis massive and expensive • Rollingmill configurations: – Two-high– two opposing large diameter rolls – Three-high– work passes through both directions – Four-high – backing rolls support smaller work rolls – Cluster mill – multiple backing rolls on smaller rolls – Tandemrolling mill – sequenceof two-high mills 11/20/2014 36Manufacturing Technology I

- 32. 11/20/2014 10 Various configurations of rolling mills: (a) 2-high rolling mill 11/20/2014 37Manufacturing Technology I Various configurations of rolling mills: (b) 3-high rolling mill 11/20/2014 38Manufacturing Technology I Various configurations of rolling mills: (c) four-high rolling mill 11/20/2014 39Manufacturing Technology I Cluster Mill Multiple backing rolls allow even smaller roll diameters Various configurations of rolling mills: (d) cluster mill 11/20/2014 40Manufacturing Technology I

- 33. 11/20/2014 11 Tandem Rolling Mill A series of rolling stands in sequence Various configurations of rolling mills: (e) tandem rolling mill 11/20/2014 41Manufacturing Technology I Thread Rolling or Shape Rolling • Bulk deformation process used to form threads on cylindrical parts by rolling them between two dies • Most important commercial process for mass producing bolts and screws • Performed by cold working in thread rolling machines Thread rolling with flat dies: (1) start of cycle, and (2) end of cycle 11/20/2014 42Manufacturing Technology I Ring rolling used to reduce the wall thickness and increase the diameter of a ring: (1) start, and (2) completion of process Ring Rolling 11/20/2014 43Manufacturing Technology I DefectsIn MetalRolling 44 Manufacturing Technology ISource: http://thelibraryofmanufacturing.com/metal_rolling.html

- 34. 11/20/2014 1 UNIT-4 SHEET METAL PROCESSES VARIOUS SHEARING OPERATIONS Sheet Metal - cupping test 2 Manufacturing Technology I 3 Manufacturing Technology I Forcedistribution during bending Elastic core during bending 4 Manufacturing Technology I Spring back

- 35. 11/20/2014 2 5 Manufacturing Technology I Compensation of spring back 6 Manufacturing Technology I Bending operationsinvolve the processes of V-bendingand edge bending V - bending Edge - bending 7 Manufacturing Technology I Bending operationsinvolve the processes of Rotarybending Rotarybending 8 Manufacturing Technology I Bending operationsinvolve the processes of Air bending and Offset bending Air bending Offset bending

- 36. 11/20/2014 3 9 Manufacturing Technology I Bending operationsinvolve the processes of Channelbending and U bending 10 Manufacturing Technology I Bending operationsinvolve the processes of Roll Bending 11 Manufacturing Technology I Tube Bending 12 Manufacturing Technology I Tube Bendingcont.,

- 37. 11/20/2014 4 13 Manufacturing Technology I Drawing • Deep drawing is a sheet-metal operation to makehollow-shaped parts from a sheet blank 14 Manufacturing Technology I DrawingProcess Drawingcont., 15 Manufacturing Technology I • RedrawingSheetMetal cont., 16 Manufacturing Technology I • RedrawingSheetMetal • Redrawing is the subsequent deep drawing of a work that has alreadyundergone a deep drawing process. • By using morethan one operationa greater magnitude of deep drawing can be accomplished.

- 38. 11/20/2014 5 17 Manufacturing Technology I • ReverseRedrawingSheetMetal • Reverse redrawing, or reverse drawing is sometimesused to redraw parts. In reverse redrawing the intermediate part is flipped over before being placed on the die for the next operation. Drawingcont., 18 Manufacturing Technology I • ForcesIn Deep Drawing 19 Manufacturing Technology I Ironing • Ironing is mostly used to achieve a uniform wall thickness in deep drawings. • Variationin wall thickness often exists in such parts as discussed in the previous section. • Ironing can be incorporatedinto a deep drawing process or can be performed separately. Sheetmetal cont., 20 Manufacturing Technology I Other sheet-metal forming operations • Rubber forming / Guerin process • Hydroforming • Stretchforming – Shear Spinning – Tube Spinning

- 39. 11/20/2014 6 Sheetmetal cont., 21 Manufacturing Technology I The Guerin process cont., Advantages: smallcost of tooling Limitations: for relatively shallow shapes Area of application: small-quantity production 22 Manufacturing Technology I Other sheet-metal forming operations • Hydroforming • It is similar to Guerin process but instead of rubber pad a rubber diaphragm filled with fluid is used 23 Manufacturing Technology I Other sheet-metal forming operations • Stretchforming • In stretch formingthe sheet metalis stretched and bent to achievethe desired shape 24 Manufacturing Technology I Other sheet-metal forming operations • Spinning • Spinning is a metal formingprocess in which an axially symmetric part is gradually shaped over a mandrel by means of a rounded toolor roller

- 40. 11/20/2014 7 25 Manufacturing Technology I Other sheet-metal forming operations • Shear Spinning • Shear spinning is a process related to conventionalspinning, and is also known as flow turning and spin forging. 26 Manufacturing Technology I Other sheet-metal forming operations • Tube Spinning • Tube spinning is performed on cylindrical parts. Tube spinning is similar to shear spinning in that metalflow occurswithin the work. 27 Manufacturing Technology I High-energy-rate Forming (HERF) • Explosiveforming • It involves the use of an explosive chargeplaced in water to form sheet into the die cavity. 28 Manufacturing Technology I High-energy-rate Forming (HERF) • Electrohydraulic forming • This is a HREF process in which a shock wave to deform the work into a die cavity is generated by the discharge of electrical energy between two electrodes submerged in water. • Similar to explosive forming, but applied only to small part sizes.

- 41. 11/20/2014 8 29 Manufacturing Technology I High-energy-rate Forming (HERF) • Electromagnetic forming (OR) magnetic pulse forming • The sheet metal is deformed by the mechanical force of an electromagnetic field induced in the workpieceby a coil Peen Forming 30 Manufacturing Technology I Peen Forming 31 Manufacturing Technology I SUPERPLASTICFORMING PROCESS

- 42. 11/20/2014 1 UNIT-5 PLASTIC PROCESSING METHODS INJECTION MOULDING-SCREW TYPE INJECTION MOULDING-PLUNGERTYPE 4 Manufacturing Technology I VacuumThermoforming • The process involves shaping a preheated thermoplastic sheet by means of vacuum produced in the mold cavityspace. • The atmospheric pressure forces the soft sheet to deform in conformity with the cavity shape. • When the plastic comes into the contact with the mold surface it cools down and hardens.

- 43. 11/20/2014 2 5 Manufacturing Technology I PressureThermoforming • The process involves shaping a preheated thermoplastic sheet by means of air pressure. • The air pressure forces the soft sheet to deform in conformity with the cavityshape. • When the plastic comes into the contact with the mold surface it cools down and hardens. 6 Manufacturing Technology I MechanicalThermoforming • The process involves shaping a preheated thermoplastic sheet by means of a direct mechanicalforce. • A core plug (positive mold) forces the soft sheet to fill the space between the plug and the negative mold. • The process provides precise dimensional tolerance and surface detailing. 7Manufacturing Technology I Film Blowing 8Manufacturing Technology I Rotational molding

- 44. 11/20/2014 3 MoldingCont., 9Manufacturing Technology I Calendaring • Molten plastic forced between two counter- rotating rolls to produce very thin sheets e.g. polyethylene sheets ExtrusionBlow Molding 10Manufacturing Technology I

- 45. 11/20/2014 4 Bonding of thermoplastics 13Manufacturing Technology I Methods of Bonding • Chemical Bonding – SolventBonding – Adhesive Bonding • Thermal welding – Friction welding Technique • Ultrasonic welding • Spin welding • Radio frequency welding • Electromagneticor Induction welding • Hot plate • Laser welding ULTRASONICWELDING 14Manufacturing Technology I 15Manufacturing Technology I 16Manufacturing Technology I • Electromagnetic or Induction welding

- 46. 11/20/2014 5 17Manufacturing Technology I Hot plate welding Cont., • When this condition is achieved the hot plate is removed, and the parts are pressed together and held until the weld joint cools and re-solidifies to create a permanent bond. • The most common form of this welding is butt heat fusion welding which welds two circular tubes end to end. LASER WELDING 18Manufacturing Technology I