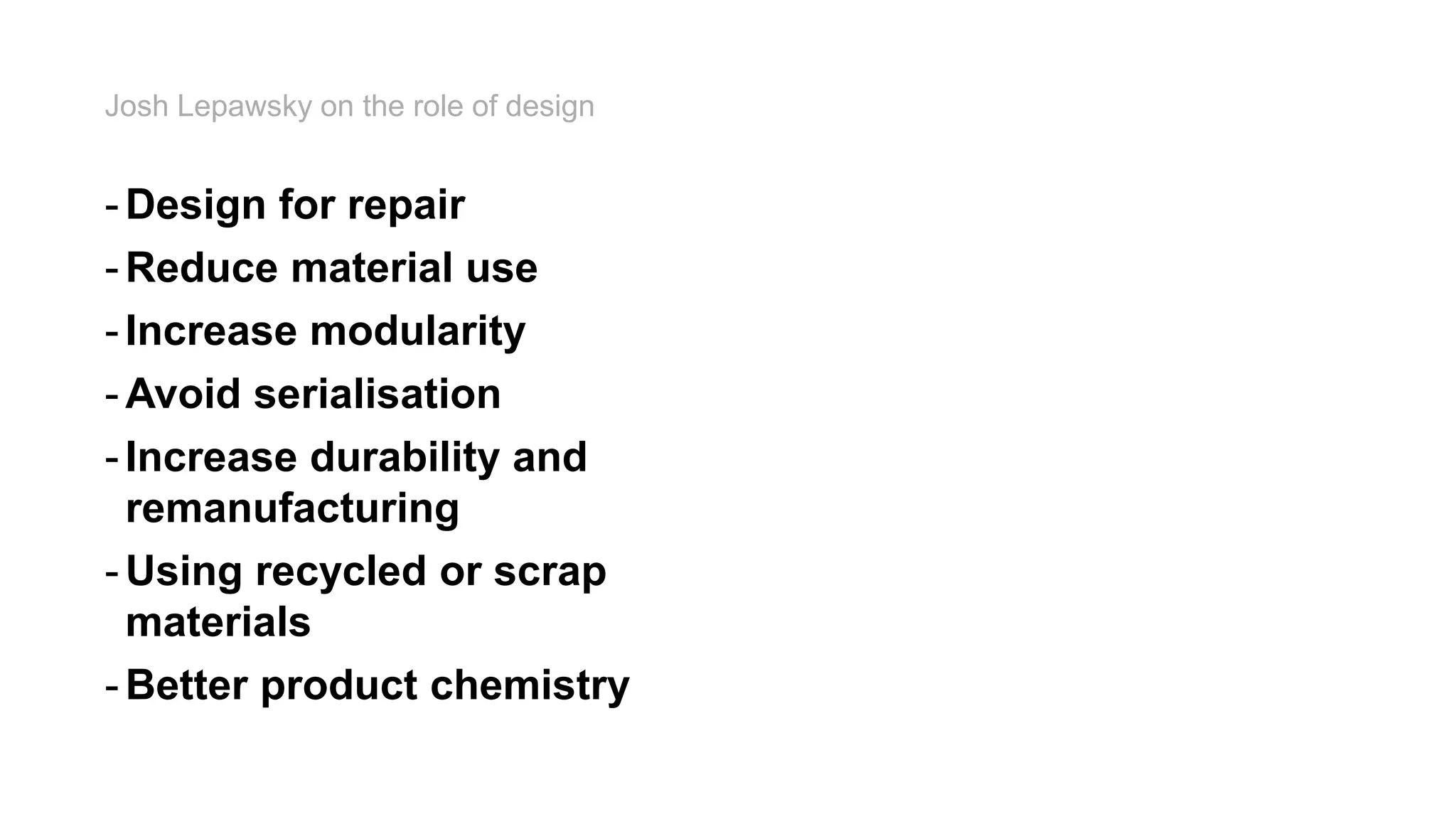

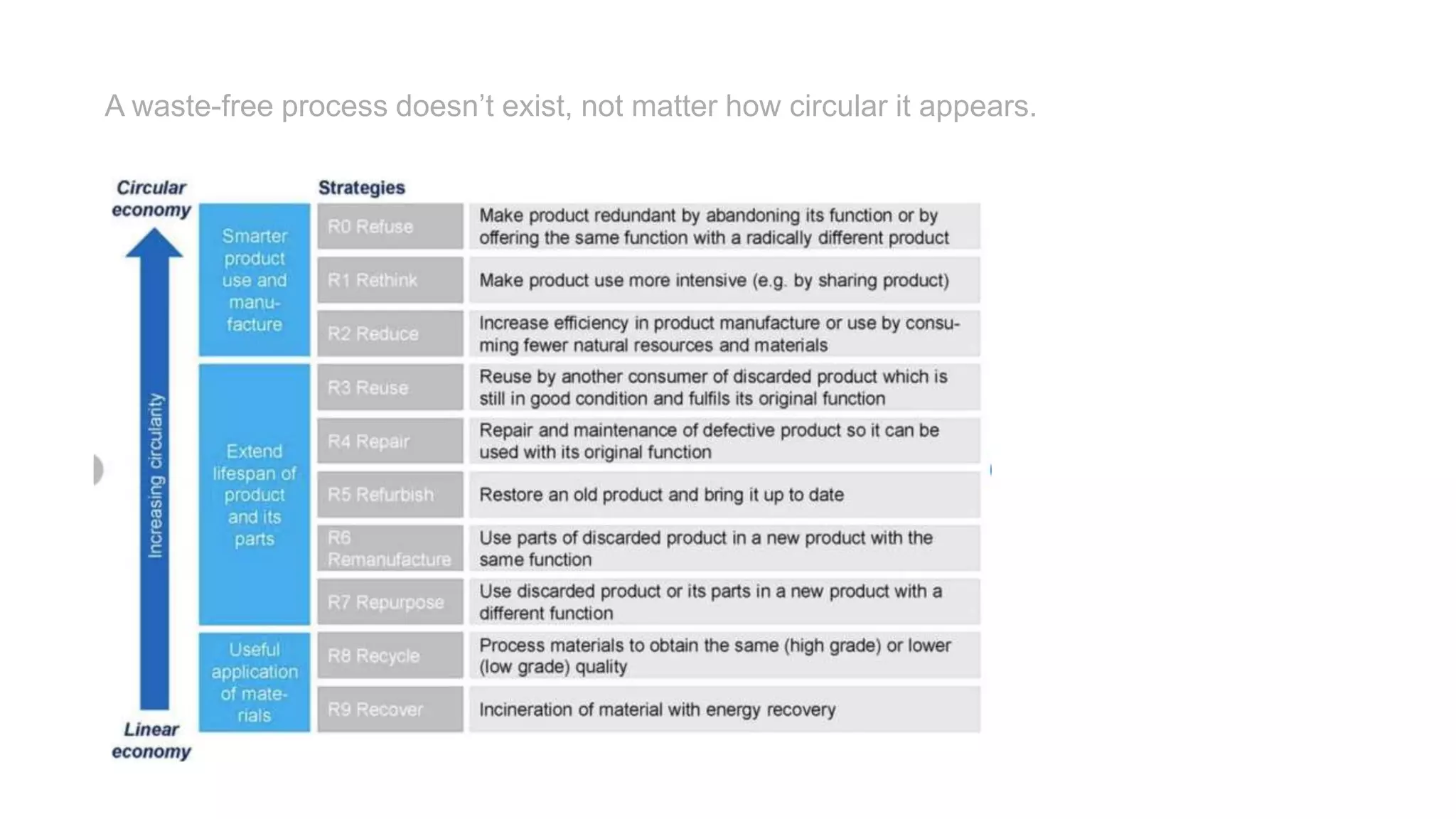

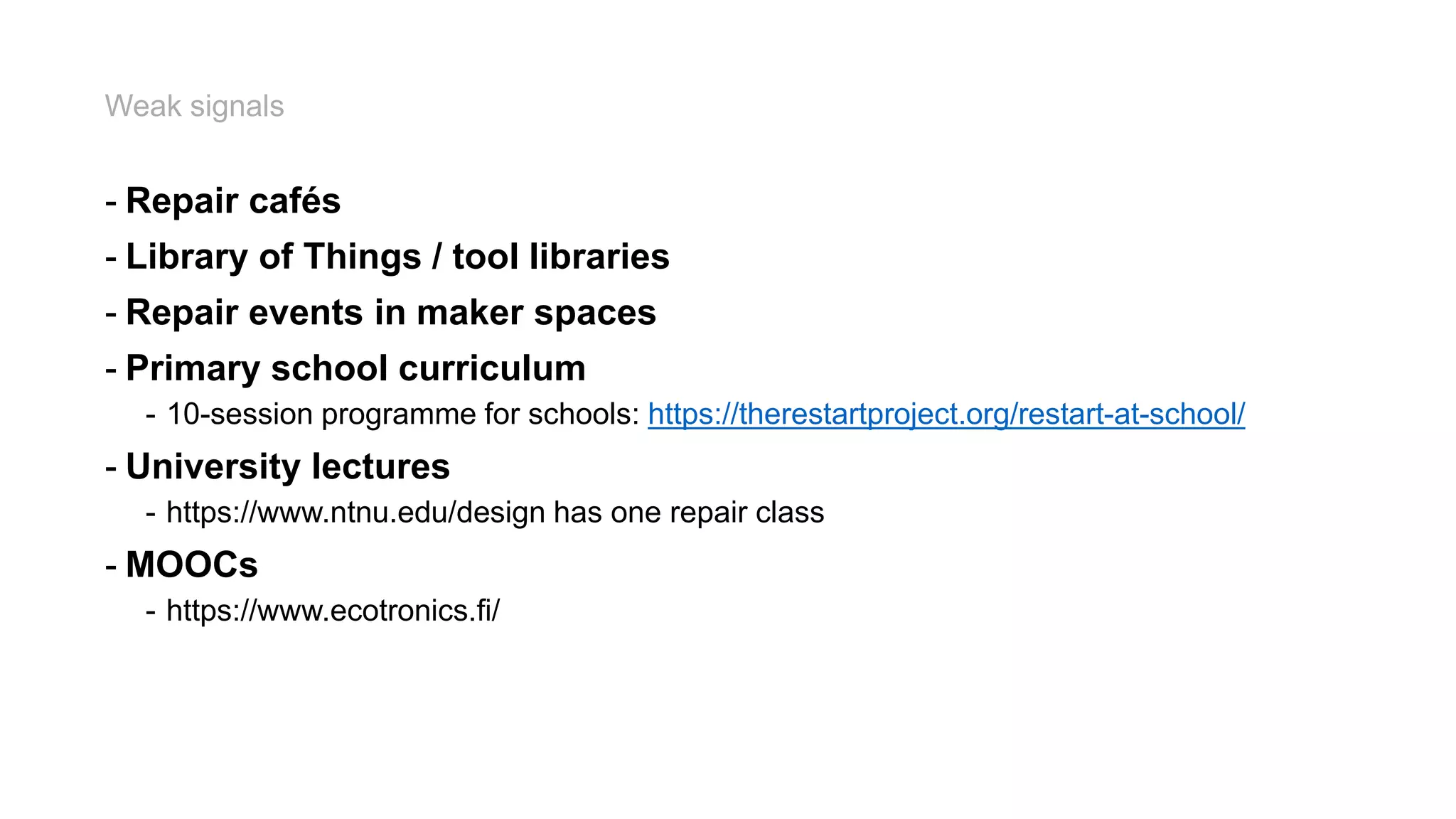

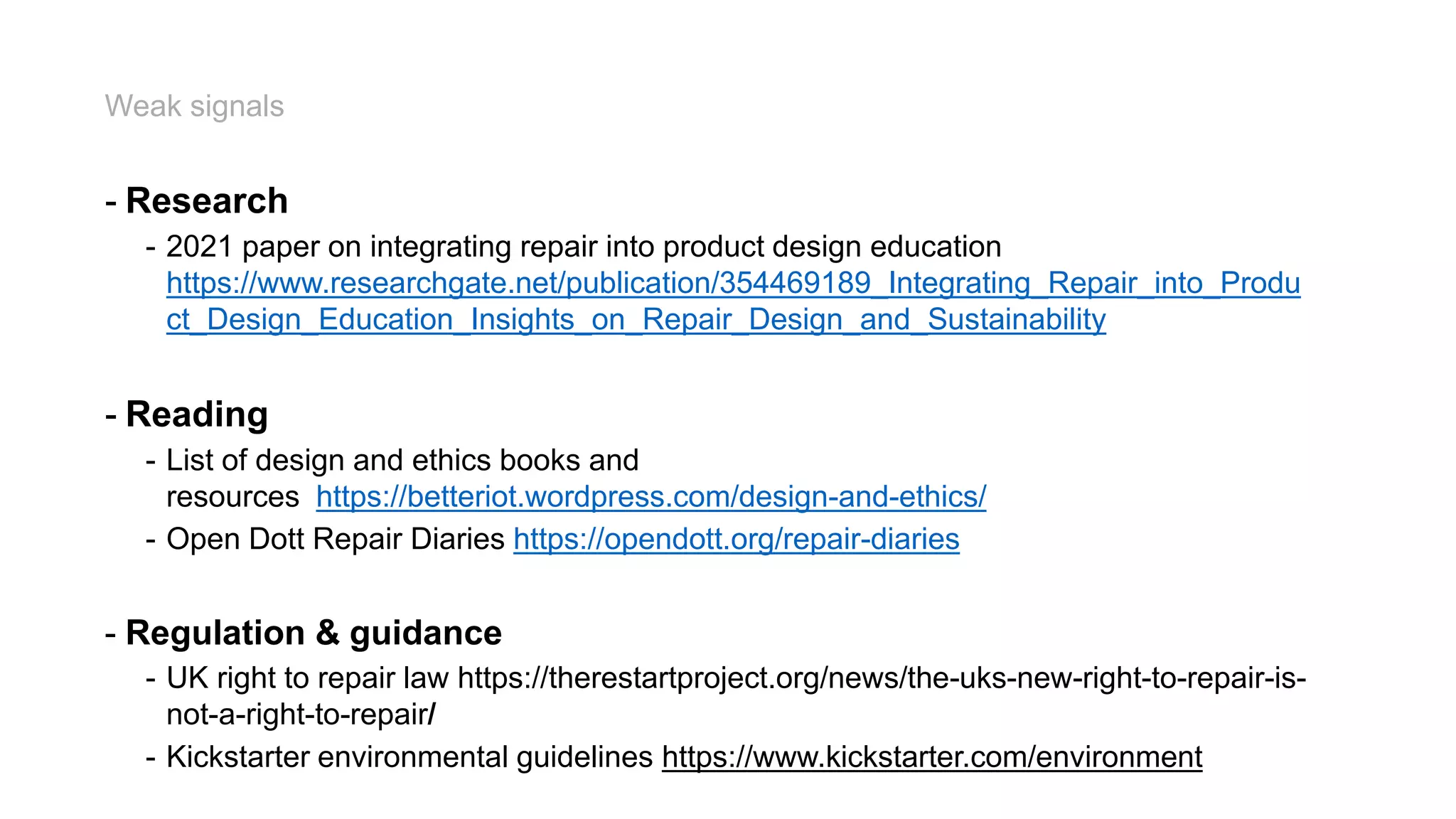

The document discusses the concept of 'repairable by design', emphasizing the need for sustainable practices in electronics manufacturing, including increased modularity, durability, and the use of recycled materials. It highlights various initiatives such as repair cafés, educational programs, and research integrating repair into design education, alongside the UK's right to repair law. Additionally, it outlines curriculum ideas for promoting repairability in product design and suggests alternative business models supportive of repair partnerships.