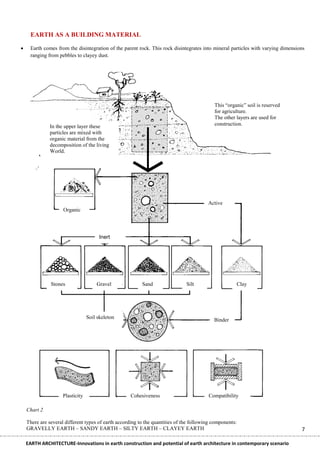

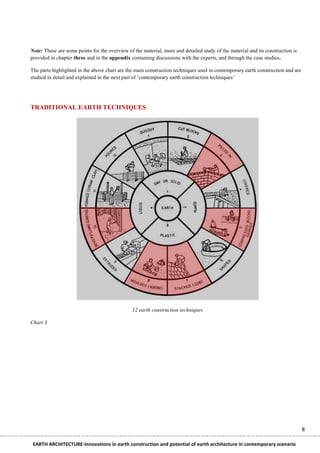

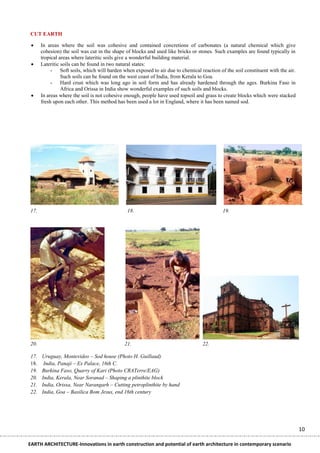

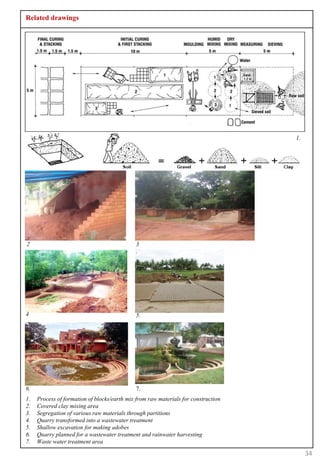

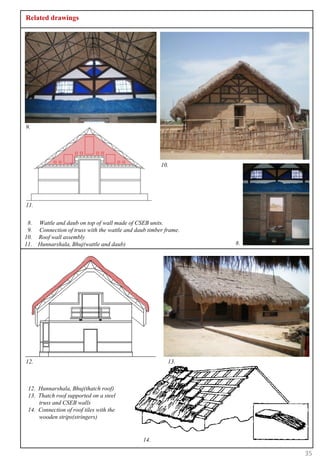

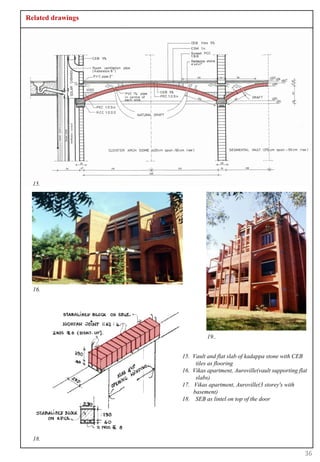

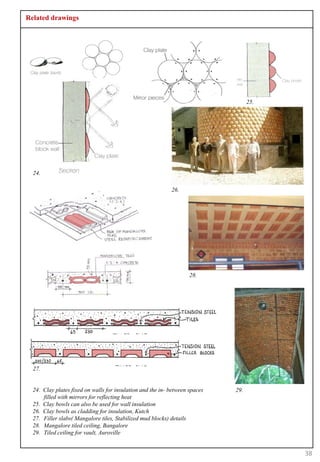

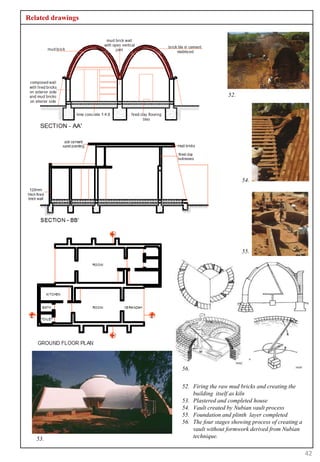

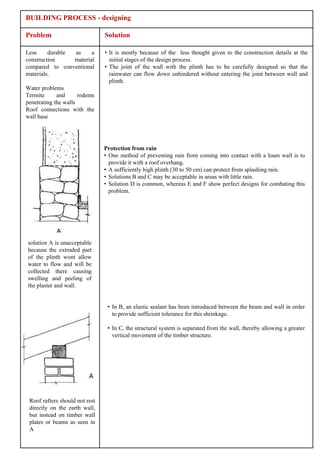

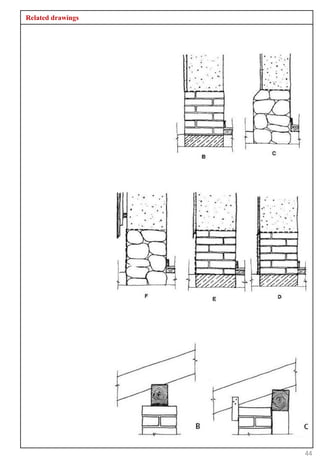

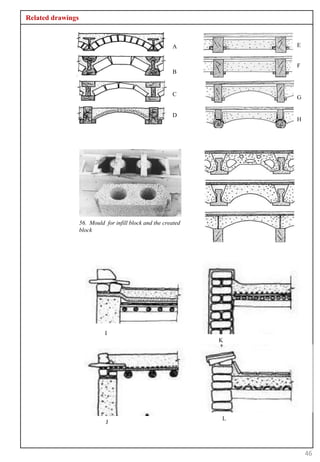

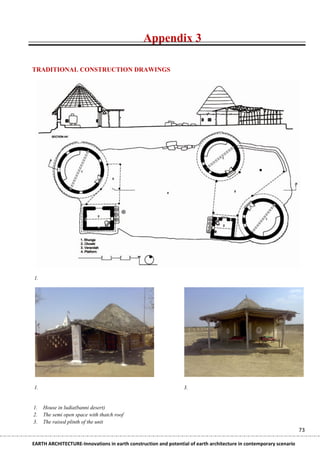

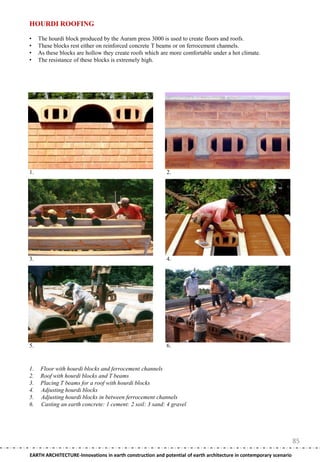

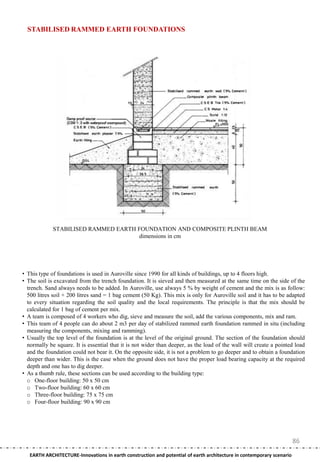

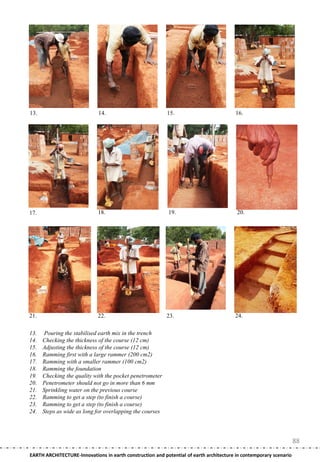

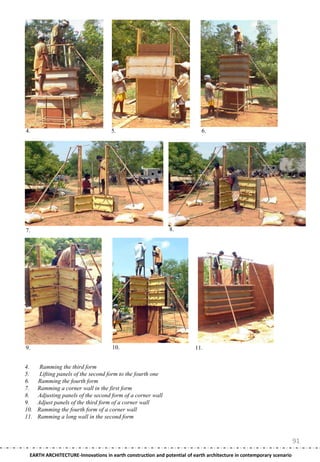

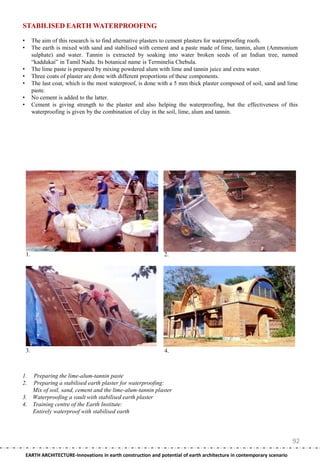

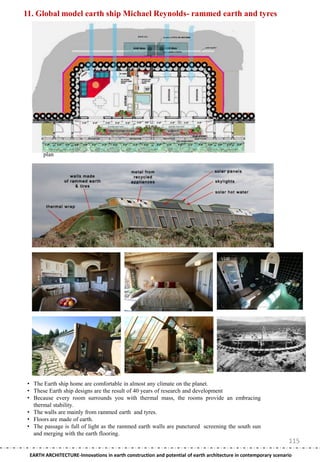

The document discusses traditional earth construction techniques that have been used for over 9,000 years around the world, outlines different types of soils used for construction, and examines contemporary innovations that can help optimize earth as a building material and make it more viable for modern architecture. It explores how studying traditional methods and addressing issues like shrinkage can help earth construction be better utilized today through improved designs, materials, and techniques.