Dom 511 supply_chain_management_sept_dec_2011

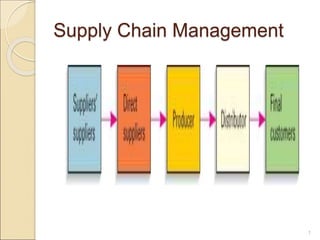

- 2. Supply Chain Management A supply chain is a set of organizations directly linked by one or more of the upstream and downstream flows of products, services, finances, and information from a source to a customer. Managing a supply chain is 'supply chain management' Supply chain management (SCM) is the management of a network of interconnected businesses involved in the ultimate provision of product and service packages required by end customers. Supply chain management spans all movement and storage of raw materials, work- in-process inventory, and finished goods from point of origin to point of consumption (supply chain). 2

- 4. 4 The Supply Chain Suppliers Manufacturers Warehouses & Distribution Centers Customers Material Costs Transportation Costs Transportation Costs Transportation CostsInventory CostsManufacturing Costs

- 5. 5 The Supply Chain – Another View Suppliers Manufacturers Warehouses & Distribution Centers Customers Material Costs Transportation Costs Transportation Costs Transportation CostsInventory CostsManufacturing Costs Plan Source Make Deliver Buy

- 6. Supply Chain for Service Providers More difficult than manufacturing Does not focus on the flow of physical goods Focuses on human resources and support services More compact and less extended

- 7. Value vs. Supply Chain Value chain ◦ every step from raw materials to the eventual end user ◦ ultimate goal is delivery of maximum value to the end user Supply chain ◦ activities that get raw materials and subassemblies into manufacturing operation Terms are used interchangeably

- 8. Supply Chain Management (SCM) Managing flow of information through supply chain in order to attain the level of synchronization that will make it more responsive to customer needs while lowering costs Keys to effective SCM ◦ information ◦ communication ◦ cooperation ◦ trust

- 9. 9 What Is Supply Chain Management (SCM)? A set of approaches used to efficiently integrate ◦ Suppliers ◦ Manufacturers ◦ Warehouses ◦ Distribution centers So that the product is produced and distributed ◦ In the right quantities ◦ To the right locations ◦ And at the right time System-wide costs are minimized and Service level requirements are satisfied Plan Source Make Deliver Buy

- 10. WHAT IS SUPPLY CHAIN MANAGEMENT " Is the strategic management of activities involved in the acquisition and conversion of materials to finished products delivered to the customer" Supplier Management Schedule / Resources Conversion Stock Deployment Delivery Customer Management Leads to Business Process Integration Material Flow Information Flow

- 11. Supply chain is the system by which organizations source, make and deliver their products or services according to market demand. Supply chain management operations and decisions are ultimately triggered by demand signals at the ultimate consumer level. Supply chain as defined by experienced practitioners extends from suppliers’ suppliers to customers’ customers.

- 12. 12 History of Supply Chain Management 1960’s - Inventory Management Focus, Cost Control 1970’s - MRP & BOM - Operations Planning 1980’s - MRPII, JIT - Materials Management, Logistics 1990’s - SCM - ERP - “Integrated” Purchasing, Financials, Manufacturing, Order Entry 2000’s - Optimized “Value Network” with Real- Time Decision Support; Synchronized & Collaborative Extended Network

- 13. 13 Why Is SCM Difficult? Uncertainty is inherent to every supply chain ◦ Travel times ◦ Breakdowns of machines and vehicles ◦ Weather, natural catastrophe, war ◦ Local politics, labor conditions, border issues The complexity of the problem to globally optimize a supply chain is significant ◦ Minimize internal costs ◦ Minimize uncertainty ◦ Deal with remaining uncertainty Plan Source Make Deliver Buy

- 14. Supply Chain Uncertainty One goal in SCM: ◦ respond to uncertainty in customer demand without creating costly excess inventory Negative effects of uncertainty ◦ lateness ◦ incomplete orders Inventory ◦ insurance against supply chain uncertainty Factors that contribute to uncertainty ◦ inaccurate demand forecasting ◦ long variable lead times ◦ late deliveries ◦ incomplete shipments ◦ product changes batch ordering ◦ price fluctuations and discounts ◦ inflated orders

- 15. CASE STUDY WHY MANAGE SUPPLY CHAINS

- 16. DIFFERENT RESPONSES OF NOKIA AND ERICSSON ON A FIRE AT ONE OF THE SUPPLIER’S FACILITY ◦ Supplier was Philips Semiconductors in Albuquerque, NM Nokia: ◦ Changed product design to source components from alternate suppliers ◦ For parts that could not be sourced from elsewhere, worked with Philips to source it from their plants in China and Netherlands ◦ All done in about five days

- 17. DIFFERENT RESPONSES OF NOKIA AND ERICSSON ON A FIRE AT ONE OF THE SUPPLIER’S FACILITY Ericsson’s experience was quite different ◦ Took 4 weeks for the news to reach upper management ◦ Realized five weeks after the fire regarding the severity of the situation. ◦ By that time, the alternative supply of chips was already taken by Nokia. ◦ Devastating impact on Ericsson $400M in potential sales was lost Part of the loss was covered by insurance. Led to component shortages Wrong product mix and marketing problems caused: $1.68B loss to Ericsson Cell Phone Division in 2000 Forced the company to exit the cell phone market

- 18. TOYOTA SUPPLY CHAIN In 1997, Aisin Seiki the sole supplier of 98% of brake fluid proportioning valves (P-valves) used by Toyota Inexpensive part (about $7 each) but important in the assembly of any car. Saturday, February 1, 1997:Fire stopped Aisin’s main factory in the industrial area of Kariya, ◦ Two weeks to restart the production ◦ Six months for complete recovery Toyota producing close to 15,500 vehicles per day. ◦ JIT meant only 2-3 days of inventory supply

- 19. Recovery Effort by Toyota Blueprints of valves were distributed among all Toyota’s suppliers Engineers from Aisin and Toyota relocated to supplier’s facilities Other manufacturers like Brother were also brought in Existing machinery adapted to build the valves according to original specifications New machinery acquired in the spot market Within days, firms with little experience with P-valves were manufacturing and delivering parts to Aisin ◦ Aisin assembled and inspected valves before shipment to Toyota ◦ About 200 of Toyota’s suppliers were involved

- 20. Outcome Accident initially cost: ◦ 7.8B Yen ($65M) to Aisin ◦ 160B Yen (or $1.3B) to Toyota Damage reduced to 30B Yen ($250M) with extra shifts and overtime Toyota issued a $100M token of appreciation to their providers as a gift for their collaboration

- 21. The Need for Supply Chain Management The need to improve operations. Increasing levels of outsourcing. Increasing transportation costs. Competitive pressures. Increasing importance of e-commerce. The need to manage inventories 21

- 22. What the supply chain is not The definitions described and developed earlier and recent industry collaborative activities indicate that supply chain management is not a standalone process. Many supply chain efforts have fallen short of the potential advantages because the term is often viewed as only relating to the supply side of the business or to the purchasing function. As indicated above, supply chain management is much more that just procurement. 22

- 23. Among the misunderstanding evidenced, SCM is not: Inventory management; Logistics management; Supplier partnerships; Driven from the supply side; A shipping strategy; Distribution management; The logistics pipeline; Procurement A computer system 23

- 24. Reasons for the slow growth of integrated SCM include the following: Lack of guidelines for creating alliances with supply chain partners. Failure to develop measures for monitoring alliances. Inability to broaden the supply chain vision beyond procurement or product distribution to encompass larger business processes. Inability to integrate the company internal procedures. 24

- 25. Reasons cont……. Lack of trust inside and outside a company. Organizational resistance to the concept. Lack of buyin-by top managers. Lack of integrated information systems and electronic commerce linking firms. 25

- 26. 26 The Importance of Supply Chain Management Dealing with uncertain environments – matching supply and demand ◦ Boeing announced a $2.6 billion write-off in 1997 due to “raw materials shortages, internal and supplier parts shortages and productivity inefficiencies” ◦ U.S Surgical Corporation announced a $22 million loss in 1993 due to “larger than anticipated inventories on the shelves of hospitals” ◦ IBM sold out its supply of its new Aptiva PC in 1994 costing it millions in potential revenue ◦ Hewlett-Packard and Dell found it difficult to obtain important components for its PC’s from Taiwanese suppliers in 1999 due to a massive earthquake U.S. firms spent $898 billion (10% of GDP) on supply- chain related activities in 1998

- 27. 27 The Importance of Supply Chain Management Shorter product life cycles of high-technology products ◦ Less opportunity to accumulate historical data on customer demand ◦ Wide choice of competing products makes it difficult to predict demand The growth of technologies such as the Internet enable greater collaboration between supply chain trading partners ◦ If you don’t do it, your competitor will ◦ Major buyers such as Wal-Mart demand a level of “supply chain maturity” of its suppliers Availability of SCM technologies on the market ◦ Firms have access to multiple products (e.g., SAP, Baan, Oracle, JD Edwards) with which to integrate internal processes

- 28. SUPPLY CHAIN INCLUDES : ◦ MATERIAL FLOWS ◦ INFORMATION FLOWS ◦ FINANCIAL FLOWS

- 29. SUPPLY CHAIN MANAGEMENT IS FACILITATED BY : ◦ PROCESSES ◦ STRUCTURE ◦ TECHNOLOGY

- 30. Supply chain serves two functions: ◦ Physical ◦ Market mediation

- 31. Supply chain objectives may differ from situation to situation. For functional products, cost efficiency is the critical factor. For innovative products, responsiveness is the important factor. Leanness + Agility together make up Leagility

- 32. SUPPLY CHAIN DRIVERS Not new. Value system of Michael Porter • Why sudden interest? – Demanding customers – Shrinking product life cycles – Proliferating product offerings – Growing retailer power in some cases – Doctrine of core competency – Emergence of specialized logistics providers – Globalization – Information technology

- 33. SUPPLY CHAIN ELEMENTS • Supply Chain Design • Resource Acquisition • Long Term Planning (1Year++) Strategic • Production/ Distribution Planning • Resource Allocation • Medium Term Planning (Qtrly,Monthly) Tactical • Shipment Scheduling • Resource Scheduling • Short Term Planning (Weekly,Daily) Operational

- 34. Supply Chain Issues Quality control Production planning and control Inventory policies Purchasing policies Production policies Transportation policies Quality policies Design of the supply chain, partnering Operating IssuesTactical IssuesStrategic Issues

- 35. Elements of Supply Chain Management Deciding how to best move and store materialsLogistics Determining location of facilitiesLocation Monitoring supplier quality, delivery, and relationsSuppliers Evaluating suppliers and supporting operationsPurchasing Meeting demand while managing inventory costsInventory Controlling quality, scheduling workProcessing Incorporating customer wants, mfg., and timeDesign Predicting quantity and timing of demandForecasting Determining what customers wantCustomers Typical IssuesElement

- 36. Elements of SCM Supply chain management involves coordinating activities across the supply chain central to these corresponding activities at each level of the supply chain. Elements Typical Issues Customers - Determining what products and/or services customers want Forecasting - Predicting the quantity and timing of customer demand. 36

- 37. Elements of SCM Cont……. Inventory - Meeting demand requirements while managing the costs of holding inventory Purchasing - Evaluating potential suppliers, supporting the needs of operations on purchased goods and services 37

- 38. 38 Elements…….. Suppliers - Monitoring supplier quality, on-time delivery, and flexibility maintaining supplier relations Location - Determining the location of facilities Logistics - Deciding how to best move information and materials

- 39. Elements cont….. Capacity Planning - Matching supply and demand Processing - Controlling quality, scheduling work 39

- 40. 40 Supply Chain Management – Key Issues Overcoming functional silos with conflicting goals Purchasing Manufacturing Distribution Customer Service/ Sales Few change- overs Stable schedules Long run lengths High inventories High service levels Regional stocks SOURCE MAKE DELIVER SELL Low pur- chase price Multipl e vendors Low invent- ories Low trans- portatio n

- 41. 41 Supply Chain Management – Key Issues ISSUE CONSIDERATIONS Network Planning • Warehouse locations and capacities • Plant locations and production levels • Transportation flows between facilities to minimize cost and time Inventory Control • How should inventory be managed? • Why does inventory fluctuate and what strategies minimize this? Supply Contracts • Impact of volume discount and revenue sharing • Pricing strategies to reduce order-shipment variability Distribution Strategies • Selection of distribution strategies (e.g., direct ship vs. cross-docking) • How many cross-dock points are needed? • Cost/Benefits of different strategies Integration and Strategic Partnering • How can integration with partners be achieved? • What level of integration is best? • What information and processes can be shared? • What partnerships should be implemented and in which situations? Outsourcing & Procurement Strategies • What are our core supply chain capabilities and which are not? • Does our product design mandate different outsourcing approaches? • Risk management Product Design • How are inventory holding and transportation costs affected by product design? • How does product design enable mass customization? Source: Simchi-Levi

- 42. 42 Supply Chain Management Operations Strategies STRATEGY WHEN TO CHOOSE BENEFITS Make to Stock standardized products, relatively predictable demand Low manufacturing costs; meet customer demands quickly Make to Order customized products, many variations Customization; reduced inventory; improved service levels Configure to Order many variations on finished product; infrequent demand Low inventory levels; wide range of product offerings; simplified planning Engineer to Order complex products, unique customer specifications Enables response to specific customer requirements Source: Simchi-Levi

- 43. 43 Supply Chain Imperatives for Success View the supply chain as a strategic asset and a differentiator ◦ Wal-Mart’s partnership with Proctor & Gamble to automatically replenish inventory ◦ Dell’s innovative direct-to-consumer sales and build-to-order manufacturing Create unique supply chain configurations that align with your company’s strategic objectives ◦ Operations strategy ◦ Outsourcing strategy ◦ Channel strategy ◦ Customer service strategy ◦ Asset network Reduce uncertainty ◦ Forecasting ◦ Collaboration ◦ Integration Supply chain configuration componen

- 44. Decision Phases in a Supply Chain • Successful supply chain management requires many decisions relating to the flow of information, product and funds. •Each decision should be made to raise the supply chain surplus •Decisions fall into three categories depending on; •Frequency of each decision. •Time frame during which decision has an impact. •Each category of decision has to consider uncertainty over the decision horizon.

- 45. Decision Phases in a Supply Chain 1. Supply Chain Strategy or Design (long term Dcns) •Company decides what the chain’s configuration will be, how resources will be allocated and what processes each stage will perform. •Decisions made by companies include; •Whether to outsource or perform a supply chain function in- house. •Location of facilities. •Capabilities of production and warehousing facilities •Products to be manufactured or sold at various locations •Modes of transportation to be made available/utilized. •Supply chain configuration should support a firms strategic objectives and increase supply chain surplus.

- 46. Decision Phases in a Supply Chain 2. Supply Chain Planning •Time frame considered is a quarter to a year. •Goal is to maximize the supply chain surplus that can be generated over the planning horizon given the constraints of phase 1. •Planning includes making decisions like; •Which markets will be supplied from which locations •Subcontracting of manufacturing •Inventory policies to be followed •As a result of the planning phase, companies define a set of operating policies that govern short-term operations

- 47. Decision Phases in a Supply Chain 3. Supply Chain Operation •Time horizon is weekly or daily •Companies make decisions regarding individual customer orders. •Supply chain configuration is considered fixed and planning policies already defined. •Goal of supply chain operations is to handle incoming customer orders in the best possible manner.

- 48. Decision Phases in a Supply Chain 3. Supply Chain Operation … During this phase; •Firms allocate inventory/production to individual orders. •Set a date that an order can be fulfilled. •Generate pick lists at a warehouse. •Allocate an order to a particular shipping mode and shipment. •Set delivery schedules of trucks •Place replenishment orders. •Operational decisions are in the short term (minutes, hours or days) hence there is less uncertainty about demand information. •Goal is to exploit the reduction of uncertainty and optimize performance with constraints of phase 1 & 2

- 49. 49 Value of Information and SCM

- 50. 50 Information In The Supply Chain Source Make Deliver Sell Suppliers Manufacturers Warehouses & Distribution Centers Retailer Order Lead Time Delivery Lead Time Production Lead Time Each facility further away from actual customer demand must make forecasts of demand Lacking actual customer buying data, each facility bases its forecasts on ‘downstream’ orders, which are more variable than actual demand To accommodate variability, inventory levels are overstocked thus increasing inventory carrying costs It’s estimated that the typical pharmaceutical company supply chain carries over 100 days of product to accommodate uncertainty Plan

- 51. Information Technology: A Supply Chain Enabler Information links all aspects of supply chain E-business ◦ replacement of physical business processes with electronic ones Electronic data interchange (EDI) ◦ a computer-to-computer exchange of business documents Bar code and point-of-sale ◦ data creates an instantaneous computer record of a sale Radio frequency identification (RFID) ◦ technology can send product data from an item to a reader via radio waves Internet ◦ allows companies to communicate with suppliers, customers, shippers and other businesses around the world, instantaneously

- 52. E-business and Supply Chain Cost savings and price reductions Reduction or elimination of the role of intermediaries Shortening supply chain response and transaction times Gaining a wider presence and increased visibility for companies Greater choices and more information for customers

- 53. E-business and Supply Chain (cont.) Improved service as a result of instant accessibility to services Collection and analysis of voluminous amounts of customer data and preferences Creation of virtual companies Leveling playing field for small companies Gaining global access to markets, suppliers, and distribution channels

- 54. 54 Methods for Improving Forecasts Accurate Forecasts Panels of Experts • Internal experts • External experts • Domain experts • Delphi technique • Moving average • Exponential smoothing • Trend analysis • Seasonality analysis Judgment Methods Time-Series Methods Causal Analysis Market Research Analysis • Relies on data other than that being predicted • Market testing • Market surveys • Focus groups

- 55. 55 Supply Chain Collaboration – What Is It? Many different definitions depending on perspective The means by which companies within the supply chain work together towards mutual goals by sharing ◦ Ideas ◦ Information ◦ Processes ◦ Knowledge ◦ Information ◦ Risks ◦ Rewards Why collaborate? ◦ Accelerate entry into new markets ◦ Changes the relationship between cost/value/profit equation

- 56. 56 Supply Chain Collaboration Cornerstone of effective SCM The focus of many of today’s SCM initiatives The only method that has the potential to eliminate or minimize the Bullwhip effect Manufacturer Distributors/ Wholesalers Suppliers Retailers Collaborative Demand Planning Collaborative Logistics Planning •Transportation services •Distribution center services Synchronized Production Scheduling Collaborative Product Development Logistics Providers

- 57. 57 Benefits of Supply Chain Collaboration CUSTOMERS MATERIAL SUPPLIERS SERVICE SUPPLIERS • Reduced inventory • Increased revenue • Lower order management costs • Higher Gross Margin • Better forecast accuracy • Better allocation of promotional budgets • Reduced inventory • Lower warehousing costs • Lower material acquisition costs • Fewer stockout conditions • Lower freight costs • Faster and more reliable delivery • Lower capital costs • Reduced depreciation • Lower fixed costs • Improved customer service • More efficient use of human resources Source: Cohen & Roussel

- 58. 58 Supply Chain Collaboration Spectrum Source: Cohen & Roussel Number of Relationships ExtentofCollaboration Many Few Limited Extensive Transactional Collaboration Synchronized Collaboration Cooperative Collaboration Coordinated Collaboration Not Viable Low Return The green arrow describes increasing complexity and sophistication of: ◦ Information systems ◦ Systems infrastructure ◦ Decision support systems ◦ Planning mechanisms ◦ Information sharing ◦ Process understanding Higher levels of collaboration imply the need for both trading partners to have equivalent (or close) levels of supply chain maturity Synchronized collaboration demands joint planning, R&D and sharing of information and processing models ◦ Movement to real-time customer demand information throughout the supply chain

- 59. 59 Successful Supply Chain Collaboration Try to collaborate internally before you try external collaboration Help your partners to work with you Share the savings Start small (a limited number of selected partners) and stay focused on what you want to achieve in the collaboration Advance your IT capabilities only to the level that you expect your partners to manage Put a comprehensive metrics program in place that allows you to monitor your partners’ performance Make sure people are kept part of the equation ◦ Systems do not replace people ◦ Make sure your organization is populated with competent professionals who’ve done this before

- 60. 60 Emerging Best Practices in SCM Strategy

- 61. Supply Chain Integration Information sharing among supply chain members ◦ Reduced bullwhip effect ◦ Early problem detection ◦ Faster response ◦ Builds trust and confidence Collaborative planning, forecasting, replenishment, and design ◦ Reduced bullwhip effect ◦ Lower Costs (material, logistics, operating, etc.) ◦ Higher capacity utilization ◦ Improved customer service levels

- 62. Coordinated workflow, production and operations, procurement ◦ Production efficiencies ◦ Fast response ◦ Improved service ◦ Quicker to market Adopt new business models and technologies ◦ Penetration of new markets ◦ Creation of new products ◦ Improved efficiency ◦ Mass customization Supply Chain Integration (cont.)

- 63. Suppliers Procurement ◦ purchase of goods and services from suppliers On-demand (direct response) delivery ◦ requires supplier to deliver goods when demanded by customer Continuous replenishment ◦ supplying orders in a short period of time according to a predetermined schedule Cross-enterprise teams coordinate processes between company and supplier

- 64. Outsourcing Sourcing ◦ selection of suppliers Outsourcing ◦ purchase of goods and services from an outside supplier Core competencies ◦ what a company does best Single sourcing ◦ a company purchases goods and services from only a few (or one) suppliers

- 65. Copyright 2006 John Wiley & Sons, Inc. 10-65 E-Procurement Direct purchase from suppliers over the Internet Direct products go directly into production process a product, indirect products not E-marketplaces ◦ web sites where companies and suppliers conduct business-to-business activities Reverse auction ◦ a company posts orders on the Internet for suppliers to bid on

- 66. Measuring Supply Chain Performance Key performance indicators ◦ inventory turnover cost of annual sales per inventory unit ◦ inventory days of supply total value of all items being held in inventory ◦ fill rate fraction of orders filled by a distribution center within a specific time period

- 67. Inventory turns = Average aggregate value of inventory Cost of goods sold Average aggregate value of inventory = =(average inventory for item i)X (unit value item i) Days of supply = (Costs of goods sold)/(365 days) Average aggregate value of inventory Key Performance Indicators

- 68. Key Performance Indicators: Example Inventory turns = $34,416,000 $425, 000, 000 Days of supply = ($425,000,000)/(365) $34,416,000 = 12.3 = 29.6 1. Cost of goods sold: $425 million 2. Production materials and parts: $4,629,000 3. Work-in-process: $17,465,000 4. Finished goods: $12,322,000 5. Total average aggregate value of inventory (2+3+4): $34,416,000

- 69. Other Measures of Supply Chain Performance Process Control ◦ used to monitor and control any process in supply chain Supply Chain Operations Reference (SCOR) ◦ establish targets to achieve “best in class” performance

- 70. GREEN SUPPLY CHAIN MANAGEMENT PRACTICES

- 71. Definition of GSCM GSC is a method to design and/or redesign the supply chain that incorporates recycling and remanufacturing into the production process and it involves minimization of the firm’s total environmental impact from start to finish of the supply chain and also from beginning to end of the product life cycle.

- 72. The practice This refers to supply chain management functions which include: ◦ Green purchasing (in-bound logistics) ◦ Design for the environment (internal supply chain) ◦ Green marketing (out-bound logistics) ◦ Reverse logistics The results of the research carried by Purba et al (2005), demonstrate that greening the inbound function, as well as greening production, lead to greening outbound, as well as to competitiveness and economic performance of the firm.

- 73. Drivers Demand – e.g organic foods, energy savers etc Regulation- e.g NEMA Own initiative - CSR Competitiveness – ISO, world class Financial enterprises- IFC terms

- 74. Benefits Cost savings Waste minimization Customer satisfaction Increased competitiveness Enhanced environmental performance Increased awareness of HSE Improved productivity Improved business-to-business relations

- 75. Global Supply Chain To compete globally requires an effective supply chain Information technology is an “enabler” of global trade Nations form trading groups No tariffs or duties