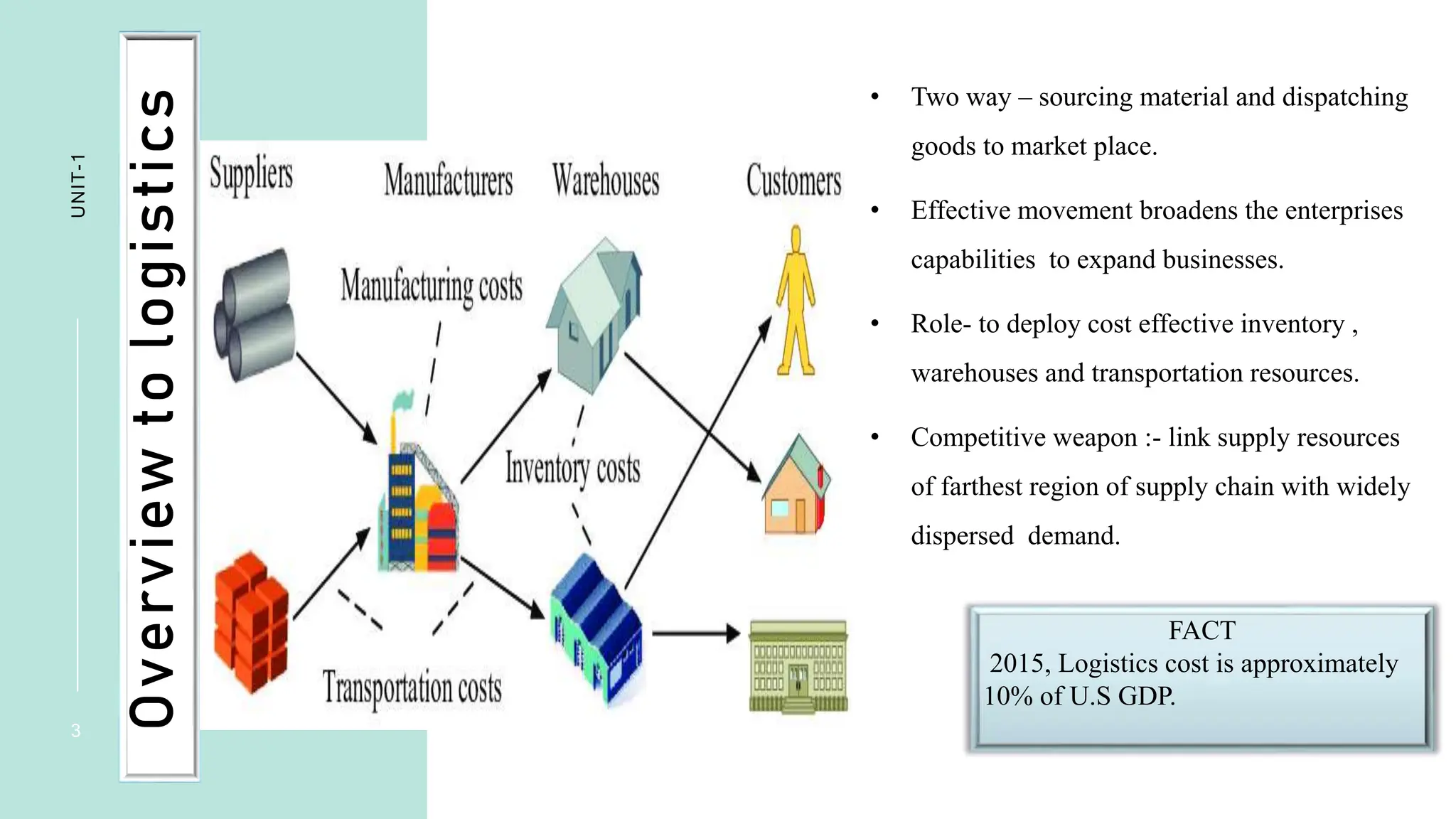

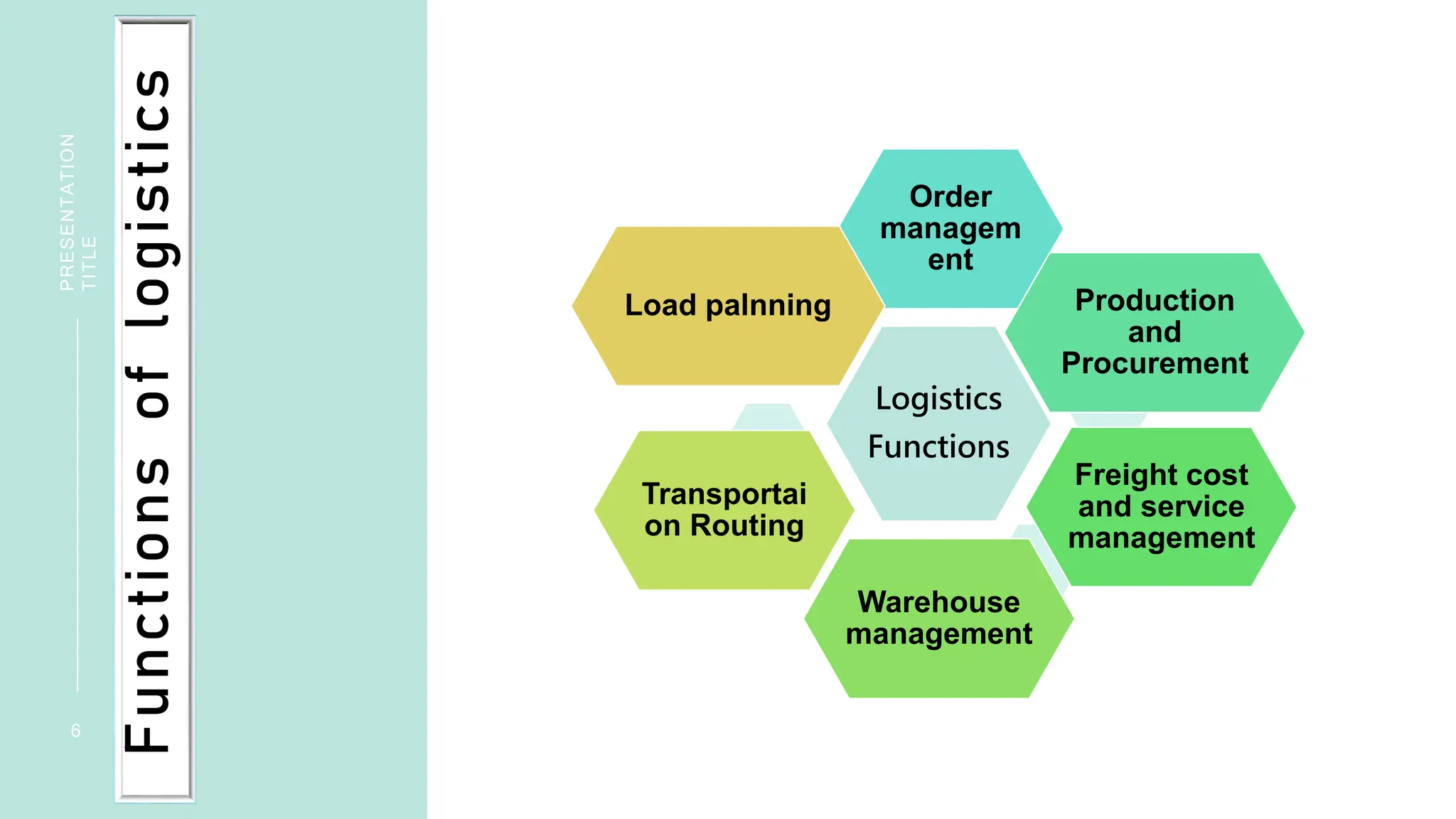

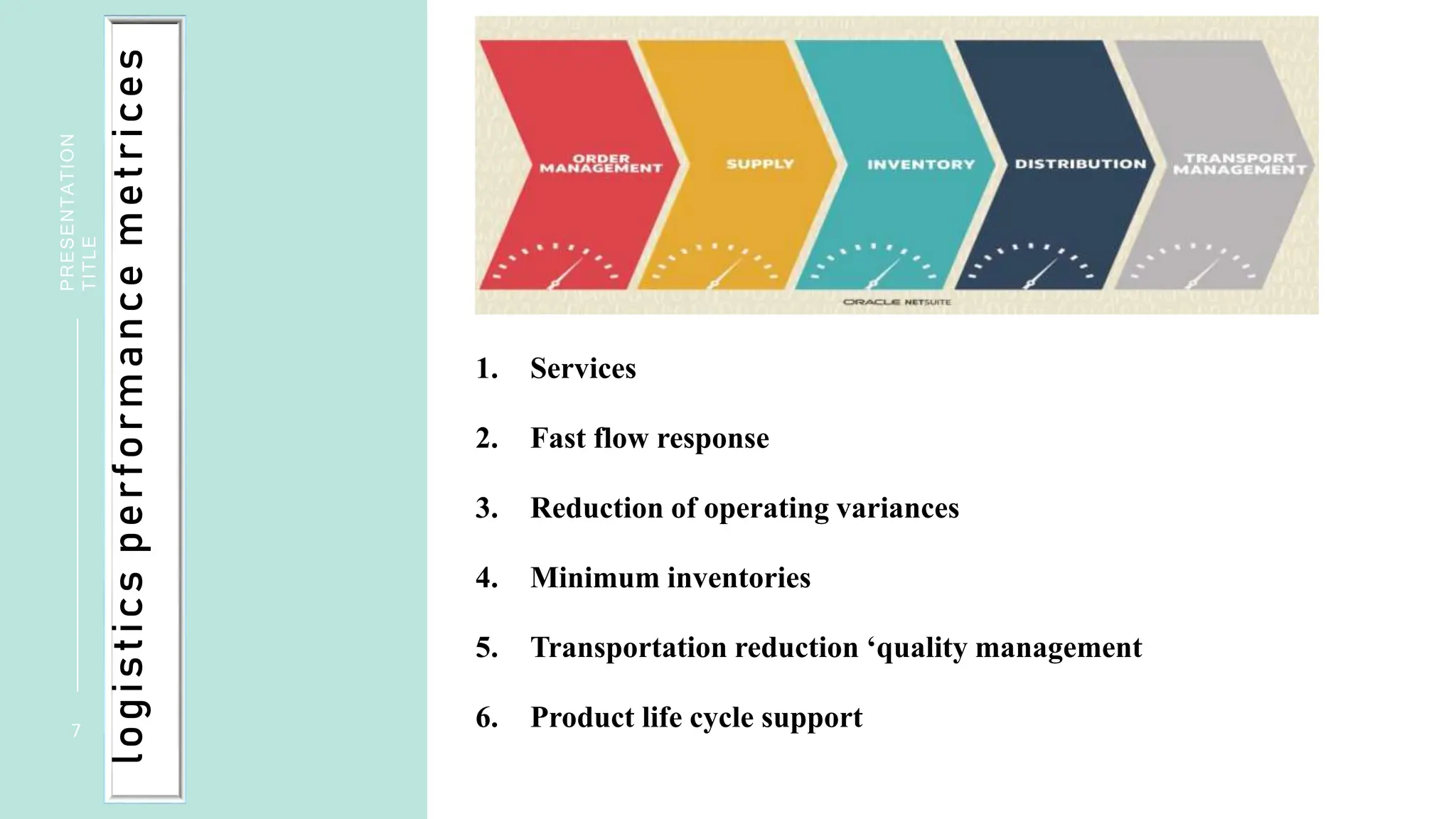

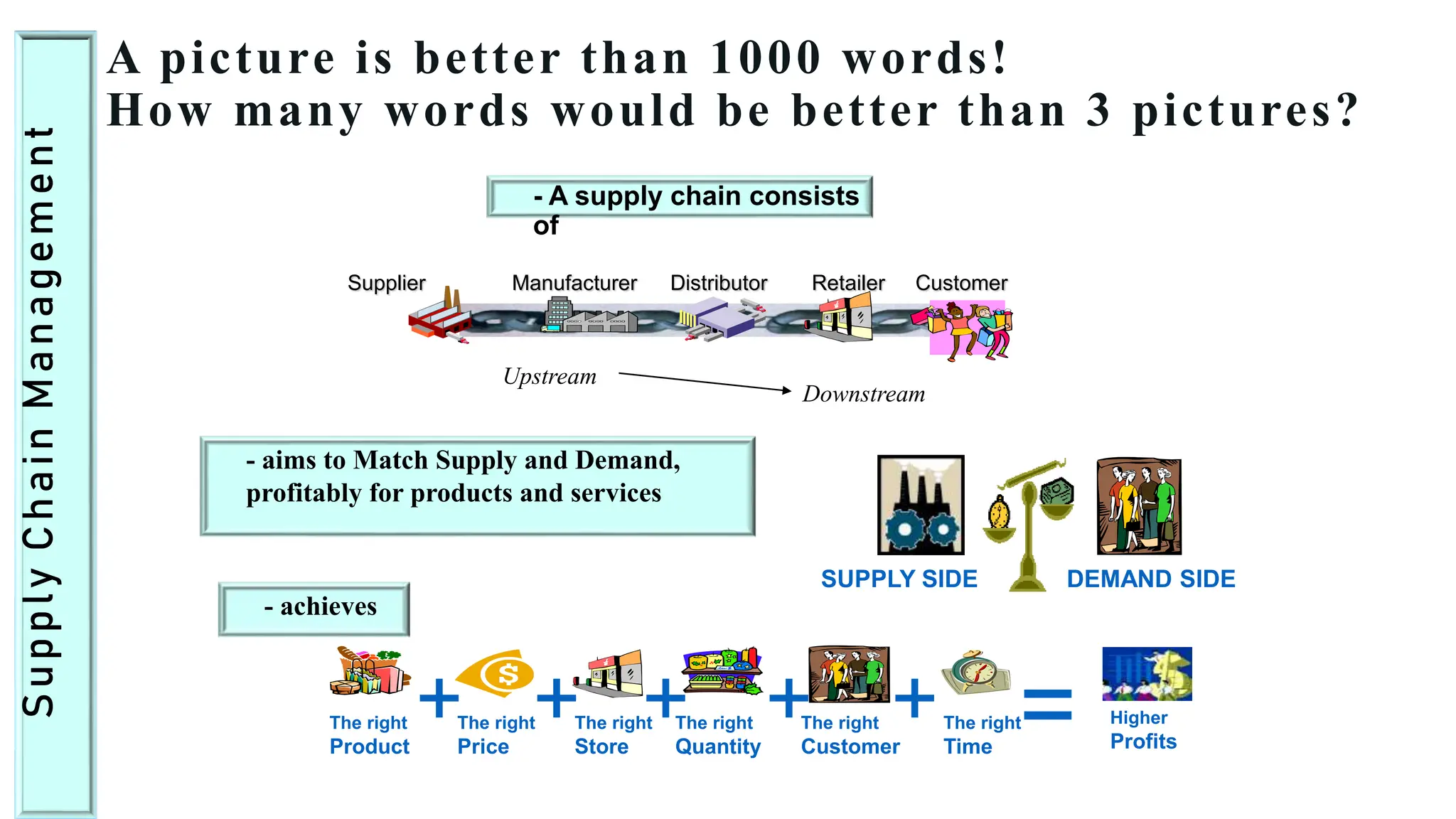

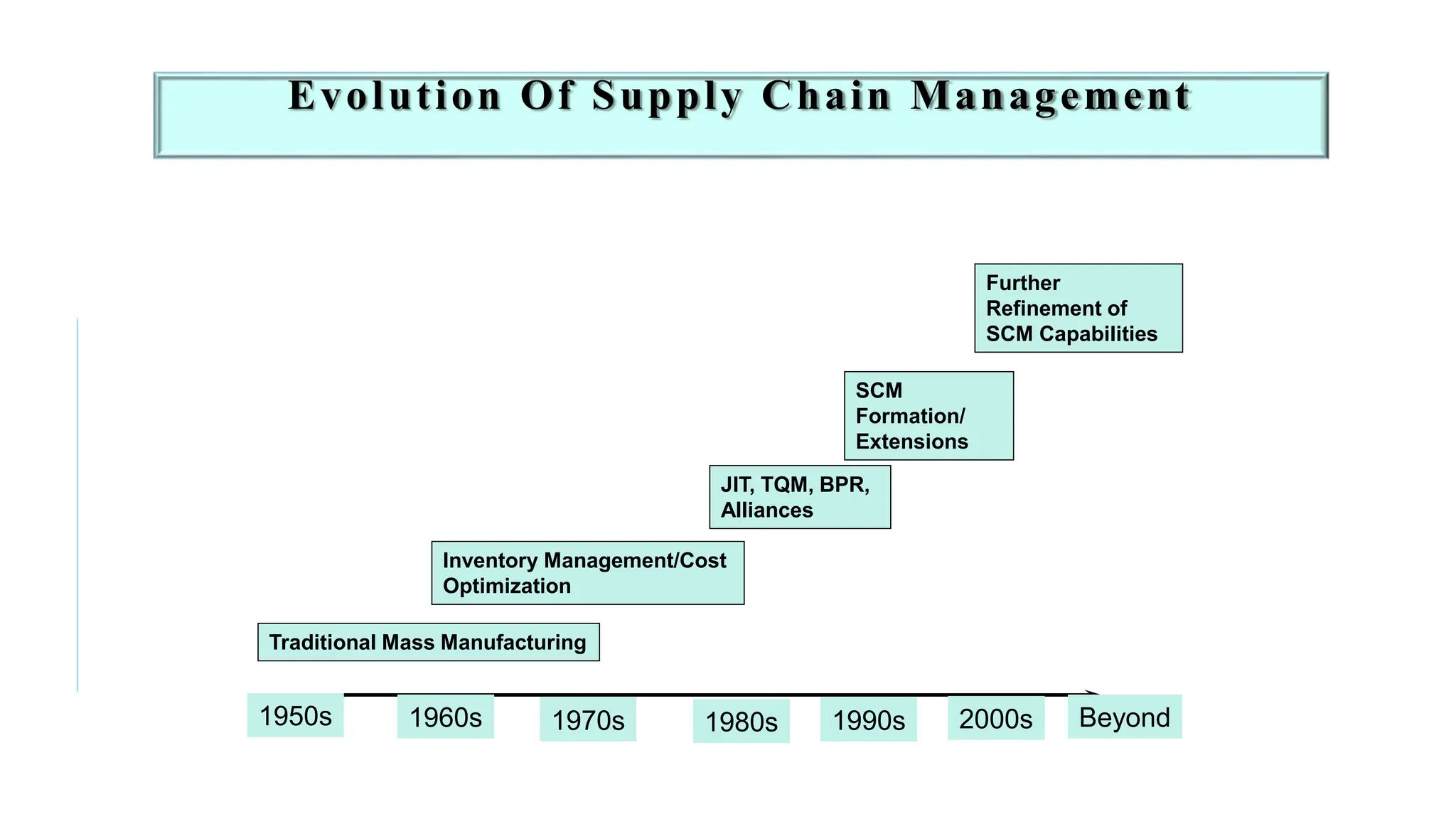

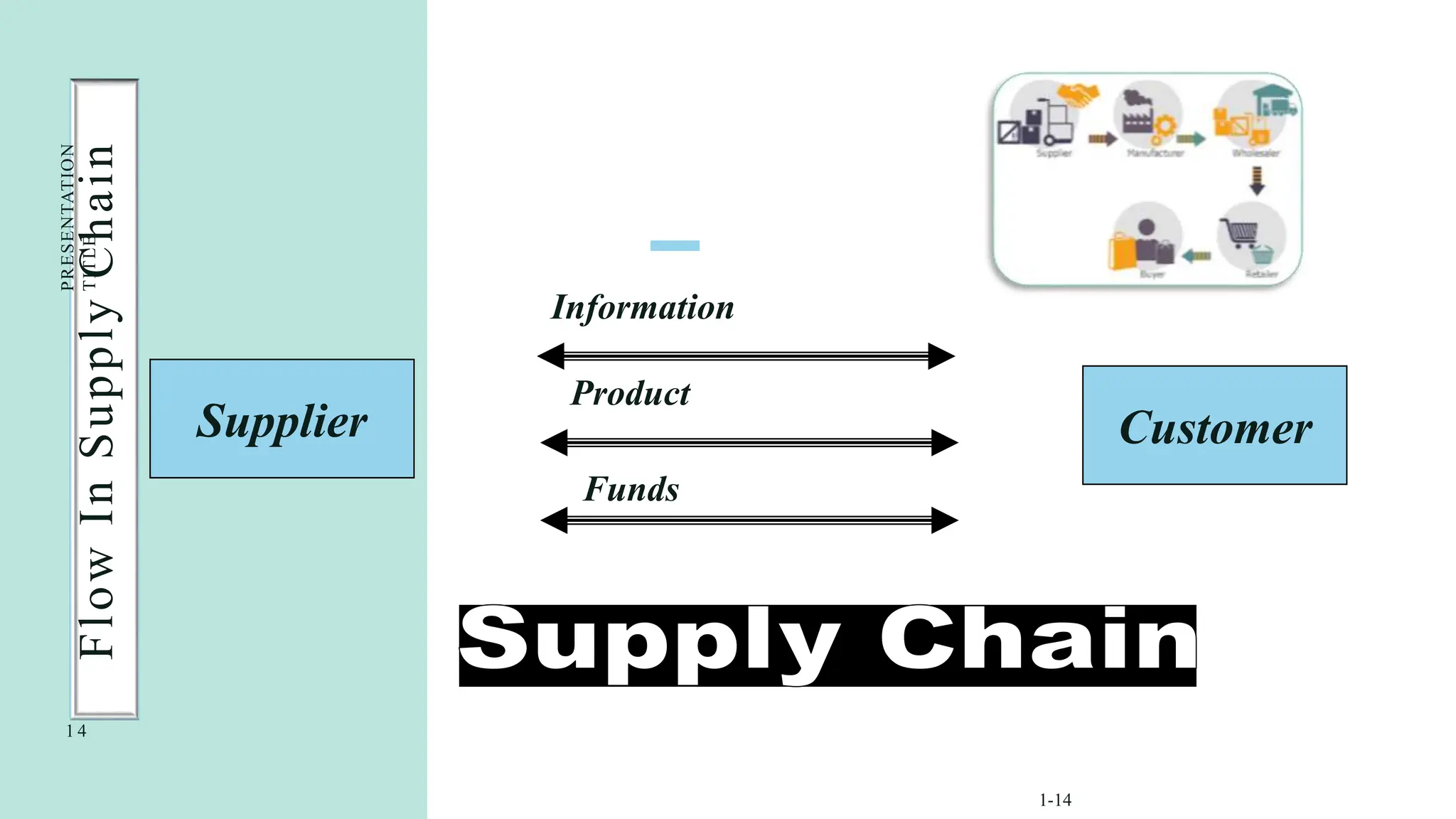

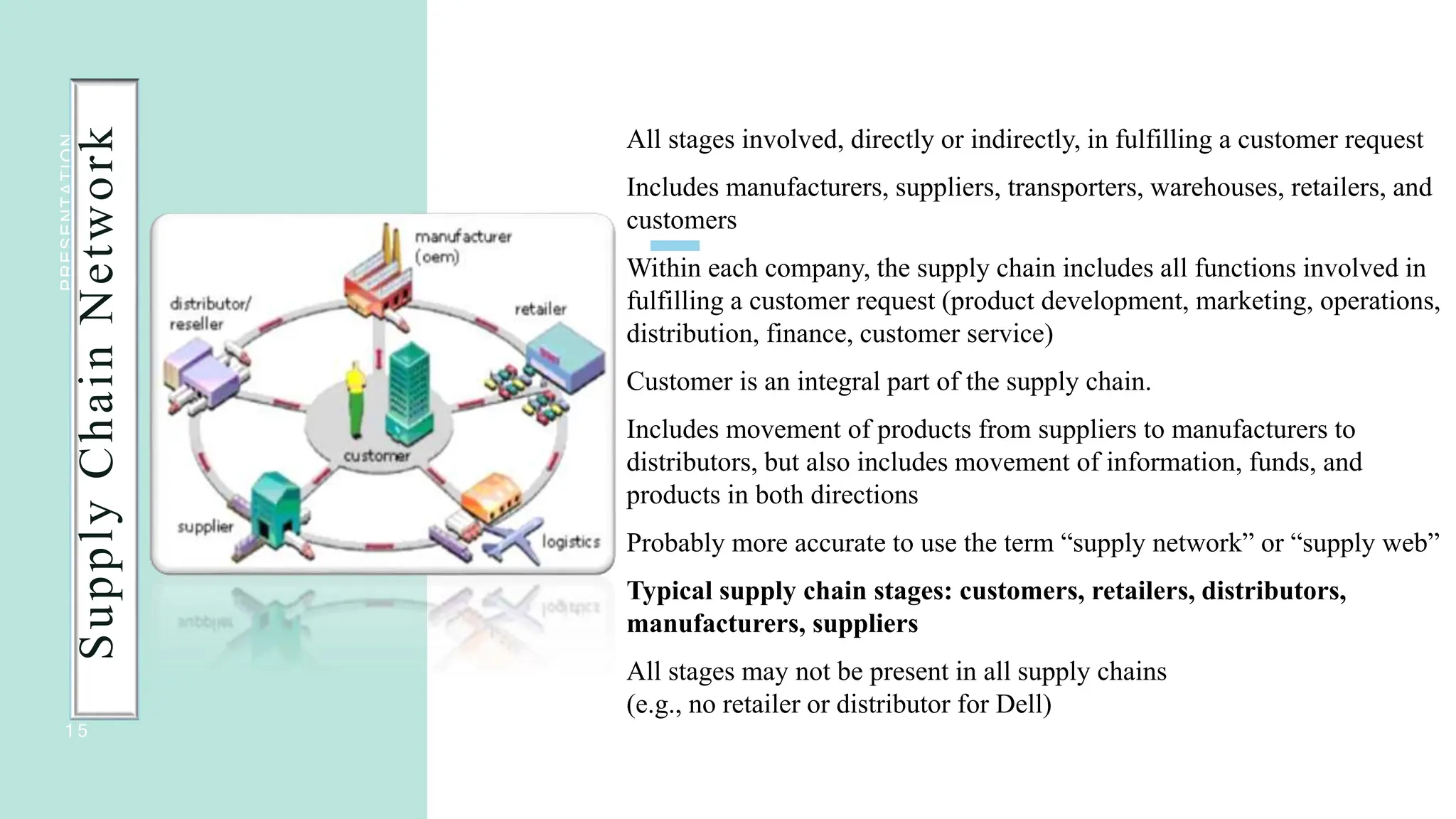

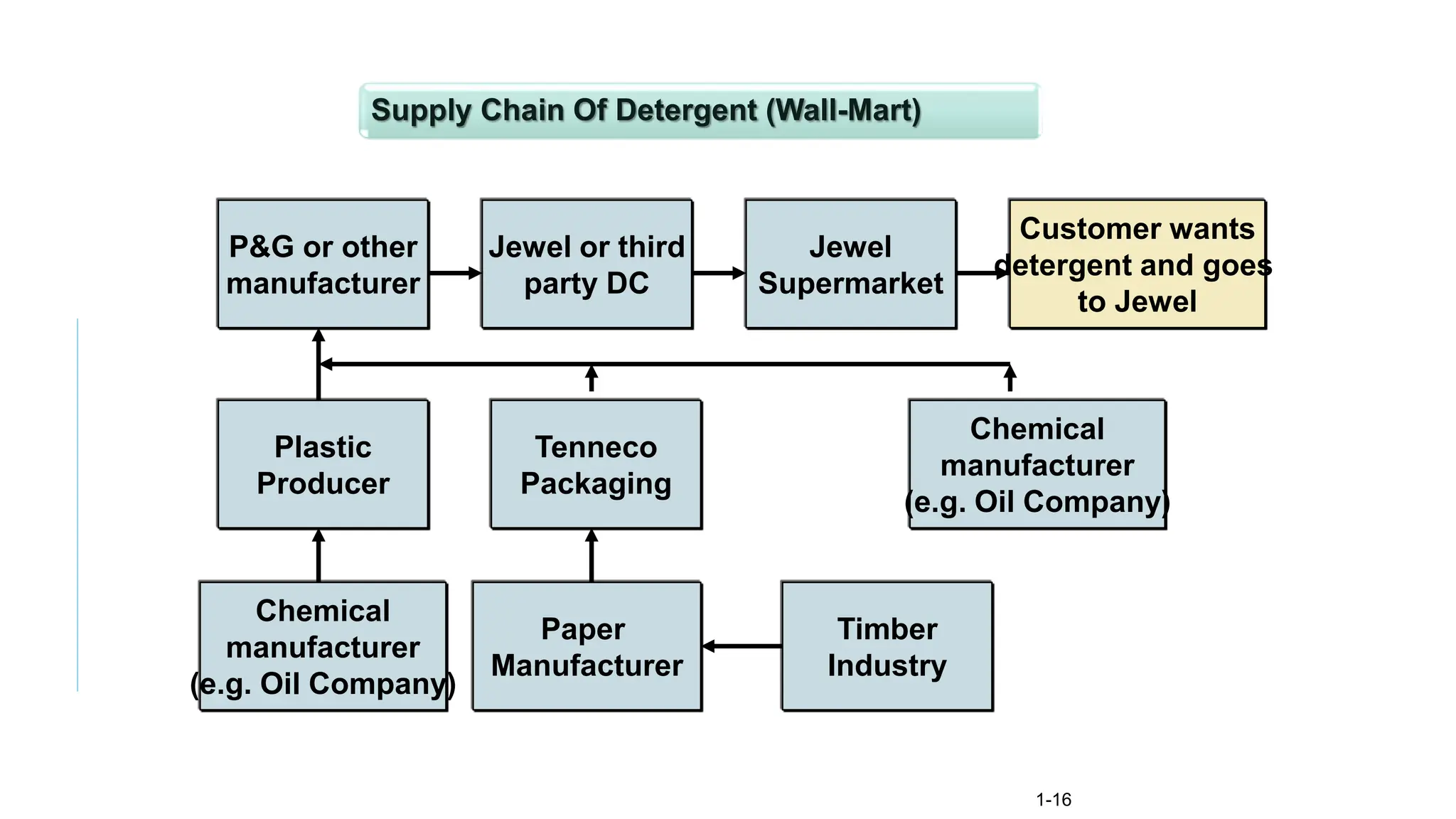

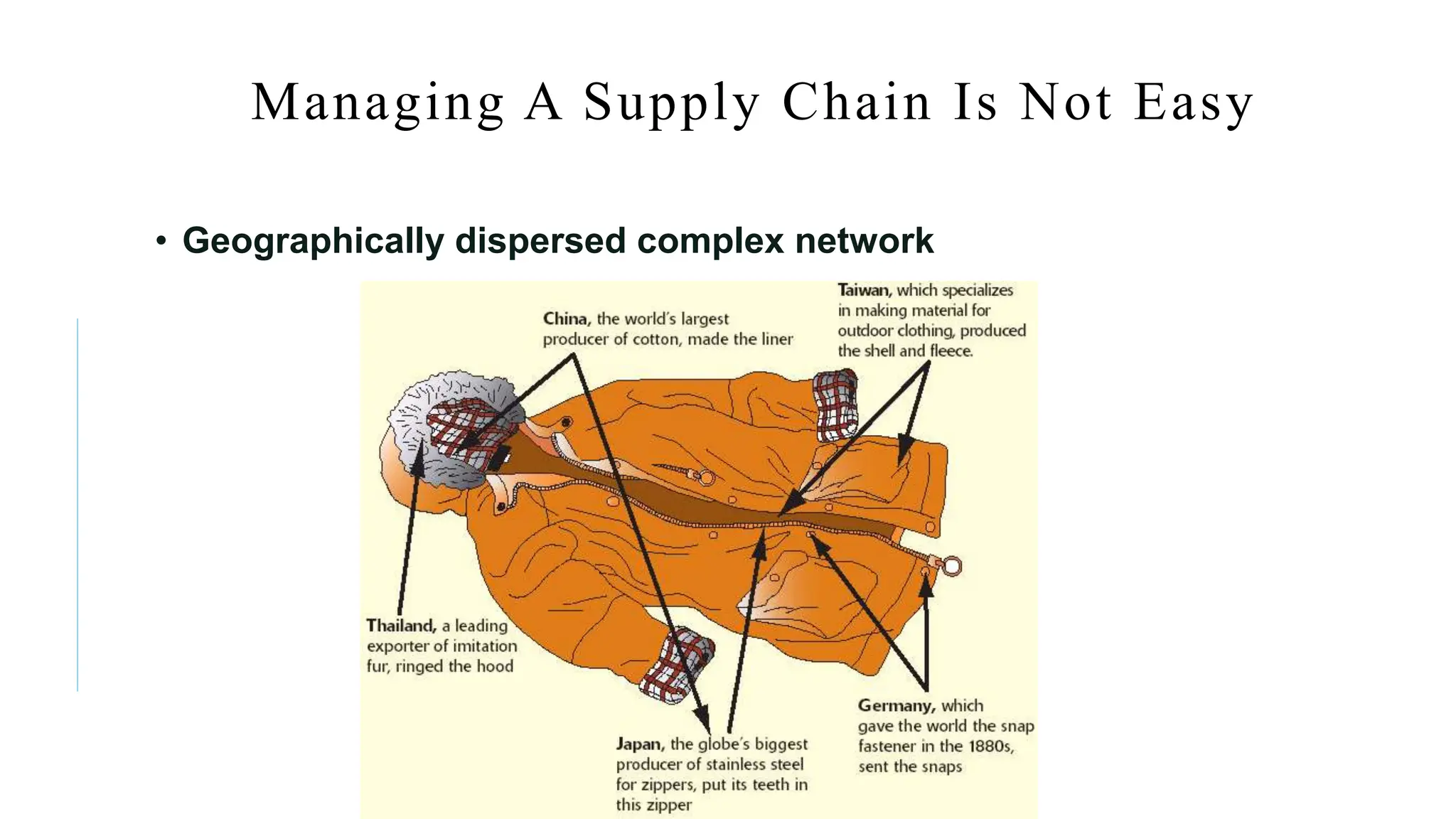

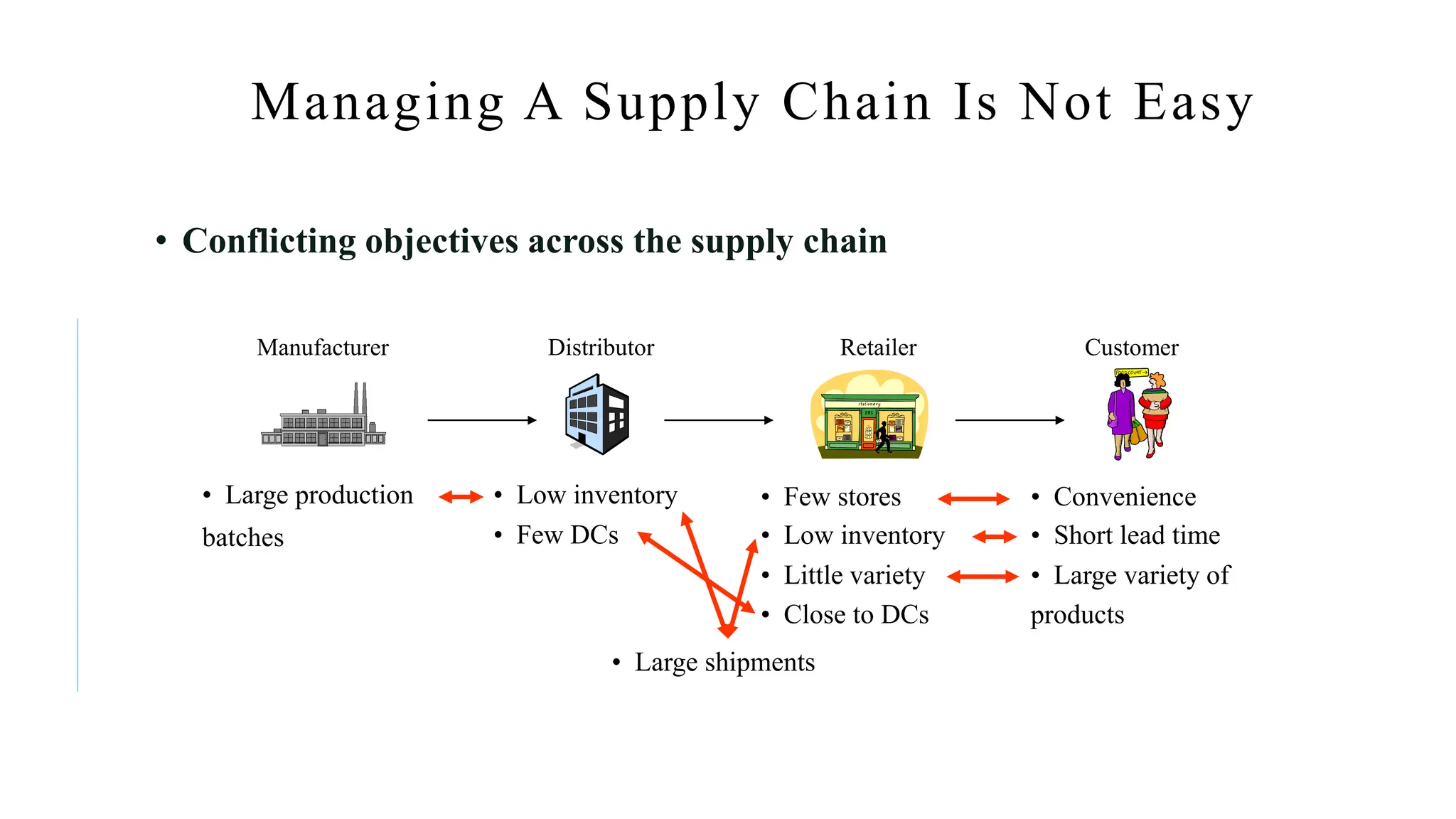

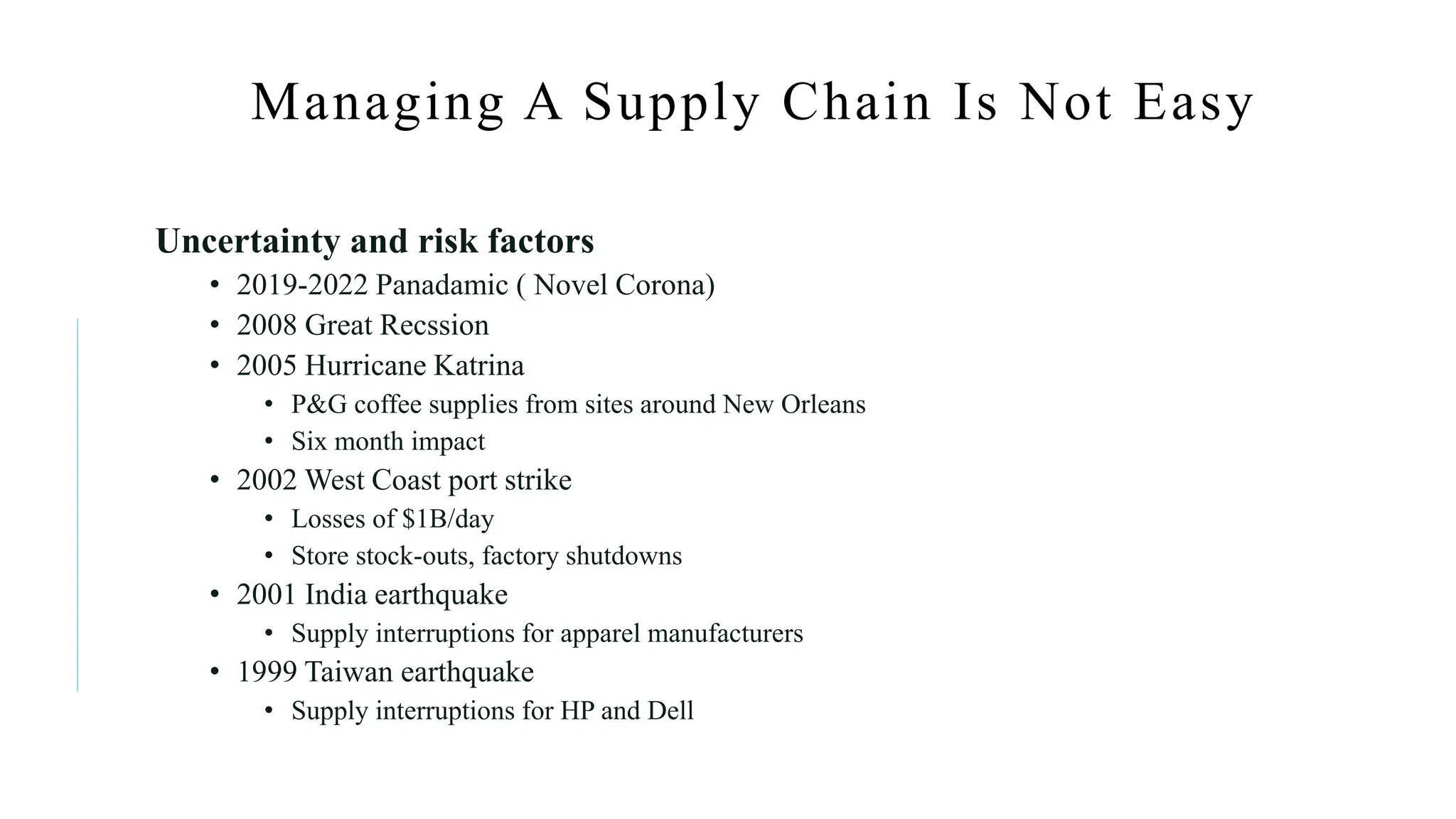

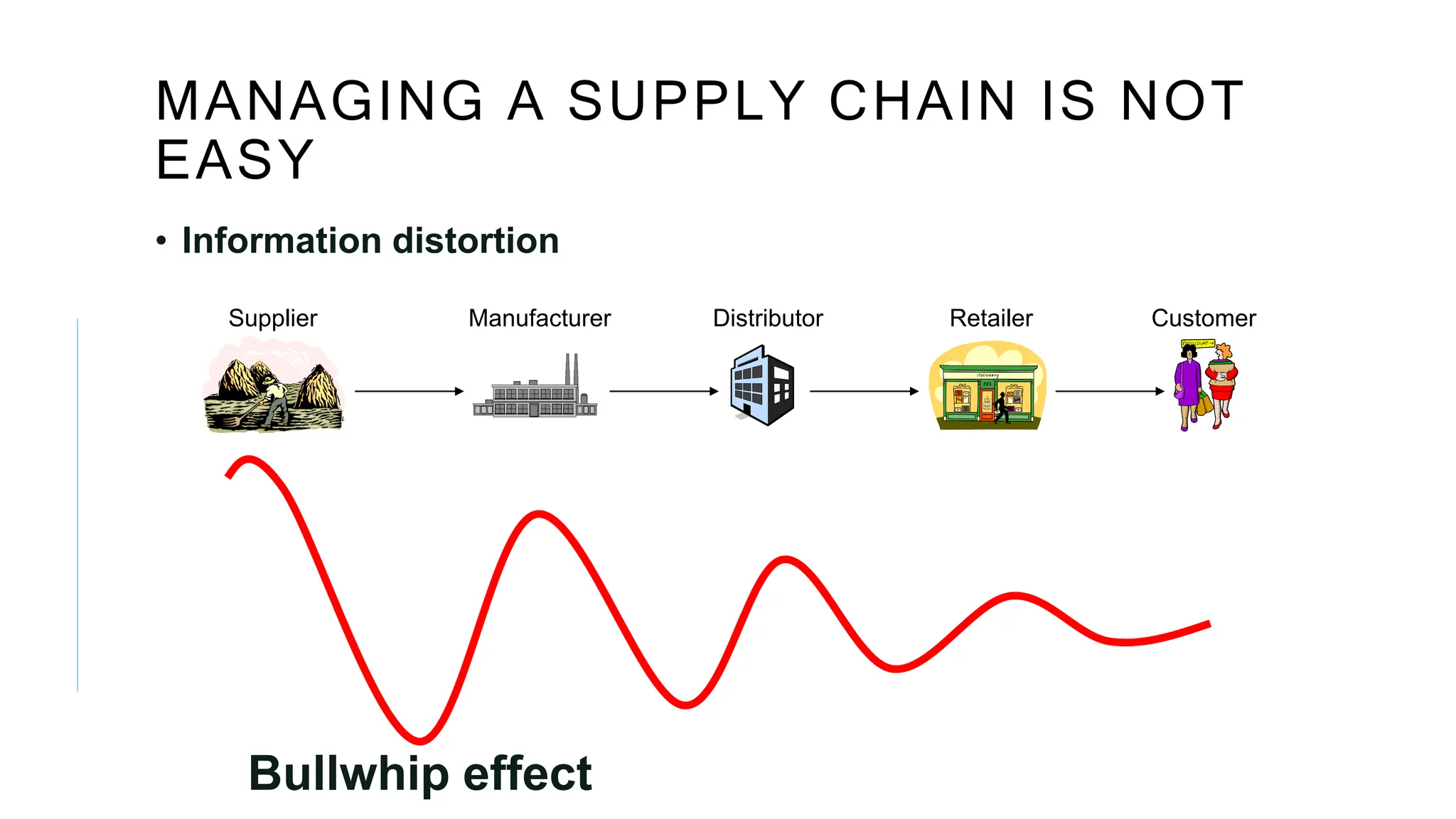

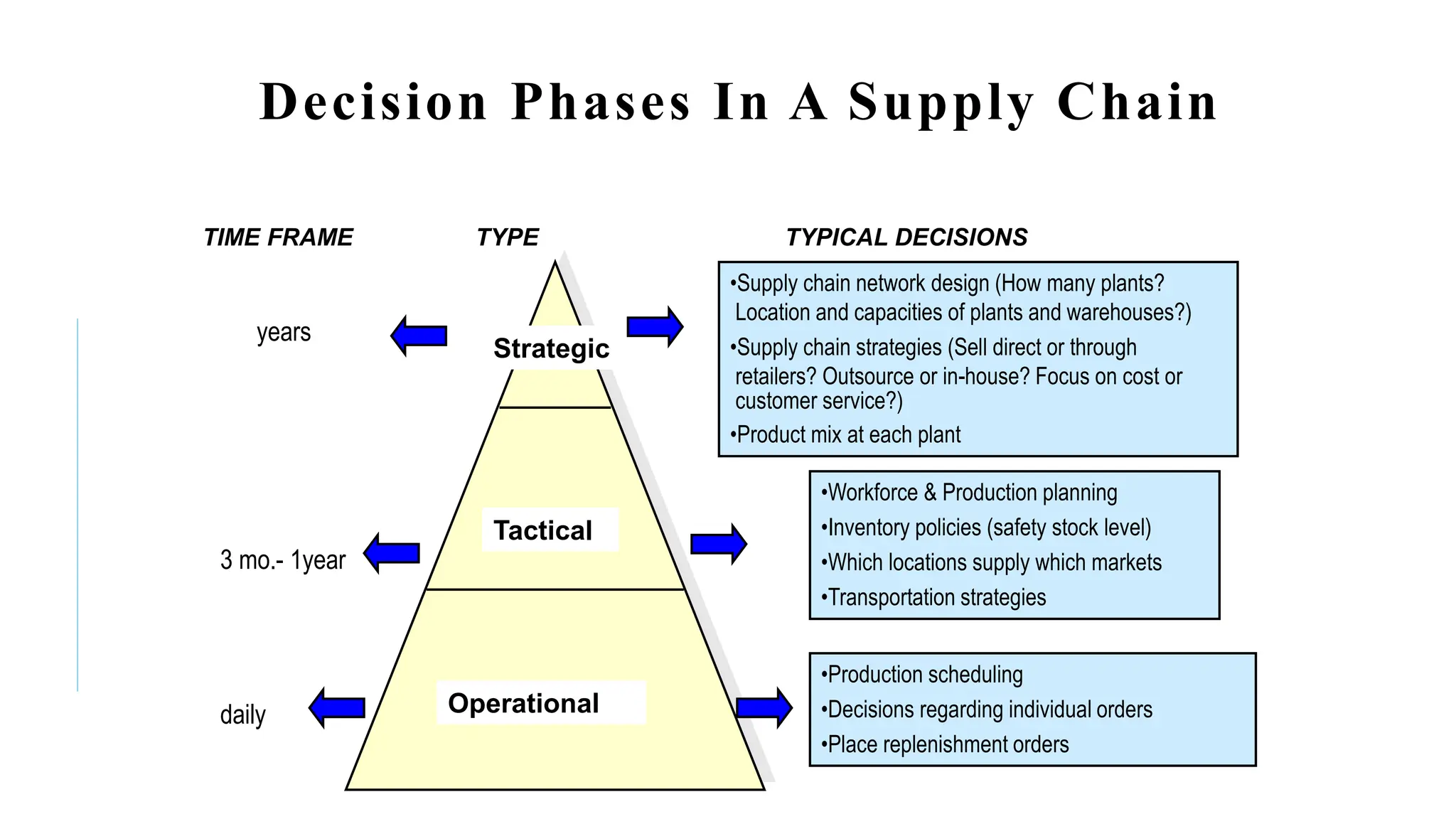

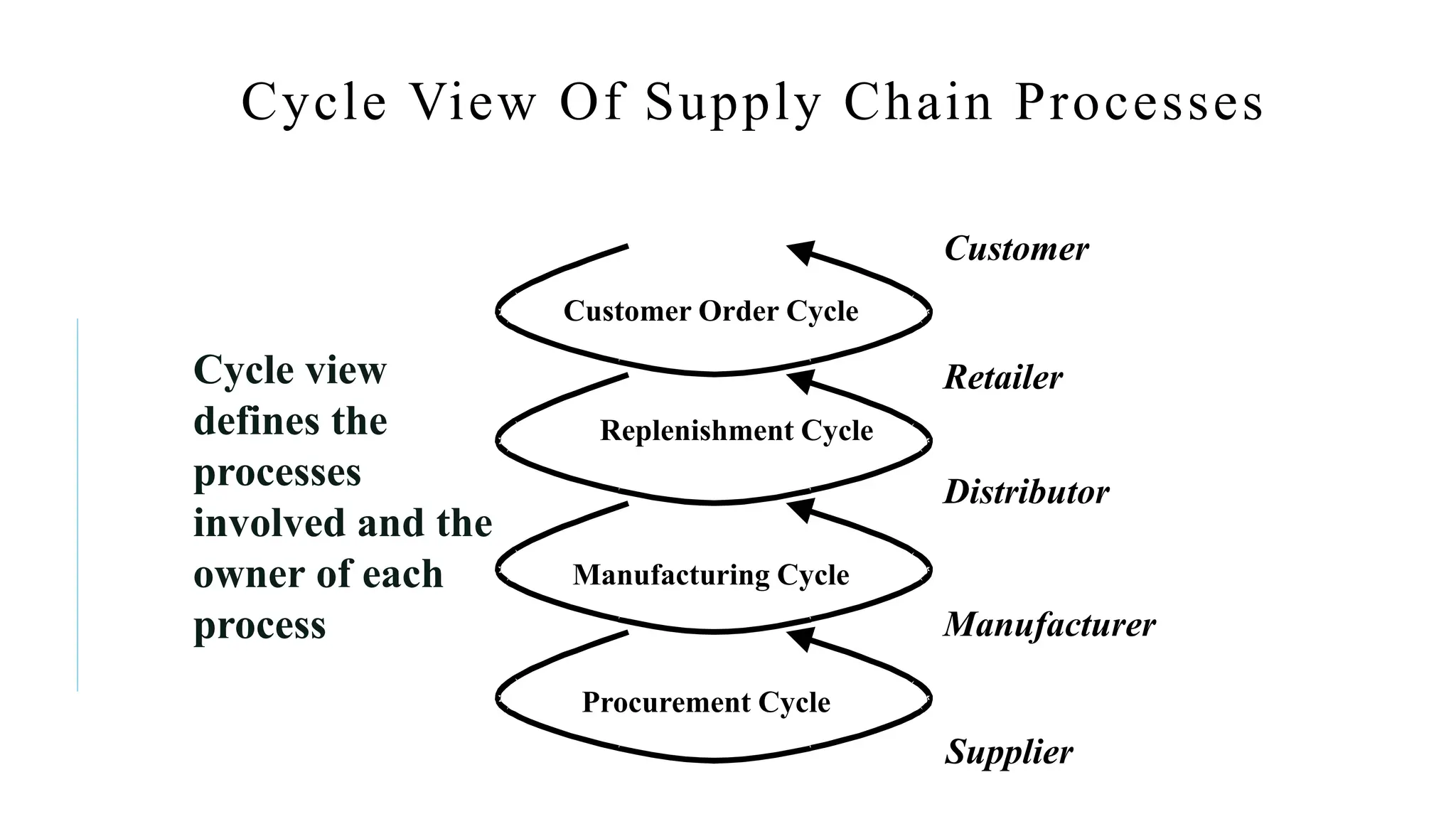

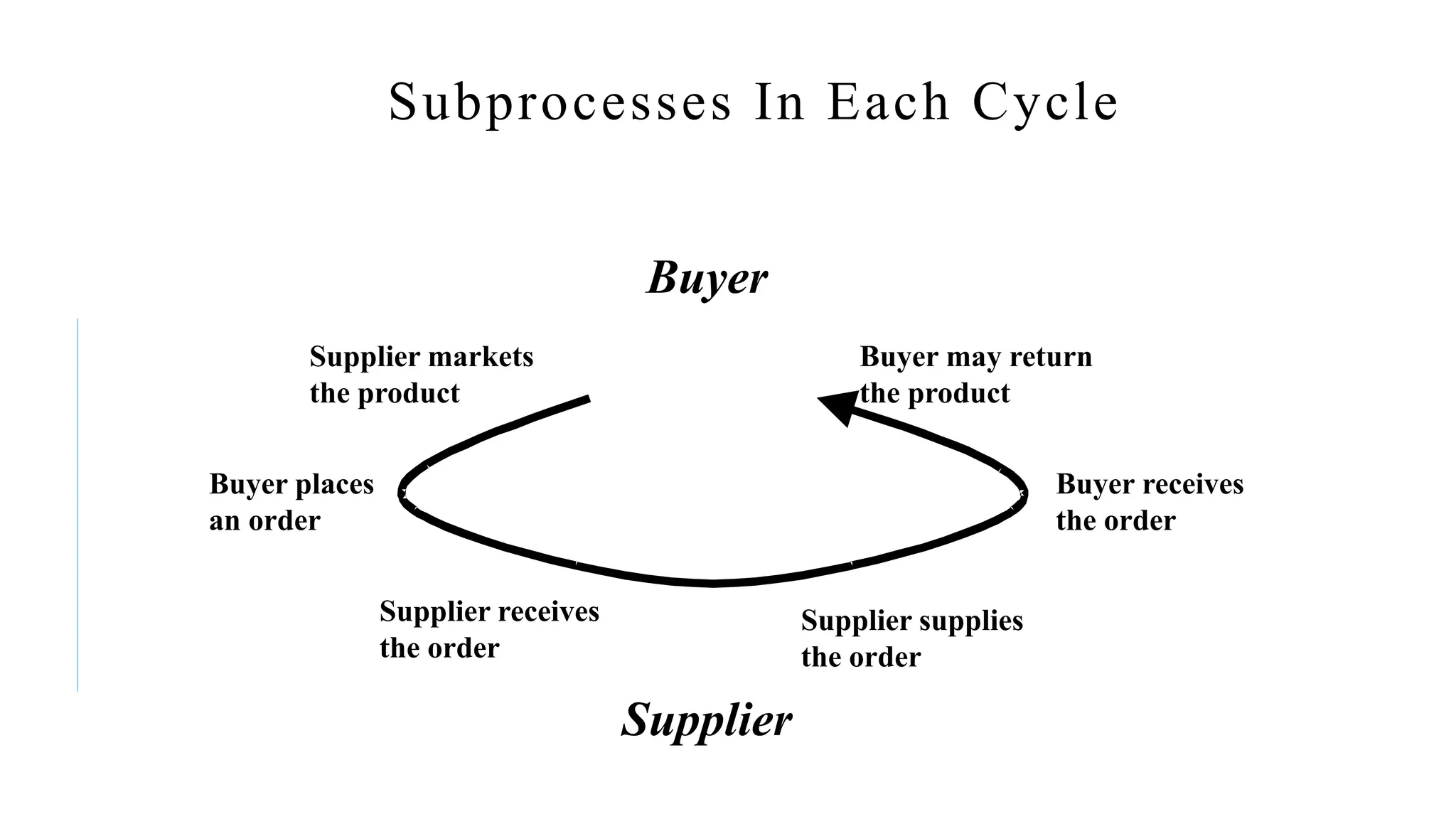

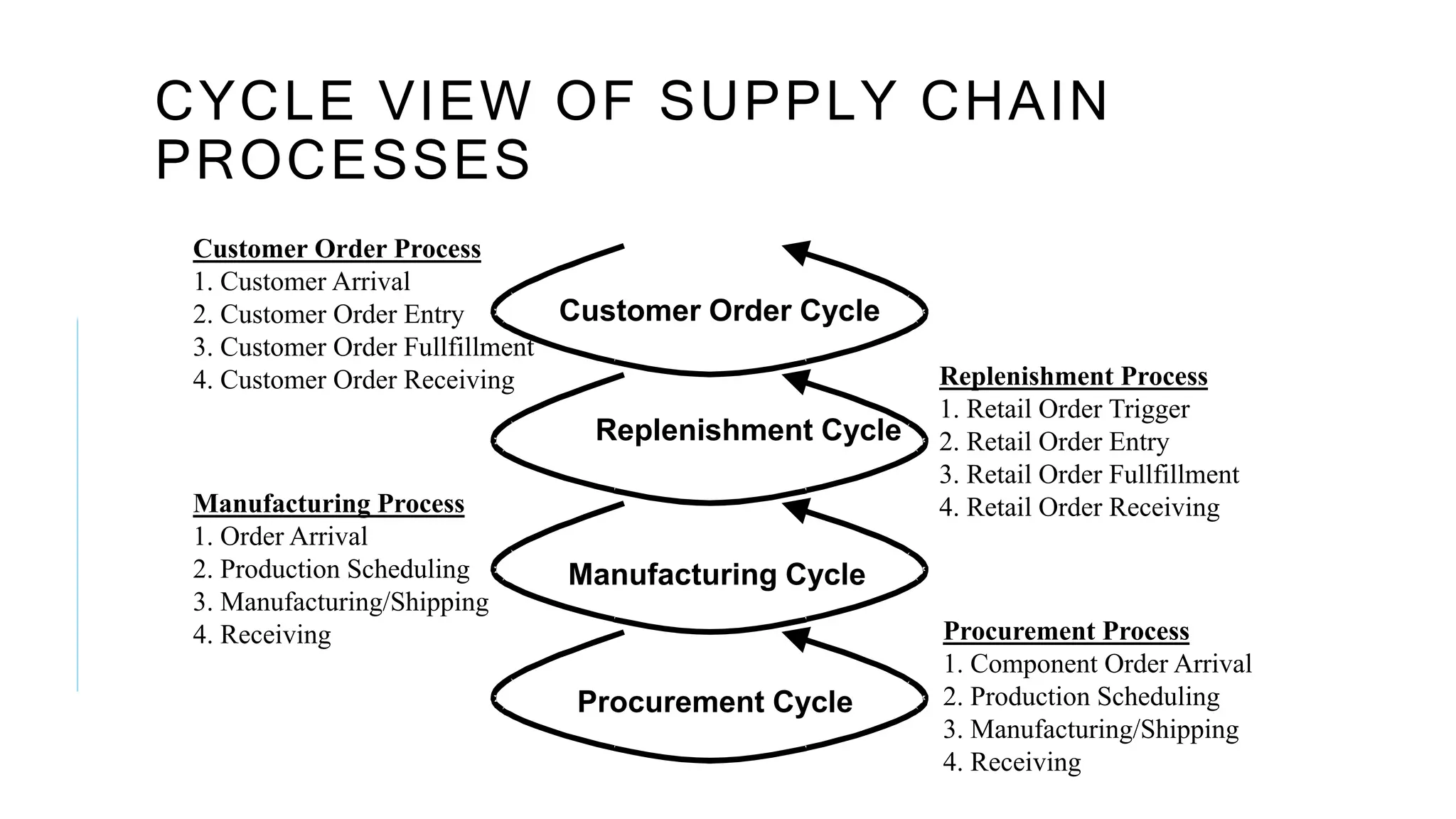

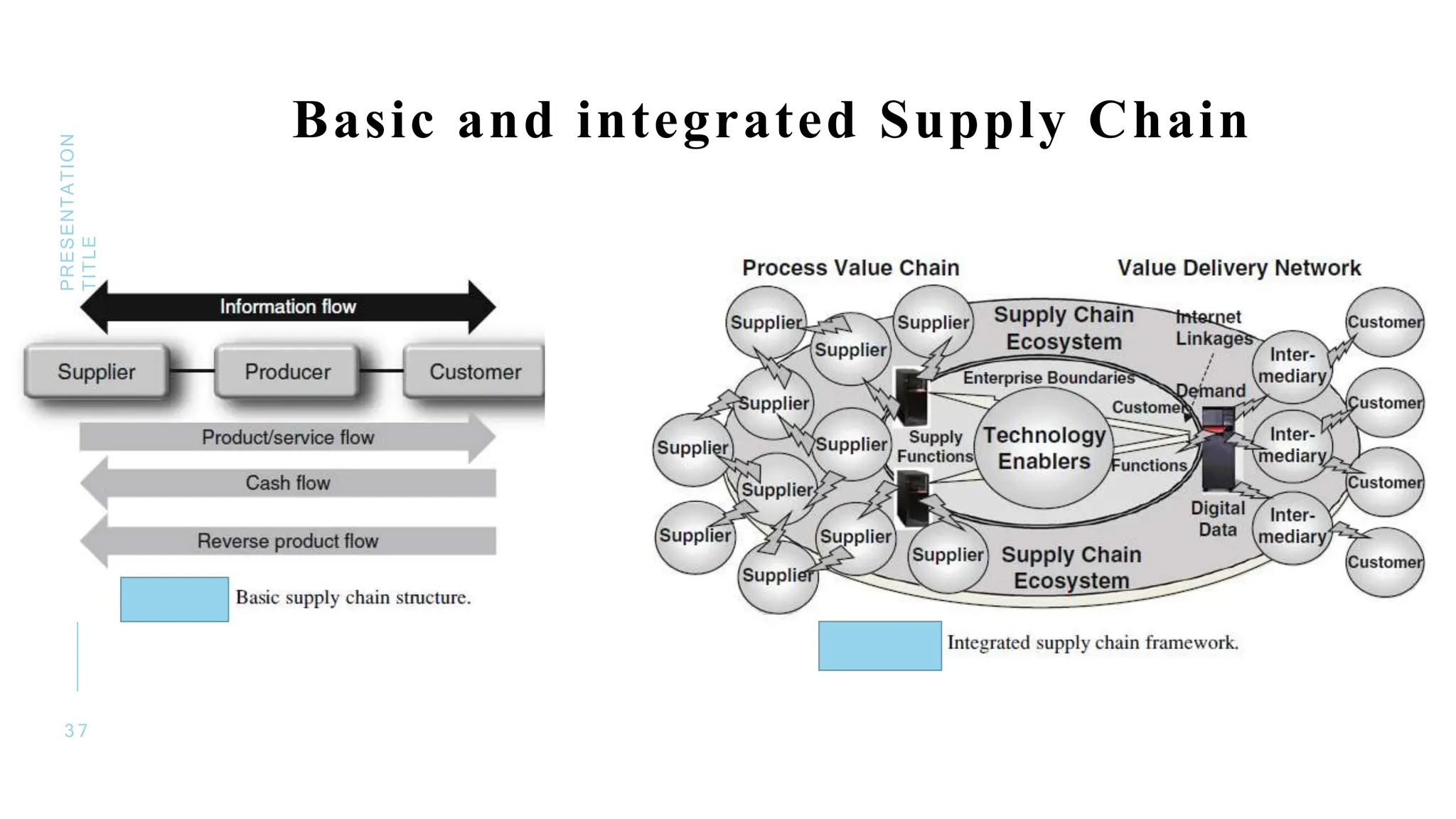

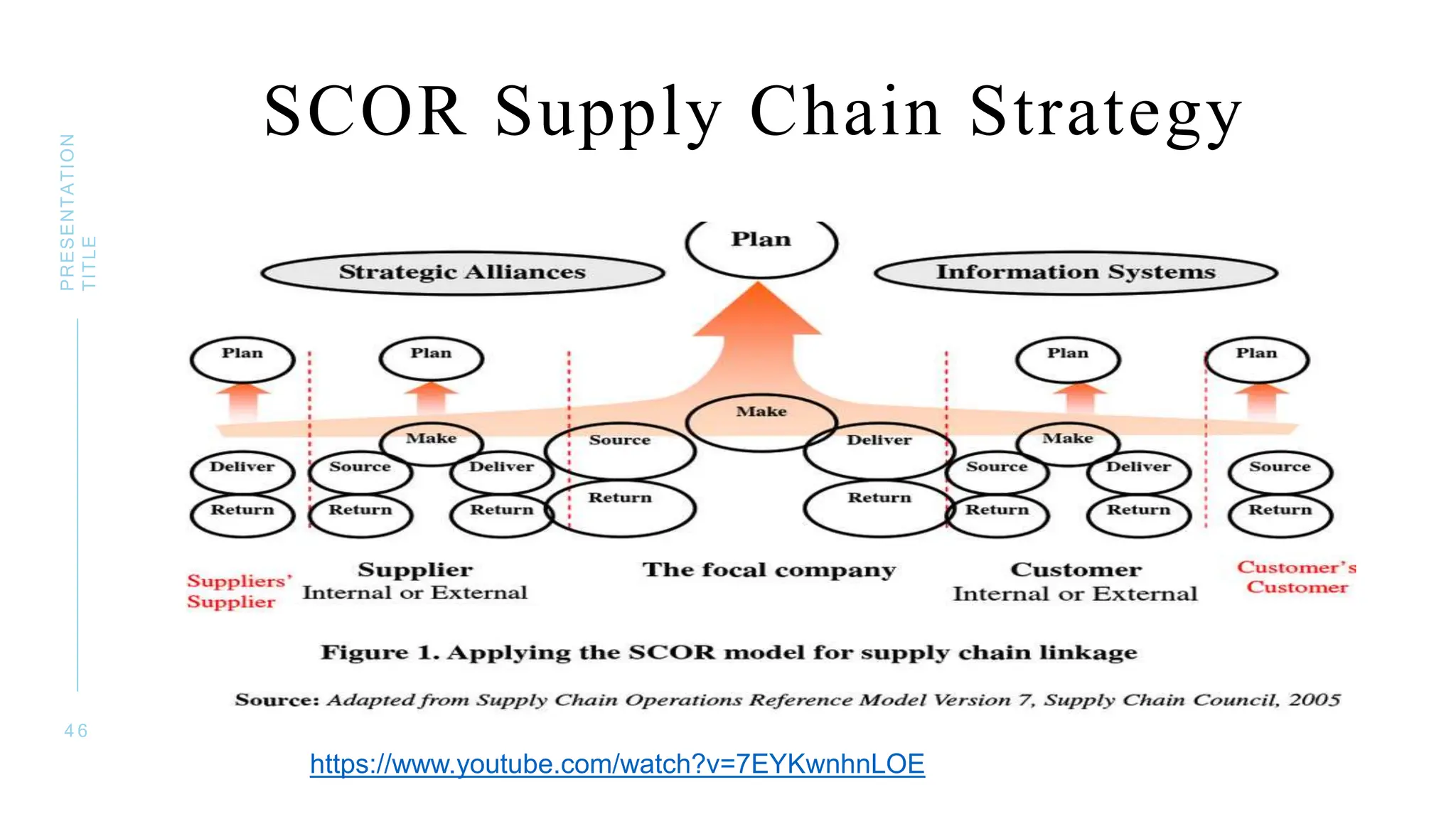

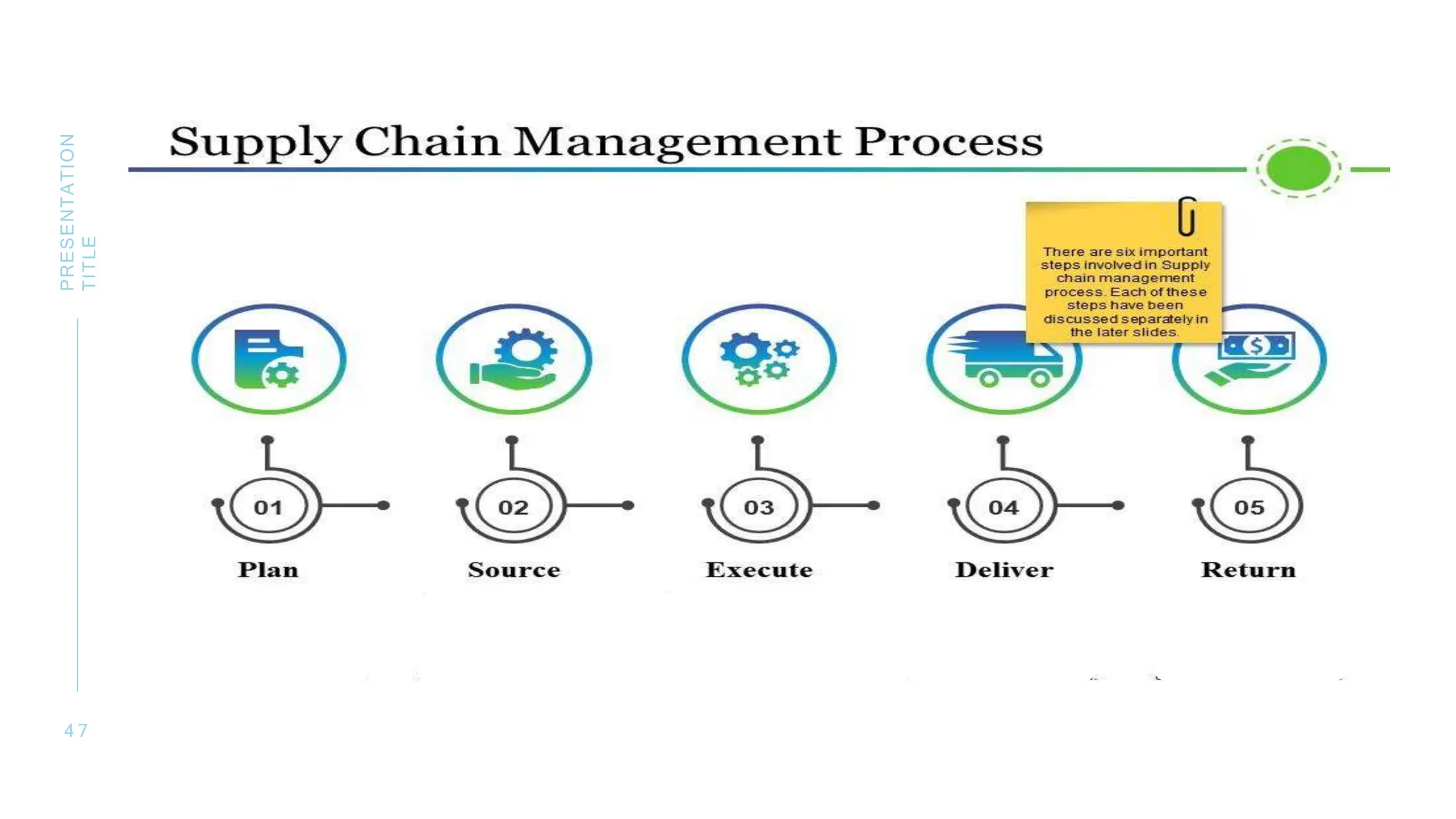

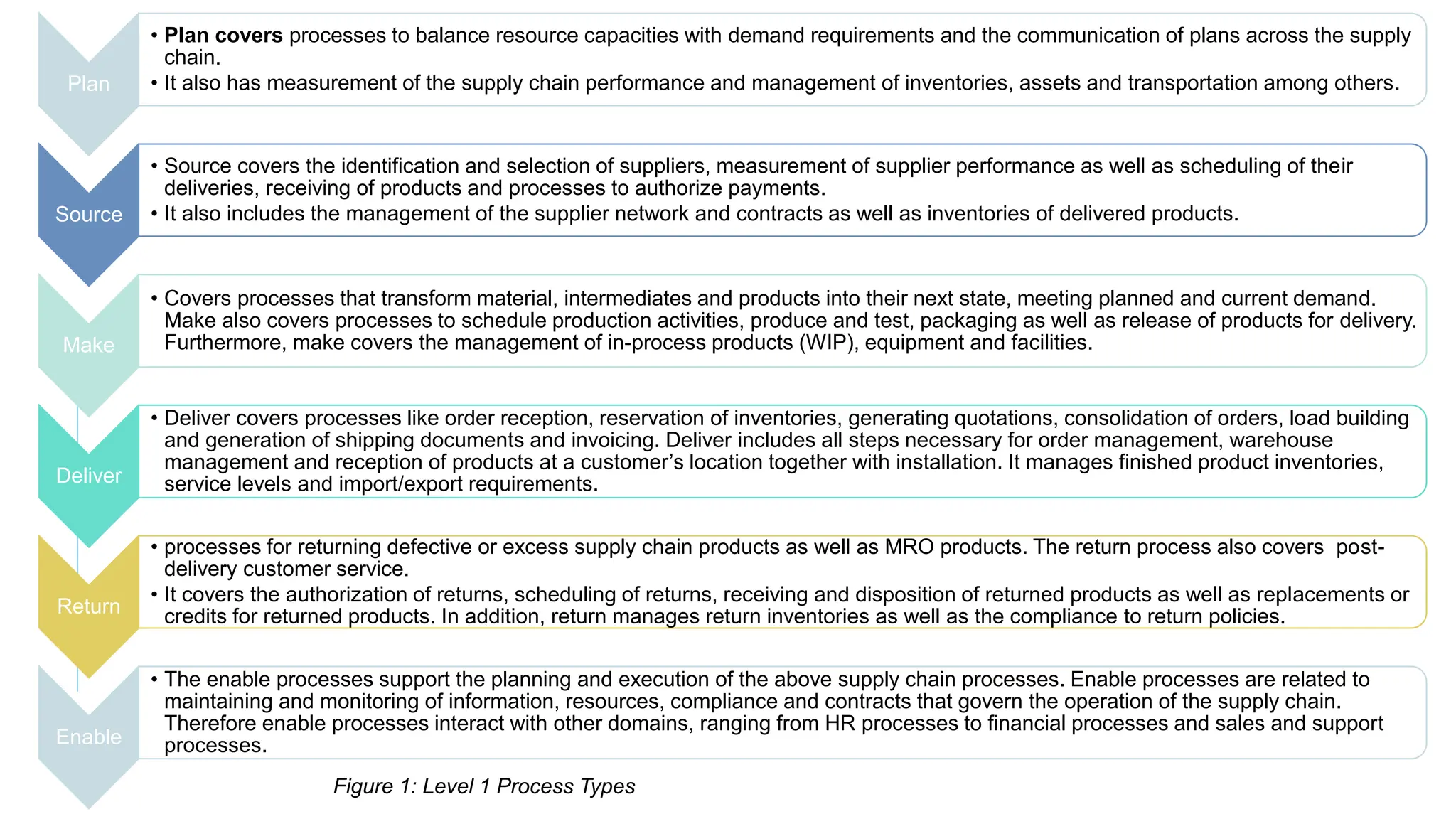

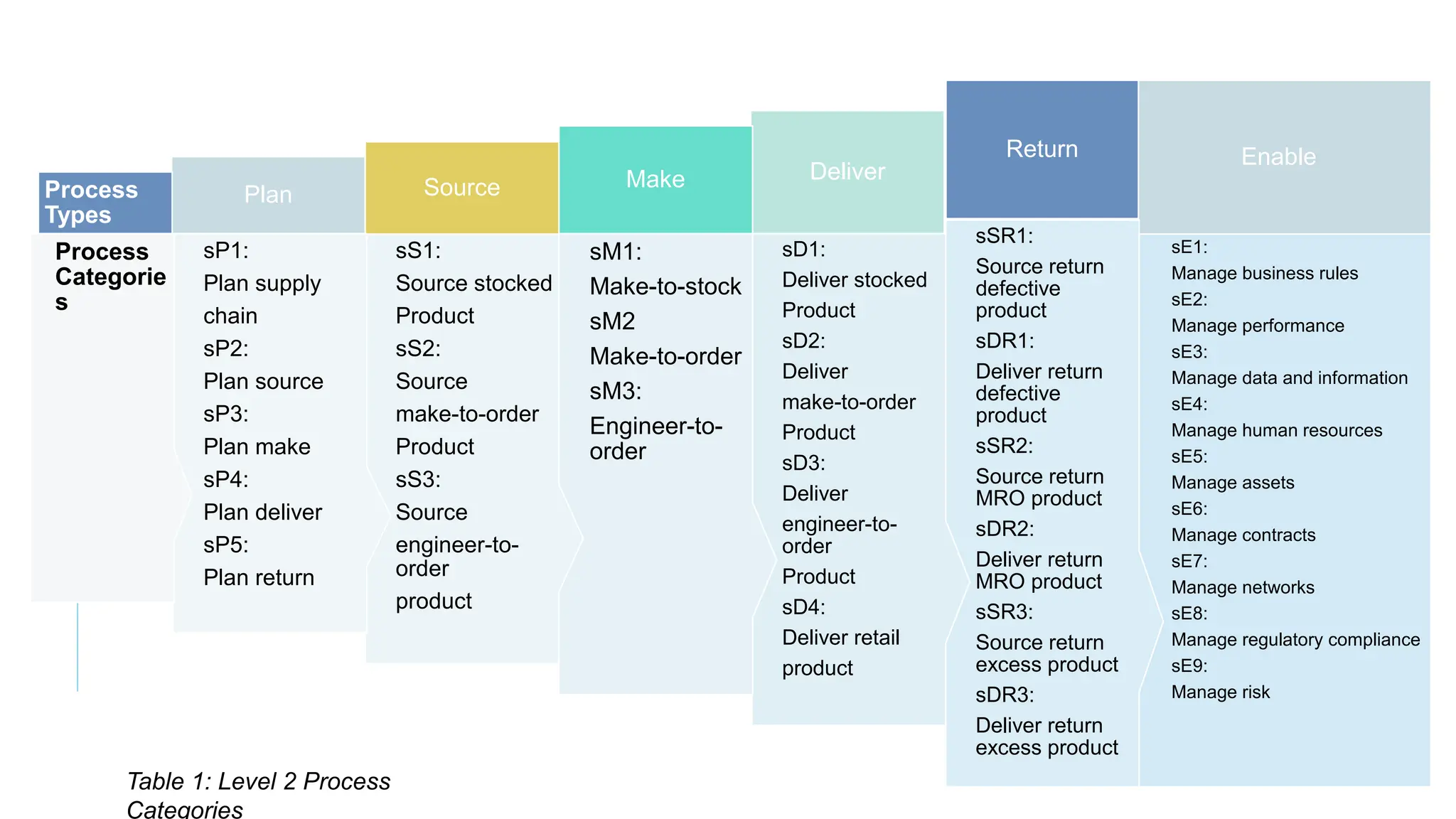

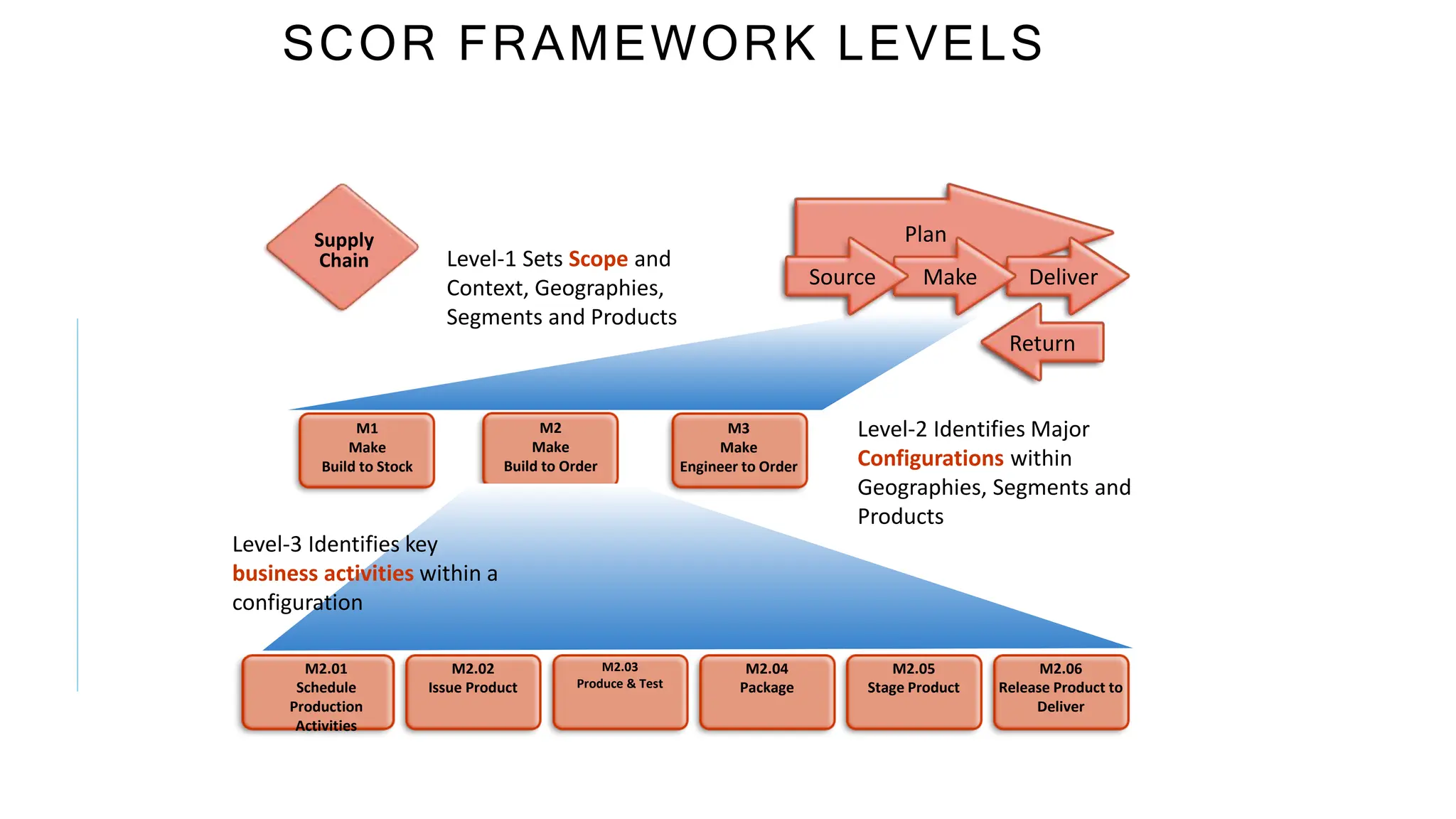

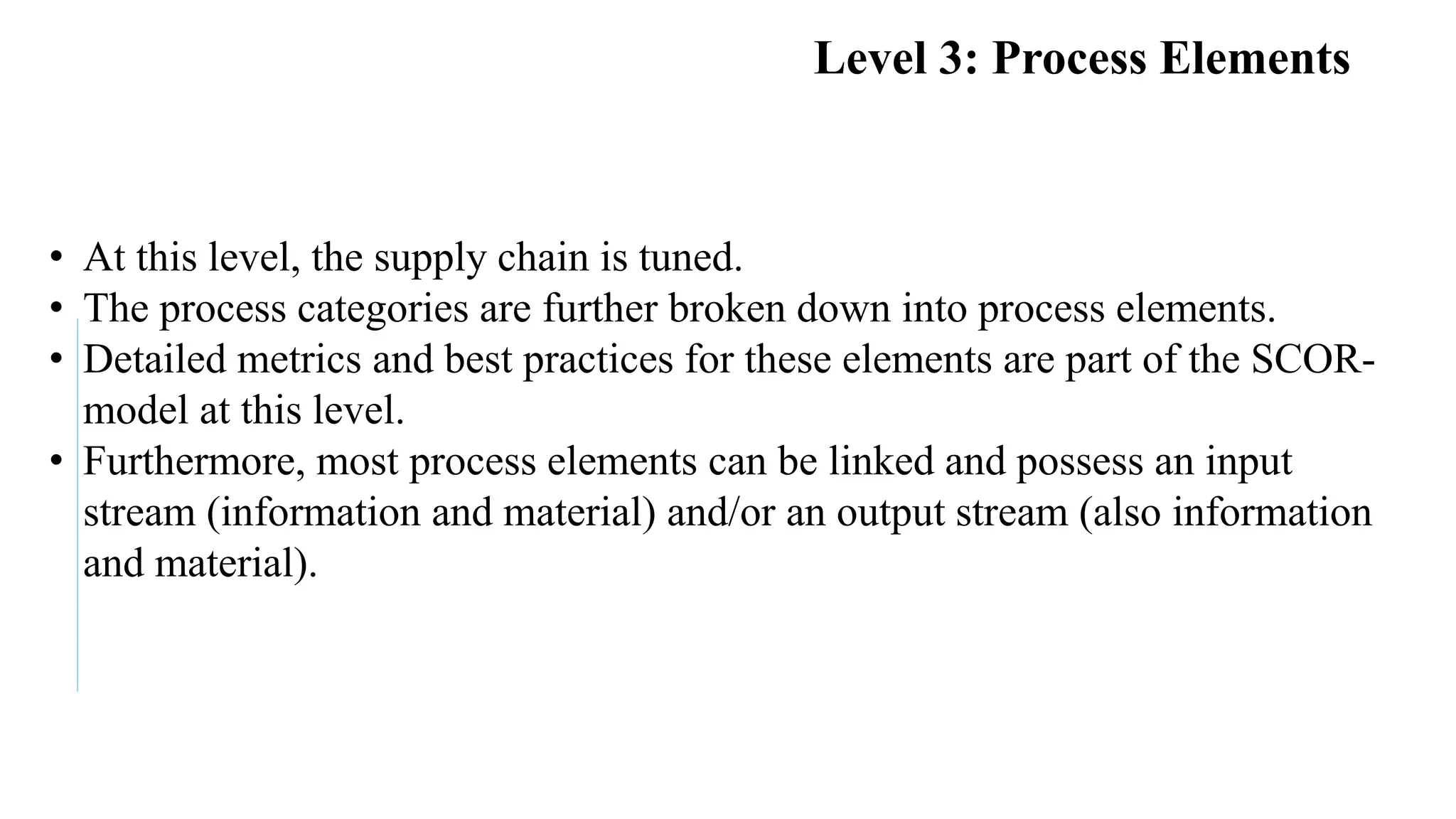

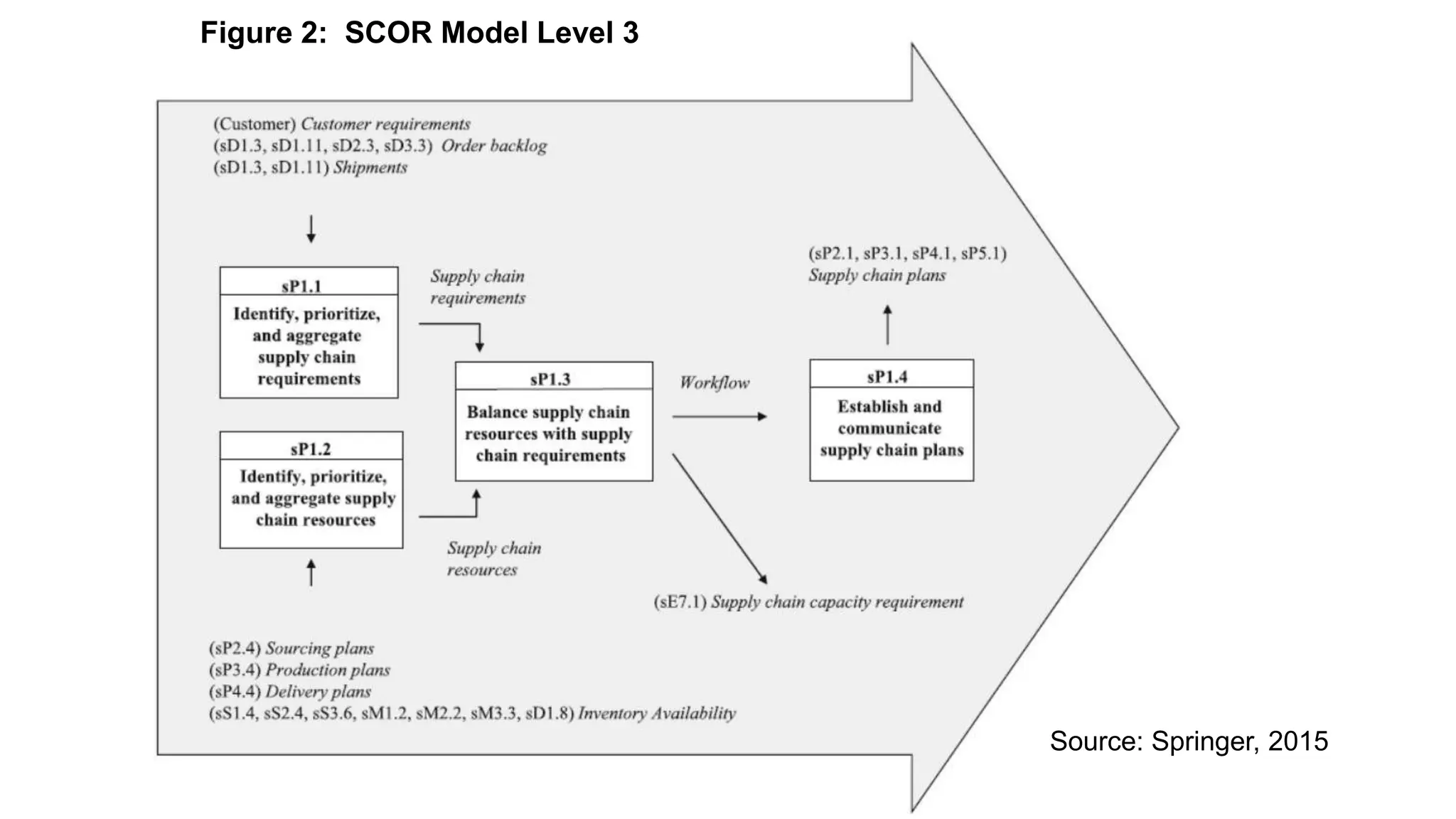

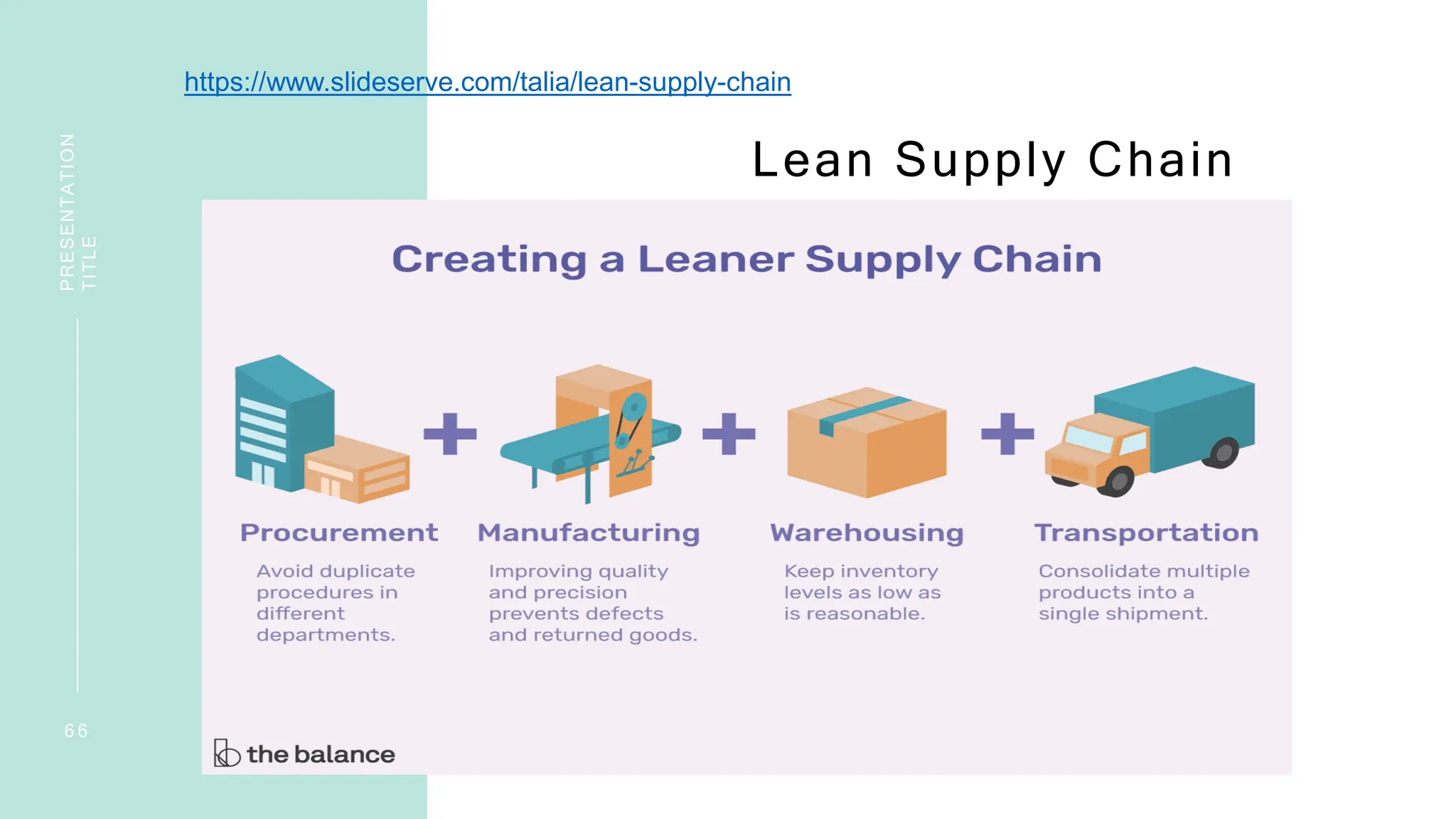

This document provides an overview and agenda for a course on supply chain management. It discusses key topics that will be covered, including logistics and SCM concepts, flows within supply chains, the evolution of SCM, supply chain processes and structures, frameworks like SCOR, trends like lean supply chains, SCM functions and goals. It also notes that managing supply chains is challenging due to factors like geographically dispersed networks, conflicting objectives across stages, uncertainties and risks, and information distortion.