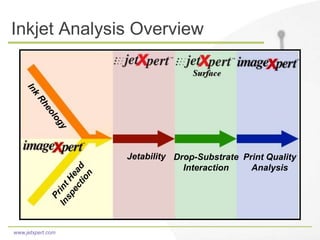

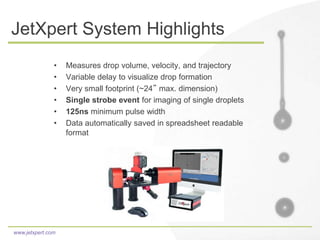

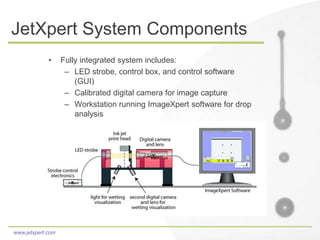

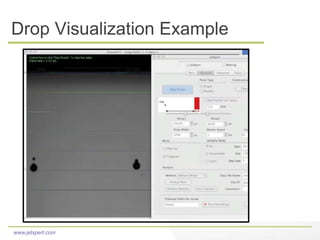

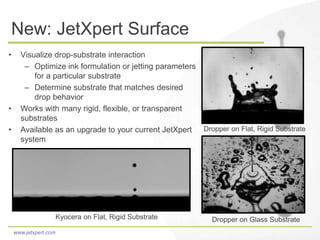

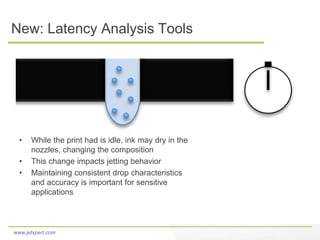

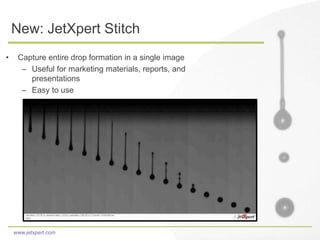

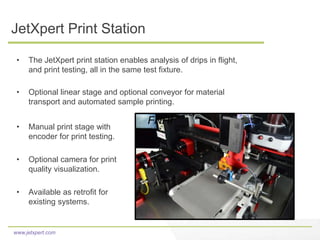

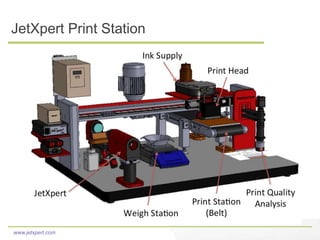

The document presents an overview of JetXpert's tools for inkjet analysis, emphasizing in-flight drop analysis, automation, and print quality inspection capabilities. It details the system's highlights, components, and new features such as latency analysis tools and enhanced visualization for drop-substrate interactions. JetXpert aims to optimize drop formation, improve sustainability, and ensure print consistency across various applications in the inkjet printing industry.