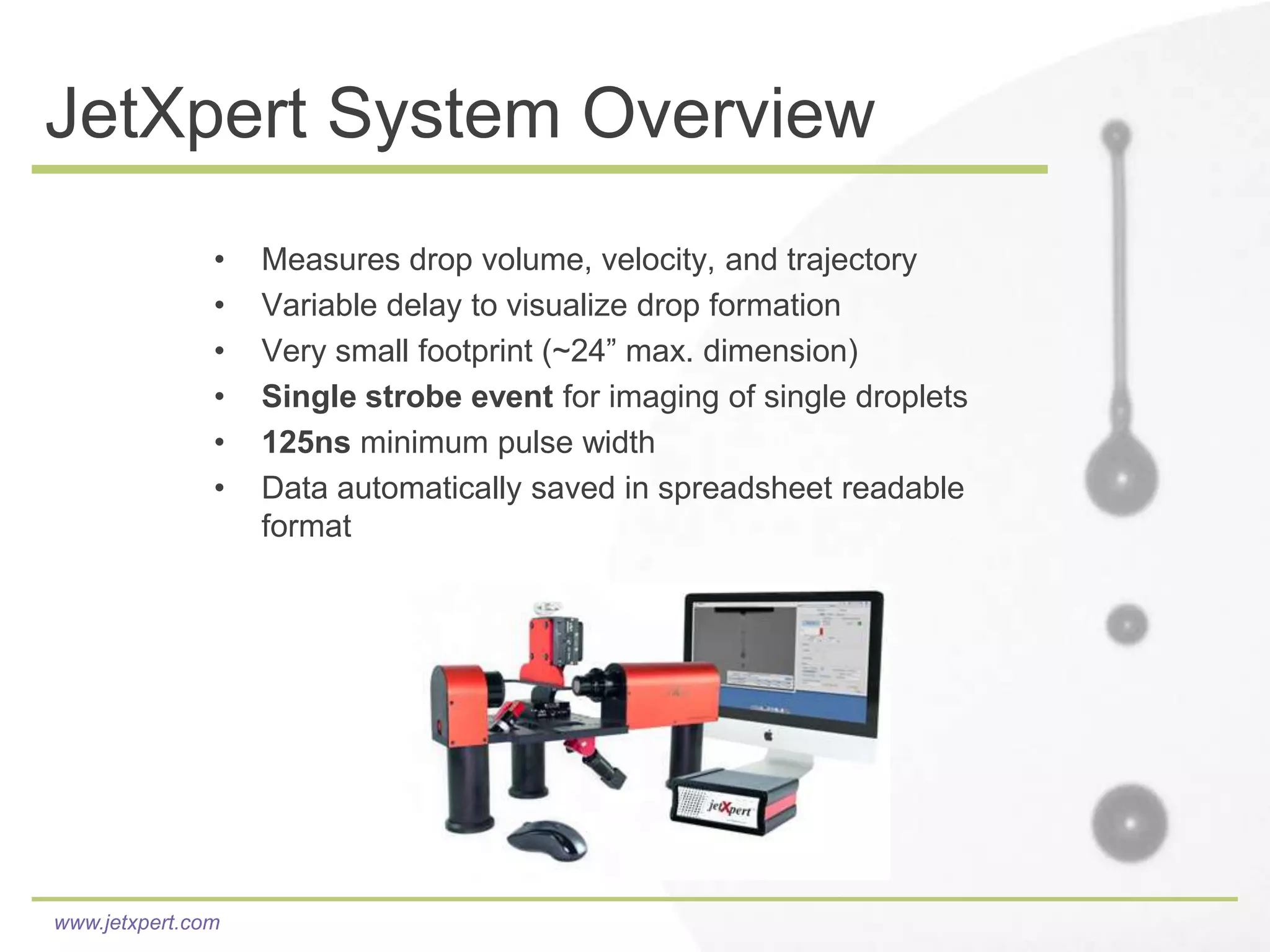

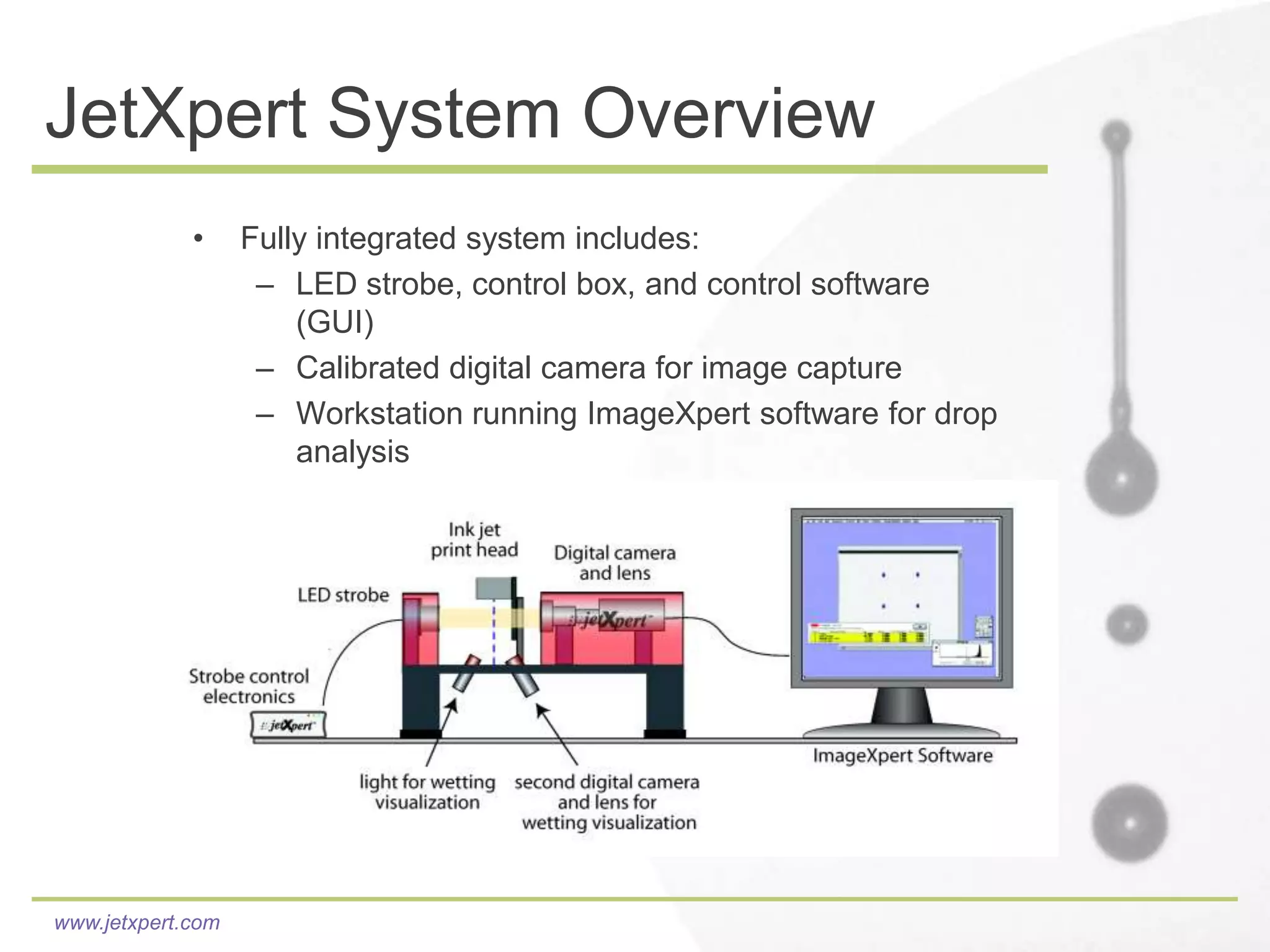

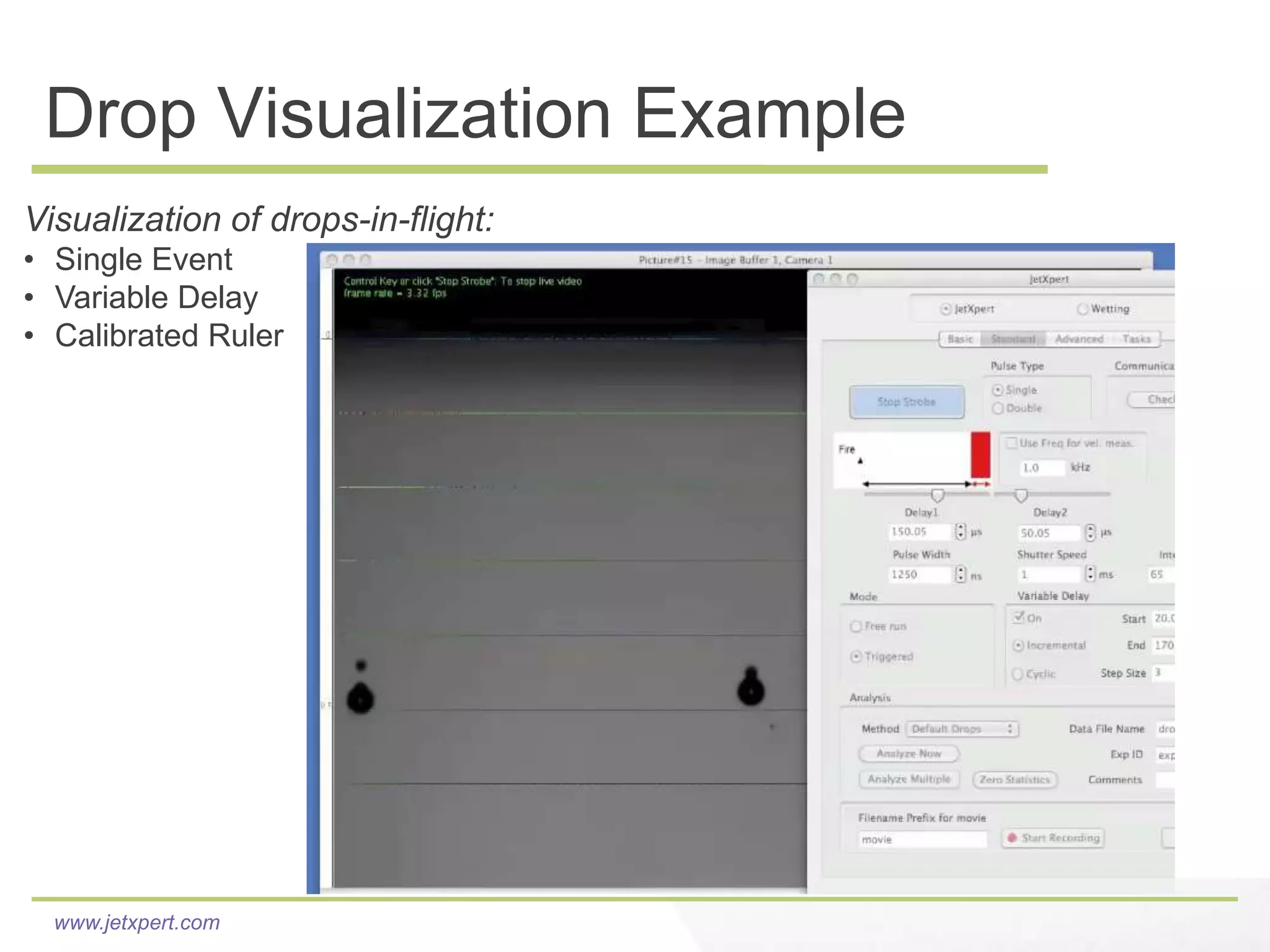

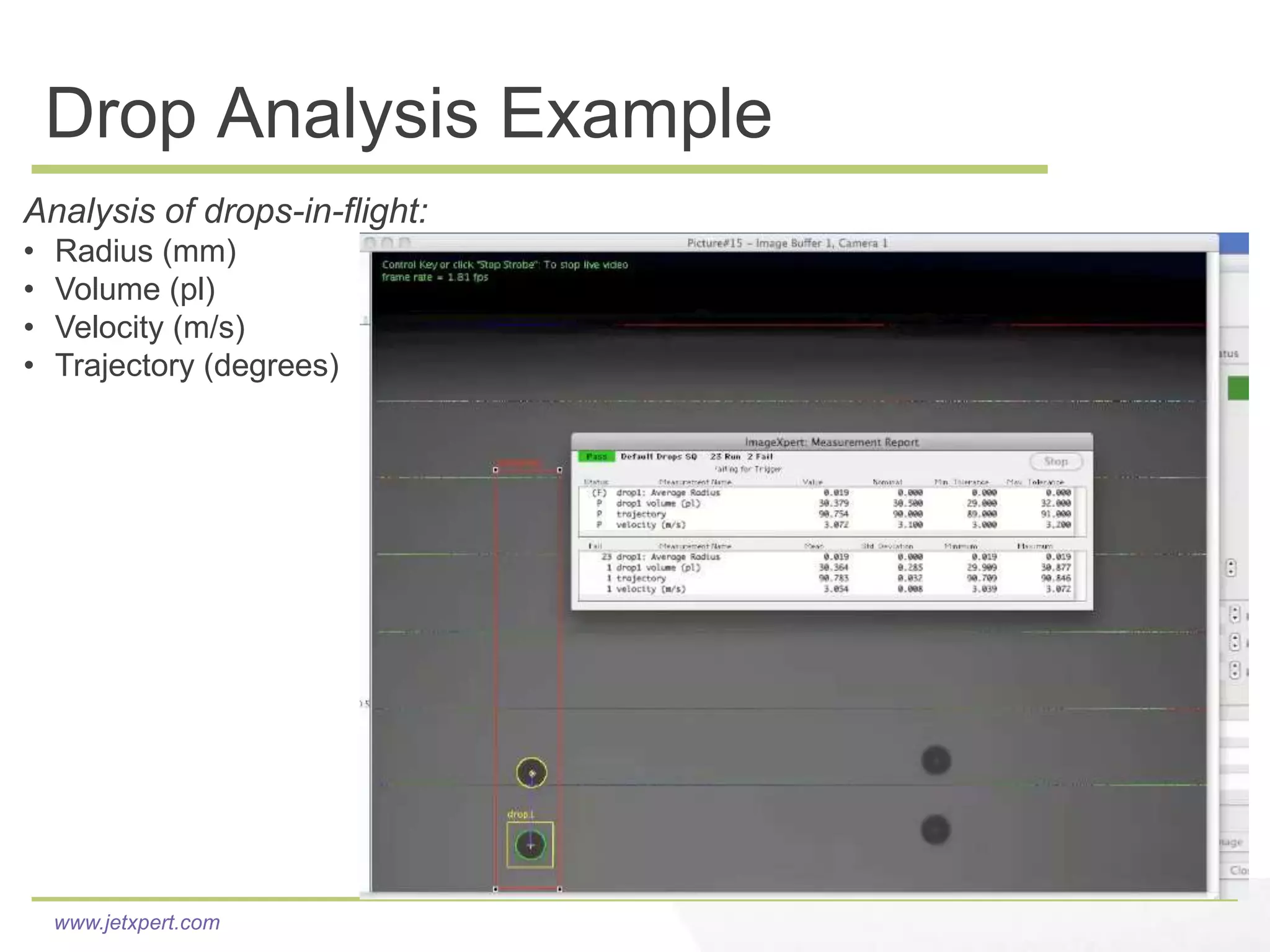

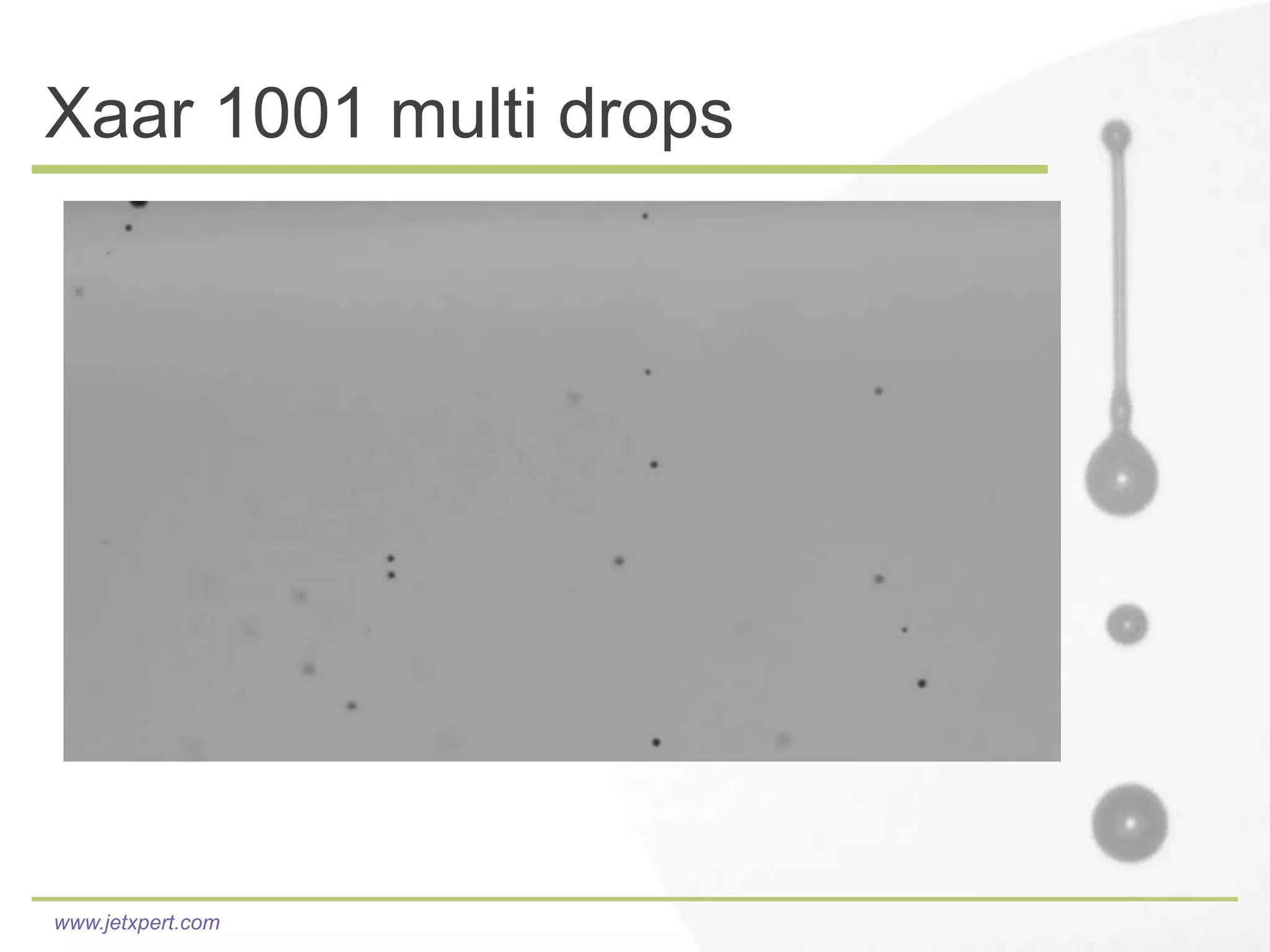

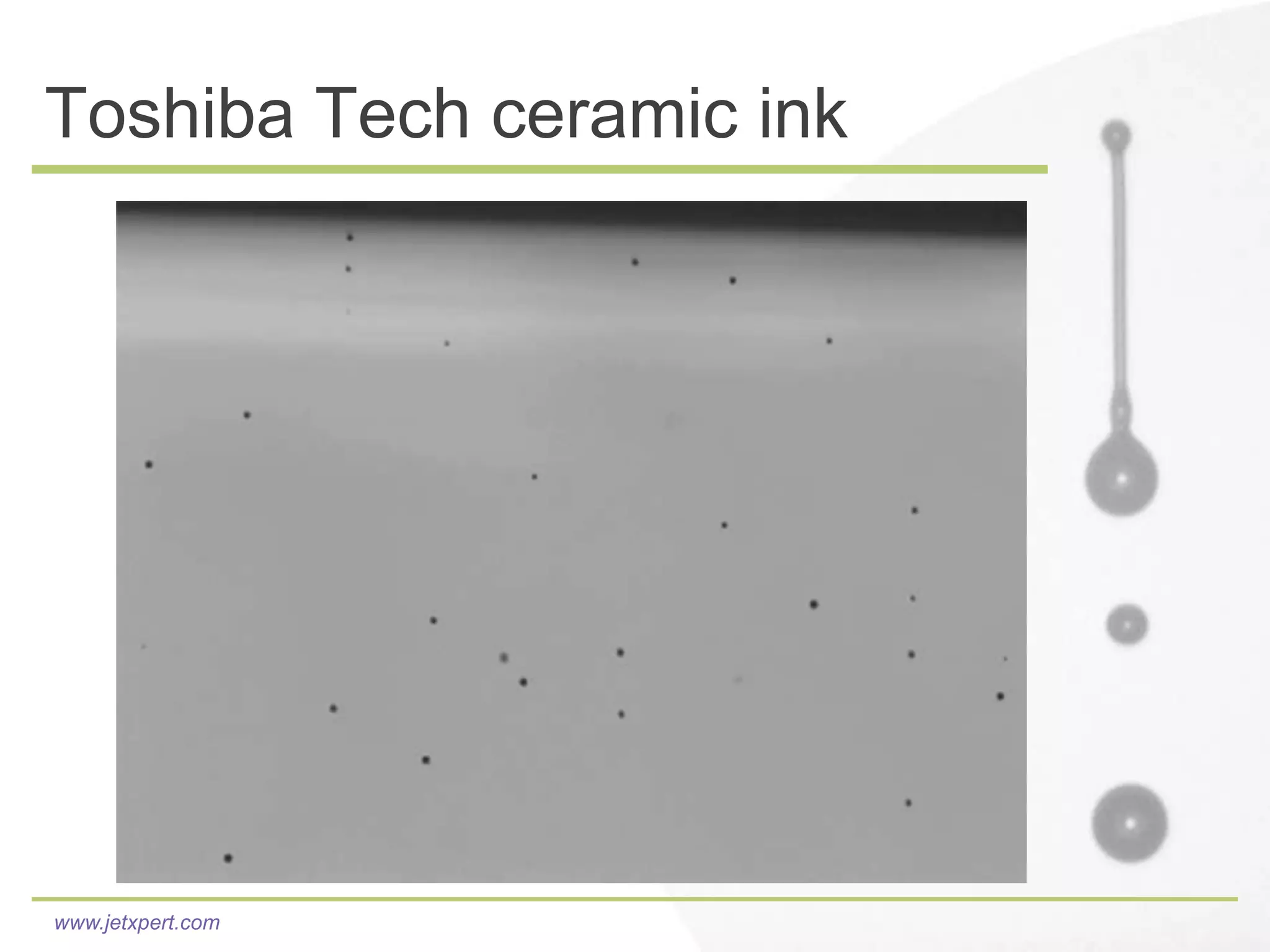

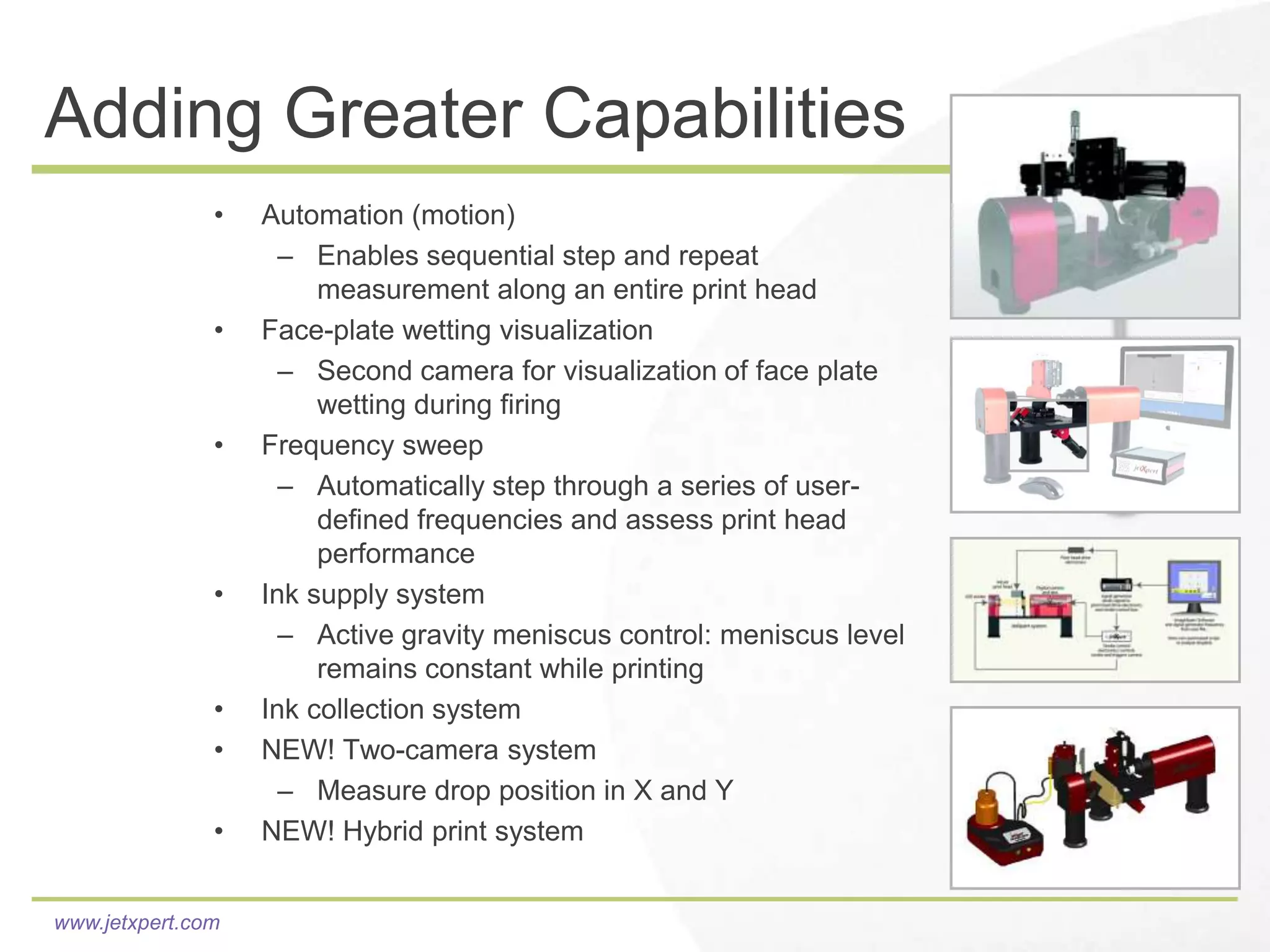

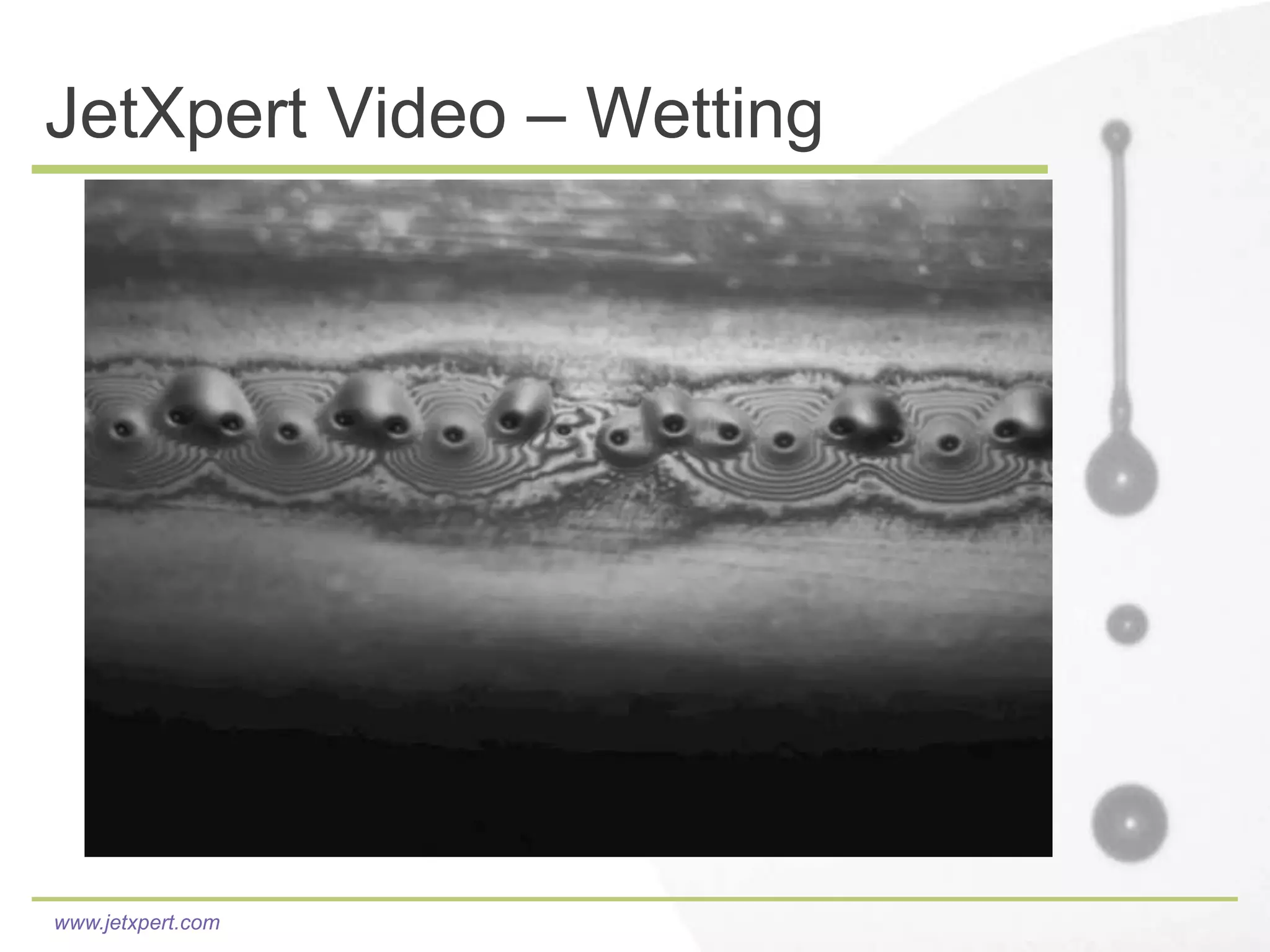

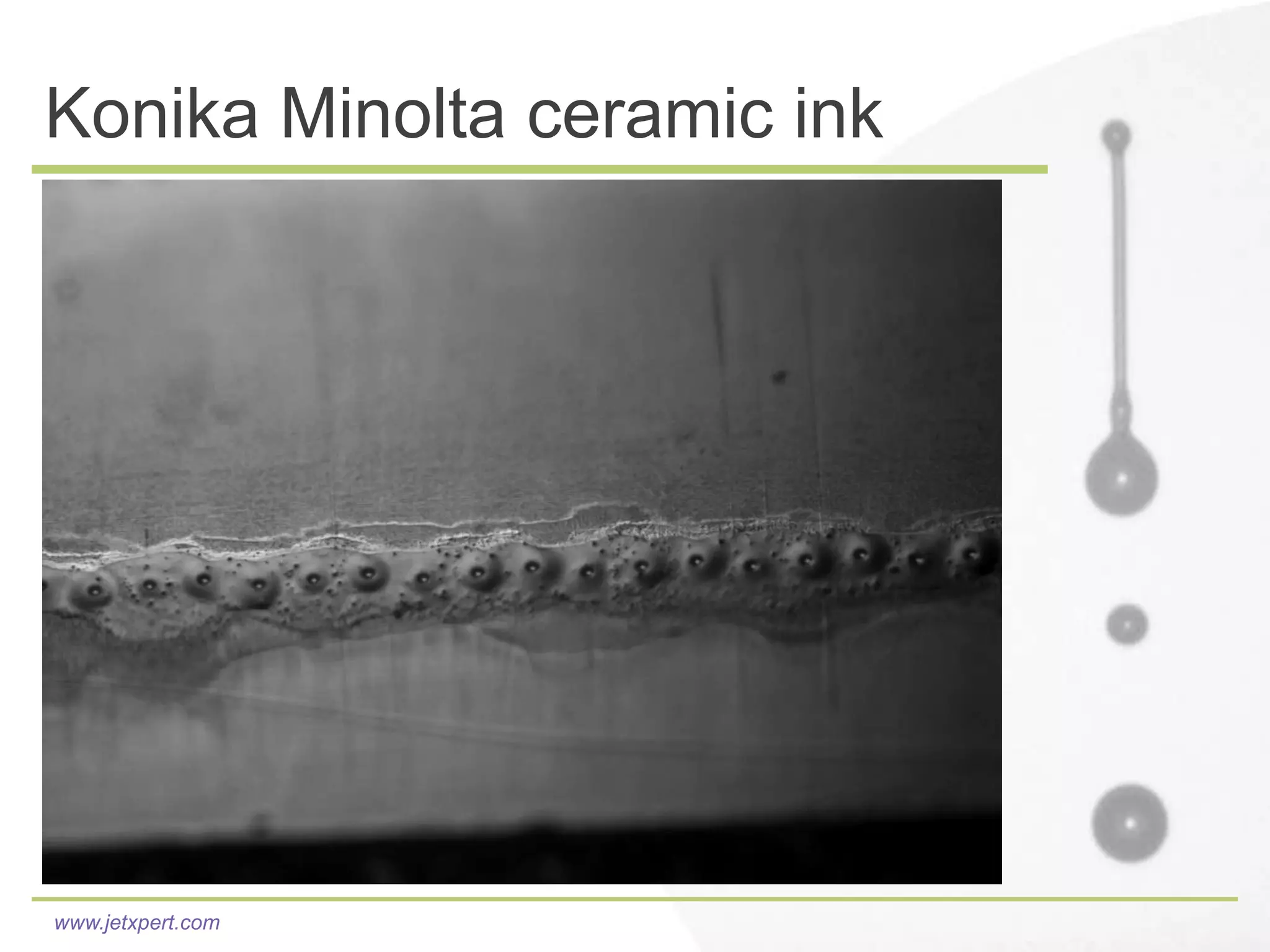

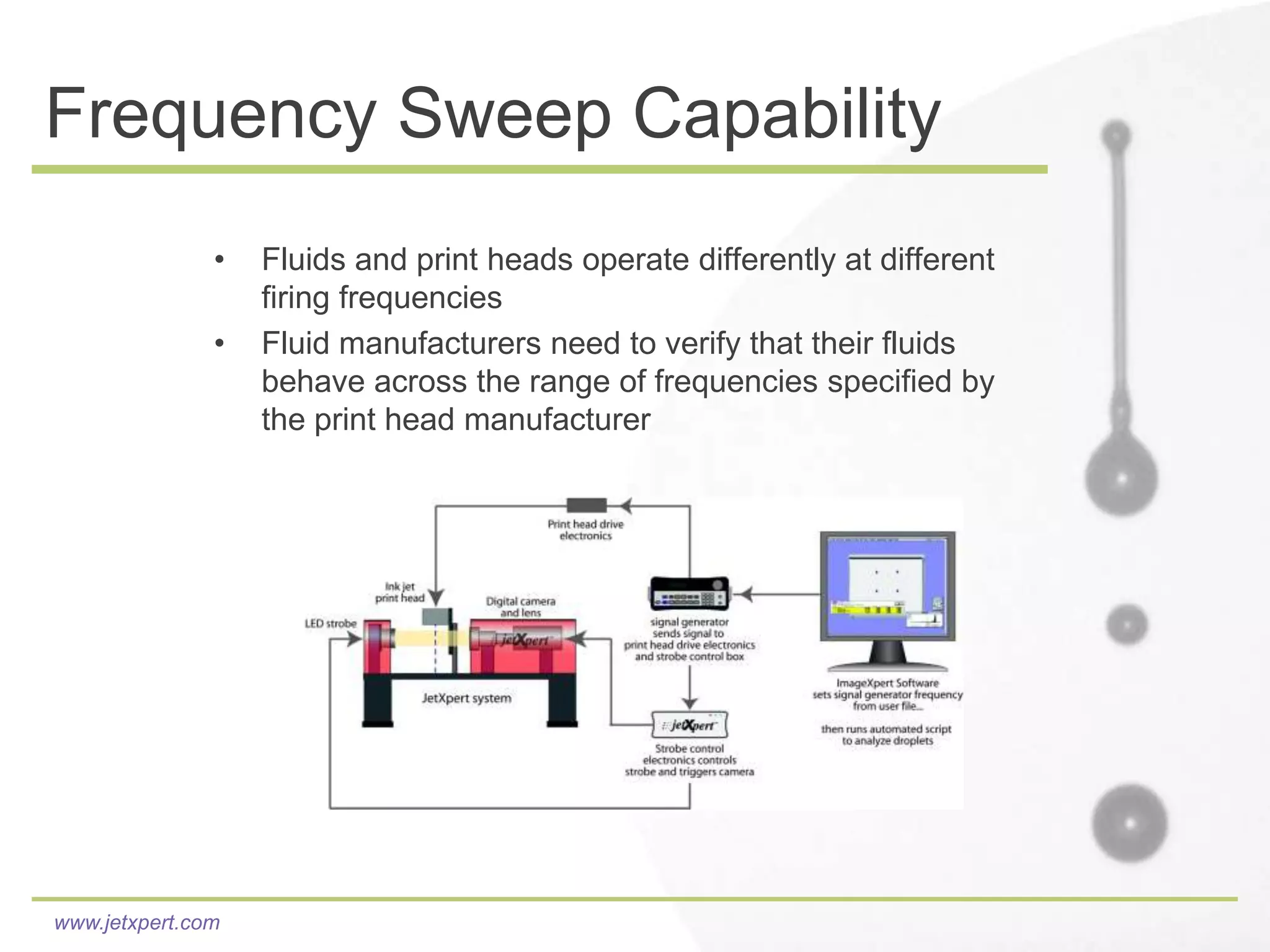

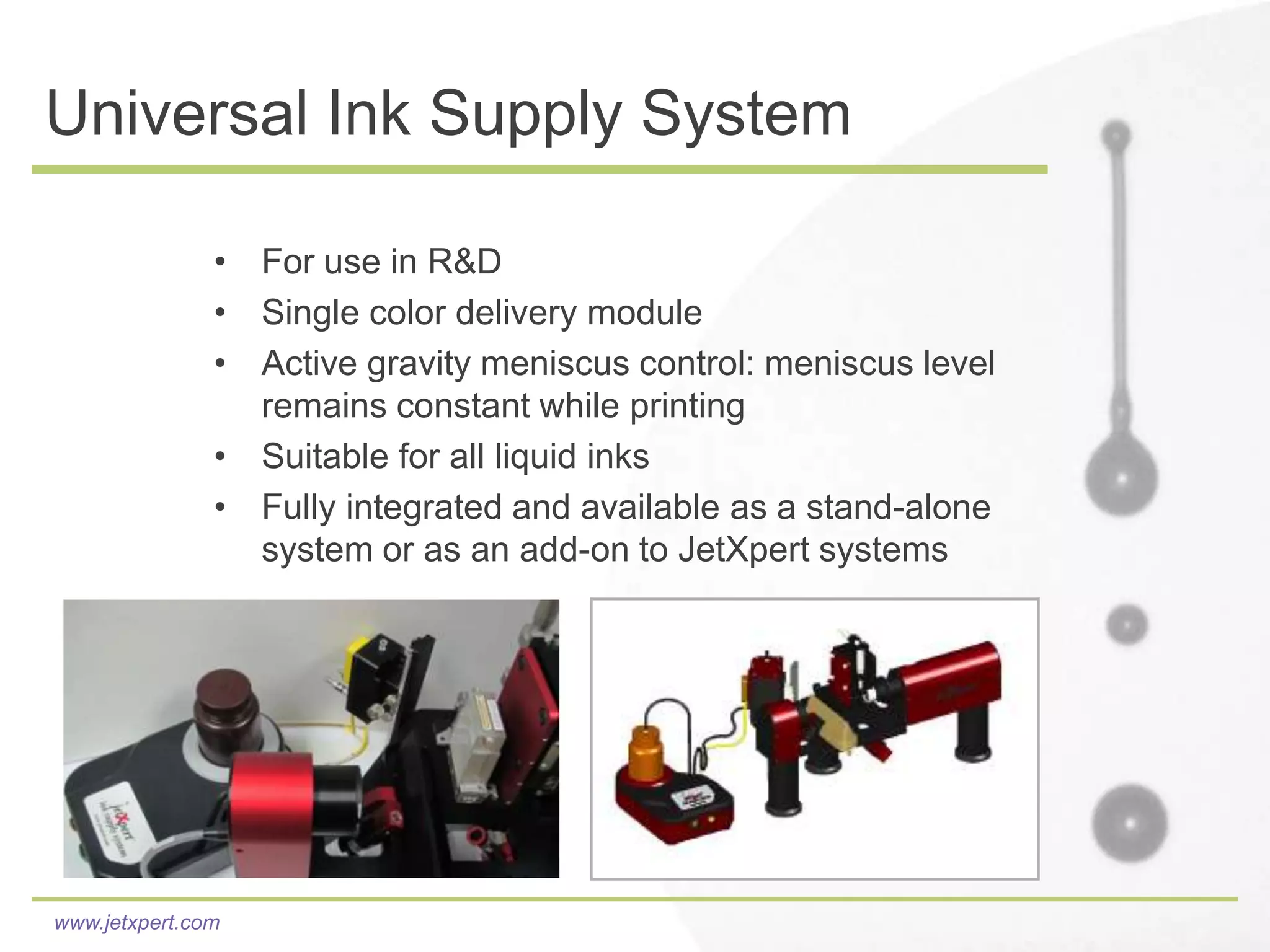

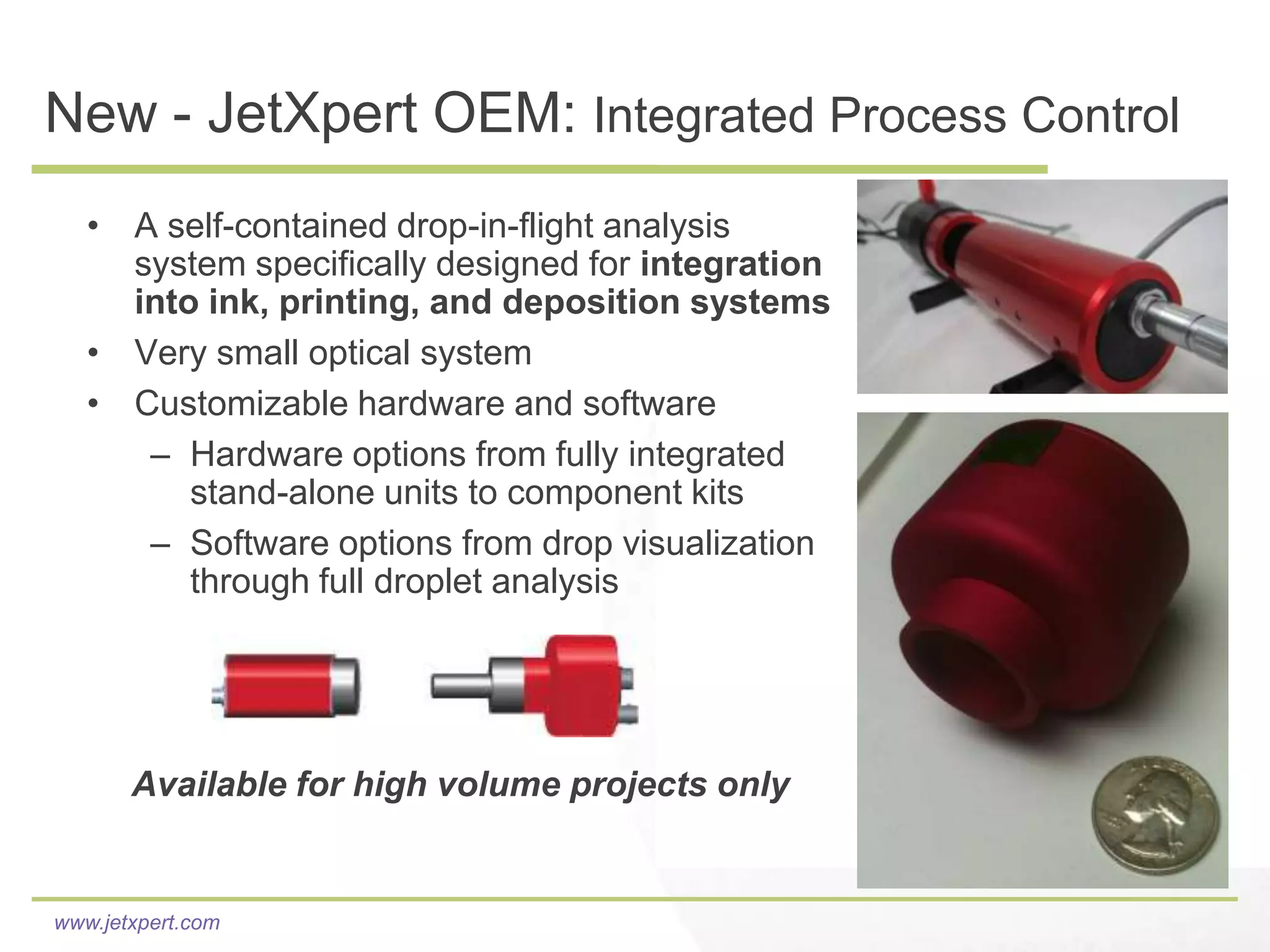

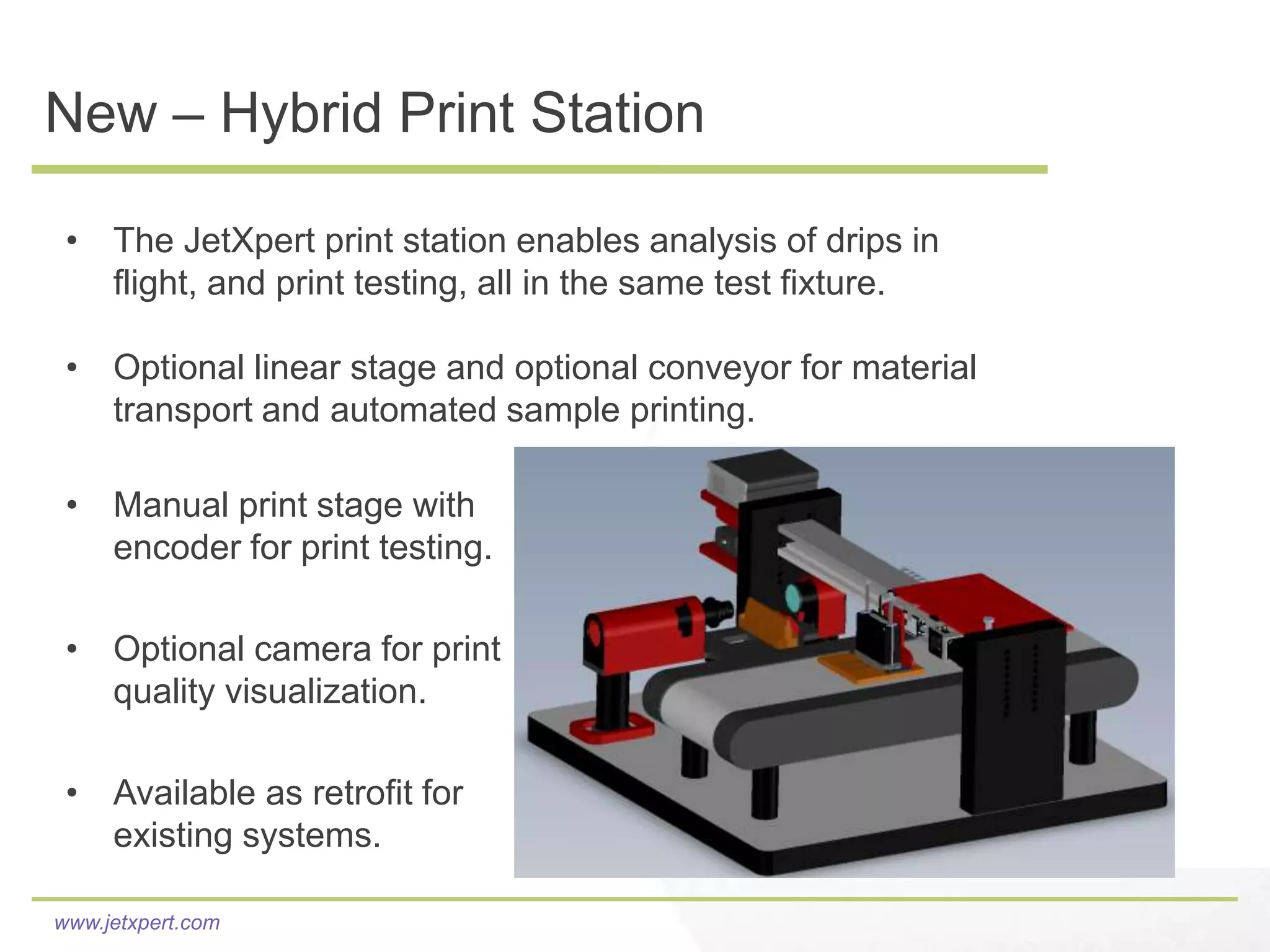

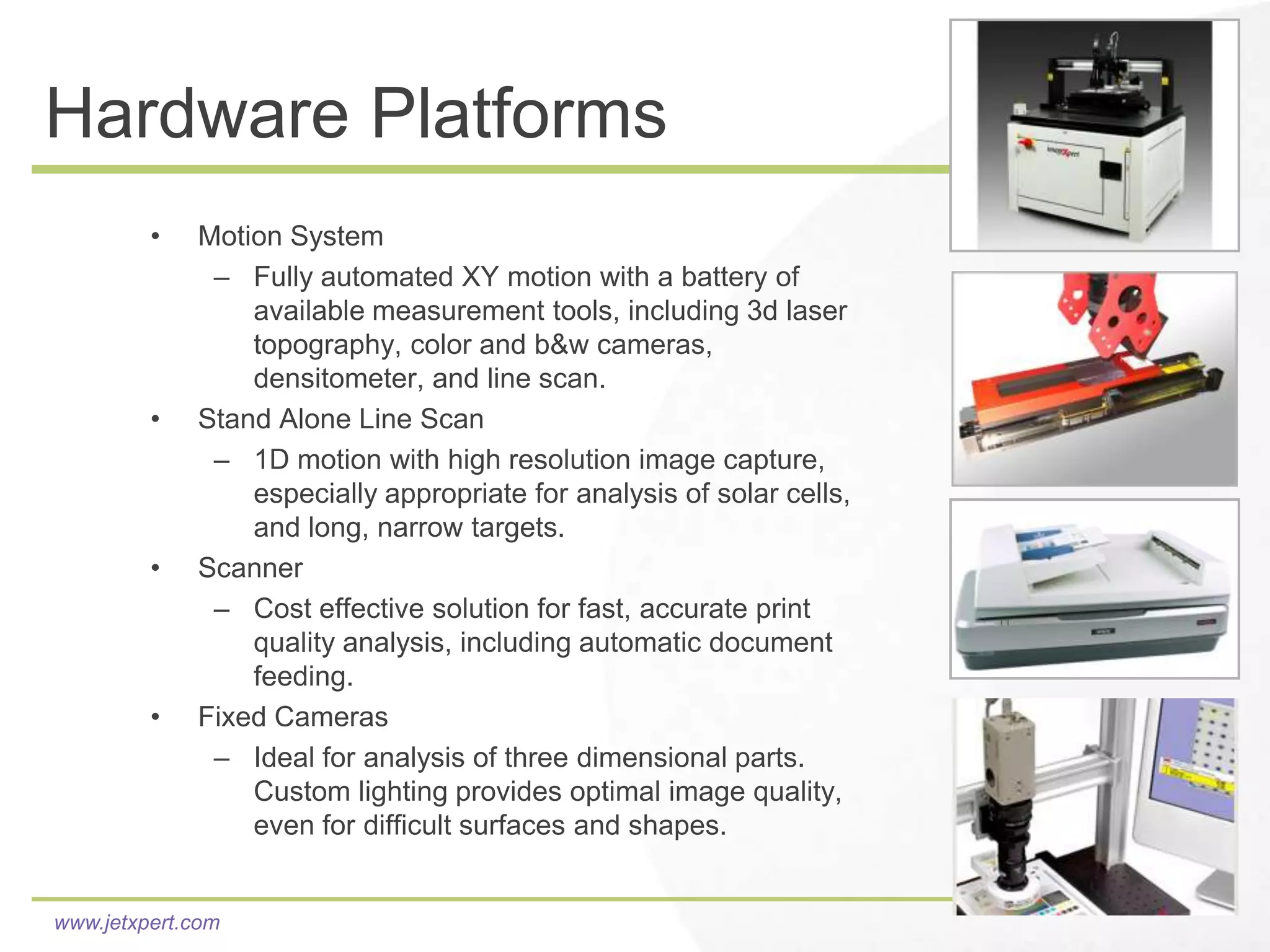

ImageXpert provides innovative ink jet analysis systems for research and development and production. Their JetXpert system allows for visualization and analysis of ink drops in flight through high-speed cameras and software. This provides insights into drop formation, sustainability, misting, and consistency that help optimize ink formulations and print parameters. JetXpert systems have helped many ink manufacturers successfully develop new inks. ImageXpert is continuously enhancing JetXpert's capabilities such as through automated motion and frequency sweep testing.