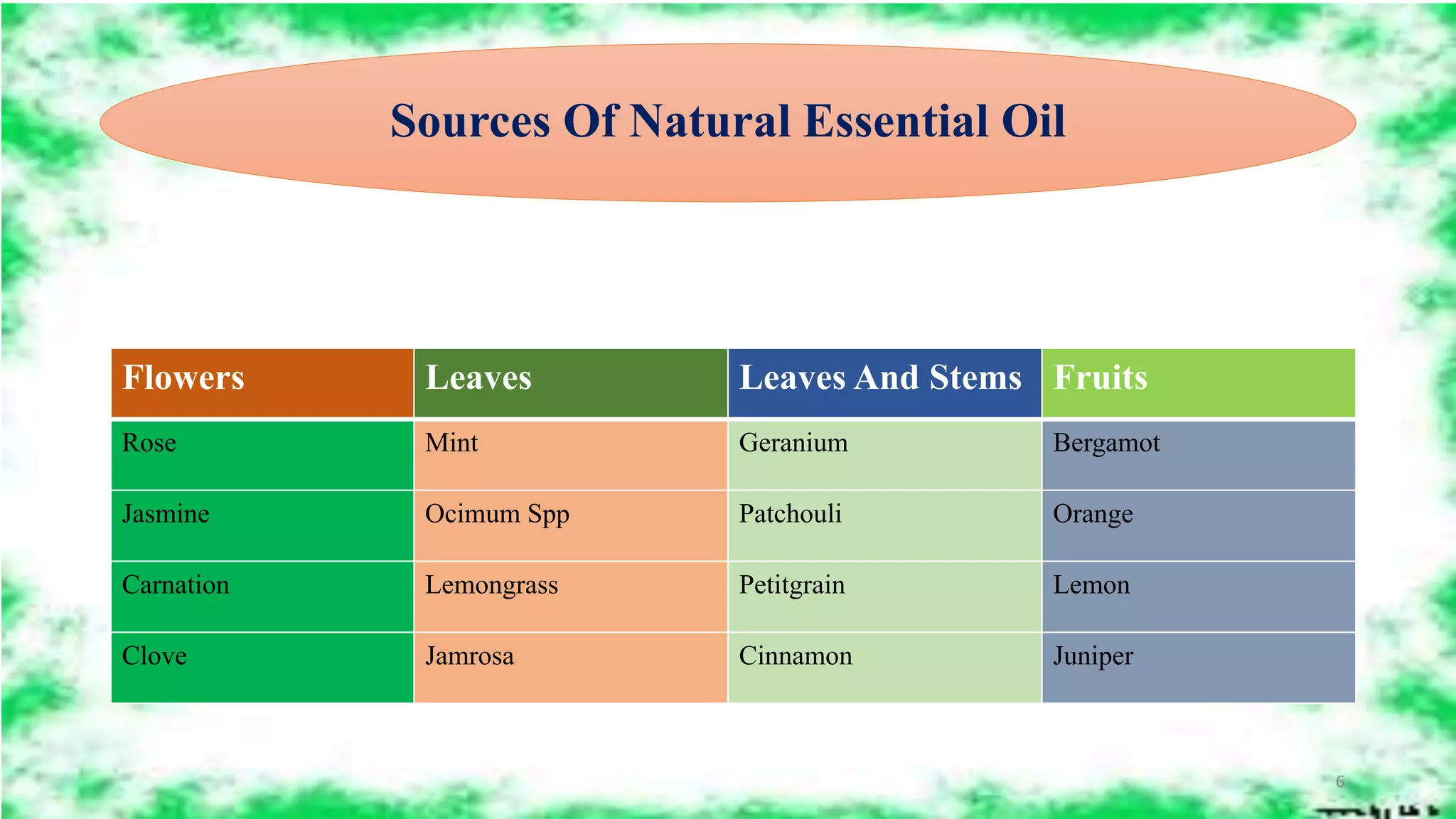

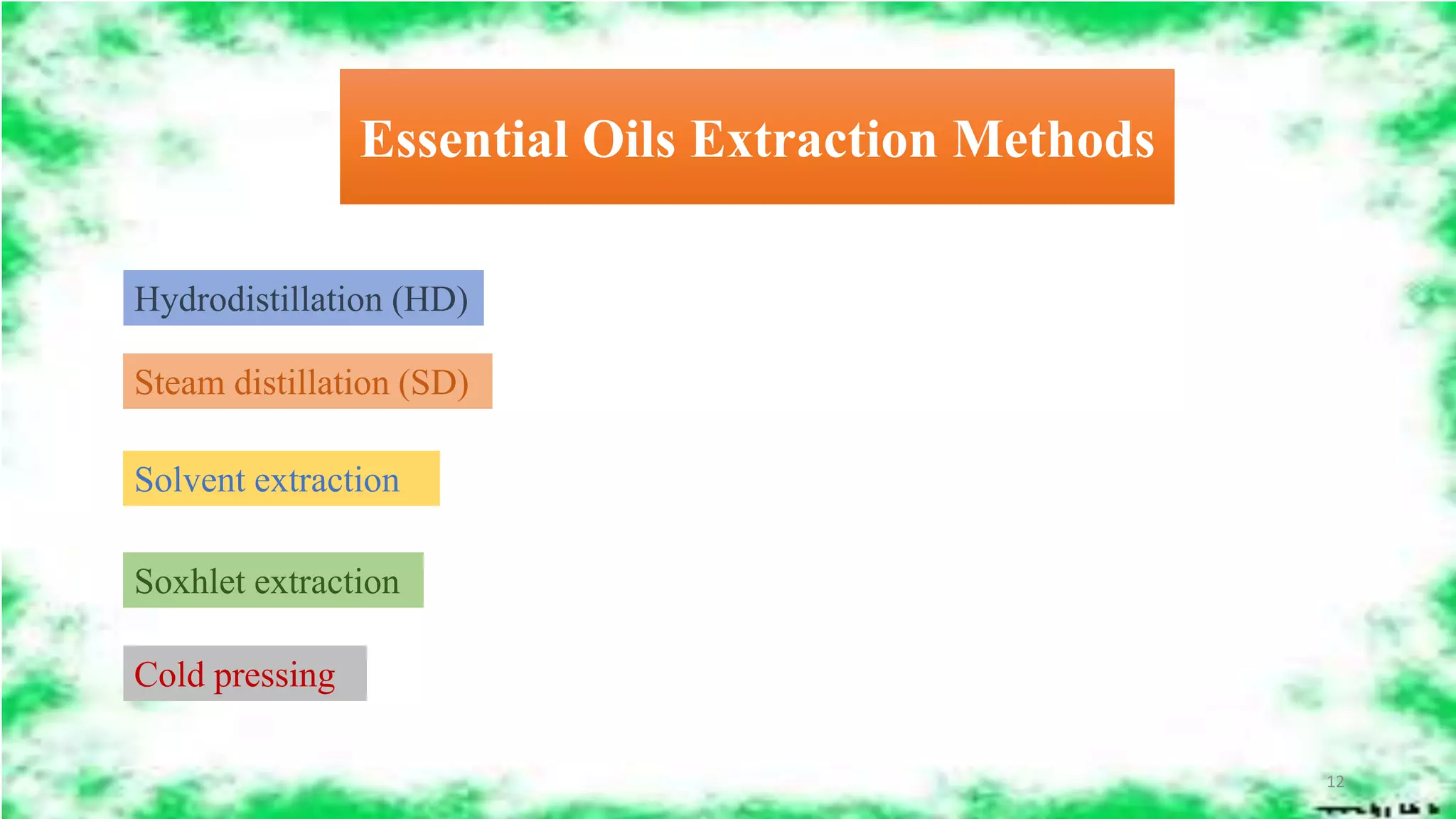

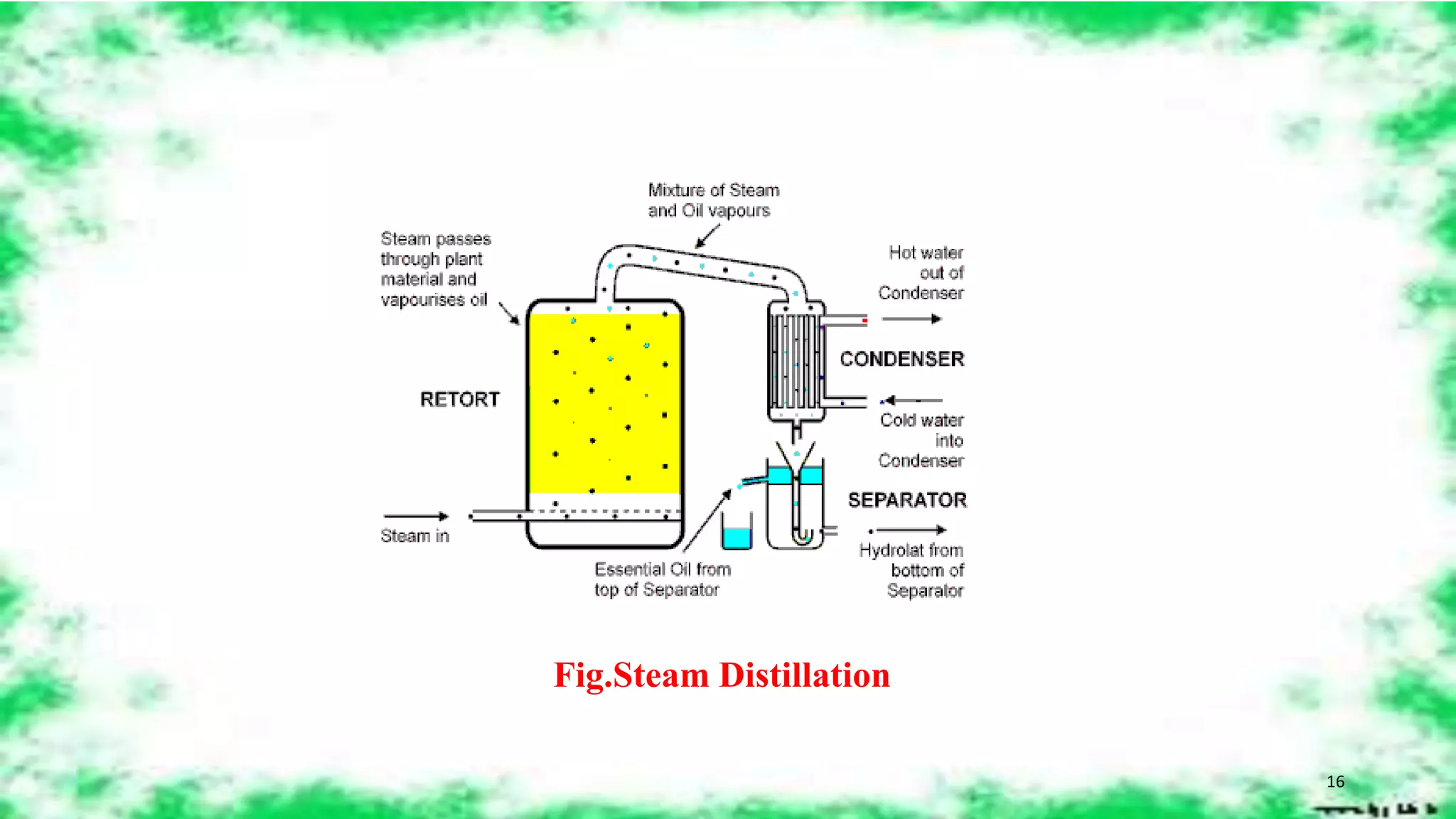

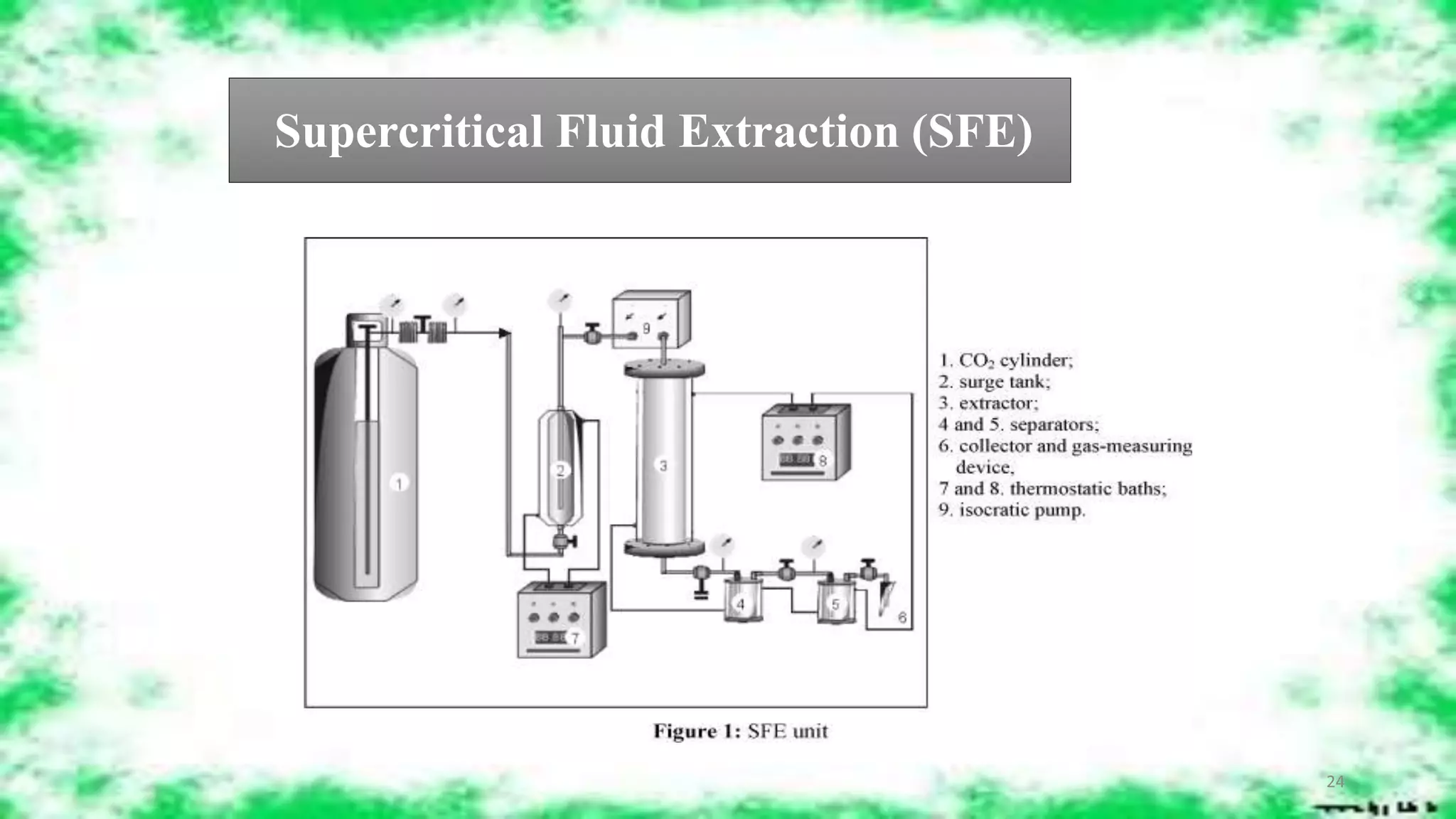

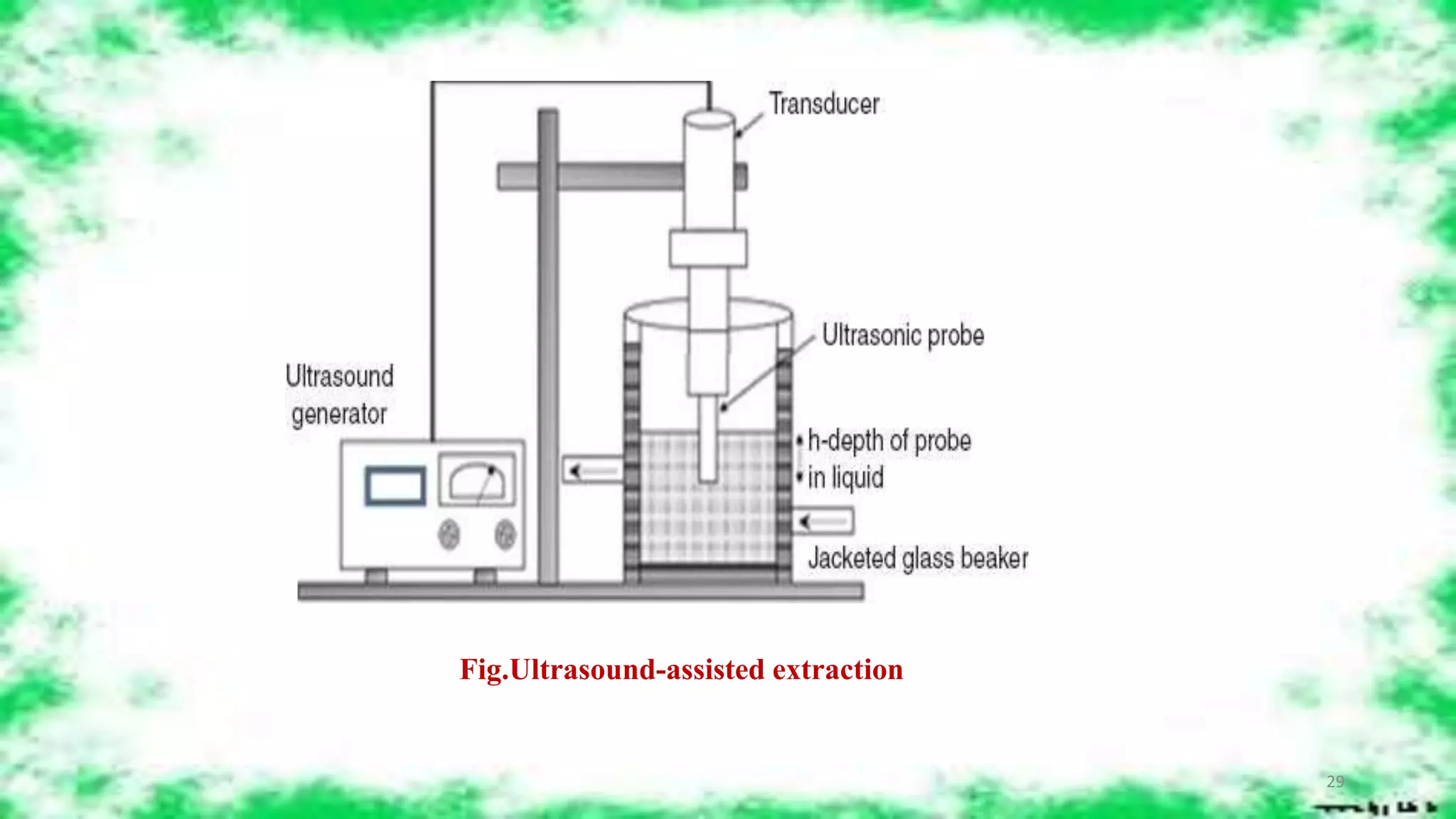

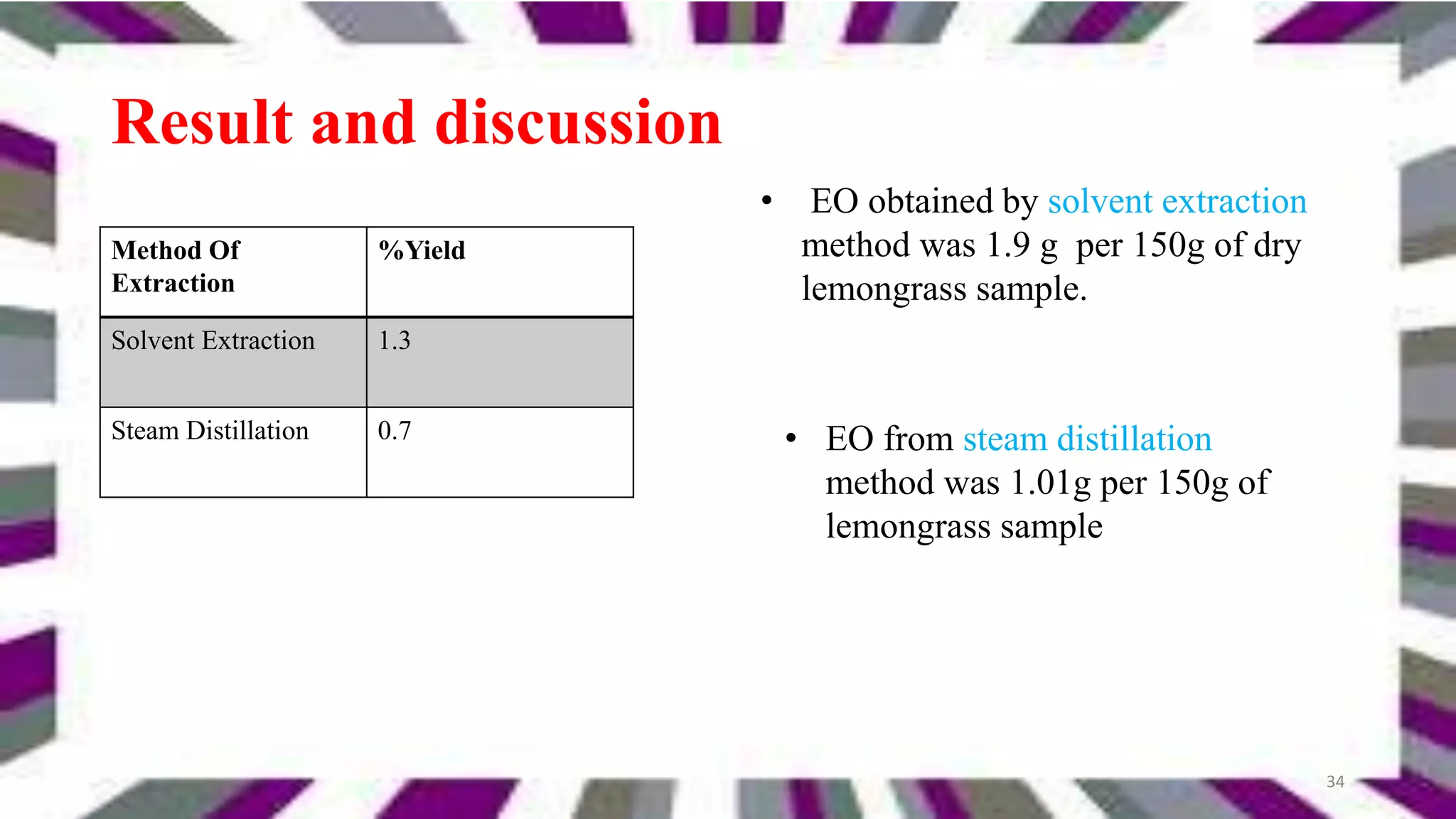

The document provides an overview of essential oils, including their sources, chemical constituents, extraction methods, and applications. It discusses both traditional methods such as hydrodistillation and steam distillation, as well as innovative techniques like supercritical fluid extraction and microwave-assisted extraction. The document concludes by highlighting the significance of essential oils in various industries, including pharmaceuticals, cosmetics, and food flavoring.