exit one optionCMDTYPE getCmdType(const char cmd).docx

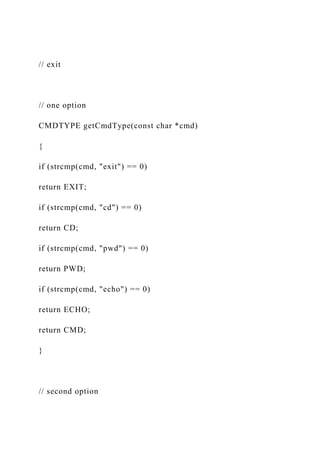

- 1. // exit // one option CMDTYPE getCmdType(const char *cmd) { if (strcmp(cmd, "exit") == 0) return EXIT; if (strcmp(cmd, "cd") == 0) return CD; if (strcmp(cmd, "pwd") == 0) return PWD; if (strcmp(cmd, "echo") == 0) return ECHO; return CMD; } // second option

- 2. void exit() { if('$1' == 'exit') { $2 $3; $1; } else if('$3' == 'exit' ) { $1 $2; $2; } } // pipelining void pipes(int a, char * pipes[100], int size) {

- 3. char* p1[10] // variable for command 1 char* p2[10] // variable for command 2 char* p3[10] // variable for command 3 int num = 0; // integer for amount of pipes int n1 = 0; // interger for command 1 array int n2 = 0; // integer for command 2 array int n3 = 0; // integer for command 3 array int status; // for status pid_t pd, pd2, pd3; //variables for pid to be forked for (int i=0; i<size; i++) //size of command line input { if(strcmp(pipes[i], "|") == 0) // if the pipe is found { num++; //increment the counter } else if(num == 0) // if no pipe found {

- 4. p1[n1] = pipes[i]; //place the command and argument into p1 n1++; // incrementing place in command 1 array } else if(num == 1) // if 1 pipe is found { p2[n2] = pipes[i]; //place the command and argumemnt into p2 n2++; //increment place in command 2 array } else if (num == 2) // if 2 pipes are found { p3[n3] = pipes[i]; //place the command and argumemnt into p3 n3++; //increment place in command 3 array } } // end of for loop p1[n1] = NULL; //setting the place in the array to NULL p2[n2] = NULL; //setting the place in the array to NULL

- 5. p3[n3] = NULL; //setting the place in the array to NULL int dir1[2], dir2[2]; // integers for directing pipe(dir1); //pipe pipe(dir2); //pipe pd = fork(); // first fork for command 1 if(pd == 0) { dup2(dir1[1] , 1); // duplicate write end of p1->p2 pipe stdout close(dir1[0]); close(dir1[1]); close(dir2[0]); close(dir2[1]);

- 6. execvp(p1[0], p1); //execute command p1 } else if(pd>0) //the parent { pd2 = fork(); // fork second chil to execute grep if(pd2 == 0) { dup2(dir1[0], 0); // duplicate read end of p1->p2 to stdin of p2 if(a == 2) // if second pipe was found { dup2(dir2[1], 1); } //close bothe ends of all created dir pipes close(dir1[0]); close(dir1[1]); close(dir2[0]);

- 7. close(dir2[1]); execvp(p2[0], p2); //execute command p2 } else if(pd2 > 0) { if(a == 2) { pd3 = fork(); if(pd3 == 0) { dup2(dir2[0], 0); //close bothe ends of all created dir pipes close(dir1[0]); close(dir1[1]); close(dir2[0]);

- 8. close(dir2[1]); execvp(p3[0], p3); //execute command p3 } else if(pd3<0) // if error { perror("FORK FAILURE"); } } else { wait( (int *)0); } } esle { perror("FORK FAILURE"); }

- 9. } // end of else if(pd>0) else { perror("FORK FAILURE"); } // only the parent gets here and close all the pipes and wait for the 3 children to finish close(dir1[0]); close(dir1[1]); close(dir2[0]); close(dir2[1]); for (int i = 0; i<(a+1); i++) { wait(&status); // waiting for the status }

- 10. } // end of void pipelining Managing Inventories Chapter 9 Copyright ©2016 Pearson Education, Limited. 9-‹#› What is a Inventory Management? Inventory Management The planning and controlling of inventories to meet the competitive priorities of the organization. Copyright ©2016 Pearson Education, Limited. 9-‹#› 2 What is Inventory? Inventory A stock of materials used to satisfy customer demand or to support the production of services or goods. Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 12. Output flow of materials Input flow of materials Figure 9.1 Copyright ©2016 Pearson Education, Limited. 9-‹#› 4 Pressures for Small Inventories Inventory holding cost

- 13. Cost of capital Storage and handling costs Taxes Insurance Shrinkage Pilferage Obsolescence Deterioration Copyright ©2016 Pearson Education, Limited. 9-‹#› 5 Pressures for Large Inventories Customer service Ordering cost Setup cost Labor and equipment utilization Transportation cost Payments to suppliers Copyright ©2016 Pearson Education, Limited. 9-‹#› 6 Types of Inventory Accounting Inventories Raw materials Work-in-process

- 14. Finished goods Copyright ©2016 Pearson Education, Limited. 9-‹#› 7 Types of Inventory Figure 9.2 Copyright ©2016 Pearson Education, Limited. 9-‹#› 8 Types of Inventory Operational Inventories Cycle Inventory Safety Stock Inventory Anticipation Inventory Pipeline Inventory Copyright ©2016 Pearson Education, Limited. 9-‹#› Cycle Inventory Lot sizing principles The lot size, Q, varies directly with the elapsed time (or cycle) between orders.

- 15. The longer the time between orders for a given item, the greater the cycle inventory must be. Average cycle inventory = = Q + 0 2 Q 2 Copyright ©2016 Pearson Education, Limited. 9-‹#› Cycle Inventory Copyright ©2013 Pearson Education 09- 11 d = Average demand per time period = Q/P = slope of the consumption linear function Copyright ©2016 Pearson Education, Limited. 9-‹#› Safety Stock Inventory Anticipation Inventory Copyright ©2013 Pearson Education 09- 12 Safety stock inventory is surplus inventory that protects against uncertainties in demand, lead time, and supply changes. Inventory used to absorb uneven rates of demand or supply, which businesses often face, is referred to as anticipation inventory

- 16. Copyright ©2016 Pearson Education, Limited. 9-‹#› Pipeline Inventory Average demand during lead time = DL Average demand per period = d Number of periods in the item’s lead time = L Pipeline inventory = DL = dL Assume that every period P we order a quantity Q. The pipeline inventory is Q during L and 0 during P-L. The average inventory is therefore: [Q⨯L+0⨯(P-L)]÷[L+(P-L)] = (Q/P) L = dL Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.1 A plant makes monthly shipments of electric drills to a wholesaler in average lot sizes of 280 drills. The wholesaler’s average demand is 70 drills a week, and the lead time from the plant is 3 weeks. The wholesaler must pay for the inventory from the moment the plant makes a shipment. If the wholesaler is willing to increase its purchase quantity to 350 units, the plant will give priority to the wholesaler and guarantee a lead time of only 2 weeks. What is the effect on the wholesaler’s cycle and pipeline inventories?

- 17. Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.1 The wholesaler’s current cycle and pipeline inventories are Cycle inventory = = 140 drills Q 2 (70 drills/week)(3 weeks) = 210 drills Pipeline inventory = DL = dL = Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.1 The wholesaler’s cycle and pipeline inventories if they accept the new proposal (70 drills/week)(2 weeks) = 140 drills Pipeline inventory = DL = dL = Cycle inventory = = 175 drills Q 2 Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 18. Inventory Reduction Tactics Cycle inventory Reduce the lot size Reduce ordering and setup costs and allow Q to be reduced Increase repeatability to eliminate the need for changeovers Safety stock inventory Place orders closer to the time when they must be received Improve demand forecasts Cut lead times Reduce supply uncertainties Rely more on equipment and labor buffers PL = primary lever SL = secondary lever Copyright ©2016 Pearson Education, Limited. 9-‹#› Inventory Reduction Tactics Anticipation inventory Match demand rate with production rates Add new products with different demand cycles Provide off-season promotional campaigns Offer seasonal pricing plans Pipeline inventory Reduce lead times Find more responsive suppliers and select new carriers Change Q in those cases where the lead time depends on the lot size Copyright ©2016 Pearson Education, Limited.

- 19. 9-‹#› What is an ABC Analysis? A stock-keeping unit (SKU) is an individual item or product that has an identifying code and is held in inventory somewhere along the supply chain. ABC analysis is the process of dividing SKUs into three classes, according to their dollar usage, so that managers can focus on items that have the highest dollar value. See Solved Problem 2 09- 19 Copyright ©2013 Pearson Education Copyright ©2016 Pearson Education, Limited. 9-‹#› What is an ABC Analysis? ABC Analysis The process of dividing SKUs into three classes, according to their dollar usage, so that managers can focus on items that have the highest dollar value. 10 20 30 40 50 60 70 80 90 100

- 20. Percentage of SKUs Percentage of dollar value 100 — 90 — 80 — 70 — 60 — 50 — 40 — 30 — 20 — 10 — 0 — Class C Class A Class B Figure 9.4 Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 21. Economic Order Quantity The lot size, Q, that minimizes total annual inventory holding and ordering costs Five assumptions Demand rate is constant and known with certainty. No constraints are placed on the size of each lot. The only two relevant costs are the inventory holding cost and the fixed cost per lot for ordering or setup. Decisions for one item can be made independently of decisions for other items. The lead time is constant and known with certainty. Copyright ©2016 Pearson Education, Limited. 9-‹#› 21 Economic Order Quantity Don’t use the EOQ Make-to-order strategy Order size is constrained Modify the EOQ Quantity discounts Replenishment not instantaneous Use the EOQ Make-to-stock strategy with relatively stable demand. Carrying and setup costs are known and relatively stable

- 22. Copyright ©2016 Pearson Education, Limited. 9-‹#› 22 Calculating EOQ Inventory depletion (demand rate) Receive order 1 cycle On-hand inventory (units) Time Q Average cycle inventory Q 2 Figure 9.5 Copyright ©2016 Pearson Education, Limited.

- 23. 9-‹#› 23 Calculating EOQ Annual holding cost Annual holding cost =(Average cycle inventory) Total costs =Annual holding cost + Annual ordering or setup cost Annual ordering cost = (Number of orders/Year) Annual ordering cost Total annual cycle inventory cost Copyright ©2016 Pearson Education, Limited. 9-‹#› 24 Annual cost (dollars) Lot Size (Q) Holding cost Ordering cost

- 24. Total cost Calculating EOQ Figure 9.6 Copyright ©2016 Pearson Education, Limited. 9-‹#› 25 Calculating EOQ Total annual cycle-inventory cost where C = total annual cycle-inventory cost Q = lot size (in units) H = holding cost per unit per year D = annual demand (in units) S = ordering or setup costs per lot C = (H) + (S) Q 2 D Q Copyright ©2016 Pearson Education, Limited. 9-‹#› 26 Example 9.2

- 25. A museum of natural history opened a gift shop which operates 52 weeks per year. Top-selling SKU is a bird feeder. Sales are 18 units per week, the supplier charges $60 per unit. Ordering cost is $45. Annual holding cost is 25 percent of a feeder’s value. Management chose a 390-unit lot size. What is the annual cycle-inventory cost of the current policy of using a 390-unit lot size? Would a lot size of 468 be better? Copyright ©2016 Pearson Education, Limited. 9-‹#› 27 Example 9.2 We begin by computing the annual demand and holding cost as D = H = C = (H) + (S) Q 2 D Q The total annual cycle-inventory cost for the alternative lot size is = ($15) + ($45) = $2,925 + $108 = $3,033 390 2

- 26. 936 390 The total annual cycle-inventory cost for the current policy is (18 units/week)(52 weeks/year) = 936 units 0.25($60/unit) = $15 C = ($15) + ($45) = $3,510 + $90 = $3,600 468 2 936 468 Copyright ©2016 Pearson Education, Limited. 9-‹#› 28 Example 9.2 3000 – 2000 – 1000 – 0 – |||||||| 50100150200250300350400 Lot Size (Q) Annual cost (dollars)

- 28. Total cost = (H) + (S) Q 2 D Q Ordering cost = (S) D Q Holding cost = (H) Q 2 Figure 9.7 Copyright ©2016 Pearson Education, Limited. 9-‹#› 29 Calculating EOQ The EOQ formula: EOQ = 2DS H

- 29. TBOEOQ = (12 months/year) EOQ D Time Between Orders (TBO): Copyright ©2016 Pearson Education, Limited. 9-‹#› 30 Example 9.3 For the bird feeders in Example 9.2, calculate the EOQ and its total annual cycle-inventory cost. How frequently will orders be placed if the EOQ is used? Using the formulas for EOQ and annual cost, we get EOQ = = 2DS H = 74.94 or 75 units 2(936)(45) 15 Copyright ©2016 Pearson Education, Limited. 9-‹#› 31

- 30. Example 9.3 Below shows that the total annual cost is much less than the $3,033 cost of the current policy of placing 390-unit orders. Figure 9.8 Copyright ©2016 Pearson Education, Limited. 9-‹#› 32 Example 9.3 When the EOQ is used, the TBO can be expressed in various ways for the same time period. TBOEOQ = EOQ D TBOEOQ = (12 months/year) EOQ D TBOEOQ = (52 weeks/year) EOQ D TBOEOQ = (365 days/year) EOQ D = = 0.080 year 75

- 31. 936 = (12) = 0.96 month 75 936 = (52) = 4.17 weeks 75 936 = (365) = 29.25 days 75 936 Copyright ©2016 Pearson Education, Limited. 9-‹#› 33 Application 9.1 Suppose that you are reviewing the inventory policies on an $80 item stocked at a hardware store. The current policy is to replenish inventory by ordering in lots of 360 units. Additional information is: D = 60 units per week, or 3,120 units per year S = $30 per order H = 25% of selling price, or $20 per unit per year What is the EOQ? EOQ = = 2DS H

- 32. = 97 units 2(3,120)(30) 20 Copyright ©2016 Pearson Education, Limited. 9-‹#› Current PolicyEOQ Policy Application 9.1 What is the total annual cost of the current policy (Q = 360), and how does it compare with the cost with using the EOQ? Q = 360 unitsQ = 97 unitsC = 3,600 + 260C = $3,860C = (360/2)(20) + (3,120/360)(30)C = 970 + 965C = $1,935C = (97/2)(20) + (3,120/97)(30) Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.1 What is the time between orders (TBO) for the current policy and the EOQ policy, expressed in weeks? TBO360 = TBOEOQ = (52 weeks per year) = 6 weeks 360 3,120 (52 weeks per year) = 1.6 weeks 97 3,120

- 33. Copyright ©2016 Pearson Education, Limited. 9-‹#› Managerial Insights from the EOQ SENSITIVITY ANALYSIS OF THE EOQParameterEOQParameter ChangeEOQ ChangeCommentsDemand↑↑Increase in lot size is in proportion to the square root of D.Order/ Setup Costs↓↓Weeks of supply decreases and inventory turnover increases because the lot size decreases.Holding Costs↓↑Larger lots are justified when holding costs decrease. Table 9.1 2DS H 2DS H 2DS H Copyright ©2016 Pearson Education, Limited. 9-‹#› 37 Continuous Review System Continuous review (Q) system Reorder point system (ROP) and fixed order quantity system Tracks inventory position (IP)

- 34. Includes scheduled receipts (SR), on-hand inventory (OH), and back orders (BO) Inventory position =On-hand inventory + Scheduled receipts – Backorders IP = OH + SR – BO Copyright ©2016 Pearson Education, Limited. 9-‹#› 38 Continuous Review System Time On-hand inventory TBO TBO L L TBO

- 36. Q OH OH OH Order received Order received Order received Order received Figure 9.9 Selecting the Reorder Point When Demand and Lead Time are Constant Copyright ©2016 Pearson Education, Limited. 9-‹#› 39

- 37. Example 9.4 Demand for chicken soup at a supermarket is always 25 cases a day and the lead time is always 4 days. The shelves were just restocked with chicken soup, leaving an on-hand inventory of only 10 cases. No backorders currently exist, but there is one open order in the pipeline for 200 cases. What is the inventory position? Should a new order be placed? R =Total demand during lead time = (25)(4) = 100 cases = 10 + 200 – 0 = 210 cases IP = OH + SR – BO Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.2 The on-hand inventory is only 10 units, and the reorder point R is 100. There are no backorders and one open order for 200 units. Should a new order be placed? IP = OH + SR – BO = 10 + 200 – 0 = 210 R = 100 Decision: Place NO new order Copyright ©2016 Pearson Education, Limited. 9-‹#› 41 Continuous Review Systems Time On-hand inventory

- 40. Selecting the Reorder Point When Demand is Variable and Lead Time is Constant Copyright ©2016 Pearson Education, Limited. 9-‹#› 42 Example 9.5 A distribution center (DC) in Wisconsin stocks Sony plasma TV sets. The center receives its inventory from a mega warehouse in Kansas with a lead time (L) of 5 days. The DC uses a reorder point (R) of 300 sets and a fixed order quantity (Q) of 250 sets. Current on-hand inventory at the end of Day 1 is 400 sets. There are no scheduled receipts (SR) and no backorders (BO). All demands and receipts occur at the end of the day. Determine when to order using a Q system Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.5DayDemandOHSRBOIPQ150 400234567 400 + 0 = 400 340 + 0 = 340 250 after ordering 260 < R before ordering 60 80 40 75 55 95 260 + 250 = 510 after ordering

- 41. 260 220 145 90 0 340 250 due Day 8 250 250 250 220 + 250 = 470 145 + 250 = 395 90 + 250 = 340 250+ 250 = 500 after ordering 0 + 250 – 5 = 245 < R before ordering 245 + 250 = 495 after ordering 250 due Day 12 5 Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.5DayDemandOHSRBOIPQ891011121314 195 + 250 = 445 150 + 250 = 400 250 120 + 250 = 370 45 30 50 60 40

- 42. 50 120 70 70 – 60 + 250 = 260 260 – 40 = 220 170 195 – 45 = 150 250 250 after ordering 250 70 + 250 = 320 220 + 250 = 470 250 260 < R before ordering 260 + 250 = 510 after ordering 250 due Day 17 170 + 250 = 420 250 250 50 0 + 250 – 50 -5 = 195 Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.5 The demands at the DC are fairly volatile and cause the reorder point to be breached quite dramatically at times.

- 43. Copyright ©2016 Pearson Education, Limited. 9-‹#› Continuous Review Systems Selecting the reorder point with variable demand and constant lead time Reorder point=Average demand during lead time + Safety stock = dL + safety stock where d= average demand per week (or day or months) L = constant lead time in weeks (or days or months) Copyright ©2016 Pearson Education, Limited. 9-‹#› 47 Continuous Review System Choosing a Reorder Point Choose an appropriate service-level policy Determine the distribution of demand during lead time Determine the safety stock and reorder point levels Copyright ©2016 Pearson Education, Limited. 9-‹#› 48

- 44. Continuous Review System Step 1: Service Level Policy Service Level (Cycle Service Level) – The desired probability of not running out of stock in any one ordering cycle, which begins at the time an order is placed and ends when it arrives in stock. Protection Interval – The period over which safety stock must the user from running out of stock. Copyright ©2016 Pearson Education, Limited. 9-‹#› Continuous Review System Specify mean and standard deviation Standard deviation of demand during lead time σdLT = σd2L = σd L Step 2: Distribution of Demand during Lead Time Copyright ©2016 Pearson Education, Limited. 9-‹#› 50 σd = 15 + 75

- 45. Demand for week 1 σdlt = 25.98 225 Demand for 3-week lead time + 75 Demand for week 2 σd = 15 = 75 Demand for week 3 σd = 15 Continuous Review System Figure 9.11 Copyright ©2016 Pearson Education, Limited. 9-‹#› 51 Continuous Review System

- 46. Average demand during lead time Cycle-service level = 85% Probability of stockout (1.0 – 0.85 = 0.15) zσdLT R Figure 9.12 Copyright ©2016 Pearson Education, Limited. 9-‹#› 52 Continuous Review System Step 3: Safety Stock and Reorder Point Safety stock = zσdLT where z =number of standard deviations needed to achieve the cycle- service level σdLT =stand deviation of demand during lead time Reorder point = R = dL + safety stock

- 47. Copyright ©2016 Pearson Education, Limited. 9-‹#› 53 Example 9.6 Let us return to the bird feeder in Example 9.3. The EOQ is 75 units. Suppose that the average demand is 18 units per week with a standard deviation of 5 units. The lead time is constant at two weeks. Determine the safety stock and reorder point if management wants a 90 percent cycle-service level. Safety stock = zσdLT = 1.28(7.07) = 9.05 or 9 units Reorder point= d L + Safety stock = 2(18) + 9 = 45 units Copyright ©2016 Pearson Education, Limited. 9-‹#› 54 Application 9.3 Suppose that the demand during lead time is normally distributed with an average of 85 and σdLT = 40. Find the safety stock, and reorder point R, for a 95 percent cycle-service level. Safety stock = zσdLT =

- 48. Find the safety stock, and reorder point R, for an 85 percent cycle-service level. R = Average demand during lead time + Safety stock R = 85 + 66 = 151 units 1.645(40) = 65.8 or 66 units Safety stock = zσdLT = 1.04(40) = 41.6 or 42 units R = Average demand during lead time + Safety stock R = 85 + 42 = 127 units Copyright ©2016 Pearson Education, Limited. 9-‹#› Continuous Review System Selecting the Reorder Point When Demand and Lead Time are Variable Safety stock = zσdLT + Safety stock =d L + Safety stock Copyright ©2016 Pearson Education, Limited. 9-‹#› 56 Example 9.7

- 49. The Office Supply Shop estimates that the average demand for a popular ball-point pen is 12,000 pens per week with a standard deviation of 3,000 pens. The current inventory policy calls for replenishment orders of 156,000 pens. The average lead time from the distributor is 5 weeks, with a standard deviation of 2 weeks. If management wants a 95 percent cycle-service level, what should the reorder point be? Copyright ©2016 Pearson Education, Limited. 9-‹#› 57 Example 9.7 Safety stock = zσdLT = (1.65)(24,919.87) =41,117.79 or 41,118 pens We have d = 12,000 pens, σd = 3,000 pens, L = 5 weeks, and σLT = 2 weeks σdLT = L σd2 + d 2σLT2 = (5)(3,000)2 + (12,000)2(2)2 = 24,919.87 pens Reorder point = d L + Safety stock= (12,000)(5) + 41,118 =101,118 pens

- 50. Copyright ©2016 Pearson Education, Limited. 9-‹#› 58 Continuous Review Systems Two-Bin system A visual system version of the Q system in which a SKU’s inventory is stored at two different locations. Calculating Total Q System Costs Total cost =Annual cycle inventory holding cost + Annual ordering cost + Annual safety stock holding cost C = (H) + (S) + (H) (Safety stock) Q 2 D Q Copyright ©2016 Pearson Education, Limited. 9-‹#› 59 Continuous Review System Advantages of the Q System

- 51. The review frequency of each SKU may be individualized. Fixed lot sizes can results in quantity discounts. The system requires low levels of safety stock for the amount of uncertainty in demands during the lead time. Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.5 The Discount Appliance Store uses a continuous review system (Q system). One of the company’s items has the following characteristics: Demand = 10 units/week (assume 52 weeks per year) Ordering or setup cost (S) = $45/order Holding cost (H) = $12/unit/year Lead time (L) = 3 weeks (constant) Standard deviation in weekly demand = 8 units Cycle-service level = 70% Copyright ©2016 Pearson Education, Limited. 9-‹#› 61 Application 9.5 What is the EOQ for this item? D = EOQ = = 2DS

- 52. H = 62 units 2(520)(45) 12 What is the desired safety stock? σdLT = σd L = 8 3 = 14 units Safety stock = zσdLT = 0.525(14) = 8 units Copyright ©2016 Pearson Education, Limited. 9-‹#› 62 Application 9.5 What is the desired reorder point R? R = Average demand during lead time + Safety stock R = What is the total annual cost? 3(10) + 8 = 38 units ($12) + ($45) + 8($12) = $845.42 62 2 520 62

- 53. C = Copyright ©2016 Pearson Education, Limited. 9-‹#› 63 Application 9.5 Suppose that the current policy is Q = 80 and R = 150. What will be the changes in average cycle inventory and safety stock if your EOQ and R values are implemented? Reducing Q from 80 to 62 Cycle inventory reduction = 40 – 31 = 9 units Safety stock reduction = 120 – 8 = 112 units Reducing R from 150 to 38 Copyright ©2016 Pearson Education, Limited. 9-‹#› 64 Periodic Review System (P) Fixed interval reorder system or periodic reorder system Four of the original EOQ assumptions maintained No constraints are placed on lot size Holding and ordering costs Independent demand Lead times are certain and supply is known

- 54. Copyright ©2016 Pearson Education, Limited. 9-‹#› 65 Periodic Review System (P) P P T L L L Protection interval

- 56. Q1 Q2 Q3 Figure 9.13 Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.8 Refer to Example 9.5 Suppose that the management want to use a Periodic Review System for the Sony TV sets. The first review is scheduled for the end of Day 2. All demands and receipts occur at the end of the day. Lead time is 5 Days and management has set T = 620 and P = 6 days. Determine how much to order (Q) using a P System. Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 57. Example 9.8DayDemandOHSRBOIPQ150234567 400 340 before ordering 280 260 + 280 = 540 60 80 40 75 55 95 260 220 145 90 + 280 – 95 = 275 90 340 620 – 340 = 280 due Day 7 280 280 280 220 + 280 = 500 145 + 280 = 425 90 + 280 = 370 400 280 after ordering 340 + 280 = 620 after ordering 270 + 0 = 275 Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.8DayDemandOHSRBOIPQ85091011121314

- 58. 340 + 0 = 340 before ordering 395 150 + 395 = 545 45 30 50 60 40 50 150 100 40 40 + 395 – 40 = 395 345 180 620 – 225 = 395 due Day 13 395 395 100 + 395 = 495 40 + 395 = 435 395 + 0 = 395 225 345 + 275 = 620 after ordering 180 + 395 = 575 395 275 after ordering 395 after ordering 225 + 0 = 225 before ordering 225 + 395 = 620 after ordering 620 – 345 = 275 due Day 19 Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 59. Example 9.8 The P system requires more inventory for the same level of protection against stockouts or backorders. Copyright ©2016 Pearson Education, Limited. 9-‹#› Periodic Review System Selecting the time between reviews, choosing P and T Selecting T when demand is variable and lead time is constant IP covers demand over a protection interval of P + L The average demand during the protection interval is d(P + L), or T = d (P + L) + safety stock for protection interval Safety stock = zσP + L , where σP + L = Copyright ©2016 Pearson Education, Limited. 9-‹#› 71 Example 9.9 Again, let us return to the bird feeder example. Recall that demand for the bird feeder is normally distributed with a mean of 18 units per week and a standard deviation in

- 60. weekly demand of 5 units. The lead time is 2 weeks, and the business operates 52 weeks per year. The Q system called for an EOQ of 75 units and a safety stock of 9 units for a cycle-service level of 90 percent. What is the equivalent P system? Answers are to be rounded to the nearest integer. Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.9 We first define D and then P. Here, P is the time between reviews, expressed in weeks because the data are expressed as demand per week: D = (18 units/week)(52 weeks/year) = 936 units P = (52) = EOQ D (52) = 4.2 or 4 weeks 75 936 Copyright ©2016 Pearson Education, Limited. 9-‹#› Example 9.9 We now find the standard deviation of demand over the protection interval (P + L) = 6: For a 90 percent cycle-service level z = 1.28: Safety stock = zσP + L = 1.28(12.25) = 15.68 or 16 units

- 61. We now solve for T: = (18 units/week)(6 weeks) + 16 units = 124 units T = Average demand during the protection interval + Safety stock = d (P + L) + safety stock Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.6 The on-hand inventory is 10 units, and T is 400. There are no back orders, but one scheduled receipt of 200 units. Now is the time to review. How much should be reordered? IP = OH + SR – BO The decision is to order 190 units = 10 + 200 – 0 = 210 T – IP = 400 – 210 = 190 Copyright ©2016 Pearson Education, Limited. 9-‹#› 75 Periodic Review System Selecting the Target Inventory Level When Demand and Lead Time are Variable Simulation Systems Based on the P System Single-Bin System Optional Replenishment System

- 62. Calculating Total P System Costs C = (H) + (S) + HzσP + L dP 2 D dP Copyright ©2016 Pearson Education, Limited. 9-‹#› Periodic Review System Advantages of the P System It is convenient because replenishments are made at fixed intervals. Orders for multiple items from the same supplier can be combined into a single purchase order. The inventory position needs to be known only when a review is made (not continuously). Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.7 Return to Discount Appliance Store (Application 9.5), but now use the P system for the item. Previous information: Demand = 10 units/wk (assume 52 weeks per year) = 520 EOQ = 62 units (with reorder point system)

- 63. Lead time (L) = 3 weeks Standard deviation in weekly demand = 8 units z = 0.525 (for cycle-service level of 70%) Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.7 Reorder interval P, if you make the average lot size using the Periodic Review System approximate the EOQ. P = (EOQ/D)(52) = (62/520)(52) = 6.2 or 6 weeks Safety stock Target inventory T = 10(6 + 3) + 13 = 103 units T = d(P + L) + safety stock for protection interval Copyright ©2016 Pearson Education, Limited. 9-‹#› Application 9.7 Total cost C = (H) + (S) + HzσP + L dP 2 = ($12) + ($45) + (13)($12) = $906.00 10(6)

- 64. 2 520 10(6) Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 1 A distribution center experiences an average weekly demand of 50 units for one of its items. The product is valued at $650 per unit. Average inbound shipments from the factory warehouse average 350 units. Average lead time (including ordering delays and transit time) is 2 weeks. The distribution center operates 52 weeks per year; it carries a 1-week supply of inventory as safety stock and no anticipation inventory. What is the value of the average aggregate inventory being held by the distribution center? Copyright ©2016 Pearson Education, Limited. 9-‹#› 81 Solved Problem 1Type of InventoryCalculation of Average InventoryCycleSafety stockAnticipationPipeline 1-week supply None Q

- 65. 2 = 350 2 = 175 units = 50 units dL = (50 units/week)(2 weeks) Average aggregate inventory Value of aggregate inventory = 100 units = 325 units = $650(325) = $211,250 Copyright ©2016 Pearson Education, Limited. 9-‹#› 82 Solved Problem 2 Booker’s Book Bindery divides SKUs into three classes, according to their dollar usage. Calculate the usage values of the following SKUs and determine which is most likely to be classified as class A.SKU NumberDescriptionQuantity Used per YearUnit Value ($)1Boxes5003.002Cardboard (square feet)18,0000.023Cover stock10,0000.754Glue (gallons)7540.005Inside covers20,0000.056Reinforcing tape (meters)3,0000.157Signatures150,0000.45 Copyright ©2016 Pearson Education, Limited.

- 66. 9-‹#› 83 Solved Problem 2SKU NumberDescriptionQuantity Used per YearUnit Value ($)Annual Dollar Usage cing tape 81,310 Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 2 Figure 9.14 Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 2 Figure 9.14 Copyright ©2016 Pearson Education, Limited. 9-‹#›

- 67. 86 Solved Problem 3 Nelson’s Hardware Store stocks a 19.2 volt cordless drill that is a popular seller. Annual demand is 5,000 units, the ordering cost is $15, and the inventory holding cost is $4/unit/year. a.What is the economic order quantity? b.What is the total annual cost for this inventory item? a. The order quantity is EOQ = = 2DS H 2(5,000)($15) $4 = 37,500 = 193.65 or 194 drills b.The total annual cost is C = (H) + (S) = Q 2 D Q ($4) + ($15) = $774.60 194 2 5,000 194

- 68. Copyright ©2016 Pearson Education, Limited. 9-‹#› 87 Solved Problem 4 A regional distributor purchases discontinued appliances from various suppliers and then sells them on demand to retailers in the region. The distributor operates 5 days per week, 52 weeks per year. Only when it is open for business can orders be received. The following data are estimated for the countertop mixer: Copyright ©2016 Pearson Education, Limited. 9-‹#› 88 Solved Problem 4 What order quantity Q, and reorder point, R, should be used? What is the total annual cost of the system? If on-hand inventory is 40 units, one open order for 440 mixers is pending, and no backorders exist, should a new order be placed? Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 4

- 69. a.Annual demand is The order quantity is D= (5 days/week)(52 weeks/year)(100 mixers/day) = 26,000 mixers/year EOQ = = 2DS H 2(26,000)($35) $9.40 = 193,167 = 440.02 or 440 mixers Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 4 The standard deviation of the demand during lead time distribution is A 92 percent cycle-service level corresponds to z = 1.41 σdLT = σd L = 30 3 = 51.96 Safety stock = zσdLT = 1.41(51.96 mixers) = 73.26 or 73 mixers Reorder point (R) = Average demand during lead time + Safety stock = 300 mixers + 73 mixers = 373 mixers With a continuous review system, Q = 440 and R = 373

- 70. 100(3) = 300 mixers Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 4 b.The total annual cost for the Q systems is C = (H) + (S) + (H)(Safety stock) Q 2 D Q C = ($9.40) + ($35) + ($9.40)(73) = $4,822.38 440 2 26,000 440 c.Inventory position =On-hand inventory + Scheduled receipts – Backorders IP = OH + SR – BO = 40 + 440 – 0 = 480 mixers Because IP (480) exceeds R (373), do not place a new order Copyright ©2016 Pearson Education, Limited. 9-‹#› 92

- 71. Solved Problem 5 Suppose that a periodic review (P) system is used at the distributor in Solved Problem 4, but otherwise the data are the same. a.Calculate the P (in workdays, rounded to the nearest day) that gives approximately the same number of orders per year as the EOQ. b.What is the target inventory level, T? Compare the P system to the Q system in Solved Problem 4. c.What is the total annual cost of the P system? d.It is time to review the item. On-hand inventory is 40 mixers; receipt of 440 mixers is scheduled, and no backorders exist. How much should be reordered? Copyright ©2016 Pearson Education, Limited. 9-‹#› 93 Solved Problem 5 a. The time between orders is P = (260 days/year) = EOQ D (260) = 4.4 or 4 days 440 26,000 Copyright ©2016 Pearson Education, Limited.

- 72. 9-‹#› Solved Problem 5 The OM Solver data below shows that T = 812 and safety stock = (1.41)(79.37) = 111.91 or about 112 mixers. The corresponding Q system for the counter-top mixer requires less safety stock. Figure 9.15 Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 5 c.The total annual cost of the P system is C = (H) + (S) + (H)(Safety stock) C = ($9.40) + ($35) + ($9.40)(1.41)(79.37) 100(4) 2 26,000 100(4) = $5,207.80 d.Inventory position is the amount on hand plus scheduled receipts minus backorders, or IP = OH + SR – BO = 40 + 440 – 0 = 480 mixers The order quantity is the target inventory level minus the inventory position, or Q = T – IP = An order for 332 mixers should be placed. 812 mixers – 480 mixers = 332 mixers

- 73. Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 6 Grey Wolf Lodge is a popular 500-room hotel in the North Woods. Managers need to keep close tabs on all room service items, including a special pine-scented bar soap. The daily demand for the soap is 275 bars, with a standard deviation of 30 bars. Ordering cost is $10 and the inventory holding cost is $0.30/bar/year. The lead time from the supplier is 5 days, with a standard deviation of 1 day. The lodge is open 365 days a year. a.What is the economic order quantity for the bar of soap? b.What should the reorder point be for the bar of soap if management wants to have a 99 percent cycle-service level? c.What is the total annual cost for the bar of soap, assuming a Q system will be used? Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 6 a.We have D = (275)(365) = 100,375 bars of soap; S = $10; and H = $0.30. The EOQ for the bar of soap is EOQ = = 2DS H 2(100,375)($10) $0.30 = 6,691,666.7 = 2,586.83 or 2,587 bars

- 74. Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 6 (5)(30)2 + (275)2(1)2 = 283.06 bars Safety stock = zσdLT = (2.33)(283.06) = 659.53 or 660 bars (275)(5) + 660 = 2,035 bars Copyright ©2016 Pearson Education, Limited. 9-‹#› Solved Problem 6 c.The total annual cost for the Q system is C = (H) + (S) + (H)(Safety stock) Q 2 D Q C = ($0.30) + ($10) + ($0.30)(660) = $974.05 2,587 2 100,375 2,587

- 75. Copyright ©2016 Pearson Education, Limited. 9-‹#› L P d + s ( ) ( ) units 13 or 12.6 3 6 8 0.525 = + = old menuPremium/NormalVeg/NonTypeNameTypeQtyPriceServingd aaaadfupload nameNormalNon-VegAppetizerChicken MomoChicken6/12 PC50Half10aChicken Momo -

- 76. HalfNormalNon-VegAppetizerChicken MomoChicken6/12 PC100Full10bChicken Momo - FullNormalNon- VegAppetizerChicken MomoChicken50Half11aChicken Momo - HalfNormalNon-VegAppetizerChicken MomoChicken100Full11bChicken Momo - FullNormalVegGravyVeg Manchurian Gravy Veg60Half12aVeg Manchurian Gravy - HalfNormalVegGravyVeg Manchurian Gravy Veg100Full12bVeg Manchurian Gravy - FullPremiumVegRiceSpecial Veg Fried Rice Premium60Half13aSpecial Veg Fried Rice - HalfPremiumVegRiceSpecial Veg Fried Rice Premium120Full13bSpecial Veg Fried Rice - FullPremiumVegNoodleChilli Garlic Noodle Premium70Half14aChilli Garlic Noodle - HalfPremiumVegNoodleChilli Garlic Noodle Premium140Full14bChilli Garlic Noodle - FullPremiumVegNoodleVeg Schezwan Noodle Premium70Half15aVeg Schezwan Noodle - HalfPremiumVegNoodleVeg Schezwan Noodle Premium140Full15bVeg Schezwan Noodle - FullNormalVegNoodlePaneer Chow Mein Paneer70Half16aPaneer Chow Mein - HalfNormalVegNoodlePaneer Chow Mein Paneer140Full16bPaneer Chow Mein - FullNormalVegNoodleMushroom Chow Mein Mushroom70Half17aMushroom Chow Mein - HalfNormalVegNoodleMushroom Chow Mein Mushroom140Full17bMushroom Chow Mein - FullNormalVegGravyVeg Manchurian Dry Veg70Half18aVeg Manchurian Dry - HalfNormalVegGravyVeg Manchurian Dry Veg110Full18bVeg Manchurian Dry - FullPremiumVegNoodleSingapore Fried Noodle Premium80Half19aSingapore Fried Noodle - HalfPremiumVegNoodleSingapore Fried Noodle Premium150Full19bSingapore Fried Noodle - FullNormalVegNoodleVeg Chow Mein Veg30Half1aVeg Chow

- 77. Mein - HalfNormalVegNoodleVeg Chow Mein Veg60Full1bVeg Chow Mein - FullPremiumVegRiceSingapore Fried Rice Premium80Half20aSingapore Fried Rice - HalfPremiumVegRiceSingapore Fried Rice Premium160Full20bSingapore Fried Rice - FullNormalVegGravyChilli Paneer Gravy Paneer80Half21aChilli Paneer Gravy - HalfNormalVegGravyChilli Paneer Gravy Paneer150Full21bChilli Paneer Gravy - FullNormalVegRicePaneer Fried Rice Paneer80Half22aPaneer Fried Rice - HalfNormalVegRicePaneer Fried Rice Paneer160Full22bPaneer Fried Rice - FullNormalNon- VegNoodleChicken Chow Mein Chicken90Half23aChicken Chow Mein - HalfNormalNon-VegNoodleChicken Chow Mein Chicken160Full23bChicken Chow Mein - FullPremiumVegNoodleHong Kong Style NoodlePremium90Half24aHong Kong Style Noodle - HalfPremiumVegNoodleHong Kong Style NoodlePremium160Full24bHong Kong Style Noodle - FullPremiumVegGravyBaby Corn Chilli SticksPremium90Half25aBaby Corn Chilli Sticks - HalfPremiumVegGravyBaby Corn Chilli SticksPremium160Full25bBaby Corn Chilli Sticks - FullNormalVegGravyChilli Paneer Dry Paneer90Half26aChilli Paneer Dry - HalfNormalVegGravyChilli Paneer Dry Paneer160Full26bChilli Paneer Dry - FullNormalVegGravyChilli Mushroom Mushroom90Half27aChilli Mushroom - HalfNormalVegGravyChilli Mushroom Mushroom160Full27bChilli Mushroom - FullNormalVegGravyPaneer 65 Paneer90Half28aPaneer 65 - HalfNormalVegGravyPaneer 65 Paneer160Full28bPaneer 65 - FullPremiumVegRiceVeg Schezwan Rice Premium90Half29aVeg Schezwan Rice - HalfPremiumVegRiceVeg Schezwan Rice Premium180Full29bVeg Schezwan Rice -

- 78. FullNormalVegAppetizerVeg MomoVeg30Half2aVeg Momo - HalfNormalVegAppetizerVeg MomoVeg60Full2bVeg Momo - FullNormalVegRiceMushroom Fried Rice Mushroom90Half30aMushroom Fried Rice - HalfNormalVegRiceMushroom Fried Rice Mushroom180Full30bMushroom Fried Rice - FullNormalNon- VegAppetizerChicken Spring Roll Chicken90Half31aChicken Spring Roll - HalfNormalNon-VegAppetizerChicken Spring Roll Chicken160Full31bChicken Spring Roll - FullNormalNon- VegRiceChicken Fried Rice Chicken100Half32aChicken Fried Rice - HalfNormalNon-VegRiceChicken Fried Rice Chicken180Full32bChicken Fried Rice - FullNormalVegGravyCrispy PaneerPaneer100Half33aCrispy Paneer - HalfNormalVegGravyCrispy PaneerPaneer180Full33bCrispy Paneer - FullNormalVegRiceMix Veg Fried Rice Veg100Half34aMix Veg Fried Rice - HalfNormalVegRiceMix Veg Fried Rice Veg200Full34bMix Veg Fried Rice - FullNormalNon- VegRiceChicken Schezwan Rice Chicken110Half35aChicken Schezwan Rice - HalfNormalNon-VegRiceChicken Schezwan Rice Chicken200Full35bChicken Schezwan Rice - FullNormalVegGravyShanghai PaneerPaneer120Half36aShanghai Paneer - HalfNormalNon- VegGravyChilli Chicken Gravy Chicken8/16 PC130Half37aChilli Chicken Gravy - HalfNormalNon- VegGravyChilli Chicken Gravy Chicken8/16 PC250Full37bChilli Chicken Gravy - FullNormalNon- VegGravyChicken LollipopChicken130Half38aChicken Lollipop - HalfNormalNon-VegGravyChicken LollipopChicken250Full38bChicken Lollipop - FullNormalNon- VegGravyChicken 65 Gravy Chicken130Half39aChicken 65 Gravy - HalfNormalNon-VegGravyChicken 65 Gravy Chicken250Full39bChicken 65 Gravy - FullNormalVegAppetizerMacaroni Macaroni30Half3aMacaroni - HalfNormalVegAppetizerMacaroni Macaroni60Full3bMacaroni - FullNormalNon-

- 79. VegGravyChicken Manchurian Gravy Chicken130Half40aChicken Manchurian Gravy - HalfNormalNon-VegGravyChicken Manchurian Gravy Chicken250Full40bChicken Manchurian Gravy - FullNormalNon-VegNoodleChicken Schezwan Noodle Chicken130Half41aChicken Schezwan Noodle - HalfNormalNon-VegNoodleChicken Schezwan Noodle Chicken250Full41bChicken Schezwan Noodle - FullNormalNon-VegGravyChilli Chicken Dry Chicken140Half42aChilli Chicken Dry - HalfNormalNon- VegGravyChilli Chicken Dry Chicken260Full42bChilli Chicken Dry - FullNormalNon-VegGravyPepper Chicken Chicken140Half43aPepper Chicken - HalfNormalNon- VegGravyPepper Chicken Chicken260Full43bPepper Chicken - FullNormalNon-VegGravyChicken 65 DryChicken140Half44aChicken 65 Dry - HalfNormalNon- VegGravyChicken 65 DryChicken260Full44bChicken 65 Dry - FullNormalNon-VegGravyChicken Manchurian Dry Chicken140Half45aChicken Manchurian Dry - HalfNormalNon- VegGravyChicken Manchurian Dry Chicken260Full45bChicken Manchurian Dry - FullNormalNon-VegGravyChicken Drumstick Chicken140Half46aChicken Drumstick - HalfNormalNon-VegGravyChicken Drumstick Chicken260Full46bChicken Drumstick - FullNormalNon- VegGravyChatkari Chicken Chicken150Half47aChatkari Chicken - HalfNormalNon-VegGravyChatkari Chicken Chicken280Full47bChatkari Chicken - FullPremiumVegNoodleHakka Noodle Premium150Full49bHakka Noodle - FullNormalVegAppetizerPaneer MomoPaneer6/1240Half4aPaneer Momo - HalfNormalVegAppetizerPaneer MomoPaneer6/1280Full4bPaneer Momo - FullPremiumVegNoodleButter White Noodle Premium150Full50bButter White Noodle - FullPremiumVegNoodleCrispy Noodle

- 80. Premium150Full51bCrispy Noodle - FullNormalVegAppetizerCrispy Chilli PotatoPotato60Full55bCrispy Chilli Potato - FullNormalVegAppetizerHoney Chilli PotatoPotato70Full56bHoney Chilli Potato - FullNormalNon- VegAmericanChicken Burger ChickenAdd Cheese 20 Rs70Full58bChicken Burger - FullNormalVegAppetizerVeg Spring Roll Veg40Half5aVeg Spring Roll - HalfNormalVegAppetizerVeg Spring Roll Veg80Full5bVeg Spring Roll - FullNormalVegSoupTomato Soup Veg40Full61bTomato Soup - FullNormalVegSoupVeg Soup Veg40Full62bVeg Soup - FullNormalVegSoupVeg Hot & Sour Soup Veg40Full63bVeg Hot & Sour Soup - FullNormalVegSoupVeg Peeking Soup Veg40Full64bVeg Peeking Soup - FullNormalVegSoupVeg Sweet Corn Soup Veg40Full65bVeg Sweet Corn Soup - FullNormalVegSoupVeg Corn Soup Veg40Full66bVeg Corn Soup - FullNormalVegSoupVeg Talimim Soup Veg40Full67bVeg Talimim Soup - FullNormalVegSoupVeg Noodle Soup Veg40Full68bVeg Noodle Soup - FullNormalVegSoupVeg Clear Soup Veg40Full69bVeg Clear Soup - FullNormalVegAmericanVeg Burger Veg40Half6aVeg Burger - HalfNormalNon-VegSoupChicken Soup Chicken60Full70bChicken Soup - FullNormalNon- VegSoupChicken Hot & Sour Soup Chicken60Full71bChicken Hot & Sour Soup - FullNormalNon-VegSoupChicken Peeking Soup Chicken60Full72bChicken Peeking Soup - FullNormalNon-VegSoupChicken Sweet Corn Soup Chicken60Full73bChicken Sweet Corn Soup - FullNormalNon- VegSoupChicken Corn Soup Chicken60Full74bChicken Corn Soup - FullNormalNon-VegSoupChicken Talimim Soup Chicken60Full75bChicken Talimim Soup - FullNormalNon- VegSoupChicken Noodle Soup Chicken60Full76bChicken Noodle Soup - FullNormalNon-VegSoupChicken Clear Soup Chicken60Full77bChicken Clear Soup - FullNormalVegGravyPaneer Manchurian Gray

- 81. Paneer80Half78aPaneer Manchurian Gray - HalfNormalVegGravyPaneer Manchurian Gray Paneer150Full78bPaneer Manchurian Gray - FullNormalVegGravyPaneer Manchurian Dry Paneer90Half79aPaneer Manchurian Dry - HalfNormalVegGravyPaneer Manchurian Dry Paneer160Full79bPaneer Manchurian Dry - FullNormalVegNoodleSpecial Veg Chow Mein Veg50Half7aSpecial Veg Chow Mein - HalfNormalVegNoodleSpecial Veg Chow Mein Veg100Full7bSpecial Veg Chow Mein - FullNormalVegRiceVeg Fried Rice Veg50Half8aVeg Fried Rice - HalfNormalVegRiceVeg Fried Rice Veg100Full8bVeg Fried Rice - FullPremiumVegAppetizerChilli MomoPremium50Half9aChilli Momo - HalfPremiumVegAppetizerChilli MomoPremium100Full9bChilli Momo - Full PlasticS.no.NamePriceQtyTotal1Daliya2Sauce Bottle3DustbinPlastic Jug EquipmentS.No.CategoryNamePriceQtyTotal1BBQChimta42BB QMitten23BBQBrush44BBQPalta45BBQSariya Square86BBQSariya Patli87BBQSariya Chapti88BBQRoti Sariya29BBQSteel Parath610BroastChanni211ChineseKarai - 2#412ChineseKarai - 1#313ChineseDabbu614ChinesePalta615ChineseTawa216Chines eChanni317ChineseSteamer218ContiKarai S219ContiFrying Pan220ContiGinger Grater221ContiGarlic Press222ContiLemon Press223ContiOrange Press224ContiEgg Whisk225ContiSizzler Plate626ContiBaked Ziti Plate627GeneralKnife S628GeneralKnife L629GeneralCutting Board230GeneralChopper Knife431GeneralTowel1232GeneralSteelbox 3 ltr433GeneralSteelbox 2 ltr634GeneralSteelbox 1 ltr635GeneralFry Karahi436GeneralTray Aluminum S837GeneralTray Aluminum M838GeneralTray Steel w/cover439GeneralTray Steel w/o cover640GeneralMasala Box

- 82. 12 sec141GeneralMasala Box 6 sec342GeneralParath443GeneralTong1444GeneralSetting Bowl S1545GeneralSetting Bowl M1546GeneralSetting Bowl L1047GeneralAlum Patila1448GeneralGravy Palta249GeneralPressure Cooker350GeneralSujata Mixi151GeneralSujata Gravy Mixi152GeneralVeg Cutter153GeneralWeigh Machine Digital154GeneralWeigh Machine (Gas) + chain155GeneralInverter156GeneralFridge Haier257GeneralFreezer158GeneralGrater259GeneralLighter660 IndianSauce Pan S661IndianFrying Pan862PizzaPizza Pan463PizzaPizza Stone164PizzaPizza Cutter265PizzaPizza Peel166GeneralSauce Bottle1267GeneralDustbin2 EQUIPMENT RecipeRecipeItemGreek Marinateolive oilGreek MarinatevinegarGreek MarinategarlicGreek MarinateonionGreek MarinaterosemaryGreek MarinatethymeGreek MarinatesaltGreek MarinatepepperTurkish MarinateGreek YogurtTurkish MarinateCumin PowderTurkish MarinateCinnamon PowderTurkish MarinateLime JuiceTurkish MarinateVinegarTurkish MarinateKetchupTurkish MarinategarlicGreek Vinegarolive oilGreek VinegarApple Cidar VinegarGreek VinegarLemon JuiceHerb FreshDhaniyaHerb FreshPudianHerb FreshLemon JuiceHerb FreshHoneyHerb FreshOilHerb FreshsaltHerb Freshpepper RNameTypeSpicy TomatoBBQCilantro YougurtRanch/WhiteMint FreshSweet Chilli sauceDynamiteMayo MustardTeriyakiOrange LemonGen TsoSesameTeriyakiKung PaoCashewTurkish KebabGreek SovlakiWingsTambra RedPambra White MenuS.No.CurrentCategoryIDNameTypePriceTypePriceTypePri ceTypePrice1xSoup2x1Hot & Sourvegck3x2Talimumvegck4x3Pekingvegck5x4Noodlevegck6x 5Thuppavegck7x6Cream of Mushroomvegck8x7Sweet Cornvegck9x8Clear vegck10x9Manchowvegck11x10Tom Ka Gaivegck12x11Tom Yumvegck13x12Wanton

- 83. vegck14x15xMomo16x1Steam17x2Fried18x3Chilli19x4BBQ20x 5Tandoori21x6Wanton Spicy Peanut22x23xSnacks24x1Spring Rollvegck25x2Chowmeinvegck26x3Wai Waivegck27x4Chilli Potatocrispyhoney29x6Baby Corn Chilli30x7Spaghettivegck31xBBQ32x1Burgervegpaneerckmutto n33x2Cheese Burgervegckmutton34x3CK Breast35x4Veg Rollvegsoya36x5Chicken Roll Afghani, Malai, Garlic Tikka, Barra, Tikka, Tandoori, Haryali37x6Mutton Seekh Rollkabobseekh38x7Wingsfranks redbbqteriyaki39x8Mutton Chopsmutton40x9Hot Dogvegck41x10Chicken Submarine Afghani, Malai, Garlic Tikka, Barra, Tikka, Tandoori, Haryali42x11Mutton Submarinekabobseekhx12Turkish Chicken Kabab13Greek Sovlaki43xBroast45x2Crispy46x3Lolipop47x4Wings48x5Pop Corn50x51x52xChinese53x1Chillimushroompaneerckmutton54x 265paneerck55x3Manchurianvegpaneerckmutton56x4Fried Ricevegpaneerckmutton57x5Noodleschili garlichakkasingaporeschezwan58x6Lolipopck59xck60xContinen tal Chinese61x1Orange paneerck62x2Lemonpaneerck63x3Gen Tsopaneerck64x4Sesamepaneerck65x5Teriyakipaneerck66x6Chi lipaneerck67x7Kung Paopaneerck67.5x8Cashew paneerck68xContinental West69x1Pasta Arribiatavegck70x2Pasta Alfredovegck73x3Sizzlervegck74x4Lemon Chicken75x5Mushroom Chicken76xTandoor77x1Paneer Tikka78x2Mushroom Tikka79x3Soya Afghan Chaap80x4Garlic Tikkahalffull81x5Afghanihalffull82x6Malaihalffull83x7Barraha lffull84x8Tikkahalffull85x9Tangdihalffull86x10Chicken Seekh Kabobhalffull87x11Tandoorihalffull88x12Hariyalihalffull89x13 Tandoori Aloo90x14Paneer Malai91x15Paneer Hariyali92x16Adana Kabobckmutton9217Mutton Seekh Kabob93xIndian Non-Veg94x1Chatkarack (h|f)mutton (h|f)95x2Butterck (h|f)96x3Kali Mirchck (h|f)mutton (h|f)97x4Curryck (h|f)mutton (h|f)98x5Masalack (h|f)mutton (h|f)100x7Karahick (h|f)mutton (h|f)101x8Handick (h|f)mutton

- 84. (h|f)102x9Mutton Roghan Joshmutton (h|f)102.1x10Bhoona Goshtmutton (h|f)102.1x11Tambda Rassa Redck (h|f)mutton (h|f)102.1x12Pandhra Rassa Whiteck (h|f)mutton (h|f)103xIndian Veg104x1Aloo Zeera105x2Mix Veg106x3Dum Aloo107x4Aloo Matar108x5Daalfrymakhani109x6Chana Masala110x7Kofta Curry111x8Malai Kofta112x113x114xIndian Paneer115x1Karahi Paneer116x2Handi Paneer117x3Paneer Dopyaza118x4Paneer Lababdaar119x5Paneer Pasanda120x6Paneer Tikka Masala121x7Matar Paneer122x8Shahi Paneer123x124x125xNaan / Roti / Rice126x1Roti127x2Rumali128x3NaanKashmiri, Butter Naan, CK Keema, Mutton Keema, Plain, 129x4ParathaAloo, Paneer, Mix Veg130x5lachha131x6ChurriPlain, Aloo, Paneer, Mix Veg132x7Afghani134x9Plain Rice135x10Zeera Rice136x11Mattar Rice137x12Kaju Rice138x13Kashmiri Rice139x14Veg Biryani140x15Non-Veg Biryanick141x142xRaita / Salad143x1Mix Raita144x2Bhoondi Raita145x3Pineapple Raita146x4Kachumber Salad147x5Green Salad148x6Punjabi Salad149xDessert150x1Brownieganacheicecream151x2Banana Split152x3Cookieregularchocolateoatmeal153x4Ice Cream154xCold Drinks155x1Mojito156x2Orange 157x3Masala158x4Water159xHot Drinks160x1Cappachino161x2Latte162x3Machiato PrepTypeMenuIngredientPrepTimeBrothCK BrothChowChowmeinBoilChowChowmeinfryChowPastaBoilckC hickenKeemackCKlolipopckCKwingsckCKGrillckCK CubeckCK Breast MarinateckCK Breast ckCK fingerfingerckCK Sabutfullck fryCK KeemaFryTandoorTandoorMutton KeemaFryDaalIndianArhaar BoilDaalIndianRajma Kali Daal ChanaBoilDairyBBQYogurt+cucumber+jalapenoGreekFlourTan doorAataGhoondaFlourTandoorBesanGhoondaFlourTandoorKha sta DoughGhoondaFlourTandoor/ChineseMaidaGhoondaFlourRollPi ta BreadPanFlourChineseSpring Roll Wet MixGravyIndianBrown GravyGravyTandoorBrown

- 85. MarinadeMarinateGravyIndianRed GravyGravyIndianWhite GravyGravyTandoorWhite MarinadeMarinateHydarateIndianRajma Kali Daal ChanaHydrateHydarateIndianRice basmatiHydarateIndianRice SellakoftaIndianMalai KoftakoftaIndianVeg KoftaMasalaIndianMasalaChoppedMasalaTandoorMasala TandoorDryMasalaTandoorMasala TandoorRoastMasalaIndianStar AniseGrindAllAllMutton KeemaPakodaChineseMushroomPakodaPaneerPaneerCubePanee rPaneerFine ChopPaneerPaneerPakodaPaneerPaneerFryPaneerPaneerPasanda CutPaneerPaneerTikka CutPaneerPaneerMashRiceIndianRice basmatiBoilRiceChineseRice SellaBoilSauceBBQSauceSauceButterMeltedSauceChili SauceSauceSauceChilli OilOilSauceChipotleSauceSauceCilantro YougurtSauceSauceDynamiteSauceSauceGarlic ButterMeltedSauceGreen SauceSauceSauceMayo SauceSauceSauceMint FreshSauceSauceMomo SauceSauceSaucePeanut Dumpling sisterSauceSaucePizza SauceSauceSauceRanch WhiteSauceSauceRed ColorSauceSpicy TomatoSauceSauceSweet Chilli SauceSauceSauceTeriyaki SauceSauceTandoorTandoorSoya Chaap BoilTandoorTandoorSoya Chaap MasalaVegVegBlack MushroomHydrateVegVegBread CrumbsDryVegVegCabbageFine ChopVegVegCabbageJulienneVegVegCabbageQuarterVegVegC abbageQuarter LrgVegVegCarrotFine ChopVegVegCarrotJulienneVegVegCarrotCubeVegVegCucumbe r PickleVegVegDhaniyaFine ChopVegVegGarlicFine ChopVegVegGarlicCrushVegVegGarlicFryVegVegGarlic SliceVegVegGingerLong SliceVegVegGingerJulienneVegVegGinger Fine ChopVegVegGinger GarlicPasteVegVegGreen BeansFine ChopVegVegGreen BeansJulienneVegVegGreen BeansMix VegVegVegGreen ChilliFine ChopVegVegGreen ChilliLong SliceVegVegGreen PepperFine ChopVegVegGreen

- 86. PepperSliceVegVegGreen PepperQuarterVegAllHerbWashVegVegMushroomFine ChopVegVegMushroomQuarterVegVegMushroomSliceVegVeg MushroomfryVegVegMushroomPakodaVegVegMushroomFullV egVegOnionFine ChopVegVegOnionQuarterVegVegOnionHalfVegVegOnionSlice VegVegOnionLrg SliceVegVegOnionFryVegVegOnionSaute SarsonVegVegOnionRingVegVegPotatoFingerVegVegPotatoCu beVegVegPotatoWedgeVegVegPotatohalfVegVegPotatoHalf DownVegVegPotatoDum AlooVegVegRed ChilliHydrateVegVegRoasted PeanutFryVegVegSpring OnionFine ChopVegVegSpring OnionJulienneVegVegSpring Onion StemHalfVegVegSweet Potato WedgeAllAllMix VegVegVegTomatoBoilVegVegTomatoGrindVegVegTomatoFin e ChopVegVegTomatoQuarterVegVegTomatoSliceVegVegTomato Puree FreshVegVegVegWashzlivezliveBaby CornLong SliceLivezlivezliveCashewRoastLivezlivezliveColeslawLivezliv ezliveCucumber SliceLivezlivezliveDhaniyaGarnishlivezlivezliveGhee Tomato Puree ButterTadkaLivezlivezlivePaneerLong SliceLivezlivezliveRaitaLivezlivezliveSaladLiveSauceSauceVin egaretteSauceTandoorTandoorCoalTandoorTandoorGreen MarinadeMarinateTandoorTandoorRed MarinadeMarinateAllTandoor/BBQGarlic ButterGarlic BreadGarlic BreadMarinara Sauce IngredientS.No.VendorTypeNameName (hindi)FrequencyQtyUnitPriceTotal1BakeryBreadBread Crumbs5pkt02BakeryBreadBrioche BunSweet BunDaily20pcs03BakeryBreadGarlic Bread40pcs04BakeryBreadHot Dog Bun20pcs05BakeryBreadSesame BunTill Bun100pcs06CKCKCK breast2.5kg07CKCKCK Keema10kg08CKCKCK legs12pcs09CKCKCK Sabut25pcs010CKCKCK Thigh011CKCKCK wings3kg012DairyMilk ProductAmul Cream

- 87. LiquidDaily3pcs013DairyMilk ProductButter 100gmDaily12pcs014DairyMilk ProductCheese SliceDaily2pkt015DairyMilk ProductChenna016DairyMilk ProductCream CheeseDaily2box017DairyMilk ProductDalda5kg018DairyMilk ProductGhee Desi3kg019DairyMilk ProductKhoyaDaily1Kg020DairyMilk ProductMilkDaily2.5kg021DairyMilk ProductMozarella Cheese 500gDaily1pkt022DairyMilk ProductPaneerDaily6kg023DairyMilk ProductYogurtDahiDaily5kg024GoodbakeryFrozenHot Dog CKWeekly 2pkt025GoodbakeryGeneralBrown Sugar2kg026GoodbakeryHerbMint Dry5bottle027GoodbakerySauceGreen curry paste50028GoodbakeryHerbRosemary5bottle029GoodbakeryFro zenHot Dog Mutton030GoodbakeryFrozenHot Dog Veg031GoodbakeryHerbThyme 5bottle032GoodbakeryNoodlesWai Wai packall10pcs1010033GoodbakerySauceAmerican Mustard1bottle696934GoodbakerySauceBBQ Sauce1bottle035GoodbakerySauceCapisco Chilli5bottle036GoodbakerySauceHP Sauce5bottle037GoodbakerySauceTom Yum paste60038GoodbakerySauceMarinara Sauce1bottle039GoodbakerySauceTeriyaki Sauce2bottle15030040GoodbakerySauceWorchestire Sauce5bottle4522541GuptaNoodlesNoodlesChowmein6pkt042G uptaSauceGreen Chilli Sauce Calcutta043GuptaSauceGreen Chili Sachet3pkt044GuptaSauceGreen Chilli Sauce2can045GuptaSauceKetchup Sachet3pkt046GuptaSauceMayonnaise White5pkt047GuptaSauceSoya Sauce2can048GuptaSauceTomato Sauce3can049GuptaSauceVinegar2can050Khateeb BhaiVeg FreshEggDaily3carton051MuttonMuttonMutton Chop052MuttonMuttonMutton Boneless1kg053MuttonMuttonMutton

- 88. Keema6kg054PlasticGeneralSilver Container large100pcs055PlasticGeneralSilver Container small100pcs056PlasticGeneralSauce container100pcs057PlasticGeneralIndian Plastic Tall100pcs058PlasticGeneralIndian Plastic Small100pcs059PlasticGeneralCarry Bag Large100pcs060PlasticGeneralSauce Panni for Veg Packing100pcs061PlasticGeneralBrown Bag Large100pcs062PlasticGeneralCarry Bag Small100pcs063RationMasalaBombay Biryani Masala064PlasticGeneralRubber Band100pcs065RationMasalaChanna Ashok Masala 066PlasticGeneralBrown Bag Small100pcs067RationCannedBaby Corn5can068RationCannedCherry2can069RationConfectionaryC hips070RationDaalChola071RationCannedFruit Cocktailtandoor5can072RationCannedPineapple5can073RationC annedSweet Corn Can5can074RationCannedCoconut milk075RationCerealNutrella Crushed5pkt076RationMasalaCoconut powder wet077RationCerealCornflakes078RationFlourCornmeal079Plas ticGeneralDisposable Plate Big080PlasticGeneralDisposable Spoon/fork081PlasticGeneralDisposable Plate Small082RationColorGreen Color1can083RationColorRed Color5can084RationColorYellow Color5can085RationCondimentAchaar Mix 5kg1can086RationCondimentBhoondi500gm087RationCondime ntGulab Jal2bottle088RationCondimentHoneyShahed2kg089RationCondi mentItar5pcs090RationCondimentKevda2bottle091RationDaalD aal Arhar5kg092RationDaalDaal Chana5kg093RationDaalDaal Rajma5kg094RationDaalDaal Urud Black Sabud5kg095RationDaalMix5kg096RationDried FruitCashewKaju1Tin097RationDried FruitKishmish500gm098RationDried VegMushroom Black1pkt099RationFlourAll purpose

- 89. FlourMaida1bori0100RationMasalaKadi Patta0101RationFlourArrarote1bori0102RationFlourBesanBesan 10kg0103RationFlourFlourAtta1bori0104RationGeneralCling Foil 722pcs0105RationGeneralSilver Foil 722pcs0106RationGeneralTooth pick10pcs0107RationMasalaKhus Khus0108RationGeneralWax Paper1Roll0109RationGeneralJhuna Steel5pcs0110RationGeneralJhuna Plastic5pcs0111RationMasalaLemon Powder0112RationGeneralNirma5kg0113RationGeneralDuster Kitchen 12x1220pcs0114RationSauceMayonnaise Red0115RationGeneralDuster Pocha 18x1820pcs0116RationGeneralPocha 24x244pcs0117RationGeneralSeekh Broom3pcs0118RationGeneralphenyl5ltr0119RationCerealOats Powder0120RationCerealOats sabud0121RationCannedOlive Black0122RationCannedOlive Green0123RationMasalaAjinamoto10pkt0124RationMasalaBaki ng Powder250gm0125RationMasalaBlack Pepper1kg0126RationSaucePasta Sauce0127RationMasalaChicken Ashok Masala 100gm10pcs0128RationSaucePizza Sauce0129RationMasalaChicken MDH Masala 100gm5pcs0130RationMasalaCinnamon Powder Keva5bottle0131RationMasalaCinnamon Sabud250gm0132RationMasalaCoconut powder dry3kg0133RationMasalaDeghi Mirch 100gm10pcs0134RationMasalaDhaniya Powder 100gm10pcs0135RationMasalaDhaniyah Sabud1kg0136RationMasalaElaichi 500gm0137RationMasalaElaichi Bari500gm0138RationMasalaElaichi Powder250gm0139RationMasalaGaram Masala 100gm10pcs0140RationMasalaSicuan0141RationMasalaGarlic Powder keva3bottle0142RationMasalaSindhi Biryani Masala 0143RationMasalaHaldi2kg0144RationMasalaJaifal250gm0145

- 90. RationMasalaJavitri250gm0146RationMasalaKala Namak1kg0147RationMasalaKashmiri Mirch 100gm10pcs0148RationMasalaKasturi Methi1kg0149RationMasalaKhara Masala Sabud Mix500gm0150RationMasalaKhatai500gm0151RationMasalaKit chen King10pkt0152RationMasalaLong250gm0153RationMasalaMag az5kg0154RationMasalaMeat Ashok Masala 100gm10pcs0155RationMasalaZeera Shahi0156RationMasalaOregano Powder5bottle0157Spl Veg FreshVeg FreshBasil Fresh0158Spl Veg FreshFrozenGalanga0159Spl Veg FreshVeg FreshKaafir lime0160Spl Veg FreshHerbLemon Grass0161RationMasalaOregano Sachet1pkt0162RationMasalaRaita Masala 100gm5pcs0163RationMasalaRed Chilli Powder2kg0164Spl Veg FreshVeg FreshTofu0165Spl Veg FreshVeg FreshZucchini0166RationMasalaRed Chilli Sachet1pkt0167Veg FreshVeg FreshBrinjal 0168Veg FreshVeg FreshBrocolli0169RationMasalaRed Dry Chilli5kg0170RationMasalaSabzi Ashok Masala 100gm10pcs0171RationMasalaSalt10kg0172RationMasalaSalt Pink5bottle0173RationMasalaStar AniseStar Phool500gm0174RationMasalaSugar5kg0175RationMasalaTej Pata250gm0176RationMasalaWhite Pepper1kg0177RationMasalaWhite SesameSafed Till1kg0178RationMasalaYeast1bottle0179RationMasalaZeera1 kg0180RationOilMustard Oil bail koluKarwa Tel5ltr0181RationOilOlive Oil1bottle800800182RationOilRefined Oil3Tin0183RationOilSesame Oil1bottle0184RationRiceBasmati Rice 25kg1bori0185RationRiceRice Double Pigeon 25kg1bori0186RationRiceStaff Rice1bori0187RationSauceLemon Juice10bottle0188RationSauceTomato Puree5pkt0189Spl Veg

- 91. FreshHerbBasil5bottle0190Spl Veg FreshSpl Veg FreshLettuce1pc0191Spl Veg FreshVeg FreshMushroom12pkt0192Spl Veg FreshVeg FreshSoya Chaap1.5kg0193Veg FreshVeg FreshBeans5kg0194Veg FreshVeg FreshCabbagePata Ghobi20pcs0195Veg FreshVeg FreshCapsicum Green12kg0196Veg FreshVeg FreshCarrot10kg0197Veg FreshVeg FreshCoriander Fresh3kg0198Veg FreshVeg FreshCucumber10pcs0199Veg FreshVeg FreshGarlic5kg0200Veg FreshVeg FreshGinger5kg0201Veg FreshVeg FreshGreen Chilli Fresh2kg0202Veg FreshVeg FreshGreen Peas 5kg1pkt0203Veg FreshVeg FreshLemon 3kg0204Veg FreshVeg FreshMint FreshPodina3kg0205Veg FreshVeg FreshOnion25kg0206Veg FreshVeg FreshOrange2kg0207Veg FreshVeg FreshPotatoAloo20kg0208Veg FreshVeg FreshRed Chilli Fresh1kg0209Veg FreshVeg FreshSpring OnionHara Pyaaz2kg0210Veg FreshVeg FreshTomato Fresh15kg0PlasticGeneralDisposable Bowl0siracha0 Ration Serving PlatesS.No.CategoryNamePriceQtyTotal1SoupBowl482SoupTra y483SoupSpoon484Momo/Spring/etcRectangle Plate M150/2005TandoorRectangle Plate L126Chow/wai/hcpChowmein Plate507Chutney Bowl S150/2008Chutney Bowl M1009CH/ContiCHIFried Rice / Noodle Bowl7210Tray2011Indian Karai612Indian Handi1213Indian Dish4814Roti Basket2415Service Spoon7216Biryani Bowl17Raita Bowl1218Salad Plate1219Spoon7220Fork7221Knife1222Staff Thali1223Plate Haddi1224Plate4825Glass48 Serving PackingNameTypeSilver Container largeSilver Container smallSauce containerIndian Plastic TallIndian Plastic

- 92. SmallCarry Bag LargeSauce Panni for Veg PackingBrown BagCarry Bag SmallRubber Band Nice Touch Hygiene Nice Touch Hygiene is a company which produces tissues and supplies hygienic products like sanitizers, hand wash, waste baskets, cleaning equipment and chemicals. They are the distributers of TTS Italy and an exclusive distributer of Jofel Dispensers. Nice Touch produces a large variety of tissues; such as face tissues, wet tissues, toilet papers, hand towels etc. The main objective of the company is to produce quality products and create a value in the minds of their customers. Nice Touch serves both the B2B and B2C customers. B2B customers: Facility management, cleaning companies, retailers as well as other selective tissue company brands by producing tissues to be sold under their respective brands. B2C customers: Five-star, three star and four-star hotels, restaurants. The above customers which the company serves now are called away from home market, which means these are the products which customers cannot get from a grocery store or hypermarkets for personal use. The products are supplied with a contract of two years with their customers Future Goals (entering home market) Nice Touch has plans of entering the home market, making their products available to customers, by supplying it to the grocery stores and hypermarkets. By entering this market, they will be exposed to various threats due to high competition. The target segments for this market are both the premium customers and the economy customers. The company will approach the premium customers with specially designed and well-presented tissue boxes and the economy customers will be presented with simple tissue boxes with smaller size tissues without compromising on the quality, making it available for the customers at a lower price. Cost structure

- 93. · Salaries of 60 staff · Machine depreciation and maintenance · Rent (one showroom and two stores) Promotional activities Offering gifts and vouchers annually to the employees of the businesses where Nice Touch Products are bought and used, to enhance customer relations. Marketing · Advertisements · Personal selling Competition · Gulf Paper Industry · Jasoor Factory · National Paper Industry. Flash Rent a car WLL. Flash rent a car provides rentals of a large variety of vehicles; Sedans, SUV’s, Pick up’s, vans and Buses. These rentals are provided to the customers with or without drivers based on their requirements. The company provides quality services by providing their customers with on time car maintenance and replacement of cars in case of accidents or car breakdowns. The firm provides vehicles of Toyota, KIA, Honda and Nissan.

- 94. The firm focuses on B2C, there are different types of services they offer, which are: · Spot rentals for Individuals: Spot rental means renting out to individuals on day to day basis. The car will be rented out by securing an advance and the passport of the individuals. · Monthly/Weekly: Renting vehicle to customers on weekly or monthly basis according to customer demand. · Car leasing to companies: Providing vehicles on annual bases or with a contract of two years. Customer Complaints Customer care is a very important factor in this industry since the firms with better customer service has the competitive advantage. The complaints received by the customers are normally regarding vehicle breakdown or vehicle problems and the complaints should be dealt with no time delay by replacement or fixing the complaints. The operations department of Flash Rent a Car is always available to the customer’s, resolving customer complaints. Offers · Commission on reference · Discount on long term contracts Variables/ factors considered in pricing · Market study · Vehicle price · Cost of maintenance · Resale value Marketing · Advertisements- Qatar Living, Facebook, Newspapers and WhatsApp, Emails. · Website- Is an identity of the firm, it helps people to get their contacts details, location and the services they offer. · Direct Sales- visiting clients CRM- customized software for vehicle tracking. Other Income As per the law in Qatar, rent a car companies can only rent out cars which are less than five years old. After five years these

- 95. cars will be sold which is another income for the company. PROJECT GUIDELINES The guidelines below will be updated whenever deemed necessary. General Project Subjects · The ultimate purpose of the project is to show the ability of the students to link the concepts studied in the chapter 9 with the real‐world. · The subject of the project must be clearly related to the selected chapter. It does not have to cover the whole chapter, but it is expected to relate to the most important concept(s) in the chapter. The subject is also expected to be relevant to Qatar. · Each group a case project (please note that the case project is different from the case analysis). o · o A case is a description and a resolution of a problem related to some of the concepts in the chapter. The ideal is to have a real problem (from a real situation); but it is acceptable to invent an imaginary one as long as it is realistic. The problem can also be based on a case from the literature (which must be duly cited). · The case is necessarily related to Qatar Important Notes All groups are expected to: · Read these guidelines very carefully before starting the project. · Read the whole chapter (especially the examples and the cases) in the book (not just rely on the slides) before starting the project. · Include in the presentation as well as in the report a title page that provides: o Course name, course code and section number o Chapter number and title o Title of the project o Name and ID number of each student in the group (the names have to be in

- 96. the same order as the presentation; the first name is that of the student that presents the first part, the second name is that of the student that presents second, etc…) o Date of the presentation · Make the presentation file (whether video or slides) available to the instructor and the students at least 12 hours before the start of the class. · Limit the presentation, in terms of time, to around 15 to 20 minutes. · Have all the students of the group participate equally in the presentation and in answering the questions. · 750‐1,000 words for case projects. · Submit the report using SafeAssign no later than one week after the presentation (Only one student in each group should submit the project on behalf of the entire group) · Tell whether the same project has been or will be used for a different course (Failing to provide this information will be considered as plagiarism). · Provide the references for the data in order to ensure verifiability thereof. Grading Criteria · The presentation is out of 7 points while that of the report is out of 5. · The grading scheme for the group presentation is as follows: Criterion Weightage How successful were the students in describing the application of some of the chapter concepts in a real‐world organization? 100 How good was the delivery? How clear, how organized, and how coherent was it? 10 How informative was the video? How clear was it? How understandable was it? How interesting and how original was it? 30 To what extent is the video related to the chapter? How successful were the students in proving their ability to

- 97. effectively explain the concepts studied in the chapter? 30 · The grading scheme for the report is as follows: Criterion Weightage How successful were the students in describing the application of some of the chapter concepts in a real‐world organization? 100 How well‐written, clear, organized, and coherent is the report? 15 To what extent does the report explain the video? 15 To what extent does the report show the relation of the video to the chapter? 20 Case Projects Deliverables This type of project has two deliverables: a presentation and a report. · Both the presentation and the report must include two major parts (clearly separated): o The problem: This part is a description of the problem faced by the organization from the perspective of non‐technical persons. o The solution: This part is the solution proposed by the group to the problem. It is like a technical report to be presented to the company. · In the presentation part, the students introduce their project, present their slides (see Appendix B), and answer the questions of the other students and the instructor. · The report is a Word document whose content must introduce the organization, describe the project, explain how the data were obtained, and provide the references. However, the most two important parts are the presentation of the problem and the solution proposed. Grading Criteria

- 98. · The presentation is out of 5 points while that of the report is out of 7. · The grading scheme for the group presentation is as follows: Criterion Weightage How successful were the students in proving their ability to effectively apply the concepts studied in the chapter to a real‐world situation? 100 How good was the delivery? How clear, organized, and coherent was the presentation? 10 How pertinent are the data? How reliable are they? How realistic is the problem? To what extent is it related to Qatar? How interesting and how original is the problem? To what extent is it related to the chapter? 20 How suitable is the solution? How convincing is it? To what extent was the course helpful in finding the solution? 20 · The grading scheme for the report is as follows: Criterion Weightage How successful were the students in proving their ability to effectively apply the concepts studied in the chapter to a real‐ world situation? 100 How well‐written, clear, organized, and coherent is the report? 25 How pertinent are the data? How reliable are they? How realistic is the problem? To what extent is it related to Qatar? How interesting and how original is the problem? To what extent is it related to the chapter? 20 How suitable is the solution? How convincing is it? To what extent was the course

- 99. 25 helpful in finding the solution? Appendix A: Group Work Contribution Policy · To ensure more equity in the grading of group works (projects, cases, etc…), each group with variation in the contribution of its members is required to complete the contribution form. · This form is not required if all the members of the group agree that they contributed equally to the work. · The grade of each member within the group depends on his/her contribution. · The sum of all the contributions must equal 100%. · Although it is better to reach a consensus, this may not be possible all the time. In such a case, the group can submit more than one form with one being completed by two or three students, for example, while the other one being completed by the other member(s) of the group. However, no student is allowed to approve more than one form. · The form has to be sent by email by one of the students of the group the same day of the submission of the work on Bb. The student who sends the form is required to copy (cc) all the students who approved it. · If the members of the group agree on getting the same grade they don’t have to complete any contribution form. · The contribution form is as provided below: Project Contribution Form Student Number Student Name Contribution in %

- 100. Total 100% Appendix B: Dynamic Delivery For a dynamic delivery, the students presenting their project should try to: · Avoid overloaded slides; try to have 10 to 15 slides, 5 to 10 bullets per slide, and 5 to 10 words per bullet. · Stand up tall and straight, stand on both feet, and move naturally, but not too much. · Gesture when appropriate. · Speak naturally and conversationally. · Use an outline for the presentation. · Have their notes ready, but not to depend on them. · Use short sentences for emphasis, longer sentences for explanation and discussion. · Be dynamic in their delivery. · Talk to the audience communicatively (establishing eye contact). Profit Crisis in the Restaurant Business A leading Pakistani Cuisine Restaurant in Qatar, Qutba, faced issues with cash flow and profitability. Further investigation with the restaurant owner revealed poor inventory management and wastage. While trying to salvage the situation, the restaurant owner tried various methods to tackling inventory management issues but always ended up affecting the quality of the food. Reverting back the quality, reduced the profits and created cash flow problems. The specific issues faced by the restaurant owner are discussed below Issues related to Inventory control and wastage faced by the restaurant are as follows: 1. Issues with availability of fresh produce, meats and poultry: The vegetable markets and wholesaler of meats and poultry are at a far distance from the restaurant location and operate within

- 101. certain hours. The delivery schedule from the wholesalers are limited and are not able to provide on demand. 2. Issues with wastage at end of service: The restaurant faced issues with having to throw both cooked and fresh ingredients at end of service every night. Being a full service restaurant, a long menu leads to having to prepare for every item on the menu. The demand however cannot be accurately predicted. While there is an element of process while preparing the final product, it is continuous and short. The inventory cannot be divided into raw material, work in progress and finished good. This is especially the case due to the fact that this is not a “McDonald” style, quick service restaurant. Every dish is prepared fresh on order. Analyzing the restaurant industry in Qatar, especially in context of material availability and logistics, the type of inventory category it falls under is operational inventory. Since the inventories lead time is one day for almost all ingredients, cycle and pipeline categories do not fit in the restaurant industry. However, Safety and Anticipatory inventories need to be stocked for emergency or unexpected demand. Since this is a “make to order” restaurant and there is no significant ordering costs, Economic Order Quantity does not particularly apply in this scenario. With the above constraints in mind, an ABC analysis was recommended to accurately stock and create the possibility for repeatability of ingredients. The list of inventory items and the costs was analyzed to find items for closets attention and tightest control. With this information, four areas of improvements was recommended to the restaurant owner as follows: 1. Sales Forecast: It was recommended to analyze daily sales from previous years in an attempt to create a weekly forecast. Similarly, Analyze months with greater sales and special occasions like New Years, Ramadhan and Eid holidays. The sales forecast will help identify the quantity of ingredients to be ordered. To do this, recipe management is necessary.

- 102. 2. Recipe Management: An as accurate as possible, every ingredient for every item on the menu needs to be calculated. The idea is to as accurately as possible maintain inventory, in an effort to avoid wastage but at the same time maintain the quality levels. 3. Mass Order discounts: Negotiate mass order discounts with vendors and wholesalers to reduce unit cost on ingredients while keeping in mind storage cost, wastage and freshness of the produce. 4. Re-Order levels: In an effort to reduce the complexity of calculating when to re-order, create bins of the size of appropriate stock that needs to be maintained. Create visual markers to accommodate lead times for all ingredients. The above recommendations will provide fruit only when they are constantly reviewed for effectiveness and efficiency. Every business has its own set of quality standards, customer satisfaction standards and expectation of profits. The restaurant industry is particularly challenging due to the fact that entry barriers are minimum and what is in fashion today may not be the choice of customers tomorrow. The additional challenge is Pakistani/Indian cuisine is that they have an extensive menu. The extensive menu is extremely ingrained into the psychology of the customers. This results into a downward spiral for restaurants, where they are trying desperately to create profits, while the inventories eat up the profits.

- 103. My suggestion about the case formation First part of the case 1. We can start the case with the problems that are directed by the restaurants in general and their need to fresh food and because food generally has a specific expiration date ... I wrote already two up but we can add more e important questions for the case : 1 - the quantity we need to provide 2 - when we need to provide 2. Also one of the problems: pressure of small inventions and The points on page 340 We can apply which suitable for the restaurants 3. Also we can talk about the type of inventory. In the restaurants *The second part*: Solution s / Be the answer to quantity and time .. I think it is possible to analyze the Excel sheet and see the more requested dishes in the restaurant and its components .. and choose it as an example of the solution to the restaurant.

- 104. We can choose a technique or more of the operational inventories ...Or EOQ if they are used for the restaurant! Or continue review system In this case, I think the second type for the demands to be Variable or the third for the Demands and the time are Variable Or we can use the Q system I think this is the most appropriate way to calculate them and to know the quantitative result and the time we need each request ... *Note*: The Excel is the one in which it is written, in which the invoices are as an example of the dimension, and in it the ingredients for some dishes ... so be the source of analysis of the data for us because we give it to Dr .. #include <string.h> void StoreInputToChar2DArray(char str[], char args[][100], char seperator) {