Digital Fabrication Studio Pavilion

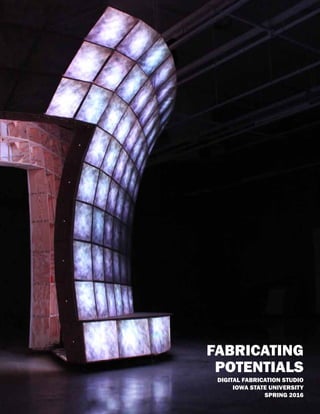

- 1. DIGITAL FABRICATION STUDIO IOWA STATE UNIVERSITY SPRING 2016 FABRICATING POTENTIALS

- 2. As an interdisciplinary studio consisting of sixteen students from architecture, industrial design, and interior design backgrounds,conductedoutreachthrough experimental design and construction in the public sphere. The challenge was to create a temporary pavilion for the 80/35 Music Festival set to occur in early July in Des Moines, Iowa. Work began in January of 2016 and continued throughout the spring semester. Students designed, developed, prototyped, and constructed a 10’x20’x15’ pavilion in studio and then re-installed the pavilion at the 80/35 festival. The team explored the potentials of digital prototyping, interaction, and construction within their design process, utilizing parametric modeling techniques within digital platforms such as Rhino and Grasshopper. The studio also utilized communication within the digital realm to better connect with classmates and peers. The group chat program, Slack, was thesite+theteam Thank You to Our Sponsors OPN Architects, Fieldstead & Company Endowment for Community Enhancement, Stan G. Thurston Professorship in Design Build, ISU College of Design, ISU Department of Architecture, Des Moines Music Coalition 80/35 Music Festival used to circulate messages throughout studio, keeping members updated about current budget and deliverables while also allowing precedents and design work to be shared and archived. In addition, a blog, Instagram, and Issuu account were set up to engage peers and the general public. Progress updates and new design schemes were frequently shared though theseplatforms.Allofthesemethodswere parts of the studio’s goal to experiment with methods of material practice and construction by implementing traditional as well as innovative computational techniques. Through the process of designing a temporary public pavilion the studio gained a greater understanding of architecture’s relationship with technology and human interaction. The studio is part of a larger effort to position the Department of Architecture at Iowa State University as a leader in digital computation and fabrication methods.

- 4. FABRICATING POTENTIALS 07theresearch Our sixteen person, interdisciplinary studio began to identify the issues faced in the creation of a construction-sensitive temporary pavilion during an initial phase of research and analysis. Exploration into experimental temporary pavilions and constructions began with a study of MoMA’s PS1 competition submissions. Examplesofinnovativepublicengagement strategies, construction techniques, and reuse strategies created a base knowledge which we could draw from throughout the design process. Questions about the purpose and impact of temporary structures were explored through the studio book, Pavilions, Pop-Ups, and Parasols by Leon Van Schaik & Fleur Watson. Goals for innovation in digital design, public engagement, and plausible reuse strategies were formulated and began to emerge during this stage. Additional research began to push into the realms of digital design and interactive technologies. First hand experience of festival culture and temporary public space was achieved through a trip to New Orleans and the Hogs for the Cause festival. FABRICATING RESEARCH POTENTIALS

- 5. FABRICATING POTENTIALS 09 MoMA PS1 From Dunescape to COSMO, MoMA’s PS1 Pavilions have promoted innovation in the way architects design and construct temporary public spaces. The Museum of Modern Art and MoMA PS1 jointly present the MoMA PS1 Young ArchitectsProgram(YAP),anannualseries of competitions that gives emerging architects the opportunity to build projectsconceivedforMoMAPS1’sfacility in Long Island City, Queens. Established in 2000, the Young Architects Program was designed to solidify the affiliation between The Museum of Modern Art and MoMA PS1. Glenn Lowry, Director of The Museum of Modern Art stated, “[MoMA PS1] furthers our curatorial mission, identifying and providing an outlet for emerging young talent, it aims to give something back to the community that has been so supportive of us.” The objective of the project is to provide visitors with an outdoor recreational area for the summer-a much-needed refuge in an urban environment-making the best use of the pre-existing space. The architects follow a program with a tight budget, and are involved in every aspect of the design, development, and construction of the project. The site, MoMA PS1’s large triangular entrance courtyard and outdoor sculpture area, is an integral part of the museum’s popular music concert series, Warm Up, which features experimental music, live bands, and DJs. The site is open to visitors throughout the summer. To choose an architect for this project, deans of architecture schools and the editors of architecture publications nominate some twenty students, recent architectural school graduates, and established architects experimenting with new styles or techniques. The group is asked to submit portfolios of their work for review by a panel comprised of Mr. Lowry, MoMA PS1 Director Klaus Biesenbach, and a host of experts in the art and architecture community. The panel selects three finalists who are invited to make preliminary proposals for the designated site; the chosen winner is announced in February. citation|momaps1.org

- 6. FABRICATING POTENTIALS 11 2015 COSMO by Andres Jaque/ Office for Political Innovation 2014 Hy-Fi by The Living 2013 Party Wall by CODA 2012 Wendy by HWKN 2011 Holding Pattern by Interboro Partners 2010 Pole Dance by Solid Objectives-Idenburg Liu 2009 afterparty by MOS 2008 P.F.1. (Public Farm One) by WORK Architecture Company 2007 Liquid Sky by Ball- Nogues 2006 BEATFUSE! by OBRA 2005 SUR by Xefirotarch 2004 Canopy by nARCHITECTS 2003 Light-Wing by Tom Wiscombe of EMERGENT 2002 Urban Beach by William E. Massie 2001 subWAVE by ROY 2000 Dunescape by SHoP 1999 Philip Johnson dunescape|2000

- 7. FABRICATING POTENTIALS 1312 IOWA STATE UNIVERSITY Dunescape by SHoP Architects (2000) SHoP Architects created an installation that is dynamic in both appearance and functionality. Dunescape as a precedent enables a greater understanding of how having a clear purpose behind the form of a structure enables comprehensive design. The purpose is directly aimed at benefiting those who use the space. By designing a pavilion that takes more than one purpose into consideration (ie. comfort, social aspects, shading, etc.), the overall product is more likely to be a success. The fact that each component of the structure is modelled and catalogued digitally is also pertinent to our studio. By understanding the purpose that we intend for our pavilion, we are likely to create a design that excels in both appearance and functionality. Wendy exemplifies everything that can come from testing the boundaries of architectural design. As a firm that strives to continuously push the limits of architecture, the firm helps set forth ideals about how testing the limits already set forth in the discipline can result in proactive means of thinking about architectural forms and space. Wendy shows us that having a radical set of ideals can push the design process forward and allow for a comprehensive design solution that takes into account social and contextual conditions as well as public engagement and influence on a space. The use of a gridded construction pattern to create a complex form, as well as the integration of lighting and digital interaction are ideas that we can reference in the development of our own pavilion. Wendy by HWKN (2012)

- 8. FABRICATING POTENTIALS 1514 IOWA STATE UNIVERSITY partywall|2013

- 9. FABRICATING POTENTIALS 1716 IOWA STATE UNIVERSITY Party Wall by CODA (2013) The strongest elements of this design involved the recycling of a common material and the way in which the installation engaged with the site. CODA was able to connect the project to a specific location and give it a strong identity. There were multiple elements that engaged the public and the surrounding space. Unique environments and experiences were created through a one wall system. The structural framework of the wall, in which panels of a certain material were attached, couldbesomethingthatwetakeintoconsideration as well as the modularity of the system which allowed for ease of construction and transport. Creating a single surface and utilizing voids in the form to add areas of discovery and interaction fit our interests moving forward. COSMO’s suspended canopy purifies water and then utilizes it to grow various plants as well as to cool down pedestrians walking by the structure. These plants as well as smaller components of the filtrationsystemcanthenbedistributedthroughout the community as a reminder of COSMO’s function while increasing knowledge about water scarcity and the purification process. Our pavilion may become a de-constructable module which can be distributed after the festival to act as a memento or possibly serve a didactic purpose. Concepts proposed such as COS community outreach and beautification are applicable to our pavilion. COSMO by Andres Jaque / Office for Political Innovation (2016)

- 10. FABRICATING POTENTIALS 1918 IOWA STATE UNIVERSITY Key questions derived from Pavilions, Pop-Ups, and Parasols by Leon Van Schaik & Fleur Watson POP-UP+PAVILION Should pavilions predetermine their use or should they afford flexibility for a user? Does a pavilion need a function, a specific aesthetic, or market? What is the contemporary role of a pop-up? Are pop-ups enabling innovation in architecture or are they parasitical structures? How might virtual spaces be made more tangible as spatial environments for exchange? What are ways in which we can derive a meaningful form (construction innovation, site context, etc)? Can short term pavilion designs trigger long term social change?

- 11. FABRICATING POTENTIALS 2120 IOWA STATE UNIVERSITY Pavilions,Pop-Ups,andParasols

- 12. FABRICATING POTENTIALS 23 DIGITAL TECHNOLOGY Exploring the potentials of interactive, technology-based design such as kinetic structures, projection mapping, and LED lighting. kineticwall|2014

- 13. FABRICATING POTENTIALS 2524 IOWA STATE UNIVERSITY Kinetic Wall by Barkow & Leibinger (2014) Designed for the Elements of Architecture exhibition at Rem Koolhaas’s 2014 Venice Biennale, this project explores the idea of kinetic motion in architecture. A simple wooden space frame houses the mechanical equipment that powers the actuators and acts as a mounting surface for the elastic synthetic fabric. The actuators are mounted to the surface of the fabric & distort the elastic surface to change the spatial condition of the site in which the wall is placed. Kinetic Structures Sydney Opera House (2012) Projection mapping technology is the use of motion graphics to create an exterior or interior condition that appears to come alive with animated forms, transforming any built surface into a dynamic construction. Projections are often mapped to fit the geometry of a building or other construction. All you need are a series of (or just one) projectors and a surface on which to project and any of a wide variety of digital programs to create the mapping. The images below show a series of projections onto the Sydney Opera House as part of a yearly art initiative. Projection Mapping

- 14. FABRICATING POTENTIALS 2726 IOWA STATE UNIVERSITY Sonia Falcone Lighting Installation (2010) Falcone created a series of video animations which began only when a person stepped near enough to the array of flat-faced columns. Interactive Lighting + LED Fields Textile Pavilion by P-A-T-T-E-R-N-S (2014) The appearance of an ever-changing textile fabric was achieved in the Textile Pavilion by the designer through an intricate projection mapping onto translucent carbon tubing stretched between steel frames.

- 15. FABRICATING POTENTIALS 2928 IOWA STATE UNIVERSITY Water Light Graffiti by Antonin Fourneau (2012) Water Light Graffiti is an interactive surface composed of thousands of LEDs which are able to be illuminated by the contact of water (water produces an electrical charge which briefly lights the led). A user is able to change the surface with a wet paintbrush, a water atomizer, spray can, or even their fingers. Swarm Light by Random International (2010) Swarm Light consists of a programmable field of LED lights which are activated by both motion and audio sensors. In addition, the LED field can be choreographed based on the intent of the designer.

- 16. FABRICATING POTENTIALS 31 TRAVEL Experiencing festival culture in New Orleans, specifically through attending the Hogs for the Cause event, helped add to our knowledge of public events and engagement. citypark,neworleans

- 17. FABRICATING POTENTIALS 3332 IOWA STATE UNIVERSITY Hogs for the Cause Hogs for the Cause is a non-profit, annual fundraising barbecue competition and music festival that raises money for families with children fighting pediatric brain cancer. The event raises money through ticket sales, direct donations, food sales, sponsorships, and fundraising efforts spearheaded by teams in the barbecue competition. As part of our studio, we were provided with full passes to each of the two days of the festival. Unfortunately, the first day of the festival was cancelled due to flooding at the festival grounds at City Park. Luckily, we more than made up for the missed time on Saturday, as we trekked through the sometimes knee deep mud to enjoy the excellent barbeque and bluegrass bands. Everyone went home with a newfound knowledge of publicly engaging temporary structures, as well as a fair bit of sunburn! Every year, around 90 teams compete in the Ben Sarrat, Jr. Cook Off for the High on the Hog Grand Champion title. The competition is fierce, and the winners claim bragging rights not only in barbecue mastery, but more importantly, fundraising prowess. Teams are a motley mix of some of the region’s best chefs, professional barbecue teams from around the country, and backyard barbecue fanatics, and all teams sell food to the public to raise money for the Cause. Winners are declared in seven categories: Whole Hog, Ribs, Pork Butt/Shoulder, Porkpourri, Sauce, Fan Favorite, and Fundraising Champion. Many of the teams also design and build custom structures or have interactive elements around their displays to attract and engage customers. Studying the interaction between people and vendors (and their accompanying structures) added a practical element to our knowledge of temporary structures gained throughout the semester. BBQ + Public Engagement

- 18. FABRICATING POTENTIALS 35initialproposals In conjunction with the initial phase of research, the process of designing an interactive pavilion for the 80/35 Festival began with a series of massing studies. Through these studies, the interdisciplinary team attempted to understand restraints dictated by the project such as scale, scope, and means of construction. A repetitive sequence of iteration,review,andrefinementfollowed, with students concurrently expanding their knowledge of digital interaction technologies. Design proposals became increasingly rigorous as teams began to utilize digital tools to understand material usage, predict construction time, and calculate budget. As the development phase progressed, major design themes relating to transportation and constructibility began to emerge. The use of a modular structural system to organize and ultimately optimize construction was agreed upon, as was the desire to integrate some form of digital interaction. The efforts put forth by the studio throughout this process allowed the team to further understand the connection between physical and digital fabrications and coincided with Iowa State University’s Department of Architecture’s goal of becoming a leader in digital computation and fabrication methods. FABRICATING DEVELOPMENT POTENTIALS

- 19. FABRICATING POTENTIALS 37 10’x 20’Initial design responses for fitting within the bounds of the site were proposed through a series of 1/4” scale models focused on demonstrating scale, form, and constructibility.

- 20. FABRICATING POTENTIALS 3938 IOWA STATE UNIVERSITY REPETITIVE PANELS An open plan can accommodatevariousprogramsandinstallations. DUAL WALLS Walls are composed of panels that could move or rotate. SINGLE SURFACE A continuous form provides seating, shade, and interaction. ARROW As you move between layers theformrevealsitself.HOUSEOFWALLSApassage that reveals and than conceals. WOOD LEGS The pavilion focuses on the idea of modularity and assembly. FRAGMENTS Space is created using a series of vertical elements. WIND CHIMES Extrusions in the form could become interactive components. LANDSCAPES A series of steps for sitting, relaxing and other human interactions. CENTRALPIVOTSeating could bestoredwithinthe structure. EXPOSED COPPER At each angle the model appears different. WAVES Light becomes distorted and casts interesting shadows below. MIRRORED FORMS The design can combine a set of repeated forms. FOLDED SIMPLICITY A single form folds itself inward to shape an enclosed space. MESH A wall provides shade and acts as a barrier. HELIX Geometric shapes are arranged to create dynamic movement.

- 21. FABRICATING POTENTIALS 41 TECHNOLOGY + DIGITAL INTERACTION The studio’s overall desire is to create a pavilion that bridges the physical and digital divide through interaction. All in order to create an atmosphere of fun, relaxation, interaction, and play. The pavilion is intended to provide a digital node for interaction within the context of the festival, creating a safe, fun, and memorable area at which people will associate their experience of 80/35. Initial considerations of the physical interaction that could occur between the user and the space included mobile panel systems and versatile seating. These two means of physical interaction would allow the user to define the space. Whether they needed a place to sit, a place to set down their drink, or a means of shading, the mobile panels would allow for individualized levels of comfort throughout the length of the festival. Multiple design strategies for utilizing digital interaction were proposed to add an interactive element to the pavilion. Lighting became of interest in several proposals in which the user directly interacts and affects the lighting conditions both within and outside of the pavilion. As the user moves through the space, various lighting conditions could occur to transform the pavilion from a stationary structure to something that highlights the dynamic characteristics of the festival. With the 80/35 festival being such a highly sensory atmosphere, a digitally controlled set of interactions would allow the pavilion to resonate with users and fit the context of the concert. In addition, the majority of the festival will be held during the evening, thus lighting and projection became a focus moving forward. Digital implications of the pavilion were further investigated through means of broadcasting and social media. connectingdigtal&physical

- 22. FABRICATING POTENTIALS 4342 IOWA STATE UNIVERSITY technologyworkflow SENSING HARDWARE SOFTWARE CONTROLLER anemometer motion thermo sound projection motion sound light

- 24. FABRICATING POTENTIALS 47 PRAGMATICS New proposals were developed after learning more about the site, resources available, budget, and interactive technologies. wood+rope

- 25. FABRICATING POTENTIALS 4948 IOWA STATE UNIVERSITY Wood + Rope This design proposal focuses itself around user interaction. Utilizing an unconventional material like rope, the pavilion is formed of blocks that begin to filter the exterior environment instead of blocking it out all together. The blocks change in their orientation to add dimension to the space and are sized so as to fit to the human scale whilst sitting, standing, and interacting. This creates a pavilion that can be formed by the people as they are able to manipulate the composition of the pavilion itself. On the street side of the pavilion is a collective surface comprised of individual pieces of rope. These ropes create a unique shading structure and are monitored by motion sensors which are triggered by movement. The manipulation of the rope creates an interactive lighting display within the modular structure of the pavilion. This creates an instrument of light out of the pavilion in which people can engage with. This pavilion is reactionary and not static. It provides transformable space to meet the needs of multiple users at different times. This space provides small gathering spaces within a larger pavilion. The pavilion itself is shaped and modified through the people who experience it. The light wall on the solid surface responds directly to the movement of people through the space and the sections of the pavilion can be moved to fit the needs of the users at the festival and Iowa State’s campus. This pavilion has both a physical and a digital interaction. The light wall shows advancements in technology while each module gives the users the freedom to adjust the space to meet their needs. Ephemeral Architecture

- 26. FABRICATING POTENTIALS 5150 IOWA STATE UNIVERSITY Light Field’s form is a meant as a reference to the repetition of Iowa’s many cornfields. The design is formed with clear PVC tubes secured to a base plate in a vertical position, with the base plate acting as a cover for all electronics as well as a platform to sit or stand on. The ends of the tubes could also be used to level out the pavilion if the installation site is uneven. The vertical tubes divide the pavilion into a range public and private spaces, and would be illuminated from below at night, ideally being controlled by an audio sensor to respond to the live sounds of the surrounding concert. The platform would act as a dance floor and increase interaction among concert-goers. The patterning at the top of each row of PVC pipes could be cut to the profile of the numbers 80 & 35 to act as a welcome and gathering piece as well. Light Field Cloud The CLOUD concept uses pneumatically inflated surface that acts as a canopy in the daylight, and usescomputer-controlledlightingatnighttocreate theillusionofafloatingcloud.Largeballoonswould be controlled by user interaction via a mechanical wheelmountedtoeachcolumn.Seatingiswrapped around the base of each column and could double as weighted supports for the base. The act of raising the core of the pavilion overhead allows the usable area at ground level to be maximized, and uses LEDs and projection mapping to turn the surface of the Cloud into a beacon for the entire festival. This concept explores the idea of using the pavilion as a broadcasting device, wherein the human activity under the canopy is visible to people inside the gates of the concert. Tracking and interpreting movement inside of the pavilion offers the opportunity to generate lighting effects in real time and to live stream media.

- 27. MODULARSYSTEMS Multiple proposals began to feature modules; implemented to solve the problems brought aboutby the buildconstraints and transportability inherent to the project. “Cubic modules can be used as a scaffold to create a complex surface” “Multiple squares can be attached to each other to create connectible modules” “The entire system can be built out of a series of similar shaped modules varying in scale” “The modules can be built into flat stacks and transported to the festival” “Stacks of modules can be connected together and rotated into the desired shape”

- 28. FABRICATING POTENTIALS 55 To fit the context of the music festival and appeal to concert-goers, strategies for digital interaction and social media were proposed within the context of modular systems. ATMOSPHERIC INTEGRATION cloudcanopy

- 29. FABRICATING POTENTIALS 5756 IOWA STATE UNIVERSITY #cloud canopy The cloud canopy acts as an overarching billboard, providing a landmark within the 80/35 festival grounds. The canopy would be built with cubic modules, each containing a programmable LED inside. The modules would form a cloud of lights above a user’s head, attracting people to the area and facilitating interaction. Projection mapping could be used to display a user’s photos above the crowds gathered below. #pop|pod The one, three and five person PODs offer seclusion from the surrounding environment. Open stools placed outside of the PODs also allow for quick stop and go for relaxation. When entering each POD, a unique interaction occurs. When vacant, the POD is dark (dead), but as soon as someone steps inside, the structure instantly lights up, establishing occupancy. The lights will pulse, thereby bringing the PODs to life.

- 30. FABRICATING POTENTIALS 5958 IOWA STATE UNIVERSITY #mixmaster #light arboretum This pavilion emulates nature’s layers through a minimalistic and modern approach. A system of modules was designed to form the entirety of the pavilion. The Light Arboretum offers shading and seating during the day, creating a retreat for the public from the sun and heat. At night the canopy transforms into a light sculpture that changes in colors. The lighting effect matches the vibrant atmosphere of the 80/35 festival. Mixmaster acts as an interactive node within the 80/35 festival offering a range of seating options and social interactions. The design is formed from a similar square module which can be built into stacks and transported in flat sections. The stacks can then be combined together on site to make the final form, which is an abstraction of the intersection of highways 80 and 35 which the festival is named after.

- 31. CONNECTIONS After deciding on a cubic-shaped module, variations of potential construction techniques were developed and prototyped. slidingcornerjoint

- 32. FABRICATING POTENTIALS 6362 IOWA STATE UNIVERSITY soliddovetailcorner

- 33. FABRICATING POTENTIALS 65prototyping&construction FABRICATING CONSTRUCTION POTENTIALS Taking into account the logistical issues involved in designing, transporting, and building a temporary pavilion in Des Moines for the 80/35 summer music festival, the interdisciplinary project team decided upon the creation of a cubic- shaped modular system to organize and simplify the fabrication and construction processes. Proposals inclusive of form, fabrication, material, assembly, and cost were introduced and modified in an attempttorespondtotheuniquedemands of the project. Modular connection types using multiple hardware and material typologies were prototyped along with studies of potential panelization systems. The integration of interactive platforms such as LED lighting and projection mapping continued to be a consideration as well. Much of the design work was accomplished through repetitive digital iterations which informed refined physical prototypes, consistent with Iowa State University’s Department of Architecture’s goal of becoming a leader in digital computation and fabrication methods.

- 34. FABRICATING POTENTIALS 6766 IOWA STATE UNIVERSITY The process of applying appropriate materials and interactive installations into the modular system was tested and optimized. STRUCTURE INTERACTION PANELIZATION tyvek mirror plywood wiring projector LED strip plywood panels bolts & washers turnbuckle cable COMPONENTS + PROCESSING

- 35. FABRICATING POTENTIALS 6968 IOWA STATE UNIVERSITY 1/2” Plywood To fit the bed of our CNC machine, each of the 130 4’x8’ sheets of plywood needed to be cut down into 2’x3’ sections. 1/2” pine plywood was chosen after consulting budget and time requirements. In the meantime, using Grasshopper and Rhino, the unique shape of each box was prepared and labelled for cutting and construction. Each box was labelled so its specific location within the pavilion’s structure would be noted. The boxes were also designed with tabs in each corner, enabling each side of the box to be formed to the correct angle. After cutting down the sheets to the correct size, digital files consisting of cutting paths for each individual box were sent to the CNC machine, and the resulting pieces were then ready to be assembled. Boxes were assembled using wood glue and a brad nailer. Hardware To connect each module into stacks and eventually rows, approximately 2,500 5/16” bolts, washers, and hex nuts were bought to secure each connection. These bolted connections were used to secure the structure in both vertical and horizontal directions. In addition, levelling feet were added at the bottom of the structure to account for the small slope on the site. These feet also create a 4” reveal at the base and prevent the boxes from sitting on the pavement, and potentially, in water. Structure modulefabrication

- 36. FABRICATING POTENTIALS 7170 IOWA STATE UNIVERSITY LEDs The specific LED product used within our pavilion is called Neopixels. This product was chosen due to its price and its ability to be purchased in bulk. The LED system consists of a total of 2,448 bulbs split into groups of four placed within the center of each module. With 11 vertical rows to the pavilion, this meant that strips of 48 LEDs (12 groups of 4) were required to fill each module. In order to have a consistent feed of power and not overload a single power source, the LEDs were grouped together as a trio of stands allowing them to receive a constant feed from a 10amp 5volt power sources. In order to connect the power to this power supply, we have to feed power and ground wires into a DC power adapter. This adapter is specifically designed to connect into the power supply while allowing a female opening for the LED wiring. Inlayed within this power supply, an electrolytic capacitor controls any unwanted spiking in voltage by keeping a constant buffer from the feed. In addition, the entire LED system is able to connect to a data source, allowing each LED or group of LEDs to be programmed accordingly. Codes were developed to allow the LEDs to react to sound or motion, creating a platform for digital interaction with users. At night, the entire structure comes alive with the reactive LEDs, being triggered by user’s interactions and the sound of the concert. The final form resembles an amorphous grid made up of large pixels, each lit from behind a Tyvek panel to create a soft, diffused lighting quality. LEDhardware Interaction

- 37. FABRICATING POTENTIALS 7372 IOWA STATE UNIVERSITY Projection Mapping Interaction with festival-goers is a cornerstone of the pavilion’s purpose, and our projection wall does just that by reflecting visitors dance moves on a larger than life screen that also reacts to sound. This is done with audio reactive computer software and projection mapping. For Broadcast 8035, we employed an Apple Macbook Pro and Vidvox’s VDMX 5 video mixing software to accomplish both the mapping and sound reactivity in one package. Projection mapping software enables a user to adjust a projected image to fit the object it’s being projected on. It’s a more advanced version of the keystone adjustment found on many retail projectors. When you set a projector on a table, it sits at an angle up to 10° above horizontal, making the image being projected on a vertical surface a skewed trapezoid shape. The automatic keystone adjustment uses an optical sensor to determine the amount of skew, and then adjusts, or projection maps, the image accordingly.-The projection wall of Broadcast 8035 is a complex compound curve, and the image being projected will be mapped to follow the shape of the pavilion. Using VDMX5, we are able to warp the output image to match the contours of the projection wall. This results in an on-screen image with very little distortion. projectionprototypes Video Mixing VDMX5 is an advanced video mixing software similar to programs that many DJs use, but the input media is visual rather than audio. VDMX5 allows a user to mix and overlay images, videos and text on one screen. In addition to video, VDMX5 also allows us to create generative graphics using programming languages such as Independent Shader Format (ISF) and Quartz Composer (QC). Generative graphics are small programs that move, grow and change color either automatically, or with input. An example of generative graphics are the colorful moving screen-savers found on many computers, while Windows Media Player’s music visualization feature demonstrates graphics which are affected by input. For the 8035 festival, we will have four layers of visuals running simultaneously, with each layer affecting the next. The backgroundandforegroundlayerswillplay videos and generative graphics. A middle layer will take input from a Microsoft Kinect depth camera and display it as an abstracted silhouette. The final layer will display text, including special messages to the audience. VDMX5 also offers advanced audio analysis filters that will give us quantified values based on certain frequency levels in real time. We can use those values to manipulate the graphics and effects being displayed on screen. On the fly adjustment can be done with the iPhone TouchOSC app. TouchOSC allows users to create custom MIDI controllers as input devices for programs on their computers. With TouchOSC we can cue the next scene, adjust the output brightness or change the sound responsiveness for all seven audio filters individually.

- 38. FABRICATING POTENTIALS 7574 IOWA STATE UNIVERSITY Tyvek Tyvek brand protective material is a tough, durable, spun-bonded olefin sheet. The material is more robust than paper and more cost-effective and versatile than fabrics. Tyvek has a higher strength- to-weight ratio than leading paper products, absorbs little or no moisture, is strong and rip-resistant, and is made of environmentally responsible material. Both bright white and silky smooth, Tyvek has a distinctive look and feel that enhances graphic images and instantly sets it apart from all other materials. The material is therefore advantageous to project onto, and additionally, it creates a soft, diffused lighting condition when backlit by LEDs. The product should also be able to withstand the rigors of the music festival. Mirrored Acrylic The use of mirrored acrylic creates an intimate experience within the hallways of our pavilion. The acrylic mirrored panels are half the weight of glass, 8 times stronger, and shatter-proof. Additionally, the panels are UV stabilize and have a working temperature range of -40°F to 180°F. The panels are cut down to follow the gridded pattern of the pavilion’s envelope and fit flush along the interior sides of one of the hallway corridors. The mirrored walls encapsulate the entirety of the pavilion’s inner corridor and stretch vertically through the top, creating a seamless visual connection between the structure and the sky. Working within the limitations of a confined footprint, the mirrored surfaces provide dynamism and life to the inner spaces, giving our pavilion a unique multidimensionality. Panelization tyvek+mirrors

- 39. CATALOG+LABEL Asystemforlabelingcomponentsthroughoutthe559unique modules was developed in Grasshopper to help coordinate the installation between structural modules, paneling, and LEDs. Connect tabs 0 and 3 to side piece 3 and tabs 1 and 2 to side piece 1 STEP 1 Connect tabs 0 and 1 to bottom piece 0 STEP 2 Connect tabs 2 and 3 to top piece 2 STEP 3 Brad nail all connections STEP 4 Add Tyvek face using glue STEP 5 Install vertical support bar and LED strips STEP 5 MODULE ASSEMBLY 0 1 1 2 3 0 1 2 3 3 2 0 0 1 2 3 0 1 2 3 0 1 2 3 4 5 7 6 7 7 1 5 4 6 45 6 MODULE ASSEMBLY 0 1 1 2 3 0 1 2 3 3 2 0 0 1 2 3 0 1 2 3 0 1 2 3 4 5 7 6 7 7 1 5 4 6 45 6

- 40. FABRICATING POTENTIALS 7978 IOWA STATE UNIVERSITY R 11 R 10 R 9 R 8 R 7 R 6 R 5 R 4 R 3 R 2 R 1 R 0 C13 C0 C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C18 C17 C15 C16 C19 C20 C21 C22 C23 C24 C25 C26 C27 C28C29 C30 C31 C32 C33 C34 C35C36 C37 C38 C39 C40 C41C42 C43 C44 C45 C46 C47 C48 C49 C50 C51 C52 C53 C54 fulllabelingsystem

- 41. FABRICATING POTENTIALS 81 Machinery such as a CNC, vinyl cutter, and soldering irons were informed through digital files to produce and organize different facets of the pavilion. FABRICATION TECHNIQUES CAMasterStinger1CNC

- 42. FABRICATING POTENTIALS 8382 IOWA STATE UNIVERSITY CNC The Stinger I CNC Router is a robust bench top machine.Builtwiththesame principlesasprevious versions, the Stinger I is a tool that is budget and size friendly, but is still rigid and flexible enough to be implemented in an intensive production environment. The machine was required to run 24/7 for three weeks straight in order to complete the pavilion, and it lived up to its billing. The Stinger I is constructed on a welded steel frame, giving it a rigid and robust, yet smooth movement. The machine is built and tested completely in Cartersville, Georgia. The machine came with a control PC that was preloaded with WinCNC (which controls the CNC) and was tested with the machine before shipping. The Stinger also comes with Vectric’s CUT 2D design software, consolidating all of the software needed to set up and run the machine. The process of translating the main structural components of the pavilion from digital to physical began by exporting tool-paths for the CNC from the base Grasshopper definition. Files were labeled by their specific row and column number, with each box being assigned a spot within the 55 (numbered 0-54) vertical stacks and 12 (0-11) horizontalrows. Eachboxconsistedofeightunique pieces including the top, bottom, and sides, as well as tabs between each corner connection, allowing each box to be built at the correct angle. Exterior faces of each box were labeled 0-3, as were the interior tabs. The labeling system guaranteed that each component was installed in the correct place, and the boxes formed at the correct angles. Additionally, holes and slots for electronics, bolts, and the tabs were included within the tool-path for each exterior face. Each box fit onto two 2’x3’ sheets of plywood, with all of the interior tabs along with the bottom and side pieces fitting on one sheet. Digital Process

- 43. LEDcoding+powertest 84 IOWA STATE UNIVERSITY FABRICATING POTENTIALS 85

- 44. FABRICATING POTENTIALS 8786 IOWA STATE UNIVERSITY Soldering In order to fit between the custom length of each unique module in the structure, the store-bought LED strips had to be spliced together between each forth bulb, which allowed each group to be centered within a module. Since the total amount of bulbs within the system was set at 2,448 based on the desired illuminance of each module, this meant that 612 splices needed to occur. In order to reconnect each group after the splice, the power, ground, and data feeds were soldered back together, restoring power and an uninterrupted data feed to the system. Finally, three sets of twelve four LED groups were connected to power packs and data feeds, allowing us to power and program every module within the pavilion. In this way, each module serves as a pixel within the entire installation. Within each module, we attached the four LED group strips with zip ties to a 2” vertical post. This post easily assembles as part of each model due to a pre routed CNC cutting path routed into each box. The matrix of LEDs is powered by a mixture of open source software and hardware. The process starts on a laptop where ambient sound around the pavilion is input via microphone. The code generates real time graphics in response to the audio, mapping them onto the LED matrix. Next, color data is sent wirelessly to a Raspberry Pi computer and then split across the seven Fadecandy microcontollers that interface with the LED strips in each column of the pavilion. Fadecandy is a tiny microchip that is designed specifically to take standard LED color data and apply a dithering algorithm before sending it to the array. This is important because the raw color data may be extremely sharp in response to a loud festival environment, but the Fadecandy ensures that all of the lighting effects are smooth. The LED matrix is powered by fifteen separate power supplies that each handle around three columns of the boxes inside the pavilion. Breaking the power into segments makes setting up and tearing down the structure more efficient and prevents the possibility of a voltage spike. Coding + Data Transfer

- 45. FABRICATING POTENTIALS 8988 IOWA STATE UNIVERSITY Vinyl Cutter VinylMaster Cut is a machine that provides precise contour cutting for both LAPOS (Laser Positioning Sensor)ormanualcontourcutting.Contourcutting is perfected with VinylMaster Cut for applications like stickers, custom labels, or unique geometry. The software that VinylMaster Cut provides gives you diagrams to preview and modify before completing your contour cuts. This preview can assist with loading digital files into your cutter correctly. VinylMaster Cut has advanced controls, providing sensitivity, speed, and directional control over the cutter. These features ensure that the cutter can be optimized to cut a variety of products such as matte, gloss, laminated, or even reflective material. The process for creating paneling for the pavilion starts within Rhino, where each panel surface was able to be flattened using a Rhino script. From this script, the panels were exported as DXF files to Adobe Illustrator. From Illustrator, the files were touched up, ensuring that all lines transferred properly from Rhino to Illustrator. Those Illustrator files were then brought into the VinylMaster Cut V4.0, the main program that comes with each Vinyl Cutter. This program takes files from Illustrator and converts them into a file type that is directly sent to the Vinyl Cutter. To ensure the correct orientation of the panels, the script put an uppercase T in the top right hand corner. This allows anyone to know the direction of which the panel needs to be installed on the assembled plywood boxes. Further markings with the row and column number were put on each panel. During fabrication, the assembler is then able to know which Tyvek panel goes to which plywood box. Digital Process

- 46. FABRICATING POTENTIALS 91 The structure ascended upwards in rows as boxes were cut, assembled, panelized, and installed. CONSTRUCTION PROCESS LEDchain

- 47. FABRICATING POTENTIALS 9392 IOWA STATE UNIVERSITY

- 48. boxassembly 94 IOWA STATE UNIVERSITY FABRICATING POTENTIALS 95

- 49. FABRICATING POTENTIALS 9796 IOWA STATE UNIVERSITY

- 50. FABRICATING POTENTIALS 99thepavilion FABRICATING PAVILION POTENTIALS In accordance with the studio’s goal of experimentation within the realms of digital design and fabrication, the final form of the pavilion was completed entirely within Grasshopper, allowing pieces of the structure to be produced digitally and fabricated with the CNC. The amorphous shape emerged as a result of digital form optimization after consulting an initial set of structural concerns, environmental factors, experiential sections, and practical uses. In addition, the sixteen person team decided to add to the atmosphere of the music festival by creatinganinteractive soundandsituation responsive lighting installation. LED strips were customized to fit within the modular structure, creating the effect of a freeform array of individual pixels. Projection mapping added another element to the digital interactivity of the design. The pavilion is meant to provide a node for digital interaction and engagement within the festival grounds, allowing studio members to gain a better understanding of architecture’s relationship with technology and human interaction. The efforts throughout the semester are consistent with Iowa State University’s Department of Architecture’s goal of becoming a leader in digital computation and fabrication methods.

- 51. FABRICATING POTENTIALS 101 The pavilion’s unique form was defined by experimental sections and optimized digitally to be freestanding and free of any complex geometry or double-curved surfaces. FORM FINDING DISCOVER INTERACT MINGLE PLAY RELAX YOGA

- 52. FABRICATING POTENTIALS 103102 IOWA STATE UNIVERSITY The initial form was derived from a series of lofted sections which acknowledged different scales and types of interaction. In plan, a serpentine curve was developed and offset in a way that allowed for self- stabilization. These lofted section curves were then constrained at their boundary, and the resulting edges were used as the parametric controls. Parametric implementation is often lauded as a highly collaborative approach, however we determined that in using a series of control points to adjust this curve within Grasshopper, we ended up with too many options and very little resolution. It was thus determined that a better approach would be to utilize a few single curves which governed the overall form. Essentially, the entire form is determined by two closed reference curves at the bottom and top of the structure. The definition in Grasshopper was then expanded using the constraints of the original two curves in order to create the unique individual modules that allow for the form to be built. The definition allowed for each module to make up part of the freeform shape by giving it a unique geometry based on its location within the form. Included within the parametric definition, each ‘box’ was split into four unique side pieces and corresponding tabs which connected each of the sides. The tabs allowed each piece of a box to conform to the correct angle, thus allowing each box to fit into its specific place within the structure. As noted earlier, each module and the specific set of unique components used to construct it was labelled to help clarify construction. Finally, the specific geometry of each module was exported from Rhino into simple line drawings, enabling them to be cut by the CNC. panelization+structure

- 53. 80/35FESTIVAL DES MOINES, IA 80/35 FESTIVAL GROUNDS 104 IOWA STATE UNIVERSITY FABRICATING POTENTIALS 105

- 54. FABRICATING POTENTIALS 107106 IOWA STATE UNIVERSITY localsiteplan

- 55. FABRICATING POTENTIALS 109108 IOWA STATE UNIVERSITY plan section

- 56. FABRICATING POTENTIALS 111 The pavilion’s structure, elevational qualities, and reuse and outreach strategies were all key features of the design. DIAGRAMS Structure STRESSED UNSTRESSED

- 57. FABRICATING POTENTIALS 113112 IOWA STATE UNIVERSITY Elevation SKY INTERACTION SEATING

- 58. FABRICATING POTENTIALS 115114 IOWA STATE UNIVERSITY Reuse + Outreach TYVEK PANEL TEACHING KITS PLYWOOD MODULE LED STRIP MICRO CONTROLLER BOARD KITS WILL ALSO COME WITH ASSEMBLY AND CODING INSTRUCTIONS AS WELL AS TEST EXPERIMENTS 1. LEARN/CREATE 2. BROADCAST 3. TRANSFER

- 59. FABRICATING POTENTIALS 117 The completed pavilion was shared in two different settings, once in our fabrication studio at Iowa State, and finally in its intended setting in Des Moines for the 80/35 festival. THE PAVILION

- 60. FABRICATING POTENTIALS 119118 IOWA STATE UNIVERSITY

- 61. FABRICATING POTENTIALS 121120 IOWA STATE UNIVERSITY

- 62. FABRICATING POTENTIALS 123122 IOWA STATE UNIVERSITY

- 63. FABRICATING POTENTIALS 125124 IOWA STATE UNIVERSITY

- 64. FABRICATING POTENTIALS 127126 IOWA STATE UNIVERSITY

- 65. FABRICATING POTENTIALS 129 Architecture Alexandra Abreu Donnie Hull Shaohua Dong Bryan Johnson Joshua Neff Kelsie Stopak Nathan Peters Rahul Attraya Cole Davis Kaitlin Izer Coralis Rodriguez Kyle Vansice Industrial Design Tom Bos Interior Design Nikki Behnke Hannah Greenfield Makaela Jimmerson Professor Shelby Doyle, AIA THE STUDIO Throughout the semester, our studio has pursuedthepotentialsofdigitallyinformed and technologically advanced interactive applications in architecture. Utilizing a collaborative and infinitely malleable parametric modeling process through the 3D platforms of Rhino and Grasshopper, the limits of digital collaboration and translation to the physical were tested. The success of this digital exploration is evident in the finalized 3D model and Grasshopper script. These single files controlled and orchestrated construction, organizing production between the variable fabrication techniques employed. Especially pertinent was the labeling system developed within the script, allowing independent fabrication to occur between the CNC, Vinyl Cutter, and the LED teams. Additionally, fabrication of the uniquegeometryinherenttothepavilion’s components was made possible through the digital realm, with our single base model acting as a foundation from which we could organize LED customization while exporting each structural module (automating each box’s unique geometry), and panelized face. However, we did encounter issues regarding the translation from digital to physical. Specifically, inherent material defects (such as poor grade plywood) affected the construction of our highly specific geometry, with some boxes having to be re-cut due to problems of tolerance. Additionally, fabrication time increased due to the complex geometry of our design, negating any quick mass production of similar components. Our environmental goals became difficult to meet as well, as excess material from CNC cutting began to build up. However, the knowledge gained from this highly ambitious proposal has been invaluable for everyone involved, allowing each student to experience firsthand the potential of digital design and fabrication. Thank You to Our Sponsors OPN Architects, Fieldstead & Company Endowment for Community Enhancement, Stan G. Thurston Professorship in Design Build, ISU College of Design, ISU Department of Architecture, Des Moines Music Coalition 80/35 Music Festival. And thank you to Dronography Iowa for the drone photographs.

- 66. FABRICATING POTENTIALS 131130 IOWA STATE UNIVERSITY