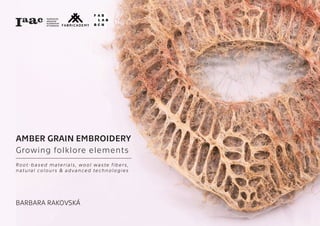

1. Root-based materials, wool waste fibers,

natural colours & advanced technologies

AMBER GRAIN EMBROIDERY

Growing folklore elements

BARBARA RAKOVSKÁ

2. Root-based materials, wool waste fibers, natural colours & advanced technologies

AMBER GRAIN EMBROIDERY | Growing folklore elements

3. Barbara Rakovská © 2024

INDEX BIOGRAPHY

@ art.raba

facebook.com/barusra

class.textile-academy.org/2024/barbara-rakovska/

6. Barbara Rakovská © 2024

Barbara Rakovská © 2024

ABOUT | Growing materials STATE OF THE ART | Existing projects research

RootSkin - from soil to soil

Roots and architecture

Zena Holloway

Wheatgrass roots

InterWoven - Diana Scherer

Oat plant roots

7. Barbara Rakovská © 2024

STATE OF THE ART | Existing projects research

Rootskin project led by Chiara Farinea. The project

researcher: Fiona Demeur and Ilaena Napier, Andrea

Conserva, Mohamad Elatab. (Archisearch 2022)

Grown root textile - InterWoven© Diana Scherer

Rootskin - biodegradable building skin fabric grown in

soil and by plant roots.

During the project, I had a very interesting conversation with Fiona

about developing textiles for the construction industry. I am

grateful for her inspiration, advice, and tips. The goal of the

project, named RootSkin, was to develop a strategy to harvest

fruits above the soil level for food and roots below the ground to

create a textile. This textile is translucent (depends on density)

and biodegradable, which makes it an excellent skin material for

buildings. The RootSkin research focused on patterns, plants, and

mold and bottom panel material to create the desired textile.

(Conserva, A; Demeur, F; Farinea, C. 2022)

9. Barbara Rakovská © 2024

Barbara Rakovská © 2024

BIODESIGN APPROACH | Fabricating textiles

TRADITIONAL: Key manufacturing stages - cotton plant to final product

Fibre

BIODESIGN APPROACH: Key manufacturing stages. The designer collaborates with nature to cultivate and control

materials' properties. Plant roots weave while searching nutrients and water.

NATURE AS A CO-

WORKER

Husbandry

principles Natural nature

Designer =

cultivator

Planting seeds

Roots are growing in

specific pattern

Harvesting roots and

assembling final product

Fabric

10. Barbara Rakovská © 2024

PROCESS | root domestication

GRASS SEEDS FOR DRY AREAS (Bermuda grass), Growth in Agar Agar, Coco coir, very fine

roots, fine patterns can be grown in agar

RADISH - fast germination, fragile roots,

grey after drying, high water content

BEANS - a little root interweaving,

no hair roots, fast germination,

good for growing through fabric

12. Barbara Rakovská © 2024

OBJECTS OF OBSERVATION | Creating the first samples

GRASS SEED FOR DRY AREAS - BERMUDA GRASS

GRASS GROWTH IN COCO COIR

6x6 cm fine-pattern form

with a pattern thickness of 3

mm

grid silicone mold (originally for waffles), thickness approximately 1.5 centimeters.

As it grows through the mesh - the roots penetrate

and then gradually decompose at the bottom of the

container that holds the water.

13. Barbara Rakovská © 2024

GRASS GROWTH IN AGAR AGAR

OBJECTS OF OBSERVATION | Creating the first samples

Relatively fine structures can be

grown in agar.

Photos show the root growth in a 6x6 cm fine-pattern form with a pattern thickness of 3 mm.

14. Barbara Rakovská © 2024

GRASS GROWTH IN AGAR AGAR

OBJECTS OF OBSERVATION | Creating the first samples

Freely waving grass roots in agar. During the experiment, I examined how roots behave in a defined border shape within a flat-

bottomed silicone mould. My aim was to explore the interaction between the roots and the mould.

Experiment with very low agar concentration (2g per liter of water) and liner pattern. The low concentration caused very slow

drying and it was difficult to separate the roots from the mould when harvesting. They literally floated in the medium and their

structure was disturbed.

Interaction of grass in agar and mold

with depressions. I placed a flat sheet

of agar on top of the silicone mold, so

the roots grew through and created a

spatial structure outside the agar gel.

15. Barbara Rakovská © 2024

OBJECTS OF OBSERVATION | Creating the first samples OBJECTS OF OBSERVATION | Creating the first samples

GRASS GROWTH IN SUBSTRATE - SOIL

Photos show the root growth in a 6x6 cm fine-pattern form with a pattern thickness of 3 mm.

Black bean roots and jute fabric Black bean roots wool fibers

17. Barbara Rakovská © 2024

WHEATGRASS | Growth characteristics

Day 1 Day 2 Day 3

Seeds are germinated in 3 days

Wheatgrass root density after 11 days, possibility to

grow HYDROPONICALLY

Roots hairs that create friction between fibers. This

friction acts as its own binding mechanism, similar

to what is typically seen in non-woven fabrics Wheatgrass growth in agar agar,

INGREDIENTS: 4g agar / 1l water

Day 1 Day 2 Day 3

Seeds are germinated in 3 days

Wheatgrass root density after 11 days, possibility to

grow HYDROPONICALLY

Roots hairs that create friction between fibers. This

friction acts as its own binding mechanism, similar

to what is typically seen in non-woven fabrics

18. Barbara Rakovská © 2024

ROOTS AND

BARRIERS

- changing the

shape using

moulds

(patterns)

GROWING

MEDIUM

- Agar, water,

soil, wool

MOULD

MATERIAL

-PLA

-Beeswax

CUTTING

ROOTS

-Growing fine

sheets

MATERIAL

WITH SEDS

-Growing 3D

patterns

GEOMETRY

-Moulds,

parametric

design

GROWING

CONDITIONS

MATERIAL

STRUCTURE

MATERIAL

POST-

PROCESSING

COLOR

- Natural dyes

- Beeswax

RESIDUAL

MATERIAL

- Grass, seeds

SURFACE

TREATMENT

- Sodium

alginate

- Beeswax

ENVIRONMENT

-Humidity, light

-Airflow

ELASTICITY

- Glycerol

- Boiling /

soaking

MODIFYING

-(heat)pressing

-Laser cutting

-Sewing

-Moulding

WHEATGRASS

BARLEY

3D patterns with

seeds

Heat-pressed residual

grass and seed layer

Fine sheets

Dried grass

19. Barbara Rakovská © 2024

WHEATGRASS | Understanding growth, ensuring appropriate conditions

Growing 3D patterns

Growing through fine fabric

Growth of fine sheets

Overgrowing

objects

Agar agar

Borders

When roots grow in agar, they develop a

residual film that enhances load

distribution. This creates a solid structure.

20. Barbara Rakovská © 2024

POST-PROCESSING | Natural dyes POST-PROCESSING | Natural dyes

Natural color - fine

sheet root-based

material

PLASTICIZER COLORANT POST-

PROCESSING

Glycerine

Soaking roots in

10% solution of

glycerine &

water for 12 h

Spraying roots

with high conc.

50% solution of

glycerine & water

Cooking roots

with natural dye

brine

Dissolved

pigments in

glycerol

Vinyl press

temperature 90

C, time 50-70s

Natural dyes,

Mica powders Heat-pressing

Black bean natural dye Natural color - fine sheets

21. Barbara Rakovská © 2024

Barbara Rakovská © 2024

POST-PROCESSING | Sodium alginate coating

POST-PROCESSING | Heat-pressing, natural dyes

Heat-pressed Mica powders & soaked roots

in 10% solution of glycerine & water for 12 h

Sodium alginate with

indigo dye

Properties : Antibacterial, Antiviral Anti-inflammatory,

Biocompostible, Biodegradable, Antifungal, Antioxidative,

Anticancer, Non-toxic

Sodium Alginate

Powdered State

CROSS-LINKING OF POLYMERS (+ CALCIUM CHLORIDE)

Ability to cross-link polymer chains with calcium solutions

resulting an INSOLUBLE, GEL-LIKE SUBSTANCE.

2g Sodium Alginate in 100ml H20

2g Calcium Chloride in 100ml H20

22. Barbara Rakovská © 2024

POST-PROCESSING | Natural dyes, sodium alginate coating POST-PROCESSING | Heat-pressing, natural dyes

3D pattern with sodium alginate

coating, indigo dye and mica powders

Cultivated wheat-grass material in 3D

printed mould

DRYING MATERIAL

3D - structures

COLORANT

Mica powders, Indigo dye

COATING

Sodium alginate

Sodium alginate has film-forming properties, which makes it useful for creating films or coatings

that improve quality and shelf life.

Dried material in the oven

60°C

Sodium alginate and &

calcium = spherification

+

23. Barbara Rakovská © 2024

processing of the residual grass

and seed layer

by separating the root

layer we get fine sheets

cooking with turmeric brine and

glycerol

Heat-pressed samples after drying

POST-PROCESSING | Residual material process POST-PROCESSING | heat-pressing, laser cutting

When harvesting the root-based

material, we obtain a fine sheet by

separating the root layer from residual

grass and seeds. This leftover material

can be treated with natural dyes,

glycerol, and heat-pressed afterwards.

We obtain a material with a higher

density that is also relatively flexible and

can be easily laser-cut.

Vinyl press temperature 90°C,

time 50-70s

24. Barbara Rakovská © 2024

Contrast of material densities - fine

sheet on top of the heat-pressed

residual grass and seed layer

25. Barbara Rakovská © 2024

Heat-pressed samples, laser cut patterns, curcuma natural dye

POST-PROCESSING | Residual material process POST-PROCESSING | Residual material process

The pressed material is about 2mm thick. The material does not burn quickly, instead it gradually

decomposes and becomes less compact. I did not observe any problems during laser cutting.

Engraving is not possible.

Laser cutting machine: Trotec SPEEDY 400

2 mm

1 000 HZ

80 1

26. Barbara Rakovská © 2024

POST-PROCESSING | heat-pressing, laser cutting, coating POST-PROCESSING | Heat-pressing comparison

Heat-pressed sample, laser cut patterns, sodium alginate coating & indigo dye Comparison of structures heat-pressed sample & dried natural structure

For coating the residual material I experimented with using 2g of Sodium Alginate in 100ml H2O with no Calcium Chloride. I then

heat-pressed the sample.

27. Barbara Rakovská © 2024

Harvesting roots and

assembling the final

product.

Roots are growing in specific pattern

POST-PROCESSING | Shaping and stitching fine sheets

I experimented with fine wheat root sheets by softening them in glycerol and felting them with wool fibers to create a 3D cap

shape.

29. Barbara Rakovská © 2024

In my research and work with grains,

I have come across various materials.

GROWING FOLKLORE ELEMENTS

30. Barbara Rakovská © 2024

Barbara Rakovská © 2024

Folklore costume elements

TRADITION

Dožínky - Slavic

harvest festival

- Parametric patterns

inspired by nature, 3D

printed moulds

Digital fabrication Growing wheatgrass &

barley embroidery

GROWING FOLKLORE | cultural heritage AMBER GRAIN | Slavic harvest festival

cultivating the material

under laboratory

conditions

TECHNOLOGY NATURE

Harvest wreath - They used all kinds of cultivated grain and very often wove in meadow flowers, Slavic harvest

festival

31. Barbara Rakovská © 2024

Barbara Rakovská © 2024

Richly decorated Slovak costumes

Šumiac, Horehronie, Slovakia - folklore crown

Traditional folklore embroidery

Traditional lace-making

TRADITIONAL FOLKLORE | Embroidery, lacemaking TRADITIONAL FOLKLORE | Festive folk costumes

Recently, I have become more interested in the folk traditions of my home country of Slovakia. While exploring the material, I was reminded

of the lace and embroidery techniques used in traditional Slovakian folk costumes. By utilizing root structures in the context of Slovakian folk

costume, I was able to blend history and culture with modern technology and nature.

33. Barbara Rakovská © 2024

Growing conditions

- Humidity 50% - 60%

- Temperature 20 - 22°C

PROCESS | growing conditions PROCESS | preparation of seeds

- Soaking time ~ 12 h

- Temperature 20 - 22°C

34. EMBROIDERY PATTERNS | 3D printed moulds

Using Lloyd's algorithm in

Grasshopper to optimize a

Voronoi surface.

35. Barbara Rakovská © 2024

EMBROIDERY PATTERNS | 3D printed moulds

Mould parameters

- depth of pattern 7 mm

- average thickness 3 mm

36. Barbara Rakovská © 2024

PROCESS | Regular care with love PROCESS | Harvesting

- Drying temperature ~ 60°C

- 7 cm grass = ready to harvest

- Grain: Seeds of barley

- Growing medium: soil & fabric

38. Barbara Rakovská © 2024

PATTERNS & MOULDS | Wheatgrass and barley

Barley embroidery - beeswax mould, spontaneous color change to red.

Wheatgrass color change after drying. Fresh roots are bright

almost white. Drying temperature ~ 60°C, hot-air oven.

I designed root based costumes inspired

by traditional folk elements

The material's final appearance is greatly

affected by the shape of the pattern and

the chosen mould material. If we compare

wheatgrass and barley, barley retains its

light beige color even after complete

drying, while wheatgrass turns brown. For

creating the lace and embroidery of the

costume, I used 3D printed PLA and

beeswax molds.

40. Barbara Rakovská © 2024

PATTERNS & MOULDS | Wheatgrass PATTERNS & MOULDS | Barley

After drying, patterns with straight lines proved to be ineffective as the roots couldn't interweave in multiple directions,

resulting in a fragile pattern that didn't adhere to the pile.

Wheatgrass Barley embroidery

I observed a shallow mould on barley with a 2mm pattern depth. The roots grew into the space and formed a thicker

pattern.

41. Barbara Rakovská © 2024

Barbara Rakovská © 2024

PATTERNS & MOULDS | Barley & beeswax mould PATTERNS & MOULDS | Symbiosis with other materials

I created the beeswax molds by casting and carving them into traditional inspired floral

patterns. This embroidery covers the largest surface area and forms the front of the vest.

Through experimentation and various changes in growing conditions, I was able to create an array of root embroidery

patterns, which I then incorporated into garments inspired by traditional Slovak folk costumes. The second crucial step

of my research was figuring out how to apply the root embroidery and lace to the garment. My primary objective was to

use only natural materials that have a connection to traditional uses. This led me to consider using wool. I was further

inspired by a workshop by the exceptionally talented Dutch artist Claudy Jongstra, where I learned about traditional wet

felting and needle felting techniques. The primary source of wool I use is short fibers of waste wool from Mallorca.

Unfortunately, since the middle of the last century, the rise of synthetic fibers has led to a steady decline in the

importance of wool in the textile sector. Nowadays, wool is a marginal fiber on the textiles market. Large quantities of

unmarked raw wool have become problematic waste, which is often burned or landfilled, instead of being an income

source for sheep farmers. (Rajabinejad, H. & Buciscanu, I. & Maier, S. 2018)

Through my experiments with beeswax, I discovered that it can be used as a natural binder for dried grass fibers. As I

take a holistic approach to materials, I try to utilize all of their components. Thus, I was excited at the possibility of

incorporating a layer of seeds into the garment, particularly on the reverse side, to provide the wearer with a unique

tactile sensation that connects them with nature.

43. Barbara Rakovská © 2024

Barbara Rakovská © 2024

WOOL AS A GROWING MEDIUM | Experiments

Wool is a highly absorbent natural material that can hold

moisture better than most other natural materials. This

property enables wool to regulate the environment around

it, making it an excellent temperature regulator. The

breathable nature of wool fibers also allows for good

aeration and root growth. Not only did I find inspiration in

wool's traditional use in clothing, but I also experimented

with reusing the wool growth medium for felting. After

harvesting the wool, I dried it and felted it..

Wheatgrass growing in wool

fibers, 3 days old sprouts

Pattern grown on felted piece

of wool fibers

Reuse of wool as a substrate for

felting

44. Barbara Rakovská © 2024

inside of the vest - furry

dried grass with seeds

Traditional vest pattern

Inspired by traditional

folklore vest pattern

wool is used for the

base of the costume

felted wool skirt with

pockets made of roots

with grass inside (sewn

on top)

headband - roots

furry barley roots

Beeswax mould

dried wheatgrass fringes

glued with beeswax

Color palette

CREATIVE PROCESS | Sketches & ideation

I used an electric sander to wet wool. This

method saved me a lot of time and allowed

me to work on larger pieces. To use it, I placed

the wool in between two layers of bubble wrap

or plastic and turned the sander on the lowest

setting.

WOOL BASE | Electric sander felting

45. Barbara Rakovská © 2024

AMBER GRAIN COSTUME | Materials, details

Raw wool - wet felting

Barley embroidery -

beeswax mould

Dried grass and fine

sheets

Needle felted pattern to

pressed sheet

Cultivated wheatgrass

structure in 3D printed mould

Felted wool sandals with

barley embroidery

Decorated double layer wool

fabric skirt

Barley embroidery decorated

belt with wheat pattern

Wheatgrass roots collar with

wheat pattern

Wheatgrass crown with felted

wool base

wool vest (wet felting) with

large embroidery grown in

beeswax mould

Heat-pressed roots with seeds laser

cut patterns curcuma natural dye

46. Barbara Rakovská © 2024

DECORATED DOUBLE LAYER WOOL FABRIC SKIRT

Barley embroidery -

beeswax mould

Simple wraping skirt

pattern

Needle felted pattern to

pressed sheet

Felted woolen fabric

Heat-pressed roots with

seeds laser cut patterns

curcuma natural dye

48. Barbara Rakovská © 2024

Wheatgrass crown with felted

wool base, collar, vest

Raw wool - wet felting

Cultivated wheatgrass

structure in 3D printed mould

Dried grass and fine

sheets

WHEATGRASS CROWN WITH FELTED WOOL BASE

Cultured patterns in 3D

printed PLA moulds

51. Barbara Rakovská © 2024

GUBA | Traditional coat of woolen

fabric worn in eastern Slovakia

52. GUBA | Coat of woolen fabric

The guba is a type of outerwear made of woolen fabric with a long pile on the surface, mostly worn by men but

sometimes by women. It has a simple straight cut with a cross seam at the chest, reaching below the waist, and

sometimes below the knees. The guba is draped over the shoulders and tied with a pair of woolen cords below the neck.

The neckline is roughly lined with red stitching. It is more commonly found in white, but can occasionally be found in

darker colors. The guba was traditionally worn in eastern Slovakia as part of everyday and festive winter clothing. It used

to be a compulsory garment for the groom until the beginning of the 20th century.

53. GUBA | Coat of woolen fabric, elements

Barley embroidery

Heat-pressed roots with seeds laser

cut patterns curcuma natural dye

Heat-pressed sample, laser cut patterns,

sodium alginate coating & indigo dye

Natural undyed brown & black

wool fibers - wet felted coat

54. The main advantage of bio-based materials within the

fashion industry is that they originate from renewable

resources and therefore enable resource-efficient

components. This, in turn, can reduce our environmental

impact and help mitigate the effects of climate change.

55. Barbara Rakovská © 2024

CONCLUSIONS

The project Amber Grain Embroidery incorporates a biodesign approach to fabricating textiles, aiming to support eco-

design and sustainable solutions in the fashion industry. As a designer, I act as a cultivator who collaborates with nature

to control and cultivate material properties. My primary focus is on researching innovative root-based materials by

experimenting with different grain seeds, growing media, patterns, and environments. The key principles of the process

involve planting appropriate seeds and allowing their roots to grow within a specific pattern or border. The material

weaves itself.

Specifically, I am cultivating textile-like materials from wheatgrass and barley seeds. Wheatgrass and barley grains are

ideal for root structures due to their dense fibrous root systems and fine root hairs that create binding friction. Through

this process, I have discovered various post-processing techniques, including coloring, altering flexibility, and applying

biodegradable coatings.

Currently, I am in the experimentation phase and I am seeking to elevate the development of the material to a more

professional research level. I have been conducting research on root structures from wheat and barley for a period of

three months at Fab Lab Barcelona @IAAC. Additionally, I have sought consultations from various experts, including

Robert Thompson, the Scientific Director of Materfad, who provided valuable advice on the potential direction of material

development. I would also like to thank the opportunity to consult with a team of researchers from Rootskin.

Root-based textiles are biodegradable, meaning they can naturally decompose at the end of their lifecycle, reducing

waste and pollution. This contrasts with synthetic materials like polyester, which can persist in the environment for

hundreds of years. These textiles offer opportunities for customization in terms of texture, color, and properties. By

adjusting growth conditions and processing techniques, manufacturers can create textiles with specific characteristics

tailored to various applications. In my opinion with ongoing advancements in biotechnology and material science, the

potential for innovation in this field is vast.

56. Barbara Rakovská © 2024

BIBLIOGRAPHY | PHOTOS | PICTURES

UNEP. (2023). “The Sustainable Fashion Communication Playbook”. (https://www.unep.org/resources/factsheet/sustainable-

fashion-communication-playbook)

Conserva, A; Demeur, F; Farinea, C. (2022). “RootSkin. From Soil to Soil” UOU scientific journal #04, 112-119.

Encyclopaedia Britannica (2021). “Root - Definition, Types, Morphology, & Functions”. (https://www.britannica.com/science/root-

plant)

Scherer D. Interview with Diana Scherer: Weaving roots at the interface between art, fashion and science. Plants, People, Planet,

2019;00:1–4. doi:10.1002/ ppp3.48

Symbio(s)cene (2021). “Interview: Zena Holloway” (https://symbioscene.com/interview-zena-holloway/)

Camere, S., Karana, E. (2018). “Fabricating materials from living organisms: An emerging design practice”. Journal of Cleaner

Production, 186, 570–584.

Rajabinejad, Hossein & Buciscanu, Ingrid-Ioana & Maier, Stelian. (2018). Current Approaches For Raw Wool Waste Management And

Unconventional Valorization: A Review. Environmental engineering and management journal. 18. 10.30638/eemj.2019.136.

Camere, S., & Karana, E. (2018). Fabricating materials from living organisms: An emerging design practice. Journal of Cleaner

Production, 186, 570–584.

Zhou, J., Barati, B., Wu, J., Scherer, D., & Karana, E. (2021). Digital biofabrication to realize the potentials of plant roots for product

design. Bio-Design and Manufacturing, 4(1), 111-122. https://doi.org/10.1007/s42242-020-00088-2

PICTURES

Rootskin: https://www.archisearch.gr/architecture/tab-2022-edible-or-the-architecture-of-metabolism-interview-with-lydia-

kallipoliti-and-areti-markopoulou-the-curators-of-6th-tallinn-architecture-biennale/attachment/14_image3-rootskin-by-chiara-

farinea-project-lead-ilaena-napier-project-researcher-fiona-demeur-andrea-conserva-mohamad-elatab-1152x1536/

InterWoven © Diana Scherer: (https://dianascherer.nl)

Holloway, Z. (2023). “Grown from Root : Woven by Nature” (https://zenaholloway.com/root/reef-dresses)

PHOTO & VIDEO (results): Petra Garajová, Lina Córdoba MODEL: Isabela Cotecchia