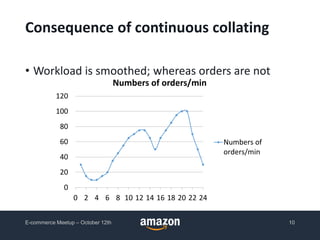

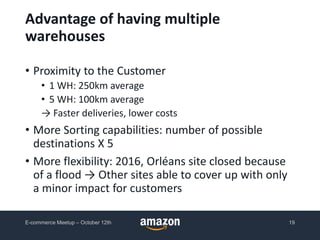

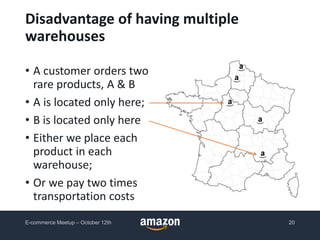

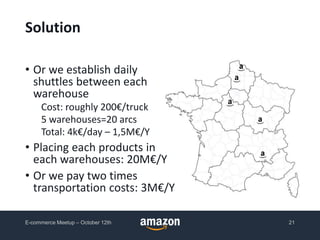

Amazon uses its extensive logistics network as a competitive advantage by optimizing warehouse operations and inventory placement. It operates multiple warehouses located closer to customers, allowing for faster delivery times and lower shipping costs. Amazon further smooths warehouse workloads and optimizes picking paths by allowing some disorder in inventory placement. This network will be expanded across Europe to provide faster pan-European delivery and buying power.