14 fundamentals vip

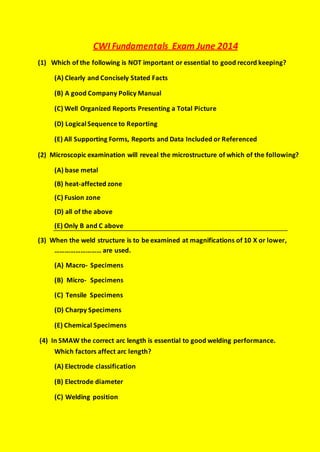

- 1. CWI Fundamentals Exam June 2014 (1) Which of the following is NOT important or essential to good record keeping? (A) Clearly and Concisely Stated Facts (B) A good Company Policy Manual (C) Well Organized Reports Presenting a Total Picture (D) LogicalSequence to Reporting (E) All Supporting Forms, Reports and Data Included or Referenced (2) Microscopic examination will reveal the microstructure of which of the following? (A) base metal (B) heat-affected zone (C) Fusion zone (D) all of the above (E) Only B and C above (3) When the weld structure is to be examined at magnifications of 10 X or lower, ……………………… are used. (A) Macro- Specimens (B) Micro- Specimens (C) Tensile Specimens (D) Charpy Specimens (E) Chemical Specimens (4) In SMAW the correct arc length is essential to good welding performance. Which factors affect arc length? (A) Electrode classification (B) Electrode diameter (C) Welding position

- 2. (D) all of the above (E) Only A and B above (5) The upper limits of preheat and interpass temperatures forquenched and tempered steel are specified forwhat reason(s)? (A) Keep deposit rate to a minimum (B) Maintain the strength in the base metal heat- affected zone (C) Keep the weld metal from becoming too strong (D) Avoid cracking in the weldment (E) Only B and D above (6) Which of the following processes can be used to join quenched and tempered steels? (A) SMAW (B) SAW (C) GMAW (D) all of the above (E) Only B and C above (7) Which of the following is/are recommended to prevent cracking in the welding low-alloy steel? (A) Controlling hydrogen content during welding (B) Using minimum required preheat and interpass temperature (C) Using grades with low carbon and alloy content (D) all of the above (E) Only B and C above

- 3. (8) In braze welding, flux may be applied by which of the following methods? (A) Using a filler rod pre-coated with flux (B) Introducing flux through the oxy fuel gas flame (C) Brushing the flux on the joint prior to brazing (D) Any of the above (E) Only A or B above (9) Plasma Arc cutting (PAC) is better suited than oxyfuel gas cutting (OFC) for cutting which of the following materials? (A) Ferrous Sheet Metal (B) Non Ferrous Metals (I.E., Aluminum, Copper, Brass, Etc) (C) Any Metals With A Thickness Over 5 Inches (D) Stainless Steel and Plate (E) A, B and D Above (10) Gas metal arc welding (GMAW) is suitable for what metals? (A) Carbon steel (B) Stainless steel (C) Aluminum (D) all of the above (E) Only A and B above (11) How should SMAWelectrodes be kept? (A) Sealed in their original container until ready for use (B) In the "gang" box (C) At 550 F (290 C) until the container is ready to be opened (D) at 350 F (175 C) until the container is ready to be opened (E) In open cans located around the job site ready for use

- 4. (12) the most extensively used weld inspection method is ---------. (A) UT (B) RT (C) MT (D) VT (E) PT (13) Hardness test method(s) for metal include(s) which of the following? (A) Rockwell (B) Knoop (C) Vickers (D) Brinell (E) All of the above (14) During Electroslag welding, how may cracks may be avoided? (A) Maintaining proper electrode feed rate (B) Maintaining proper current (C) Maintaining proper spacing between electrodes or guide tubes (D) all of the above (E) Only A and C above (15) A CWI s records may be used for which of the following? (A) To Help Recall and Verify Past Decisions (B) Used To Verify the Payment of Work Invoices (C) To Verify Man-HourRecords For the Shop (D) As Packing Slips for Shipping (E) All of The Above

- 5. (16) Which lens shade numberis recommended when oxyacetylene welding 16 gauge steel? (A) Shade # 4 or 5 (B) The same lens shade as recommended for submerged arc welding (C) Shade # 6 or 8 (D) Shade # 10 or 12 (E) Shade # 2 (17) Sensitization of stainless steel primarily refers to its loss of which property? (A) Strength (B) Toughness (C) Ductility (D) Corrosion Resistance (E) Impact Resistance (18) Which of the following are true regarding good inspection records? (A) They Record As Much Detail As Necessary. (B) They Include Explanation Of Repairers. (C) They State That The Work Stayed Within Press Prescribed Tolerances. (D) All of The Above (E) Only B and C Above (19) which of the following documentation shall a CWI have the responsibility of verifying? (A) Records of Welder Qualification (B) Records of Tacker Qualification (C) Records of Welding Operator Qualifications

- 6. (D) Records of Welding Procedure Qualifications (E) All of The Above (20) Which of the following is/are sometimes used to control distortion in a weldment? (A) Peening (B) Preheating (C) Fixtures and Stress Relief (D) Back Step Welding (E) All of The Above (22) An ultrasonic test of a plate shows a trace on the CRT with peaks as shown in figure 13. If the sweep is from left to right, the peak at (2) may indicate ------. (A) A Flaw at the Surface (B) A Flaw near The Center (C) A Reflection from the Back (D) A Flaw at the Back (E) There Is No Flaw Indicated On the Trace (23) The qualification of a CWI covers which of the following areas? (A) Specify Welding Procedures (B) Compute Allowable Stresses (C) Perform Radiographic Examinations (D) Conduct Tests for Analysis of Base Material Composition (E) None of The Above (24) The welding inspector must verify that --------. (A) All Record Are Completed By The Time Hardware Is Shipped Even Though They May Not Have Been Completed At The End Of The Operations.

- 7. (B) Record Of Qualification ,Certification ,Fabrication And Testing Are Complete And That They Meet Appropriate Code And /Or SpecificationRequirements Specified For The Job. (C) All the General Points Are Covered In Inspection, Since Detail Is Never Allowed In Such Reports (D) The Hardware Was Completed, And That The Shop Promises To Complete The Records Before Shipment. (E) That The Quality Manual Meets The Appropriate Quality System National Or International Standard For Welding Such As ISO 9000 Or GS 9000. (25) A CWI shall be familiar with and understand the fundamentals of what? (A) SMAW (B) FCAW (C) GMAW (D) GTAW (E) all of the above (26) During examination of a production weldment the inspector noted that discontinuity indications found by MT method were not found by PT method what does the indicate? (A) There Are No Flaws (B) The Discontinuities Are All On the Surface (C) The Discontinuities Size Are Too Small For PT (D) The Discontinuities Are Not Exposed To the Surface (E) None of The Above (27) Which of the following slows the rate of cooling in a weld bead? (A) Decreasing the Heat Input per Inch of Weld (B) Preheating the Weldment (C) Reducing the Electrode Size

- 8. (D) Increasing the Speed of Travel (E) Increasing the Amperage and Travel Speed Proportionally (28) Liquid penetrant inspection is used for detecting ---------. (A) Weld Undercut (B) Excessive Weld Reinforcement (C) Weld Discontinuities Open To The Surface (D) Short Fillet Weld Leg Size (E) Depth of Weld Penetration (29) The liquid penetrant applied to the surface of a test specimen (A) Flows into Discontinuities upon Application of Developer (B) Is Absorbed By Discontinuities (C) Is Drawn Into a Discontinuities by Capillary Action (D) Runs into Discontinuities by Gravity (E) Penetrates the Surface by Chemical Action (30) Which of the following should be true regarding inspection reports? (A) Clearly Written (B) Contain All Required Information (C) Readily Accessible (D) All of The Above (E) Only A and B Above (31) In GMAW, which of the following is the least affected by selecting shielding gas? (A) Electrode Extension. (B) MechanicalProperties. (C) Welding Speed.

- 9. (D) Metal transfer mode (E) Penetration. (32) In GMAW, which of the following is the greatest affected by selecting shielding gas? (A) Electrode Extension. (B) MechanicalProperties. (C) Welding Speed. (D) Metal transfer mode (E) Penetration. (33) Most influence on the shielding effectiveness of argon A. High Conductivity B. Low Cost C. High Density D. Ability to Form Plasma E. Higher Flow Rate (34) Low carbon steel is more weld ability than: (A) Stainless steel (B) High alloy steels (C) Only A & B (35) FCAW electrode classification uses the letter “ T ” (A) Tungsten (B) Tubular (C) Tantalum (D) Thorium (E) Titanium

- 10. (36) In GTAW Electrode Designation (ER) means that: (A) Electrode or Rod. (B) Electrode and Rolled. (37) Which of the following that may minimize slag - (A) Changing the Electrodes Types (B) Thorough Stag Removal between Passes (C) Proper Positioning Of the Joint (D) All of The Above (E) Only B and C Above (38) Which of the following is not considered soldering process? (A) Cold Soldering (39) Which of the following is not considered a factor when selecting a brazing filler metal? A. Base Metal Compatibility B. Joint Design C. Service Requirement D. Temp and Heating E. Position (40) The filler metals for GMAW are: (A) 36” (91.44 cm) cut length (B) Not consumables (41) The brazing differs from other welding Processes in that: (A) The base metals are not melted. (B) The melting temperature of filler metal is greater than 840F

- 11. (42) During Cutting or welding in confined spaces, where should gas cylinder and welding power sources be located? A. Close To Operator B. On Wheels C. In a Pick up Truck D. Outside the Confined Space E. In the Immediate Area (43) An advantage of plasma arc gouging overcarbon arc gouging A. Less Cost Equipment B. Less Grinding To Clean Up the Join C. Elimination of Carbon Pick Up Problem D. All of The Above (E) B & C (44) The most accurate regarding the selection of a filler metal of GTAW application A. GTAW electrodes are not consumed in the GTAW process B. AWS not specified the selection of filler metal in GTAW C. To match the properties of the base metal in the welded condition D. Reaction between filler metal and shielding gas is very important E. Because of tungsten, in GTAW process filler materials do not clean like other process (45) GTAW process a typical cause of tungsten inclusion A. Excessive Fit Up B. Insufficient Welding Current C. Straight Polarity Welding D. Contact on the Electrode Tip with the Weld Pool E. None of The Above

- 12. (46) GTAW can be used to weld most metals, which of the following is most useful A. Cast Iron B. Rein Forcing C. Heavy Steel Plate D. Thin Gauge Aluminium E. Galvanized Parts (47) A CWI records may be used A. To Help Recall and Verify Past Decisions B. Used To Verify Man-Hour Records For the Shop C. For Packing Slips for Shipping D. Used To Verify the Payment to Work Invoices E. All The Above (48) The function of the covering on a covered arc welding electrode is providing……… A. Shielding Gas Cover B. Protective Slag C. Deoxidized Weld Metal D. Arc Stabilization E. All of The Above (49) Why should the CWI keep accurate and up –to- date records and reports A. To Keep the Superintendent Informed B. To Impress the Chief Inspector C. So That He Can Write Better Procedures D. To Satisfy Governments Agencies E. To Assure Compliance with Standards and Specifications

- 13. (50) Brazed joints can be destructively tested by which of the following testing methods A. Metallographic B. Peel C. Torsion D. UT E. All of The Above (51) The destructive test samples may be used to determine notch toughness A. Drop-Weight Nil Ductility B. Charpy V C. Crack Tip Opening Displacement D. All of The Above E. A&B. (52) The hardness of a ferrous material…. A. Is the Ability to Withstand a Sudden Blow B. Is the Ability to Withstand Indentation. C. Cannot Estimated By a Bent Test D. Has No Useful Purpose To The Inspector. E. Can Be Measured By The Load Test. (53) The base metal next to the weld that has been heated to a sufficiently high temperature to cause a change in microstructure is the…. A. Tempered Zone B. Heat Affected Zone C. Untempered Zone D. Pearlite Area E. Base Plate

- 14. (54) The upper limits of preheat and interpose temperatures for quenched and tempered steels are specified for what reason(s)? A. Keep Deposit Rate to a Minimum B. Maintain the Strength in the Base Metal Heat Affected Zone C. Keep the Weld Metal from Becoming To Strong D. Avoid Cracking in the Weldment E. Letters B and D Above (55) The carbon equivalent unit is employed to predict the tendency to form which of the following: A. Lammelar Pearlite B. Upper Bainite C. Martensite D. Austenite E. Acicular Ferrite (56) The following slows the rate of cooling in a weld bead A. Pre Heating the Weldment B. Reducing the Electrode Size C. Increasing the Speed of Travel D. Decreasing the Heat Input per Inch of Weld E. Increasing the Same and Travel Speed Proportionally (57) For SMAW, which of the following requires higher preheat temperature? A. High Carbon Steels B. Low Hydrogen Electrodes C. High Strength Low Alloy Steels D. All of The Above E. A and C Above

- 15. (58) To find out all direction discontinuity in the weld by magnetic particle testing methods? A. Transverse Direction B. Longitudinal Direction C. Perpendicular Direction D. Parallel Direction E. Two Directions – 90 Degree Apart. (59) In comparison to surface cracks, the sensitivity of magnetic particle inspection to flaws1/4 – inch or more below the surface of a thick. A. Generally Much Less B. Approximately Equal C. Nearly Equal If the Flaws Are Fine Non-Metallic Strings D. Nearly Equal If the Internal and External Flaws Have Equal Widths E. Greater If The Flaws Are Located Near The Welds Axis And Ac Current Is Used. (60) Before commences of groove weld fit-up, the following variables need to check for an inspector. A. Planar alignment (Hi/Lo) B. Angular Alignment C. Groove angle. D. All of the above E. A & B (61) Which NDT method can be used to detect all of the following flaws /errors: wrong electrode, excessive travel speed, and /or improper edge preparations? A. Radiographic B. Visual C. Dye Penetrant D. Hardness

- 16. E. None of The Above (62) Which Non – Destructive testing is economicalfor find out tungsten inclusion in Aluminum welds. A. RT B. ET C. PT D. MT E. VT (63) The following are affects the sensitivity of P.T: A. Surface Condition of the Weld B. Application of Penetrant C. Post Cleaning of Developer D. A & B E. All of The Above (64) Which of the discontinuities is not commonly detected by RT? A. Undercut B. Porosity C. Lamination D. Slag (65) The factor which is most important to the reliability of a test is A. Ease of Conducting Test B. Cost of Required Equipment C. Reproducibility of Test Conditions D. Speed of Testing E. Portability of Equipment

- 17. (66) What should be known for proper interpretation of liquid penetrant indications? A. Previous Manufacturing Processes Performed On the Part B. Technique Used In Applying and Removing the Penetrant C. Method Used To Clean Part Prior To Inspections D. All of The Above E. None of The Above (67) During examination of a production weldment , The inspector noted that discontinuity indications found by the method were not found by the PT method. What does that indicate? A. There Are No Flaws B. The Discontinuities Are All On the Surface C. The Discontinuity Sizes Are Too Small For Pt Sensitivity. D. The Discontinuity Are Not Exposed To the Surface E. None of The Above (68) Prior to welding, a CWI should check A. If The Welding Procedures Qualified In Accordance With The Contract Spec. B. If the Weld Is Qualified For the Process and Position C. If the Joint Design and Joint Preparations Meet the Requirements Of The Welding Procedure D. The Inspection Requirements Called Out By The Contract Spec. E. All of The Above (69) What aspects of fabrication can be checked through visual inspection during welding? A. Proper Preheat B. Interpass Cleaning C. Filler metal controland handling

- 18. D. All of The Above E. A and B Above (70) Which of the following could interfere with liquid penetrant testing? A. An Oily Surface B. A Wet Surface C. A Rough Weld D. All of The Above E. Only A and B Above (71) Which of the following is an advantage of florescent penetrants over visible dye penetrants? A. The Inspection Can Be Carried Out In a Well-Lighted Area B. Small Indications Are More Easily Seen C. It Can Be Used Where Contact with Water Is Objectionable D. It Is Less Sensitive To Contamination of Discontinuities E. The Dye Requires No Vehicle or Solvent (72) At which of the following times should the CWI inspect to assure compliance with the welding procedure? A. Only During the Qualification Activity B. Prior To, During and After Production Welding C. When Requested To By the Welding Foreman D. Once each Job E. Approximately Every 6 Months.

- 19. (73) When should visual inspection be performed preferably to produce the most cost effective quality per specification? A. After Welding B. When the Foreman Tells You C. Prior to Welding D. During Welding E. A, C and D Above. (74) A traveler, or production plan, requires UT examination of the faying surface of a weld joint, the faying surface is described as… A. He Surface Of The Joint Which Will Be Ground Upon Completion Of Welding. B. The Face-Side of a Weldment C. The Surface of a Weldment Which Will Come In Contact With Any Other Surface D. B & C Above E. The Mating Surface of a member that Is in Contact With or In Close Proximity To Another Member To Which It Is To Be Joined. (75) Recommended method for prevent cracking in the weld of low alloy steels. (A) Using Minimum Required Preheat And Interpass Temp. (B) Using Grades with Low Carbon and Low Alloy Content. (C) Controlling Of Hydrogen Content during Welding (D) A & B (E) All of the Above. (76) In radiography, the image of a completely cracked weld on the film will (A) Appear as a fine dark high density transverse line. (B) Appear as a reasonably well-defined high density line. (C) Appear a fine dark high density longitudinal line. (D) Appear as a row of high density spots or dots. (E) A and C Above

- 20. (77) When a clerical mistake is made while completing an inspection report the inspector should. (A) Erase the error and fill in the correct information. (B) Cross out the error and supply the proper information (C) Cross out the error and supply the proper information, as well as initialing and dating the occurrence. (D) Attach a note to the report explaining the reason for the change (E) None of the above. (78) Equal thicknesses of steel, cast iron, aluminium, lead and copper are radiographer using the same exposure condition. Which martial will result in the darkest radiograph? (A)Lead (B)Steel (C)Aluminium (D)Copper (E) Cast iron (79) The marking of a rejected weld should: (A)be clear and understandable to all involved (B)Be made with a steel impression stamp. (C)Note the proper repair procedure (D)Always be in red (E) Always include the welder’s identification (80) The symbolin figure 1 requires: a. Field welding b. weld all around c. a fillet weld d. The use of shielded metal arc welding e. all of the above (81) The first operation required by the above symbolis: a. Ultrasonic Inspection of the Base Metal.b. Visual Inspection of Joint Preparation.c. Performance of Groove Weld. d. Performance of Back Weld. e. Back Gouging.

- 21. (82) The width of the cut produced during a cutting process is referred to as: a. Root Opening b. Kerf. c. Bevel d. Bevel Angle e. Chamfer (83) It is suspected that a GMAW weld was produced in an area where there was an excessive draft which non-destructive test would best reveal the internal discontinuities which may have resulted? a. PT b. MT c. RT d. UT e. None of the above (84) Acetylene becomes unstable when its pressure exceeds the value of: (A) 15 MPa (B) 15 Ksi (C) 15 bar (D) 15 psi (E) 15 Pa (85) The Figure below Shows Which Welding process: (A) SMAW (B) FCAW (C) ESW (D) GTAW (E) SW

- 22. (86) The SymbolShowConfigurates Of A (A) U-Groove Weld (B) Bevel Groove Weld (C) J-Groove Weld (D) Fillet Weld (E) Flare-V-Groove Weld (87) During welding, the amount of fumes produced depends upon which of the following: (A) Type of welding process (B) Type and Grade of Materials being welded. (C) Type of shielding gas used. (D) The Ventilation method used. (E) All of the above For Questions from 88 to 91 the Welding Symbols in the Figure Below (1) (2) (3) 1/2 4 - 6 1/4 (3/8) 3/8 (4/16) (4) (5) (6) 1/2 3/8 (7) (8) (9) 1/4 6 3/16 4 (10)

- 23. (A) 2 (B) 7 (C) 6 (D) 3 (E) 10 For Questions from 92 to 94 the Figure Below Applied (88) A Weld That Extends All Around the Joint Is Shown At Number (A) 9 (B) 4 (C) 7 (D) 3 (E) 8 (89) An Intermittent Fillet Weld Is Shown At Number (A) 1 (B) 9 (C) 4 (D) 7 (E) 6 (90) A plug Weld Indicating Depth of Fill Is Shown At Number (A) 6 (B) 3 (C) 7 (D) 5 (E) 8 (91) A groove Weld with Melt-Through Is Shown At Number

- 24. (92) The Profile of the Fillet Weld Shown On the Figure above a Discontinuity at No. 1 Known as What? (A) A Wagon Truck (B) A Toe Crack (C) Under Lap (D) Under Cut (E) Under Bead Cracking (93) The Profile Of The Fillet Weld Shown On The Figure Above A Discontinuity At No. 2 Known As What ? (A) Overlap (B) A Toe Crack (C) Over Fill (D) Under Cut (E) Toe Lamination (94) The Profile Of The Fillet Weld Shown On The Figure Above A Discontinuity At No. 3 Known As What ? (A) Macro fissure (B) Incomplete Fusion (C) Piping Porosity (D) Under Cut (E) Under Bead Crack (95) The SymbolIn The Figure Below Require What Type Of Testing ? PRT (A) Penetrant Testing On The Other Side Of Part (B) Proof Testing on the other Side of the Part (C) Penetrant Testing On The Arrow Side Of The Part (D) Proof Testing On The Arrow Side Of The Part (E) Penetrant And Radiographic Testing From Other Side

- 25. For Questions from 96 to 100 the Figure Below Applies (2) (3) (1) (6) (4) (5) (96) For The Weld In The Figure Above No. 1 Indicates The A) Beads B) Weld Root C) Weld Toe D) Face Reinforcement E) Weld Face (97) For The Weld In The Figure Above No. 2 Indicates The (A) Beads (B) Weld Root (C) Weld Toe (D) Face Reinforcement (E) Weld Face (98) For The Weld In The Figure Above No. 3 Indicates The (A) Beads (B) Weld Root (C) Weld Toe (D) Face Reinforcement (E) Weld Face (99) For The Weld In The Figure Above No. 4 Indicates The (A) Beads (B) Weld Roots (C) Weld Toe (D) Face Reinforcement (E) Weld Face

- 26. (100) For The Weld In The Figure Above No. 5 Indicates The (A) Beads (B) Weld Root (C) Weld Toe (D) Face Reinforcement (E) Weld Face (101) Which of the following is not considered a type of Joint : (A) Butt (B) T (C) Fillet (D) Corner (E) Edge (102) (103) When a weld joint preparation is found to be defective, the inspector: A. Should allow welding to proceed if he feels that the welder can produce a satisfactory weld. B. Should instruct the welder in how to overcome the problem. C. Report the deficiency to the proper supervisory personnel. D. Require that the parts be disassembled and properly assembled. E. None of the above

- 27. (104) Which of the following is an acceptable method for control of GTAW electrodes : a. Colour coding b. Alpha-numeric coding c. chronological arrangement d. location segregation e. none of the above For Questions from 105 to 106, the Figure below Applies (105) The weld in Figure No.1 above is said to be welded in the …….. (A) Flat Position (B) Horizontal position (C) Vertical position (D) Over Head position (E) None of the above (106) The weld in Figure No.2 above is said to be welded in the …….. (A) Flat Position (B) Horizontal position (C) Vertical position (D) Over Head position (E) None of the above (107) The weld in Figure No.3 above is said to be welded in the …….. (A) Flat Position (B) Horizontal position (C) Vertical position (D) Over Head position (E) None of the above

- 28. (108) If the prods shown in method # 2 of figure 10 are placed on the face (axis) of a groove weld {as shown in figure 10 (2)}, which of the following flaws would cause the clearest indication? (A) A Transverse Surface Crack (B) Lack of Fusion on the Root (C) A Plate Lamination (D) A Longitudinal Surface Crack (E) A Tungsten Inclusion (109) Which of the following documentation shall not the CWI have the responsibility of verifying? (A) Records of Welder Qualification (B) Records of Tacker Qualification (C) Records of Welding Operator Qualifications (D) Records of Welding Supervisors Qualifications (E) None of The Above (110) In the SMAW electrode designation E 309L , the No. 309 related to (A) Tensile Strength (B) Alloy (C) Operating Characteristics (D) Position (E) None of the above

- 29. (111) AS a CWI, when you are intended to use aprequalified WPS belongs to another Employer for your newer EmployerWhat the action you should take: (A) Take permission from the new employer to use that WPS. (B) Take permission from the old employer to use his old WPS. (C) You must qualify new WPS and use it instead. (D) You will use it directly without any permission from others, (112) The CWI can publically express an opinion on the welding inspection subjects in the condition of …………………………. (A)When talking about old information. (B)When talking about information seems to be facts. (C)When he is the consensus of the inspection department. (D) When taking legal permission. (113) Which of the following documents is considered to be Specific (A) Welder qualification Testing.(B) Performance Qualification Record.(C) Welding performance specification.(D) Welding Precedure specification. (114) People working adjacent to the welding areas can be protected from the radiant areas by : (A) Wearing sun glasses. (B) Using filters (C) Wearing protective clothes (D) Using Protective Screens. (115) The optimum air flow around the welder head during using a respirator for ventilation is preferred to be ……………………. (A) In the higher part of the welding place. (B) In the lower part of the welding place. (C) Longitudinally across the welding place. (D) Laterally across the welding place.

- 30. (116) The specification used to describe the welding symbols is (A) AWS 2.4 (B) AWS 3.0 (C) AWS 5.1 (D) AWS 1.0 (117) Gloves for welders (according to ANSI-Z49.1) shall be ……………………. (A) Dry. (B) Flame resistant. (C) Protective from electrical shocks. (D) All of the above (E) Only B and C (118) The problem most likely to be encountered by soldering process is (A) Weld dissimilar metals.(B) Weld thick plates. (C) Weld attachments to plates. (D) Weld metals of melting point lower than 840 F (119) The greatest limitation related to using Soldering processes is: (A) Lack of fusion of welds. (B) Great amount of spatter produced. (C) Contaminated or dirty surfaces. (D) High skills & performance required. (E) Used only for joining metals lower than 840 F (120) GMAW is essentially replaced for welding process ………………. In many applications. (A) GTAW (B) SMAW (C) FCAW (D) PAW (E) SAW (121) A welding inspector must be ethical primarily in order to …….. A. Insure That the Employer Receives Fair Value For Inspection Fees B. Render Impartial Decisions C. Reject Every Weld the First Time in Inspection D. Safeguard the Public’s Health and Well-

- 31. being E. B and D above

- 32. (122) Interpass cleaning should be verified to ……………………………. A. Avoid Subsequent Incomplete Fusion B. Avoid Porosity C. Avoid Welding Over Crack D. Ensure Slag Removal E. All of The Above (123) The sketch shows what mode of metal Transfer related to GMAW Process: (A) Pulsed arc transfer mode. (B) Spray transfer mode. (C) Short circuiting transfer mode. (D) Globular transfer mode. (E) Open circuiting transfer mode. (124) The sketch below is a specimen for : (A) Bend Test (B) Tensile Test (C) Charpy V Test (D) Neck Break Test (E) Macro Specimen Test (125) Whenever the use of respirator is required , what should be implemented: (A) Establish a program for proper selection and use of respirators.(126) The hardness of base metals is affected by : (A) Heat Treatment Applied. (B) Cold working of the base metals.

- 33. (C) Composition of the base metal and weld metal. (D) Metallurgical effects of the welding process. (E) All of the above (127)SMAW is less favorable than GMAW due to: (A) SMAW High productivity. (B) GMAW is portable. (C) SMAW deposition rate is considerably less. (D) SMAW produces less smoky atmosphere. (E) None of the above. (128) Technical accuracy of the welding procedure is responsibility of the : (A) The welding inspector. (B) The company man. (C) The Fabricator, the contractor, the manufacturer. (D) All of the above. (E) Only A & B (129) High quality with Arc Stud Welding can be obtained when : (A) Making test before starting. (B) Using sufficient power energy source. (C) High skillful operators are required. (D) All of the above. (E) Only A & B. (130)The sketch below is a specimen for : (A) Bend Test (B) Tensile Test (C) Charpy V Test (D) Neck Break Test (E) Macro Specimen Test

- 34. Important DrawingsShould Be Revised Well: