Cswip 3.1 qustion -1.pdf Azam Files

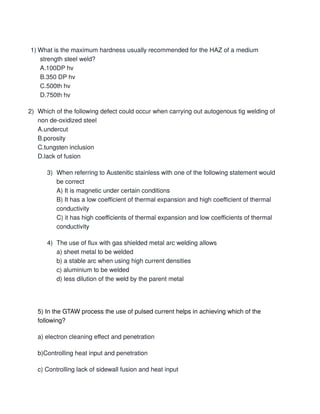

- 1. 1) What is the maximum hardness usually recommended for the HAZ of a medium strength steel weld? A.100DP hv B.350 DP hv C.500th hv D.750th hv 2) Which of the following defect could occur when carrying out autogenous tig welding of non de-oxidized steel A.undercut B.porosity C.tungsten inclusion D.lack of fusion 3) When referring to Austenitic stainless with one of the following statement would be correct A) It is magnetic under certain conditions B) It has a low coefficient of thermal expansion and high coefficient of thermal conductivity C) it has high coefficients of thermal expansion and low coefficients of thermal conductivity 4) The use of flux with gas shielded metal arc welding allows a) sheet metal to be welded b) a stable arc when using high current densities c) aluminium to be welded d) less dilution of the weld by the parent metal 5) In the GTAW process the use of pulsed current helps in achieving which of the following? a) electron cleaning effect and penetration b)Controlling heat input and penetration c) Controlling lack of sidewall fusion and heat input

- 2. d) Controlling spatter and penetration 6) Austenitic stainless steel not susceptible for HIC because? A ) they are magnetic B) they are stainless@ contain chromium C) they do not harden during heating@ cooling D they are highly ductile 7) In a fillet weld fracture test the specimen is broken with A. The fillet weld in tension B. The fillet weld in compression C. No specific method need to be adapted D. Suitable machining 8) What is the main purpose post flow function on TIG welding Machine? A. Avoid tungsten electrode contamination B. Cool the weld during solidification C Give the welder time to adjust the welding condition D. Purge the gas line

- 3. 9) A medium carbon steel weld should be inspected: a. as soon as it is safe to do so b. when the weld is finished c. 48hrs after the completion d. After NDT examination 10) The surface finish of the charpy impact specimen is: A .rough b smooth and surface ground c. turned in a lathe d. surface finish is not important 11) Which one of these joints would be more susceptible to lamellar tearing a. U butt b. Vee butt c. double vee butt d. compound weld 12) Which of the following is considered the main restriction of the radiography method of NDT The detection of planer defects oriented parallel to the beam direction

- 4. The range of material thickness it can be used for Can't be used for remote site work The range of material type it can be used for 13) The size and number of tack weld are a) An important consideration b) They are depend on the thickness and base material being welded c) For some material preheat may have to be used d) All of the above 14) Which of the following weld may be in an open corner joint? A. Plug weld B. Fillet Weld C. butt weld D. Any of the above 15) Solidification cracking takes place in carbon steels, a. after post weld heat treatment

- 5. b. In the base metal c. immediately after welding d. after a few hours 16)For all weld tensile test which of the following is true? 1. The specimen is rectangular in cross section 2. The specimen contains base metal and weld metal 3. The specimen is taken in the longitudinal direction 4. Specimen is taken in the Z direction 17) What is the greatest advantage of radiographic inspection over ultrasonics inspection a. can be done by anywhere b. can give you a three dimensional of the imperfection c. can be used on any material d. equipment is cheaper to purchase 18) Ductile brittle transformation of a welded specimen is affected by a. material composition b. welding heat input c. pre and post weld heat treatments

- 6. d. all of the above 19) Which standard is used for the basic requirement of visual inspection? a. BSEN 17637 b. API 1104 c. BS EN 7079 d. BS EN 4515 20) During welding sometimes the removal of residual stress are carried out by heat treatment. What typical heating range? a. 450*C B. 550-700*C C.700-800*C D.850-1000*C 21) An advantage of SAW process is that A. It can be used in the vertical down (PG) position B. Little or No ozone or UV Light is produced / emitted. C. It is not affected by arc blow D. It is not prone to solidification cracking

- 7. 22) The main problem with solution treatment of stainless steel is that A. Controlling the rate of temperature rise B. Controlling the cooling rate C. Length of the soak period D. High risk of distortion 23) Overlap influenced by? A poor welding technique B welding process C weld position D all of above 24) In welder qualification testing of 10mm plate, 2 roots and 2 face bends were tested, 1 root bend failed. What course of action would you follow? A. Accept those as 75% were acceptable, you are allowed one failure B. Two more root bend should be prepared and tested C. Two more root and 2 more face bends should be prepared and tested D. retest the welder

- 8. 25) When welding vertically up with MMA process weaving is sometimes restricted to 2.5 x electrode diameter, this restriction is mainly applied to A. reduce the overall width of the weld B. Limit the heat input into the joint C. reduce the no. of electrode in the joint D. Reduce the time require to finish the weld 26. What is the answer for the throat thickness of a % inch fillet weld is? 1) 27.5 mm 2) 24 mm 3) 13.3 mm 4) 12.5 mm 27. The main purpose of preheat? A. remove moisture B. remove hydrogen C.delay cooling rate D. improve fusion 28.The toes of the cap on a butt weld: a) Must overlap on the external surface of a pipe or plate by at least 1.5mm b) Must be grounded

- 9. c) Must never be grounded d) None of the above 29) When the carbon content of iron is reduced below 2% it is called A. steel B. gray iron C. white iron D. ductile iron 30) Stress relief is not helpful in one of the following cases. Which one? a. in improving resistance to stress corrosion cracking b. in dimensional stability after machining improving c. in lowering the peak residual stress d. in softening the steel 31) A recrystalization heat treatment is; a. used to improve the toughness of weld metal b. used to restore the ductility of the base material after bending and shaping c. another name for a post weld stress relief heat treatment d. is used to reduce the hardness of the HAZ 32) If submerged welding to be used to make butt welds, which would you be most critical of: a) The root gap tolerance b) The angle of penetration c) The root face width d) The gas cut finish

- 10. 33) In submerged arc welding, excessive arc voltage may cause? a) Excessive penetration b) Change in weld metal composition c) Narrow weld width d) Excessive bead profile 34) A welding process using equipment with a flat characteristic: (a) Will require a permanent or temporary backing to be pre placed on the root side of the welds (b) Has the advantage of being able to use any type or size of electrode (c) Is likely to be using an electrode less than 2 mm dia. (d) Is likely to be using an electrode more than 2 mm dia. 35) Which is the most commonly used isotope for radiographic examination of welds? A ytterbium 169 B iridium 192 36) A martensite grain structure: (a) Is always present in welds on steel (b) Is brittle grain structure (c) Is obtained when the preheat temperature exceeds 200*c (d) All of the above

- 11. 37) What is the UTS of a material? (a) The proof stress (b) The maximum load a specimen can withstand (c) The limit of proportionality (d) The point of plastic deformation 38) A MMA ELECTRODE IS DESIGNATED AS AN E 42 O R TYPE ACCORDING TO BS EN 499. WHAT DOES 42 INDICATE? A 40 JOULES AT A TEST TEMPERATURE OF 20°C B 42 % ELONGATION C 420 N/MM2 YIELD STRENGTH D 42 N/MM2 TENSILE STRENGTH 39) Welding a single V butt with laminations showing on the side wall may give rise to: (a) Lamellar tearing (b) Solidification cracking (c) Martensite (d) Undercut 40) You could determined that an electrode is cellulose by its A. BS 639 coding B.colour C.Trade name D.BS 499 coding

- 12. 41) On a single-V butt weld the distance through the center of the weld from root to face is called a.Reinforcement b.Penetration c.Throat thickness d. None of the above 42) The possible effects of having a travel speed too fast: (a) Low toughness, slag inclusions and undercut (b) High hardness, slag inclusions and a narrow thin weld bead (c) High hardness, excessive deposition and cold laps (d) Low toughness, poor fusion and slag inclusions 43) What does the 70 represent on a E7010 AWS classified electrode? a. 70 N/mm2 minimum U.T.S. b. 70 N/mm2 maximum U.T.S. c. 70,000 psi minimum U.T.S. d. 70,000 psi minimum yield strength 44) In TIG welding the nozzle is usually made: (a) Copper (b) Aluminum

- 13. (c) Ceramic (d) Copper / Zinc 45) Which material property has the greatest influence on distortion that occurs in welded joints? a. yield strength b. co-efficient of thermal expansion c. tensile ductility d. co-efficient of electrical conductivity 46) Which of the following materials has the poorest weldability? (a) Austenitic stainless steel (b) Martensitic stainless steel (c) Carbon manganese steel (d) HSLA steel 47) A fusible insert is: a. filler material placed in the weld joint before welding b. permanent backing strip c. the core wire in a manual metal arc welding electrode d. applicable only to bracing 48) Prod is used in which NDT process UT RT MPT VT 49) What five parameters would be checked when calibrating welding equipment for mechanized MAG welding:

- 14. (a) Joint set up, flux coating, polarity, travel speed and amps / volts (b) Amps / volts, WFS, gas flow rate, polarity and travel speed (c) Amps / volts, WFS, wire diameter, polarity and travel speed (d) Electrode stick out, WFS, amps / volts, polarity and wire diameter 50) In a transverse tensile test, brittleness would be indicated if........ A. there is a reduction in cross-section at the position of fracture B. the fracture surface is flat and featureless but has a rough surface C. fracture occurred in the weld metal D. the fracture face shows beach marks 51) A crack running along the centre line of a weld bead could be caused by......... A. use of damp flux B. lack of preheat C. arc voltage being too high D. weld bead being too deep and very narrow 52) What type of power source characteristic is required for manual welding? a) Constant voltage b) Flat Characteristic c) Drooping Characteristic d) Motor Generator 53) Which of the following discontinuities could be classified as a service induced discontinuity? (a) Fatigue crack (b) Porosity

- 15. (c) Machining tear (d) Lap 54) In EN 499, what does the number 50 represent in the following electrode classification? E 50 3 1Ni B 160 0 1 H5 a. a minimum of 50 N/mm2 yield strength b. a minimum of 500 N/mm2 tensile strength c. a minimum 50000 psi yield strength d. a minimum of 50000 psi tensile strength e. none of the above 55) High Phosphorous contents in carbon steels may cause: (a) Cold shortness (b) Hot shortness (c) An increase in ductility (d) An increase in malleability 56) In a tensile test, a brittle material would be indicated if the fracture surface? a) Shows reduction in size b) Is flat and featureless c) Breaks in the weld metal d) Breaks in the parent material 57) Austenitic stainless steels are more susceptible to distortion when compared to ferritic steels this is because: a. high coefficient, low thermal conductivity

- 16. b. high coefficient, high thermal conductivity c. low coefficient, high thermal conductivity d. low coefficient, low thermal conductivity 58) Which of the following butt weld preparations is most likely to be considered for the welding of a 6mm thick plate? a. Double-V butt. b. Asymmetrical double-V butt. .c. Single-U butt. d. Single-V butt. 59) One of the advantages of a multi-pass MMA weld is that it generally produces a: (a) High tensile strength (b) High degree of ductility (c) Coarse grain structure (d) Fine grain structure 60) An undesirable property of aluminium oxide residue, when welding is that it: a. Decrease weld pool fluidity. b. Requires more heat to melt it when compared to aluminium. c. Causes the welder to travel to quickly. d. The presence of the oxide makes aluminium impossible to weld. 61) When considering thermal cutting local hardening can be reduced by: a. Increasing the cutting speed. b. The use of propane as a fuel gas.

- 17. c. Pre heating the material to be cut. d. All of the above. 62) Welding procedures may require welds to be deposited at a controlled rate heat input. High heat input would: (a) Have poor profile (b) Have larger grain size (c) Have high hardness in the HAZ (d) Have low elongation properties 63) The need for pre-heat for steel will increase if: a. The material thickness reduces. b. Faster welding speeds c. The use of a larger welding electrode d. All of the above. 64) The important point of high temperature steels is that: (a) They can withstand creep failure (b) They may suffer re-heat cracking problems (c) They may suffer loss of toughness (d) All of the above 65) When a medium to high carbon steel is quenched: (a) It becomes malleable (b) Its hardness increases (c) It becomes ductile (d) The plasticity is increased

- 18. 66) When 2 different material types are welded together, the joint may be referred to as…….. a. a composite joint b. a transition joint c. a dissimilar metal joint d. either b or c 67) Which of the following can arise from copper inclusions in a ferrite steel weld? a) Weld metal cracks b) HAZ cracks c) Lamellar tearing d) Porosity 68) What is an active flux? (a) A material used to clean surfaces of the joint through continued chemical reaction (b) A material used to protect the molten weld pool during welding (c) A material used to aid fusion (d) All of the above 69) Which gas cannot sustain spray transfer in GMAW welding A.carbon dioxide B.argon C.Helium D.oxygen 70) Which of the following electrodes is classified to BS EN 499? a. E 38 3 R

- 19. b. E 6013 c. E 7018 - G d. E 51 33 B 71) The carbon content in low carbon steel is ? A...6 to 25 points of carbon B....25 to 50 points of carbon C...0.6% to 0.25% carbon D....6 to 25 and 0.6% to 0.25% carbon 72) Internal stress may lead too A....wrapping B....cold cracking C....hot cracking D....all of the above E....wraping and cold cracks 73) Segregation within an ingot maybe detect by which of the following technique A...ultrasonic B...Sulphur painting C....Visual examination D....all of the above 74) Low temperature heating giving rise to the small readjustment in the position of the atoms is known A... recrystallsation B... recovery C...grain growth D..aneeling

- 20. 75) If too great forging reduction is attempted in one operation may occur A...preferred orientation of the grains B....inadequate grain growth C...forging buts D.....forging laps 76) A Segregation is associated with the serious metallurgical defects A....non metallic inclusion B.....shrinking cavities C....hydrogen cracks D...non metallic inclusion and shrinking cavities 77) Which welding process produce the highest level of hydrogen? A. TIG autogenous B. MIG Solid wire C. FCAW D. MMA Basic electrode 78) MIG/MAG welding what would be affected if the CTWD was extended? a. amperage b. voltage c. inductance d. travel speed 79) Which of the following discontinuities could be as a primary processing discontinuity often found in cast material? (a) Fatigue crack

- 21. (b) Stress corrosion crack (c) Porosity (d) Lack of penetration 80) Which of the following steels is likely to be more susceptible to hydrogen cracking? a. Carbon equivalent of less than 0.25 %. b. Carbon equivalent of 0.35%. c. Carbon equivalent of 0.38%. d. Carbon equivalent of 0.43%. 81) Elements completed with other electron cell A...highly reactive B...inert C...metallic in nature D...high melting point metal 82) Which electrodes are very susceptible to causing porosity in the deposited welds if long arc employed? a) Basic b) Cellulosic c) Rutile d) None of the above 83) According EN 22553, if the symbol is on the identification line where does the weld go? a. On both sides b. On the arrow side c. Opposite arrow side d. It does not matter

- 22. 84) You are to oversee the arc welding of some machined fittings and find they are cadmium plated. Would you: (a) Permit it to proceed (b) Permit it to proceed with fume extraction (c) Stop the operation at once (d) Advise the welder to drink milk and proceed 85) According to AWS2.4 where does the symbol go for welding on the arrow side? a. Below solid line b. Above solid line c. Depends on the joint d. Always weld where the arrow is pointing 86) Many of the meters, instruments & controls on the machine are not welding machine are not working proper their calibration certificate are also out date. What will you do? a. Permit welding to proceed with no further action b. Use a MAP separate measuring instrument and permit welding c. Stop welding until corrective measures are completed to rectify the situation d. Being welding and then report to their management when time is available 87) which is solid state welding A...Saw B...MMA. C...GMAW D...Friction welding 88) A Bessemer converter is ?

- 23. A...method of producing cost iron B....method of producing pig iron C...method of producing wrought iron D...method of producing steel 89) A plug weld and a slot weld differ in which of the following a. a plug weld has a hole in one member b. a slot weld has a hole in one member c. a slot weld is an arc weld d. a plug weld is a friction weld 90) cathodic cleaning is used to remove ? a. sign waves b. oxides c. surface inclusions d. low melting point compounds 91) FOR CROSS-COUNTRY PIPELINES, WHICH TYPE OF MMA ELECTRODE REQUIRE THE USE OF A HOT PASS TECHNIQUE TO REDUCE THE RISK OF CRACKING A IRON POWDER B BASIC C CELLULOSIC D RUTILE 92) Solidification cracking occurs: a. in the HAZ b. in the weld metal c. use low hydrogen electrodes d. all of the above

- 24. 93) Asymmetrical weld symbols to EN 22553 are: a. The same side of the arrow b. Different each side of the arrow c. Show fillet weld only d. Show butt weld only 94) WHICH OF THE FOLLOWING MAY INCREASE THE RISK OF HAZ CRACKING WHEN WELDING THICK SECTION CARBON MANGNESE STEELS ? A SLOW COOLING AFTER WELDING B LOW MOISTURE CONTENT IN THE ELECTRODE COVERING C USE OF STEEL GRADE WITH A LOW CEV D USE OF A LOW HEAT INPUT 95) The welder have increased the electrode strike out length of the SAW set, what would be effect on the weld? A. No effect B. Weld width would be narrow C. Penetration will be increased D. The deposition rate will be greater if wire feed rate is increased also 96) If the heat input in the process is increases then which of following statement is correct ? A) toughness reduced & hardness increases . B) toughness increases & hardness reduces . C) toughness increases & hardness increases. D) toughness reduces & hardness reduces . 97) Which one of these test would most probably used for welder qualification on a plate butt weld using 13mm low carbon steel

- 25. A. CTOD B. Nick break test C. Fracture fillet test D. IZOD 98) Half life is a term used to describe A. The penetrating ability of a gamma ray source B. Half the time the gamma source will be usefull C. The time taken of the gamma source to reduce the strength by half D. Time of decay of an X ray tube 99) A CODE GIVES THE ACCEPTANCE STANDARD FOR EXSCESS WELD METAL “h” AS: H < 1mm + 0.1 b MAX. 5 mm WHERE “b” IS THIE WIDTH OF THE CAP. FOR WHICH OF THE FOLLOWING ALTUATIONS IS THE ESCESS WELD METAL ACCEPTABLE. A b=15 H=3.0 B b=22 H=3.0 C b=28 H=4.0 D b=40 H=5.4 100) How are the tack weld lengths during assembly and fit-up determined? A. By the welder as they have extensive knowledge B. As the welding specification will give minimum tack length requirement C. As the welding drawing will give the information D. As the specification weld do 101) Tensile test :- A - will give an indication of reduction in area B - will only show the elastic range

- 26. C - show how good the welder D - will determine the transition range 102) Which cutting method is described by the following statement? The arc is formed between the tip of electrode and the work place is requires special purpose electrodes with thick flux coatings to generate a strong arc force and gas stream A. oxy- fuel cutting B. manual metal arc gauging C. arc air gauging D. plasma arc cutting 103) Very high deposition efficiency electrodes (180%) have what disadvantages A. higher yield strength of weld metals B .higher level of hydrogen in the weld metal C. operation is limited to only some positions D. they produce very hard weld metals 104) Which of the following would you not need to check in a welding consumable store? a. the oven temp. b. Quarantine consumables c. Calibrations of the ovens d. the humidity 105) which of the following welding process uses a resistive heating system to achieve weld metal deposition??? 1.MMA 2.RESISTANCE SPOT WELD

- 27. 3.eLECTRO SLAG WELDING 4.FRICTION WELDING 106) The use of cobalt as an isotope would generally be used on a.thin plate b. tee joint c. plate thickness greater than 25mm d. none of these 107) Which of the following electrodes is the most likely to contain the largest quantity of combustible organic compounds? a. Basic b. Acidic c. Rutile d. Cellulose. 108) which of the following in a fusion weld usually has the highest tensile strength??? 1.weld metal 2.parent metal 3.haz 4.fusion zone

- 28. 109) When referring to TIG welding, the shielding gas could be; 1.ARGON+HYDROGEN 2.ARGON+HE. 3.ARGON+NITROGEN 4.ALL OF THE ABOVE. 110) Which electrode has highest recovery rate? 1. Rutile 2. Basic 3. Cellulosic 4. Iron powder 111) What destructive test would be required to ascertain the likelihood of crack in the HAZ of a weld a.nick break b.side bend test c.charpy impact d. macro test 112) What is the main cause of undercut is: a. current too low b.excessive travel speed c.excessive OCV d.excessive amps

- 29. 113) Voltage and amperage meter have been removed from MIG/MAG(GMAW) calibration invalid, the equipment should be a. quarantined b. only used for tack welds c. only used if validated d. monitored density by the welding inspector for amperage and voltage 114) Rutile electrodes are often sold packed in cardboard box covered with a plastic film, if upon you found they were damp and the ends were rusting what course of action would you recommended? A. Use them as a rutile electrode for only purpose welding B. Re dry at 120 degree C and issue to the shop floor C. Quarantine them D. Only use them for tack welding 115) Which of the following is most apt to render the post-emulsification test ineffective : (a) Too long of a penetrant time. (b) Too long of a developing time. (c) Too long of an emulsifying time. (d) None of the above. 116) Which of the following statements is true : (a) Oxygen-fuel gas cutting is essentially an oxidization thermal cutting Process. (b) Oxygen-fuel gas cutting is essentially a melting process. (c) The only fuel gas used is acetylene.

- 30. 117) In general it is not easy to mechanise the MMA welding process because : (a) Short electrode length, the control of the arc length and the process uses A flat characteristic. (b) Short electrode length, the control of the arc length and flux coverings. (c) The control of the arc length, stop start problems and short electrode length, (d) Flux coverings, short electrode lengths and relationship between amps And volts. 118) Clustered porosity found internally in the body of a C-Mn in the MMA welding is usually associated with a. poor inter pass cleaning b. the open circuit current being too high c. poor stop/start technique or damp electrode coating d. low open circuit voltage 119) High intensity energy beams are associated with which of the following welding process a. Laser b. Electron beam c. Plasma d. All of the above 120) Basic coated electrodes provided in standard packaging : (a) Are deep penetrating electrodes. (b) Should be heated prior to welding to obtain a low H2 content in the weld. (c) Should be heated to totally eliminate H2 in the weld. (d) Should not be preheated as this will detrimentally effect welding

- 31. 121) When MMA welding what will be the effect on the weld if the electrode was changed from DC +ve to AC a. None b. Lower depositon rate c. It would be lesser penetration or slight increase in deposition rate d. The arc would become unstable 122) A repair has been made using MMA on a double V butt weld on a 10 m diameter tank. The defect repaired was lack of penetration and it had been excavated with a disc grinder prior to repair. After repair it was determined that the wrong electrodes had been used. What action should the inspector take : (a) Have the repair area ground and re-repair. (b) Accept the work if the electrodes were the same flux type. (c) Heat treat the area. (d) Consult the senior inspector or welding engineer if the specification or Procedure does not cover the course of action. 123) The likelihood of brittle fracture in steel will increase with??? a) A large grain formation b)a reduction of in service temperature to sub zero temperature c)ferritic rather then austenitic steel d)all of above 124) How do you convert psi to N/mm2 : (a) Divide by 144.9. (b) Multiply by 25.4. (c) Divide by 14.7. (d) Multiply by 14.7. 125) A martensite grain structure :

- 32. (a) Is always present in welds on steel. (b) Is brittle grain structure . (c) Is obtained when the preheat temperature exceeds 200*c. (d) All of the above. 126) How many Mpa are equal to 1 N/mm2 : (a) 144.9. (b) 25.4. (c) 14.7. (d) 1. 127) If arc strikes are found on carbon steel ( C eq of .5% ), what undesirable grain structure may be present : (a) Perlite. (b) Martensite. (c) Bainite. (d) All of the above are undesirable grain structures in constructional steels. 128) Most metals expand when heated, the change in length is expressed as : (a) Thermal conductivity. (b) Modulus of elasticity. (c) Coefficient. (d) Yielding. 129) Name the fourth weld process crack which has a totally different formation mechanism to HICC (H2 induced cold crack),solidification cracking and lamellar tearing : (a) Liquation cracking.

- 33. (b) Reheat cracking. (c) Crater cracking. (d) Hot tearing. 130) A welder qualified in the PG position would normally be qualified for welding : (a) All diameters of pipe. (b) Welding positions PA,PG, and PF. (c) In position PG only. (d) All pipe wall thickness. 131) The welder has increased electrode stick out length of the SAW set, what would be the effect on the weld a. No effect b. weld width would be narrow c. penetration will be increased d. deposition rate would be greater if the wire speed rate is also increased 132)Which heat treatment methods can be applied to a material to give maximum toughness? A. Normalising B. Tempering C. Annealing D. Both A & B 133)Which of the following materials is considered to be the easiest to weld ? a. mild steel b. medium carbon steel c. martensitic stainless steel

- 34. d. forging steel. 134)Which of the following best describes a semi automatic welding process : (a) The welder is responsible for the arc gap and travel speed. (b) The welder is responsible for the travel speed only. (c) The welding plant controls both travel speed and arc gap but under Constant supervision. (d) The welding plant controls both travel speed and arc gap, no Supervision required. 135)What action must the welding inspector request if a lamination is found extending into the bevel face : (a) Cut back the material until a lamination free area is found. (b) Accept the bevel unless the lamination exceeds 5mm. (c) Place a sealing run over the lamination and dress flush, then make the weld as normal. (d) Action to take will depend on the agreed specification (or welding engineer / client if specification does not state the action ). 136)Which arc welding process technique is likely to be used to repair localised porosity in a weld : (a) MMA (b) Mechanised arc welding. (c) Sub Arc. (d) All of the above 137)E6013 electrode would most probably used for welding. A. Low pressure pipe work. B. High pressure pipe work.

- 35. C. Vertical down welding on storage tank. D. In a situation when low hydrogen welds are specified. 138)which of the following is applicable if the heat input is high during a deposition of weld metal using the MMA process A.low toughness B.high susceptible of hydrogen entrapment C.high hardness D.high susceptible of lack of fusion 139)The fusion Boundary of a fillet weld is the : A . Boundary between the weld metal and HAZ . B . Boundary between individual weld runs . C . Depth of root penetration . D . Boundary between the HAZ and parent material. 140)Which of the following welding process uses a resistive heating system to achieve weld metal deposition a. MMA b. Resistant spot welding c. Electro-slag d. Friction welding 141)Which of the following could contribute to distortion:? A. Internal porosity. B. Incorrect weld pass sequence. C. Slag inclusions. D. Inadequate root face.

- 36. 142) Which of the following defects will have more severe effect on the load bearing condition? a. Undercut b. Incomplete filled grove c. Irregular width d. Excess penetration 143)Which of the following would require highest preheat if all other factors were same? A. MMA weld with Cellulosic electrodes B. MMA weld with Rutile electrodes C. MMA weld with Basic electrodes D. MAG weld with solid wire 144)Why would visual inspection of the excess weld metal at the bottom of the cross country pipeline be important? A. Its the most difficult area to weld B. Its the difficult part of pipe as it is near the ground C. Welder always forget to weld at bottom D. Its most difficult area to radiograph 145)Shrinkage stresses are greater when welding metals that have A. a high coefficient of thermal expansion B. no restraint C. a low coefficient of expansion D. a high melting point 146)Which of the following is normally true?

- 37. a. Impact energy is specified in N/mm2 b. Heat input is specified in KI/mm2 c. Yield strength specified in N/mm2 d. Diffusible hydrogen in ml 147)SAW in single pass weld will give : (a) Poor profile. (b) Burn rapidly. (c) Good penetration. (d) None of the above. 148)When comparing properties of plain carbon steel and authentic stainless steel following measurements true? a. Carbon steel have better thermal conductivity b. Stainless steel have low expansion and contraction c. Carbon steel have higher expansion rate in the Z direction d. Stainless steel have lowest chromium 149)What are the possible results of having a too lower heat input (a) An increase in hardness, lower yield strength and lack of fusion. (b) A reduction in toughness, hydrogen entrapment and an increase in hardness. (c) Entrapped hydrogen, an increase in hardness and lack of fusion. (d) Entrapped hydrogen, a reduction in carbon content and lack of fusion. 150)Which of the following may be classed as liquation material to steel A.copper B.sulphur C.zinc

- 38. D.all of above 151)Preheating may not be necessary during welding in which of the following cases a. Welding of cast iron b. Welding of low alloy steels c. Welding of Manganese steels d. Welding if austenitic stainless steels 152)The nick break specimen is removed. A .longitudinal with the weld axis B.transverse with the weld axis C.from all weld metal D.by machining 153)Carbon dioxide shielding is NOT suitable for MAG Welding of Austenitic stainless steel a. Carbon di oxide is heavier gas b. Carbon dioxide is an active gas c. Heat content of these gas is very high d. There is insufficient gas coverage 154)A visual examination after welding will reveal which of the following A. overlap B. under bead cracks C. weld inclusions above the hot pass D. internal porosity

- 39. 155)In SAW process if voltage and current is increased and travel speed is decreased,What will be the effect in the profile : (a) Wider weld. (b) Higher weld reinforcement. (c) Concave weld surface. (d) Both a and b 156)What is mean by terms of duty cycle? a. How long a welder can weld in given period b. The amount of time the electrode being is used. c. The amount of time welding machine can be used. d. The amount electricity being consumed 157) which of the following influence the amount of distortion on a component during and after welding A.heat input B.lack of restraint C.material properties D.all of above 158) In a single pass weld, which of the zone in which longitudinal residual stress are tensile is, a. Independent of the weld width b. Narrow then the weld metal c. Same width as weld metal d. Wider than the weld metal and HAZ 159) What is the problem with restraint resistance during welding A.it does not a problem

- 40. B.it may lead to cracking,especially with small welds between large component C.it cause distortion D .restraint is term not used in relation to welding 160) In general thicker materials required higher pre heat temperatures, but for a given CEV and arc energy heat input, they are likely to remain similar for wall thicknesses up to approximately a.10mm b.20mm c.40mm d.50mm 161) Post flow function in TIG welding is A.Avoid tungsten contamination B.cool the weld during solidification C.give welder time to adjust welding condition D.purge the gas line 162) Which of the following is applicable to electrode efficiency? A.the mass of metal deposit as a percentage of the mass of the core melted B.iron powder electrode have efficiency above 100% C.electrode of high efficiency tend to produce weld of a smooth flat profile D.a and b E.all of above 163) Chromium, when added to steel as an alloying element, has the effect of making the alloy more: a. Ductile. b. Plastic.

- 41. c. Hardenable. d. Malleable 164) Submerged Arc Welding utilises A. Deep penetration characteristic B. High deposition rate on DC+ve C. Flat PA welding only. 165)Which of the following AWS A5.1 electrodes has a rutile covering:? a E 6010 b E 7016 c E 7018 d E 6013 166) When a longitudinal load is put on a lap joint, the stress set up is normally: a. Shear stress. b. Tensile stress. c. Compressive stress. d. Residual stress. 167) when using the GMAW process for aluminium the liner should made of A.nylon B.graphite C.steel. D.teflon 168) Which electrodes are very susceptible to causing porosity in the deposited weld if long arc employed

- 42. A.basic B.cellulosic C.rutile D.all of above 169) A lack of root penetration difference from a lack of root fusion defects in which of the following respects A. they are the same and do not different B. lack of root penetration shows two straight edges C. lack of root fusion shows one straight edges D. both b & c are true 170) Which is the following may increase the risk of HAZ cracking the welding in carbon manganese steels A. slow cooling after welding B. low moisture content in the electrode covering C. use of a steel grade with a low CEV D. use of a low heat input 171) To BS EN ISO 15607 an essential variable influences the A. the amount of skill the welder has B. mechanical properties of the joint C. quality of the joint D. mechanical & metallurgical properties of the joint 172) A weld joint between dissimilar material types is known as A. homogenous weld B. mismatch weld

- 43. C. transition weld D. compound weld 173) What is main difference between EN and ASME Welding procedures A. NDT requirements B. bends requirements C. tensile requirements D. visual acceptance 174) Which one of the following codes/ standards is not a qualification code? a. ASME section IX b. AWS D1.1 c. EN ISO 15614 d. ASME B31.3 175) Arc welding of some machine fittings are found to be cadmium plated. As a welding inspector you should.. A. Permit to proceed B. Permit to proceed with fume extraction C. Stop the operation at once D. Advice welder to proceed after some time 176) The similarities b/w BS EN 22553 and AWS 2.4 welding symbols are A. Both having same rule for depicting weld all around B. Both having same rule for depicting other side C. Both having same rule for depicting sequence of operations D. Both having same method for depicting welding process

- 44. 177) In fusion weld which of the following has the highest tensile strength? A.Weld metal B.Parent metal C.Heat affected zone D.Fusion Zone 178) Stray arc are undesirable since they: a. Leave a poor surface finish. b. Cause weld metal cracking. c. Reduce corrosion resistance. d. Cause local hardening and cracking in the parent material. 179) Which material is most susceptible to re-heat cracking? A. High carbon steel B. Killed steel C. Creep resistance steel D. Austenitic stainless steel 180) If magnification is used for visual inspection in according with BS EN ISO 17637 it should be magnified how many times A.5 - 10 B. 2-5 C. 2-10 D. as many as required finding the defects 181) What does the term high frequency mean when referring to TIG welding? A. a high integrity weld is easily achievable

- 45. B. the power source gives a high duty cycles C. a high voltage spark is used to initiate the arc D. the output from the power source is high 182) Which would be general the least angular distortion when welding a 50 mm thick plate A. single v preparation using MMA B. single v preparation using MIG C. square edge open butt using electro slag welding D. single u preparation using submerged arc welding 183) solidification cracking takes place in carbon steels, a. after post weld heat treatment b. in the base metal c. immediately after welding d. after a few hours 184) Which of the following NDT method could be used on fillet weld on aluminium A.DPT B.UT C.RT D.MTI 185) An amount of which of the following element is positively required to make steels stainless? A. carbon B. manganese

- 46. C .boron D. chromium 186) Cast and helix are terms that refer to : a. Ingredients in the flux covering b. Bead deposition techniques for distortion control c. Quality of the welding wires d. Sources from which wires are drawn 187) Toe blending is important as it may affect. 1 corrosion 2 fatigue life 3 over lap type defects 4 all of the above. 188) The soak temperature specified by code depend on the type of steel, low alloy steels (such as cr-mo steels used for elevated temperature service) require temperatures typically in the range of A.700 - 960 c B.900 - 1100 c C.600 - 650 c D.700 - 760 c 189) The surface finish of the charpy impact specimen is: a. Rough b. smooth and surface ground c. turned in a lathe d. surface finish is not important

- 47. 190) You find several unacceptable welds and reject them the welding supervisor indicates they are acceptable be signs then off and request NDT what action would you take. a.nothing as be is a welding supervisor and knows a great deal above b. Raise the issue with the QC department supervisor c.it is not my problem us be has signed them off so i will not be blamed d. Look at the NDT results and if they know reasonable I would accept them. 191) When referring TIG welding the shielding gas could be A.argon+hydrogen B.argon+helium C.argon+nitrogen D.all of above 192) In the GTAW process the use of pulsed current helps in a achieving which of the following? a. electron cleaning effect and penetration b. controlling heat input and penetration c. controlling lack of sidewall fusion and heat input d. controlling spatter and penetration 193) In MIG/MAG welding which mode of transfer is referred to as non-desired? a. dip b. pulse c. spray d. globular

- 48. 194) In GMAW, MIG/MAG welding which mode of metal transfer uses frequencies in cycle time A. spray transfer B. pulse transfer C. dip transfer D. globular transfer 195) On cross country pipe line, to ensure the root defects of the same, which NDT method to be suitable to be carried out a) Radiography testing b) Ultrasonic testing c) Magnetic particle testing d) a and b 196) When welding with GMAW a typical mixture of gas for stainless steel would be A.98%argon + 2% oxygen B.60%argon+40% oxygen C.80%argon +20%carbon di oxide D.9%nitrogen+91%carbon di oxide 197) Very high deposition efficiency electrodes (180%) have what disadvantages A. higher yield strength of weld metals B .higher level of hydrogen in the weld metal C. operation is limited to only some positions D. they produce very hard weld metals 198) The welding position usually positioning the greatest risk of fumes inhalation is A. horizontal/vertical (PC)

- 49. B. vertical up (PF) C. down hand (PA) D. overhead (PE) 199) Low alloy steels having a high carbon equivalent before welding will require: a. A reduction in carbon content. b. High pre-heat temperatures. c. Low pre-heat temperatures. d. No pre-heating 200) A martensitic transformation takes place in plain carbon steels only A. when the material is cooled sufficiently rapidly B. when the carbon content is sufficiently high C. when there is a formation of austenite D. all of the above 201) Loss of ductility is often one of the reasons for a hydrogen crack to occur. What will happen to ductility we increase tensile strength? a. Ductility will be greater b. Ductility will not change c. ductility will be less d. Ductility is tensile not affected by tensile strength 202) A nick break test reveals defects in the: a. heat affected zone b. the weld metal c. the parent metal d. all of the above

- 50. 203) An eutectoid mixture in steel is: a. A mixture of ferrite and austenite. b. A mixture comprising a substitutinal solid solution. c. Called pearlite. d. Called ledeburite. 204) In acccordance with BS 2901 which of the following is classified as tripple deoxidised filler wire?? a)17 wire b) 18 wire c) 15 wire d)all 205) A welder is working on PA, which mechanical test get affected when he changes to PF ?? A. Tensile test B.Hardness test C. Impact test D. All 206) What destructive test would be required to ascertain the likelihood of cracking in the HAZ of a weld? a. Nick break b. Side bend test c. Charpy impact d. Marco test

- 51. 207) When open site working, serious porosity in metal arc welds is brought to your attention. What would you investigate? a) Electrode type b) Electrode storage c) Day temperature d) Power plant type 208) Which of these test would normally be used for welder qualification on plate butt weld using 13 mm low carbon steel? 1.CTOD 2.Nick break 3.Fracture fillet 4.IZOD 209) Degreasing components are essential for quality welding,when welded some agents may; A. Cause corrosion problems B. Leave residues C. Give off toxic gases D. All of the above 210) Hot cracking a) In steel weldments occurs along the fusion line. b) In steel weldments occurs in the last metal to soldify c) In steel weldments only occurs weld center line. d) In steel weldments occurs in areas of the lowest dilution. 211) What is an active flux?

- 52. (a) A material used to clean surfaces of the joint through continued chemical reaction (b) A material used to protect the molten weld pool during welding (c) A material used to aid fusion (d) All of the above 212) Radiography testing: a) lack of root fusion would most likely show up as dark straight line with a light root b) lack of root fusion would most likely show up as a dark root with straight edges c) lack of root fusion would most likely show up as a dark uneven line following the edge of the root d) lack of root fusion cannot be seen on a radiograph. 213) Which of the following additions may be added to an electrode's flux to act as a stabilizer? a) Sodium silicate b) Silicon c) Manganese d) Titanium dioxide 214) What is the main purpose of microscopic examination of a weld a.to determine the number and type of defect present. b.to determine the grain size. c.to determine the strength of weld d. both a and b e. all of the above 215) If a steel has a Cev of 0.48%:

- 53. (a) PWHT would always be necessary (b) It will probably require a pre-heat temperature above 300*C prior to welding (c) It will probably require a pre-heat temperature above 100*C prior to welding (d) The heat affected zone will be very tough 216) The hardest part of a multi-pass welded joint, assuming no post weld heat treatment has have taken place is : a. The HAZ of the cap b. The HAZ of the root c. The root d. The cap 217) Which of the following welding process is not as classed as arc welding process? A.electro slag welding B.thermit welding C.plasma welding D.a and b E.all of above 218) Which of the following elements if present in significant quantities in steel may lead to cold shortness a. Sulphur b. Phosphorus c. Silicon d. Copper 219) E6014 electrode would most probably used for welding

- 54. a. Low pressure pipework b. High- pressure pipework c. Vertical down welding on storage tanks d. In a situation where low hydrogen welds are specified 220) Which of the following flame types would you expect to be used for the cutting of mild steel? a. Carburising flame b. Oxidizing flame c. Reducing flame d. Neutral flame 221) What welding process is 136 stands for? a. fcaw b. mig/mag c.mma d.saw 222) when welding procedure may not be valid in PA position,if the welding is done in PF position, if a) No NDT is carried out. b) Tensile strength are specified, c) Impact strength are specified. d) No PWHT is carried out 223) Cellulose electrode are often used for the deposition of a root pass on pipes welded in the filled this is because? a.hydrogen control is required. b.the high deposition rate due to the iron powder content.

- 55. c.the hydrogen gas produced in the flux increases the arc voltage. d.all of above. 224) In accordance with BS 5135 which of the following is applicable for scale “C” with regards to hydrogen content per 100g of deposited weld metal? (a) > 15 ml (b) > 15 ml < 25 ml (c) > 10 ml < 15 ml (d) > 5 ml < 10 ml 225) Which of the following defects would show up as light indications on a radiograph? a. Slag inclusions and copper inclusion b. Tungsten inclusions and excessive root penetration c. Cap undercut and root piping d. Excessive cap height and incomplete root penetration 226) Cellulose electrodes have which of the following properties? a. Viscous slag, large volumes of shielding gas and UTS values above 90,000 PSI b. Large volumes of shielding gas, hydrogen contents>15 ml per 100g of weld metal deposited and should be never baked c. Large volumes of shielding gas, high spatter contents and hydrogen levels < 15 ml per 100g of weld metal deposited d. High spatter contents ,high deposition and large volumes of gas shield 227) When ac only is required for welding, the power supply unit is almost always: (a) A transformer, rectifier and a means to change the current (b) A transformer, inverter and a means to change the current (c) A rectifier, alternator and a means to change the current

- 56. (d) A transformer or alternator and a means to change the current 228) Which of the following statements is true when using a flat characteristic power source? (a) The electrode is always dc –ve (b) The shielding is always pure argon (c) The wire feed speed remains constant (d) The electrode extension will have no effect on weld quality 229) When welding a double V butt joint with SAW process the presence of centerline porosity may be due to: (a) Damp flux (b) Contaminated joint preparation (c) Incorrect stick out lengths (d) All of the above 230) In accordance with BS 5135 what is the recommended minimum time allowed for the pre heat temperature to equalize? (a) 2 Min for each 25 mm of parent material thickness (b) 5 Min for each 25 mm of parent material thickness (c) 2 Min for each 50 mm of parent material thickness (d) 5 Min for each 50 mm of parent material thickness 231) Which of the following units is used to express heat input? A.joules B.N/mm2 C.J/mm2 D.KJ/mm

- 57. 232) Defects outside of the limits specified in a standard should always be.... a. repaired b. reported to a senior person c. assessed along the with other defects d.all of the above 233) Which of the following is applicable of the heat treatment process of normalizing C-Mn steel A.it always carried out below the lower critical limit B.it is carried out to ensure the material has maximum tensile strength C.it is carried out to ensure the material is to maximum ductility and malleability in preparation D.it is carried out at approx. 910C for the purpose of grain refinement 234) An transverse tensile test from a weld procedure approval record test plate is used to measure a. the tensile strength of the weld b.the tensile strenth of the joint c.the stress strain characteristics of the weld d.the stres strain characteristics of the joint 235) An austenitic stainless steel may suffer: a. weld decay b. sensitisation c. solidification cracking d. all of the above 236) Which of the following is the odd out? (a) Neon

- 58. (b) Xenon (c) Argon (d) Nitrogen 237) What kind of steel is used for making filler rod? (a) Killed steel (b) Rimming steel (c) Carbon steel 238) Welding process that use flux are sometime considered to be better than non fluxed processes because A.fluxes may be dried to give low hydrogen level B.fluxes may have higher tolerance to surface contamination C.they are good for welding good reactive metals D.all of above 239) What is the maximum allowable HI/LO for 8 mm thick material if the following is applied.Linear misalignment is permissible if the maximum d A. 0.8 mm B.2 mm C. 8.0 mm D. it cannot be sentenced as an other side is shown by the symbol 240) Which of the following abbreviations is the odd one out? A.GMAW B.MMA C.SMAW

- 59. D.GTAW 241) Which of the following electrode coding in BS EN E50 3 1NI B 140 0 1 H5,what does the 3 represent A.a minimum charpy value of 30 joule B.a minimum impact value of 47 joule C.a minimum impact temperature of -30o C at a given joule value D.none of the above 242) what would be the effect in haz if the heat input use higher than specified in wps. a. longer haz b. wider haz c. deeper haz d. narrow haz 243) what element have in tig electrodes a. iridium b. silica c. cerium d. titanium 244) When MIG welding aluminum alloy in the overhead position which current type would be expected to be used. 1. AC 2.DC -ve 3.Drooping 4.DC +ve

- 60. 245) which of the following test would you normally expect a test house to use for the assessment of HAZ hardness, for procedure approval in the uk. 1. Rockweel 2.CTOD 3.Brinel 4. Vickers 246) what type of welding covering will an electrode have that is suitable for welding 60mm C-Mn steel and can give good weld metal toughness at -50 degree centigrade. 1. rutile 2.basic 3.cellulose 4. choice will depond on the welding position 247) How many temperature indicating crayons would be required to ensure the pre heat temperature was lying with in a specified range. a.1 b.2 c.3 d. as many as possible 248) When welding low carbon steel with GMAW process on dip transfer,one purpose of the inductance control is to reduce A.spatter B.lack of fusion C.porosity D.cold lap

- 61. 249) The HAZ associated with a fusion weld on steel has up to how many separate region of micro structure. a.4 b.6 c.1 d.2 250) Ultrasonic testing is preferable to radiographic testing due to a. Ability to find all defects b. Lower amount of operator skill required c. Ability to detect laminations d. None of the above