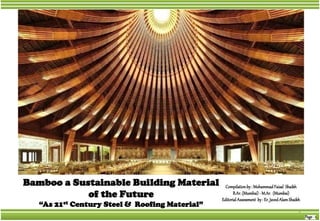

Bamboo as a sustainable building material of the future

- 1. 1 Compilationby : MohammadFaisal Shaikh B.Ar.(Mumbai)- M.Ar. (Mumbai) EditorialAssessment by: Er. JavedAlamShaikh Bamboo a Sustainable Building Material of the Future “As 21st Century Steel & Roofing Material”

- 2. 2 Page 01 Bamboo the “ GREAT WILD GRASS ” Bamboo has been regarded as a sacred species from the time immemorial. Its very nature symbolizes growth, grace, patience, strength, flexibility, endurance and longevity has been woven not only physically but also Meta physically over the livelihoods of people throughout the ASIA. Is Bamboo the Sustainable Building Material of the Future ? One of the biggest benefits, and the reason why bamboo be the material of the future, is its sustainability. It’s technically a wild grass and there are more than 1000 species growing unimpeded in tropical regions. Bamboo can support heavy loads plus it is flexible and earthquake-resistant. Bamboo can be a very sustainable crop , a fast growing grass, it requires no fertilizer and self- regenerates from its own roots, so does not need to be replanted Bamboo is really exceptional green building material. It is a sustainable material that requires very less to energy to nurture, restrain soil erosion, supplies bio fuel, extend wildlife refuge and manufacture a wholesome food source for both humans and wildlife. What are the Advantages of bamboo in construction? One Its elasticity allows it to weather storms and earthquakes that would break or crumble other building materials. Due to the high composition of water and silicate acid bamboo has natural fire resistance. It can withstand temperature up to 400 degree Celsius. Bamboo is making its mark in architecture with better then ever strengths, shooting up and above. With the great green draught throughout the world and the need for sustainability spikes Bamboo is now becoming popular material for architect working on humanitarian projects in ASIA and beyond, owing to its sustainable nature, low cost, strength, and flexibility.

- 3. 1. Abstract 2. Introduction 3. Bamboos 4. Distribution of bamboos 5. Properties of bamboos 6. Properties of bamboos 7. Comparison between steel and bamboos 3 8. Selection and preparation of bamboos 9. Construction principles 10. Roofing with bamboos 11. Advantages of bamboo as structural member 12. Disadvantages of bamboo as structural member 13. Conclusion 14. References

- 4. 4 In recent years, steel prices have soared. For developing countries, steel is difficult to obtain because of expensive prices, and for the construction industry, usage of steel is currently limited heavily. The production of steel has high consumption of fossil fuels, so, the steel discharge in the construction of structures has been presented, showing the possibility of drastic reduction by research institutes. Meanwhile, for developing countries, it is important to make the development of buildings construction; low cost, no requirement of sophisticated technologies and reliable construction methods. The present presentation deals with cost-wise comparison of steel reinforcement with bamboo reinforcement. The utilization of bamboo reinforcement as replacement of steel reinforcement is gaining immense importance today, mainly on account of the improvement in the economical aspect combined with ecological benefits. Recently, in the attention in response to global warming issues and sustainable society, the manufacturing using natural materials has become actively. Bamboo, low cost, fast growing, and broad distribution of growth, is expected to contribute significantly to earthquake-resistant construction and seismic retrofit technology in the developing countries

- 5. 5 Bamboos belong to the grass family Poaceae (Gramineae). In India, there are 125 indigenous as well as exotic species of bamboos belonging to 23 genera. Bamboo forests occupy an area of 10.03 million ha, roughly 12.8% of the total forest area in the country. Bamboos are some of the fastest-growing plants in the world, due to a unique rhizome-dependent system. Certain species of bamboo can grow 35 inches/890 mm within a 24-hour period, at a rate of 0.00003 km/h (a growth of approximately 1 mm (or 0.02 inches) every 2 minutes). Historical use of bamboos. Around 16th – 17th Centuries BC this time, bamboo was being used to manufacture bows, arrows and other hunting materials as the wood is plentiful and extremely durable. Of course, bamboo was also being used to create household items and even the structure of the house itself.

- 6. Table1.0 : Distribution of Bamboo Genus Numberof Species Distribution Bambusa C37 Tropical & subtropical Asia, especially in monsoon & wet tropics; mostly cultivated Cephalostachyum 11 From north eastern Himalayas to Thailand and Mindoro; mountain to lowland forest Dendrocalamus C.29 From Indian subcontinent throughout South- East Asia; dry and humid tropics Dinochloa C.20 Malaysia; hill and lowland dipterocarp forest Gigantochloa C.24 South-East Asia, wild or cultivated; humid tropics 6 Page 01 The geographical distribution of bamboos is governed largely by the conditions of rainfall, temperature, altitude and soil. Most of the bamboos require a temperature from 8 degree c to 36 degree c, a minimum annual rainfall of 1000 mm and high atmospheric humidity for good growth. Following are the some of the certain species across the world

- 7. Properties Steel (FE500) as per B/S -IS1786-2008 Bamboos Yield strength 379.02 N/MM2 180.6 N/MM2 Ultimate tensile strength 500.23 N/MM2 220.88 N/MM2 Elongation in % 20 15.07 Carbon Emission (for 3m length to support 300kg load) 15 to 17 0 to 0.1 Mass per 3 meter length 10kg 6.5kg 7 Page 01 Some specific properties of Bamboo (bambusa and dendrocalamus) are as given below: Specific gravity : 0.575 to 0.655 Average weight : 0.625 kg/m Modulus of rupture : 610 to 1600 kg/cm2 Modulus of Elasticity: 1.5 to 2.0 x105 kg/cm2 Ultimate compressive stress-:794 to 864 kg/cm2 Safe working stress in compression :105 kg/cm2 Safe working stress in tension:160 to 350 kg/cm2 Safe working stress in shear: 115 to 180 kg/cm2 Bond stress : 5.6kg/cm2 Properties Red brick Bamboos Steel Density 1920 kg/m3 0.3 to 0.4 7750 to 8050 kg/m3 Thermal conductivity 0.6 0.04 to 0.12 50.2 Carbon emission 1.3 0 to 0.1 15 to 17 Composition By weight Silica(sand),-50% Alumina(clay)-20% Lime-2 to 5% Natural Grade

- 8. 8 Page 01 The following factors should be considered in the selection of bamboo culms (whole plants) for use as reinforcement in concrete structures: Use only bamboo showing a pronounced brown colour. This will insure that the plant is at least three years old. Select the longest large diameter culms available. Do not use whole culms of green, unseasoned bamboo. Avoid bamboo cut in spring or early summer. These culms are generally weaker due to increased fibre moisture content. The culms should be well seasoned before use so that sweetness of the bamboo will be lost and insect attacks will be minimised which is used for construction 8.2.1 Sizing : Splints are generally more desirable than whole culms as reinforcement. Larger culms should be split into splints approximately 3/4 inch wide. Whole culms less than 3/4 inch in diameter can be used without splitting. Splitting the bamboo can he done by separating the base with a sharp knife and then pulling a dulled blade through the stem. The dull blade will force the stem to split open; this is more desirable than cutting the bamboo since splitting will result in continuous fibres and a nearly straight section 8.2.2 Seasoning : When possible, the bamboo should be cut and allowed to dry and season for three to four weeks before using. The culms must be supported at regular spacing to reduce warping. When seasoned bamboo, either split or whole, is used as reinforcement, it should receive a waterproof coating to reduce swelling when in contact with concrete. Without some type of coating, bamboo will swell before the concrete has developed sufficient strength to prevent cracking and the member may be damaged, especially if more than 4 percent bamboo is used. The type of coating will depend on the materials available. A brush coat or dip coat of asphalt emulsion is preferable. Native latex, coal tar, paint, dilute varnish, and water-glass (sodium silicate) are other suitable coatings. In any case, only a thin coating should be applied; a thick coating will lubricate the surface and weaken the bond with the concrete.

- 9. 9 Page 01 In general, techniques used in conventional reinforced concrete construction need not the changed when bamboo is to be used for reinforcement. Bamboo reinforcement should not be placed less than 1- 1/2 inches from the face of the concrete surface. When using whole culms, the top and bottom of the stems should be alternated in every row and the nodes or collars, should be staggered. This will insure a fairly uniform cross section of the bamboo throughout the length of the member, and the wedging effect obtained at the nodes will materially increase the bond between concrete and bamboo. Clear spacing between bamboo rods or splints should not be less than the maximum size aggregate plus 1/4 inch. Reinforcement should be evenly spaced and lashed together on short sticks placed at right angles to the main reinforcement. When more than one layer is required, the layers should also be tied together. Ties should preferably be made with wire in important members. For secondary members, ties can be made with vegetation strips. The same mix designs can be used as would normally be used with steel reinforced concrete. Concrete slump should be as low as workability will allow. Excess water causes swelling of the bamboo. High early-strength cement is preferred to minimize cracks caused by swelling of bamboo when seasoned bamboo cannot be waterproofed.

- 10. 10 Page 01 9. Construction principles…. 9. Construction principles…. Bamboo must be securely tied down before placing the concrete. It should be fixed at regular intervals of 3 to 4 feet to prevent it from floating up in the concrete during placement and vibration. 9.3 Placement of Concrete 9.3 Placement of Concrete Additional diagonal tension reinforcement in the form of stirrups must be used near the supports. The vertical stirrups can be made from wire or packing case straps when available; they can also be improvised from split sections of bamboo bent into U-shape, and tied securely to both bottom longitudinal reinforcement and bent-up reinforcement. Spacing of the stirrups should not exceed 6 inches. In flexural members continuous, one-half to two-thirds of the bottom longitudinal reinforcement should be bent up near the supports. This is especially recommended in members continuous over several supports.

- 11. 10. Roofing with bamboos 10. Roofing with bamboos It is a proven shield against forces of nature or animals and are considerably light weighted which makes them easy to install. Bamboo is one of the best roofing materials and provides ample sturdiness to the structure. The bamboo roofs encompass purlins, rafters and trusses.

- 12. 10.1.1 Traditional Bamboo truss. 10.1.1 Traditional Bamboo truss. 12 Page 01 10.1 Different Roofing designs 10.1 Different Roofing designs In the past bamboo truss was made by putting the bamboo poles together and strapping a rope around them. He issue with this type of bamboo truss connectors is that the load of the roof was not equally distributed. There is friction which may compromise the strength of the roof. 10.1.2 Modern Bamboo Truss. 10.1.2 Modern Bamboo Truss. New joiners and connectors have been designed in recent times. Thanks to advancement in technology, skilled engineers and architects. These joiners and connectors can be made in various shapes and sizes. This depends on the number of poles to be connected and the design of the roof. With the modern joiners there is rarely any friction between the poles. The weight is equally distributed. Incorporation of little steel helps in overcoming the problems faced in traditional system. steel joiners do not need a lot of investment and hence the cost of the entire Bamboo structure is low. The amount of skilled labour required is also low. This means even in the rural areas these structures can be built using modern joiners. 10.1.3 Halved bamboo columns 10.1.3 Halved bamboo columns Another way of covering the roof with bamboo is to cut open the bamboo exactly in half. The nodes within he bamboo column are removed and cut into adequate sizes. The bamboo halves are then placed in an interlocking manner. One have faced the ground and the other faces the sky. The half facing the ground is holding 2 halves facing the sky.

- 13. 13 It has almost zero carbon emission. Some of the species of bamboo has more tensile strength than steel. Due to its high elasticity nature, structures made with bamboos are more capable of withstand against earthquake. It does not requires sophisticated tools or equipment for its cutting. In each of its nodes, bamboo has a dividing and transverse wall that maintains strength and allows bending, thus preventing rupturing when bent. Easily available across the world. It is lighter material thus it can be use in substitution of other same property heavier materials. It has very low thermal conductivity. Resistance of electricity. No skilled labour is required for cutting and construction. 11. Advantages of bamboos as structural member 11. Advantages of bamboos as structural member 12. Disadvantages of bamboo as structural member 12. Disadvantages of bamboo as structural member Water absorption is very high, the bamboo used as a reinforcement absorb water from concrete mixture thus it reduces the strength of concrete as well as its tensile strength. It requires waterproofing agent before its placement. Since bamboo is a natural material, every bamboo has not same tensile and compressive strength. Thus we have to check the properties of every bamboo each time before placing. Most important it is a brittle material hence it will not give any warning before its failure. Due to smooth surface of bamboo the bond between concrete and bamboo will be very less. It is not fire resistance. Every bamboo has irregular shape even a single bamboo differs its dimensions after one or more nodes.

- 14. 14 Page 01 13. Conclusion 13. Conclusion As per above study we can conclude that bamboo has similar characteristics as steel but it has major faults too like waterproofing, brittle nature, low bonding with concrete, requires more maintenance than steel. It cannot be recommended for reinforcement in sky scrapers, important buildings, dams, and other certain construction. On the other hand, bamboo has very low carbon emission and low thermal conductivity as compare to other building materials which cannot be ignorable thus bamboo can be used in low rise buildings such as G+1 and G+2 and where the steel is not available. Thus, In the green building concept use of bamboo reinforced concrete may be recommendable.

- 15. 15 Page 01 14. REFERENCES – OTHER TOPICS OF STUDIES 14. REFERENCES – OTHER TOPICS OF STUDIES Bamboo a SustainableBuilding Material of the Future “As 21st Century Steel” OTHERRELAVENT TOPICS OF STUDIES “Replacement of Steel by Bamboo Reinforcement’’ “Investigation on properties of bamboo as reinforcingmaterial in concrete’’ “Bamboo reinforced concrete construction’’ “ Design Bamboo As Green Alterative To Concrete And Steel For Modern Structures.” Complilation/ Edited by : Mohammad Faisal Shaikh B.Arch (Mumbai) M.Arch. Urban Design (Mumbai) Editorial Assessment by : Javed AlamShaikh