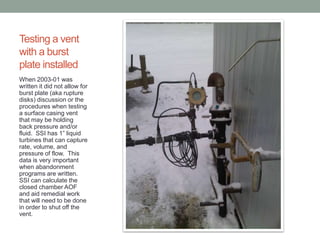

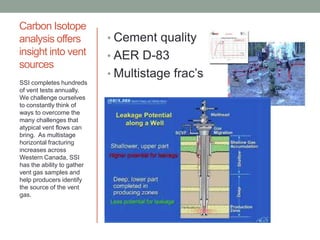

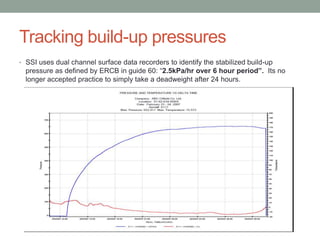

This document discusses surface casing vent testing procedures and issues. It outlines the key points of AER directive 2003-01, which established universal procedures for testing and identifying serious and non-serious surface casing vents across Canada. It also discusses different types of vent issues seen in the field, such as gas or liquid venting, and the equipment and procedures used to properly test and monitor vents. The conclusion emphasizes that Surface Solutions uses established industry procedures and innovative techniques to effectively test vents and provide operators with the data needed to make important operational and regulatory decisions.