DEFECT CLASSIFICATION

- 1. DEFECT CLASSIFICATION (FABRIC)

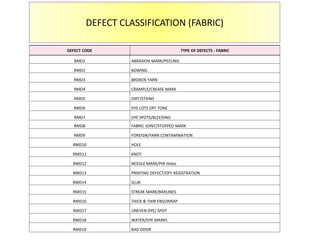

DEFECT CODE TYPE OF DEFECTS - FABRIC

RMD1 ABRASION MARK/PEELING

RMD2 BOWING

RMD3 BROKEN YARN

RMD4 CRAMPLE/CREASE MARK

RMD5 DIRT/STAINS

RMD6 DYE LOTS OFF TONE

RMD7 DYE SPOTS/BLEEDING

RMD8 FABRIC JOINT/STOPPED MARK

RMD9 FOREIGN/YARN CONTAMINATION

RMD10 HOLE

RMD11 KNOT

RMD12 NEEDLE MARK/PIN Holes

RMD13 PRINTING DEFECT/OFF REGISTRATION

RMD14 SLUB

RMD15 STREAK MARK/BARLINES

RMD16 THICK & THIN END/WRAP

RMD17 UNEVEN DYE/ SPOT

RMD18 WATER/DYE MARKS

RMD19 BAD ODOR

- 3. DEF. CODE TYPE OF DEFECTS - CUTTING

CD1 SPREADING JOINT/SPLICED PANEL

CD2 INCONSISTENT SPREADING ( LOOSE/TIGHT )

CD3 SPREADING WAVY

CD4 PLY COUNT INACCURATE

CD5 PLY HEIGHT TOO HIGH

CD6 STRIPE MISALIGNMENT/BOWING

CD7 WRONG PINING / CLIPPING FOR STRIPE FABRIC

CD8 FABRIC/ WIDE LACE WRONG FACE SIDE

CD9 LACE SCALLOP / EMBROIDERY NOT MATCHING

CD10 WRONG MARKER

CD11 CUT PARTS NOT MACTH WITH PATTERN

CD12 MARKER AND SPREADING WIDTH NOT MATCH

CD13 OFF GRAIN CUTTING

CD14 MISSING NOTCH / INCORRECT PLACEMENT

CD15 LEANING (SIDE EDGE MISALIGNED)

CD16 REMNANTS LOT UNIDENTIFIED

CD17 FABRIC FLAWS

CD18 MISCUT

CD19 RAGGED CUTTING

CD20 PARTS COUNT INCOMPLETE ( BUNDLING PROBLEM)

CD21

BUNDLING NOT FOLLOW COLOR COMBINATION AGAINST MO/ TRIM CARD REQUIRED

CD22 BUNDLES UNMATCHED/INCOMPLETE PART COUNT

CD23 BUNDLING MIXED SIZES AND DYE LOTS

CD24 HEAT TRANSFER GLUE EXPOSED

CD25 HEAT TRANSFER WRONG PLACEMENT/QUALITY

CD26 HEAT TRANSFER LABEL/TRIMS DELAMINATED

CD27 HEAT TRANSFER LABEL/TRIMS DISCOLORATION

CD28 BINDING WIDTH INCONSISTENT

CD29 BINDING OFF GRAIN

CD30 RE-CUT WRONG DYE LOT

CD31 OTHERS

DEFECT CLASSIFICATION (CUTTING)

- 4. DEFECT CLASSIFICATION (SEWING)

DEF. CODE

TYPE OF DEFECTS - SEWING

ENGLISH

SW1 SKIP/RUN OFF STITCHES/ POOR JOIN STITCHES

SW2 RAW EDGES

SW3 BROKEN STITCHES

SW4 CHALK/PEN MARKS / DIRTS

SW5 PUCKERING/TWISTED SEAMS

SW6 STITCH COUNT NOT ACCURATE

SW7 UNEVEN SEAM WIDTH

SW8 HIGH/LOW

SW9 UNTRIMMED THREADS

SW10 POOR/OUT OF SHAPE

SW11 HOLES / CUT DAMAGED

SW12 OIL STAINS

SW13 FULLNESS/BUBBLING

SW14 LOOSE STITCHES

SW15 WRONG SIZE

SW16 OVERLAPPING / MISALIGNED STITCHES

SW17 MISSING STITCH/PLEATED/OPENED SEAM

SW18 TIGHT TENSION

SW19 NEEDLE HOLES

SW20 DIRTY/SOILAGE

SW21 OFF SHADING WITHIN THE GMTS

SW22 OUT OF SPEC

SW23 HOOK & EYE INSECURED/UNEVEN

SW24 WIRE PLAY TIGHT/LOOSE

SW25 CUP LOOSE/TIGHT

SW26 SIDE CUP WAVY/CURLING UP

SW27 CRACKING STITCHES WHEN STRETCHED

SW28 FABRIC WRONG SIDE/INVERTED

SW29 BARTACK - TIGHT/TOO WIDE/MISPLACED/ MISSING / SLANTED

SW30 STRAPS INSECURED/MISPLACED/UNEVEN/ TWISTED

- 5. DEF.CODE

TYPE OF DEFECT (SEWING)

ENGLISH

SW31 LOOSE THREADS IN / OUT OF THE GMTS

SW32 EXPOSED BASTING STITCHES ON GMTS

SW33 PLEATED SEAMS

SW34 DAMAGED TRIMS

SW35 POINTY

SW36 CENTER FRONT GORE OUT OF SHAPE / SLANTED / HI-LOW

SW37 BOW/ BUTTON / METAL TRIMS WITH LOGO MISPLACED / MISSING / INSECURED

SW38 WRONG MATERIALS USED ON GMTS

SW39

LABEL MISPLACED/MISSING

SW40

LABEL WRONG/NOTREADABLE

SW41

WIRE INCORRECT/PULL OUT

SW42

WAVY

SW43

UNEVEN SEAM ALLOWANCE

SW44

REVERSE ATTACHMENT

SW45 HIKING

SW46 CREASE MARK

SW47 FIBREFILL BROKEN

SW48 UNEVEN DISTANCE

SW49 FLIPPING UP/CURLING DOWN

SW50 GUSSET OUT OF SHAPE/BUBBLING

SW51 UNEVEN SHIRRING

SW52 SHARP EDGES

SW53 SNAGS / FRAYING EDGES

SW54 HANDLING PROBLEM / PULLING

SW55 NEEDLE CUTS

SW56 FEED DOG/ SHINY / PRESSER FOOT MARKS

SW57 OTHERS

DEFECT CLASSIFICATION (SEWING)

- 6. DEFECT CLASSIFICATION (PACKING)

DEF. CODE

TYPES OF DEFECT(PACKING)

ENGLISH

PK 1 PACKING STANDARD INCORRECT

PK 2 POLYBAG WRONG SIZE/PRINTING/THICKNESS/

PK 3 HANGER ARTICLE / SIZE INCORRECT

PK 4 HANGTAG / OVER RIDDER / ADDITIONAL STICKER INCORRECT

PK 5 PRICE TICKET INCORRECT

PK 6 FLASHER / PAPER TAG WRONG POSITION / INSECURE / DAMAGE

PK 7 WRONG TAG PIN SIZE

PK 8 SIZER / LABEL / HANGTAGS UNMATCHED

PK9 WRONG CARTON DIMENTION

PK10 PLY TYPE / PLY COUNT INCORRECT

PK11 I NCORRECT ASSORTMENT

PK12 WRONG SIZE OF GARMENTS INSIDE THE CARTONS

PK13 CARTON SHIPPING MARKINGS INCORRECT

PK14 BARCODE STICKER WRONG / UNREADABLE

PK15 MISSING / WRONG STICKERS ON CARTON

PK16 PACKING CONDITION TIGHT/LOOSE

PK17 I NCORRECT CORD KNOT

PK18 STICKER ATTACHED SLANTED

PK19 HANGER MARK ON GARMENTS

PK20 BROKEN / SHARP EDGES ON PACKAGING TRIMS

PK21 MISSING PRICE TICKET / HYGENIC STICKER / ADDITIONAL STICKER

PK22 IINSECT /FUNGUS FOUND INSIDE THE POLY OR CARTON OR WITH GARMENTS.

PK23 POLY FOLDING WRONG

PK24 FOAM MOULD CUP CREASE / OFF SHAPE / CRASH MARK

PK25 INCORRECT QUANTITY (SHORT / OVER)

PK26 INCORRECT CARTON WEIGHT

PK27 MOISTURE LEVEL OUT OF STANDARD

PK28 POOR APPEARANCE AFTER PACKING

PK29 HANGER SETTING HI-LOW

PK30 INNER BOX (OFF SHAPE PRINTING / WRONG COUNTRY BLOCK / INSECURE / DAMAGE)

PK31 OTHERS