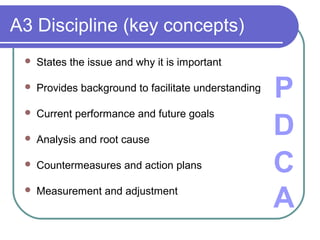

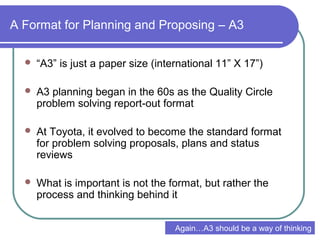

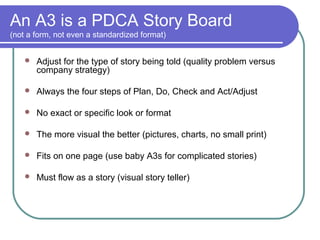

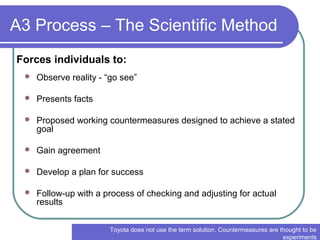

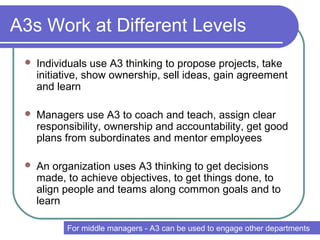

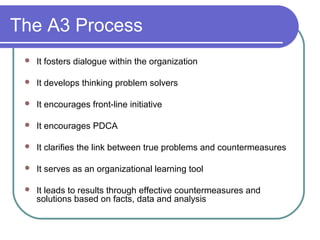

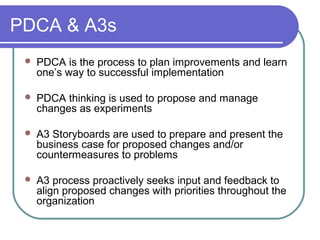

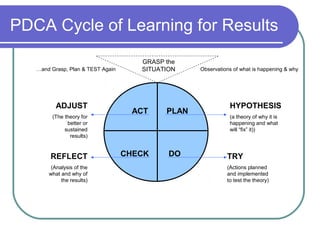

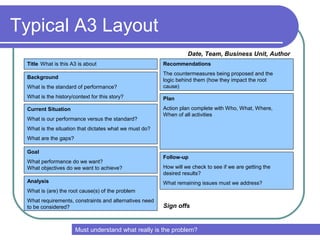

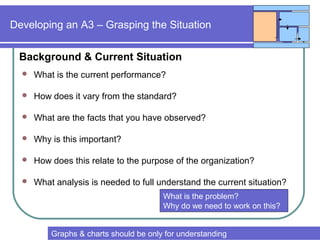

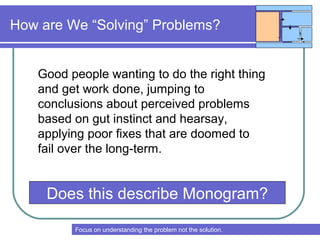

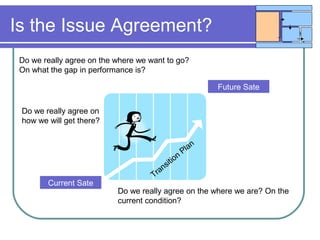

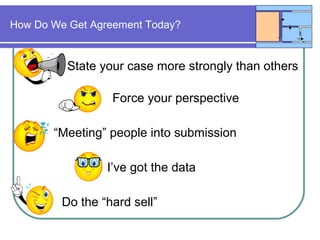

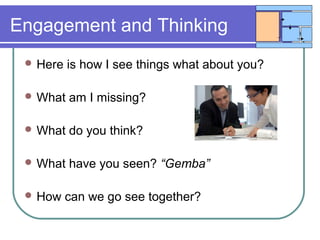

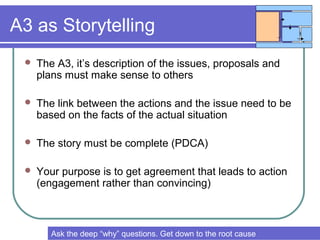

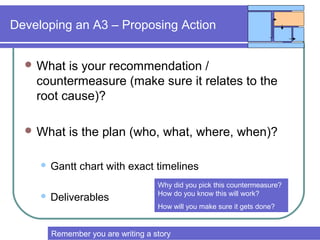

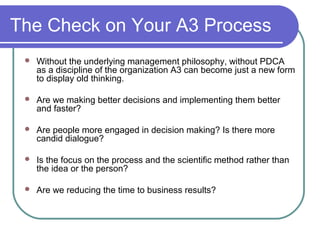

The A3 management process is a problem-solving methodology designed to achieve alignment on organizational issues, countermeasures, and actions through collaboration and continuous improvement. It emphasizes the importance of observing reality, engaging dialogue, and utilizing a structured, visual format for planning and proposing actions. The A3 process leverages the PDCA (Plan-Do-Check-Act) cycle to enhance decision-making, promote engagement, and focus on evidence-based solutions.