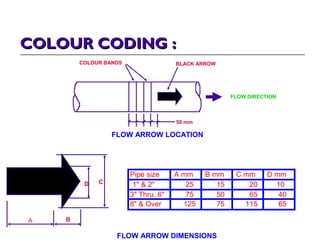

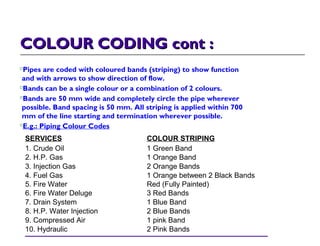

The document outlines key components of piping drawings, including flow diagrams and piping and instrumentation diagrams (P&ID) that provide essential information for system design. It describes the piping identification system which includes line size, conveyed fluid, line number, material classification, and insulation types, along with specifics on color coding to indicate different services. Additionally, it details the significance of color bands and flow direction arrows on pipes for easier identification and functionality.