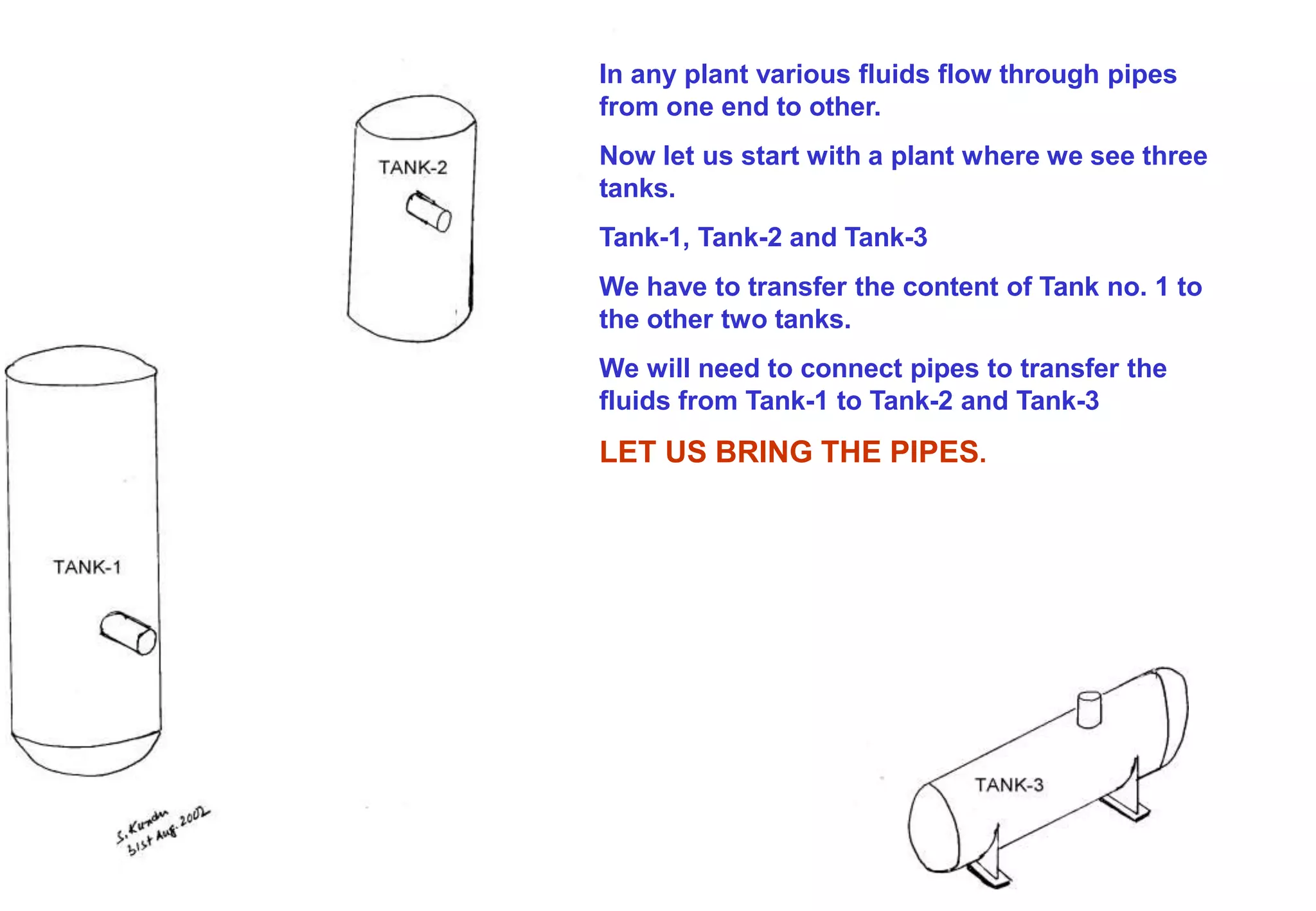

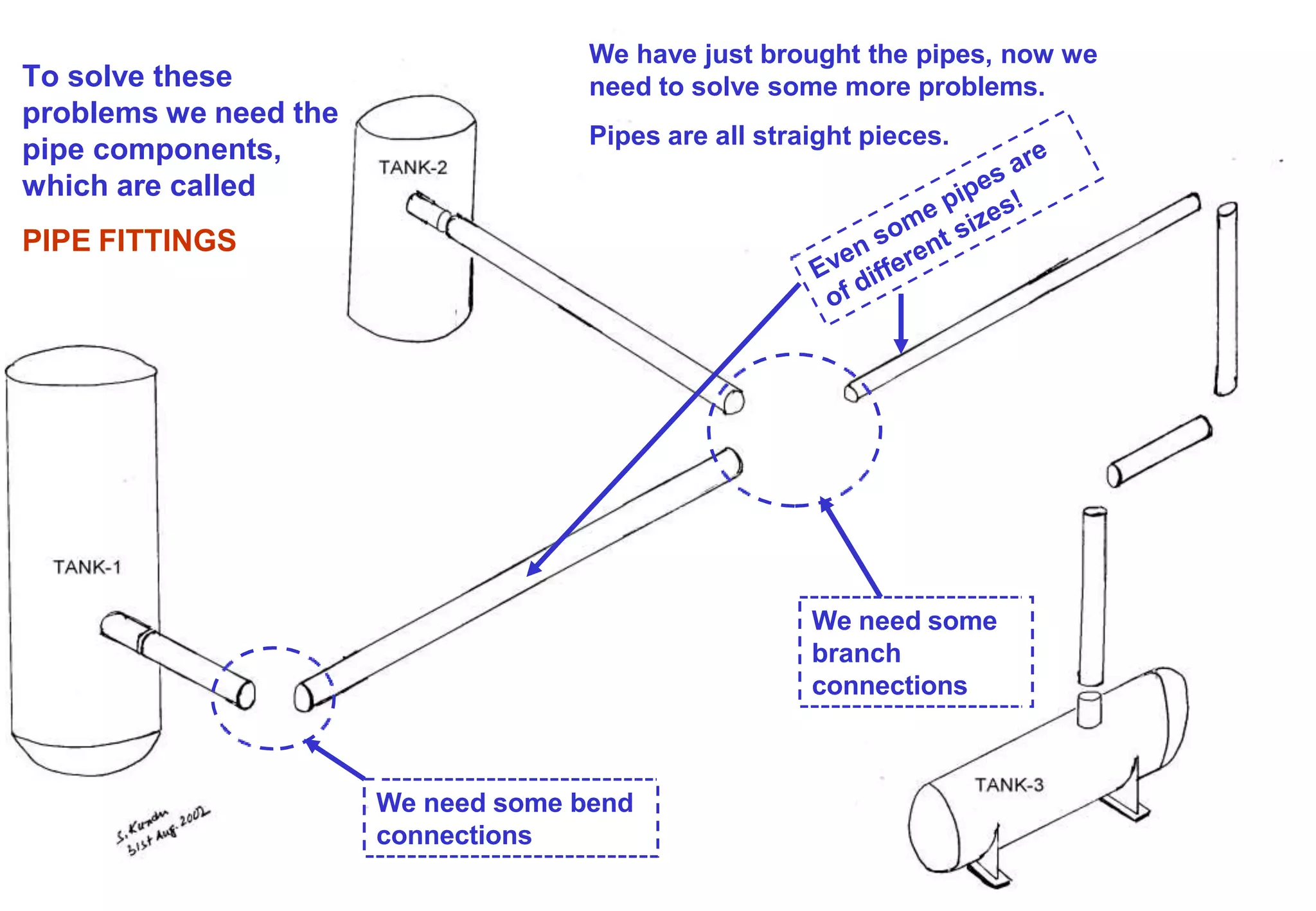

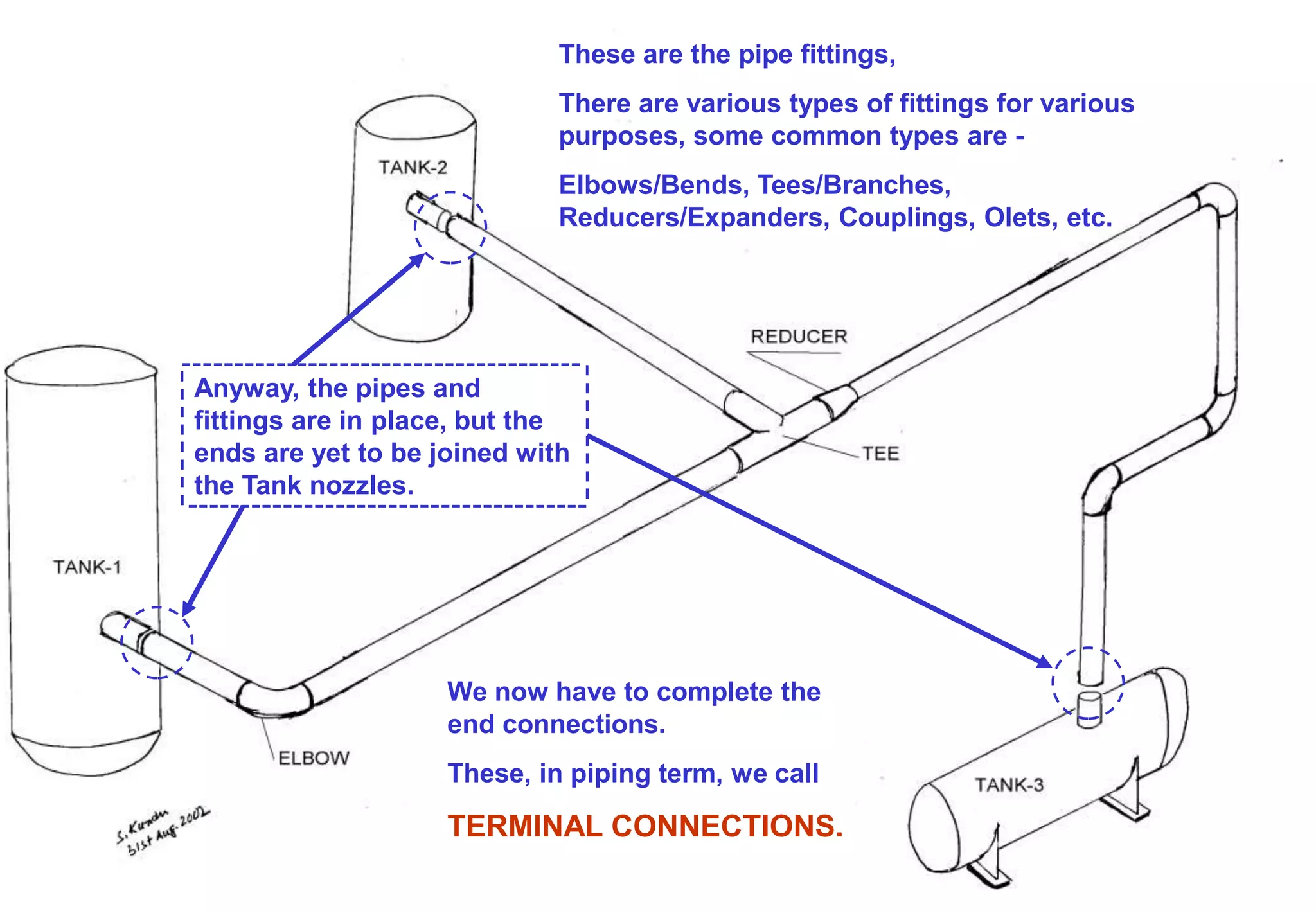

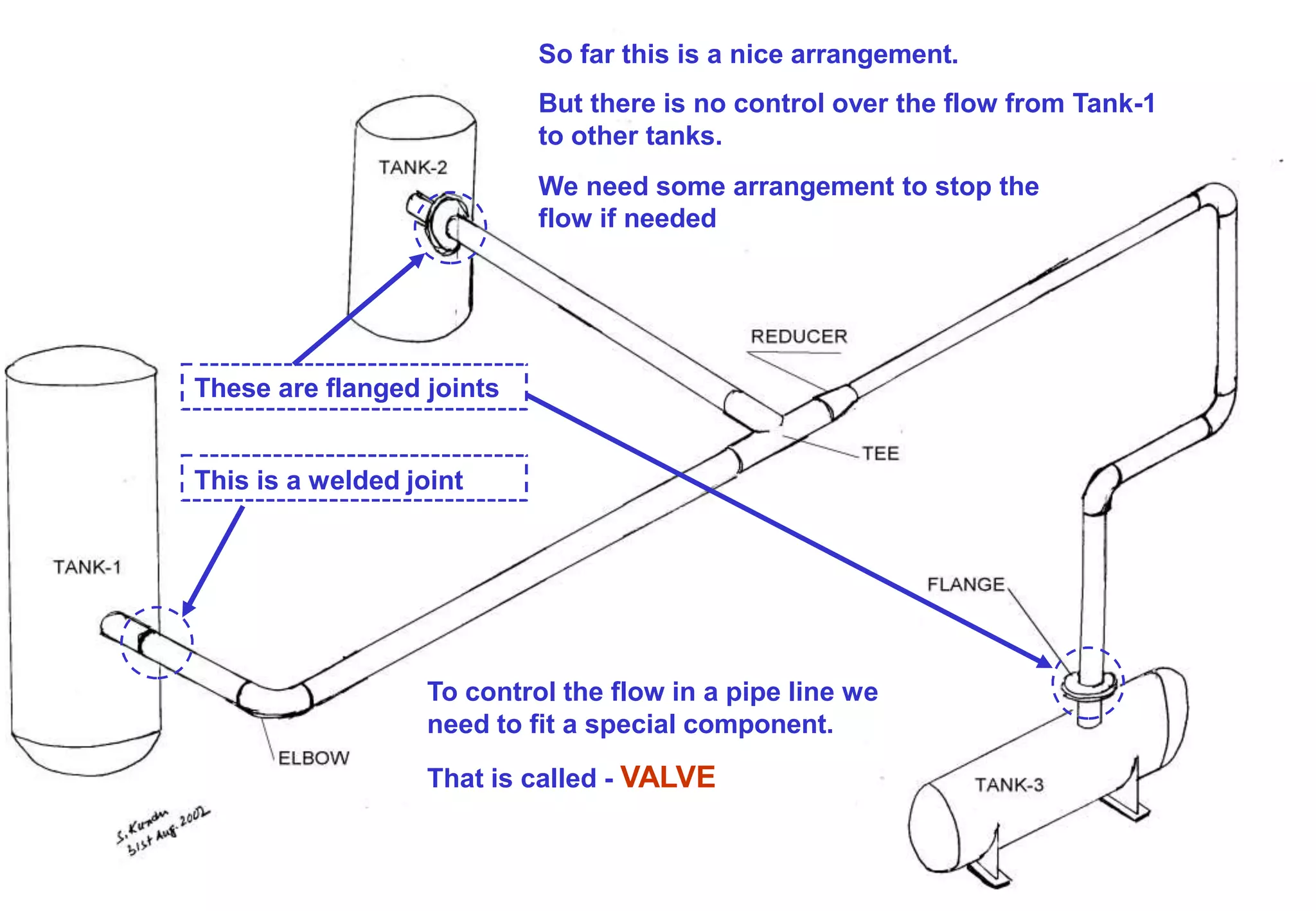

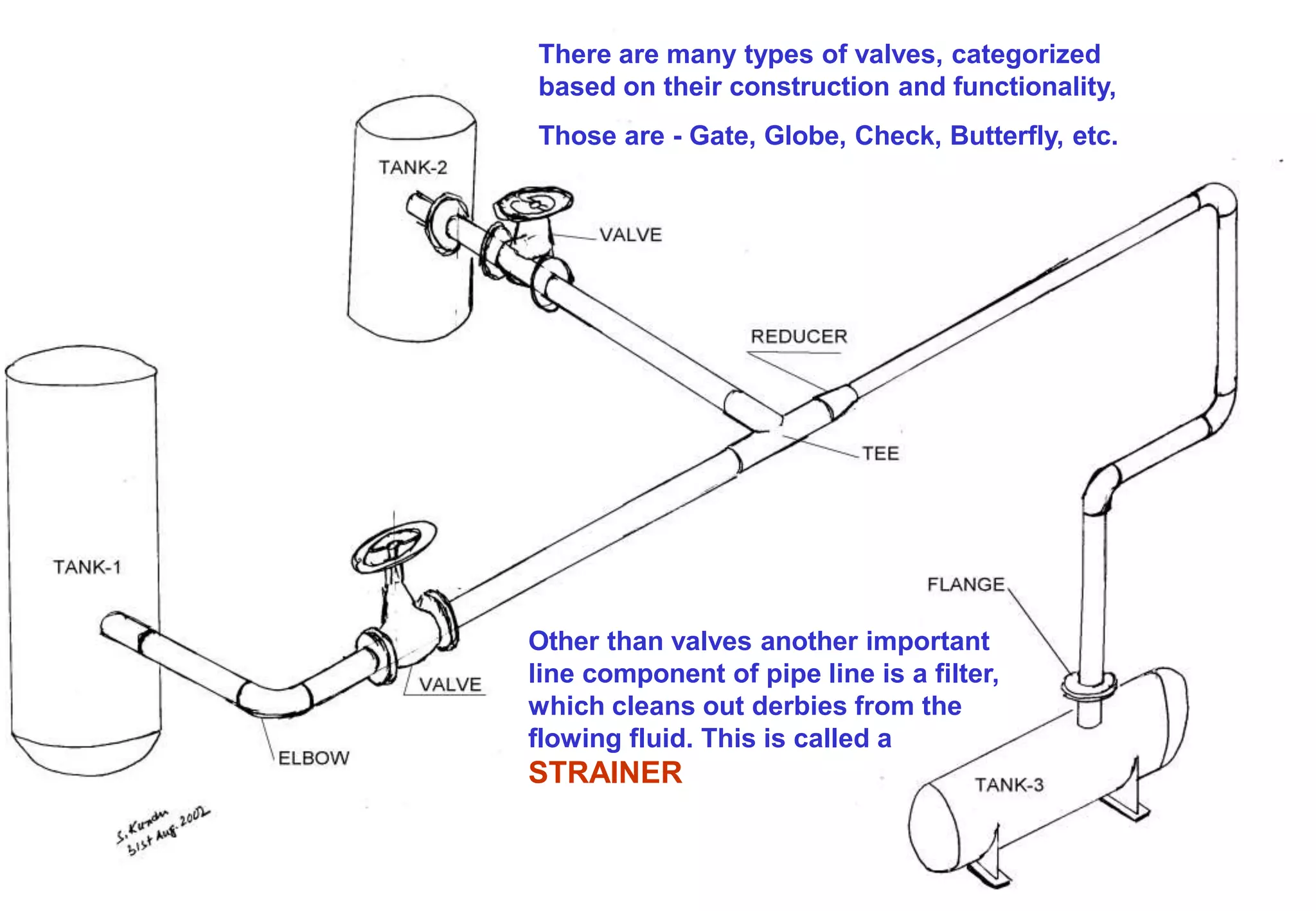

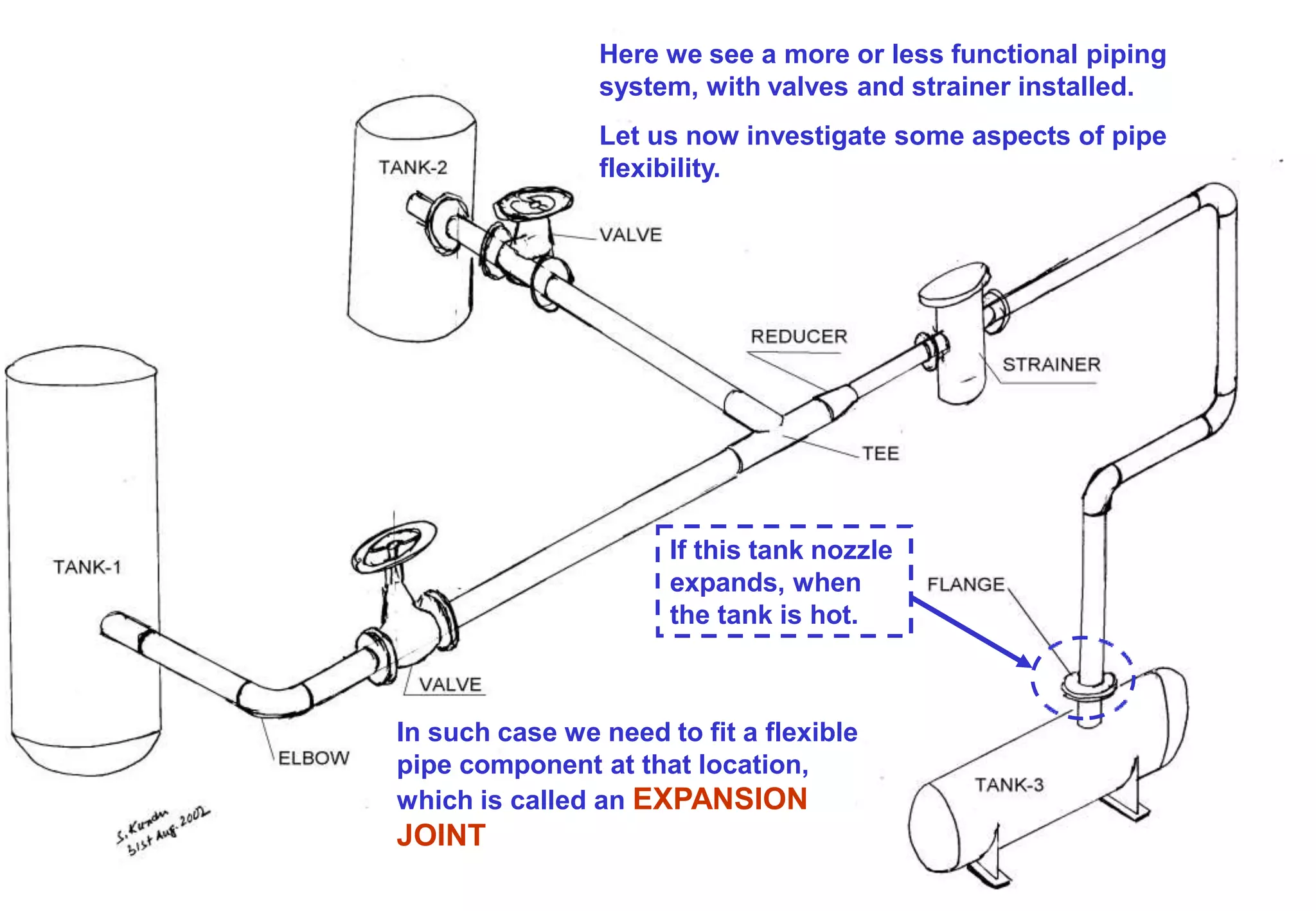

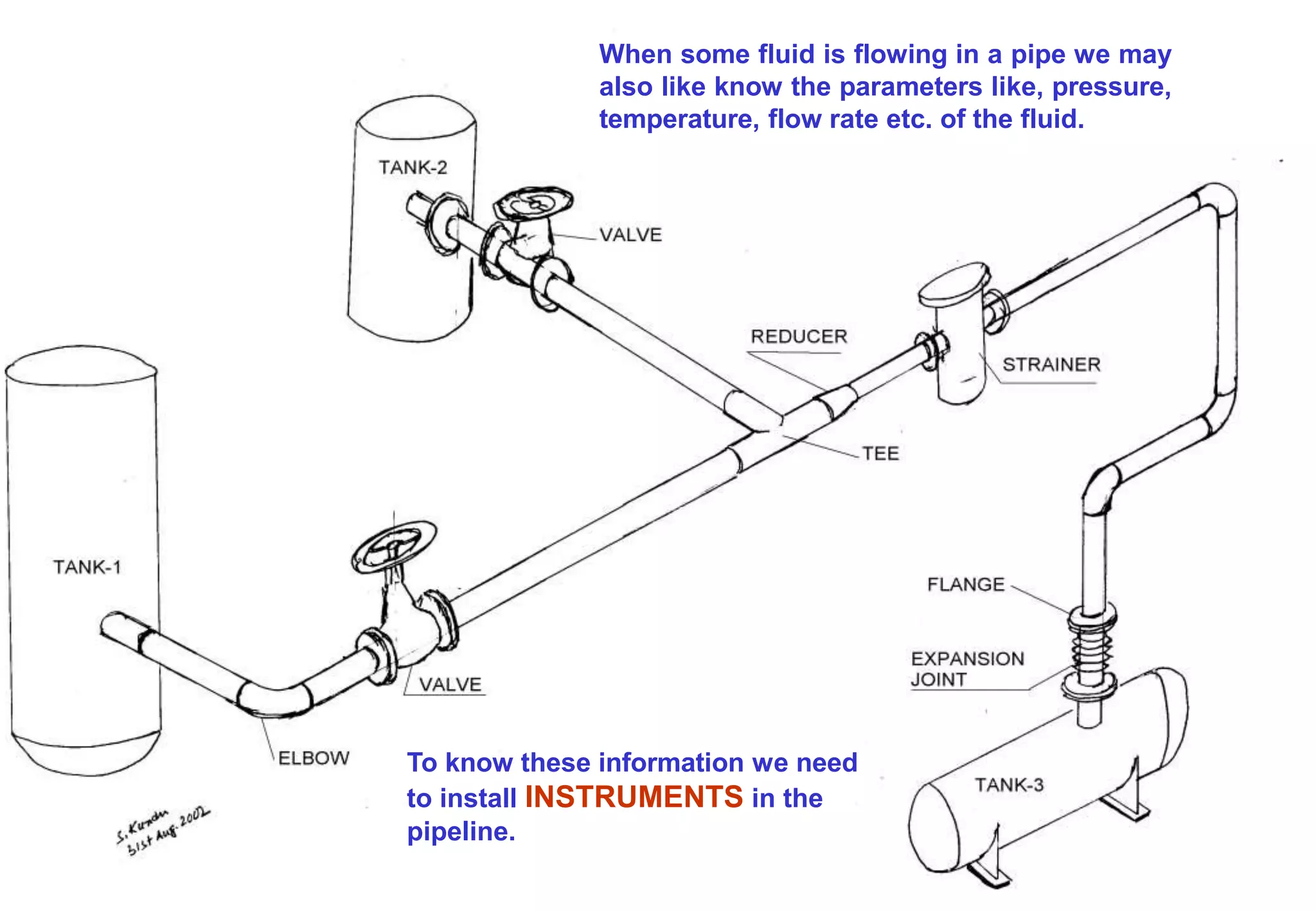

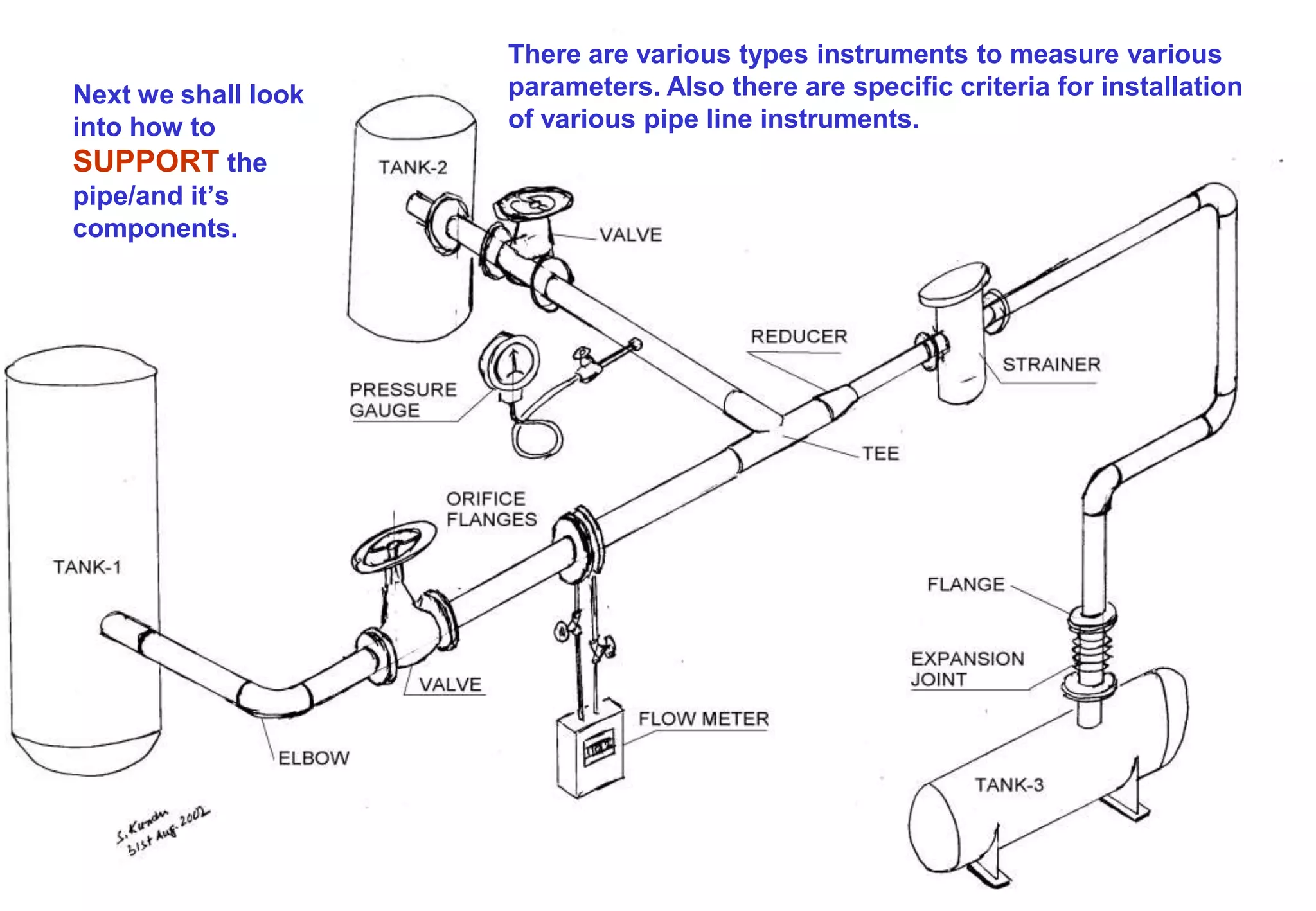

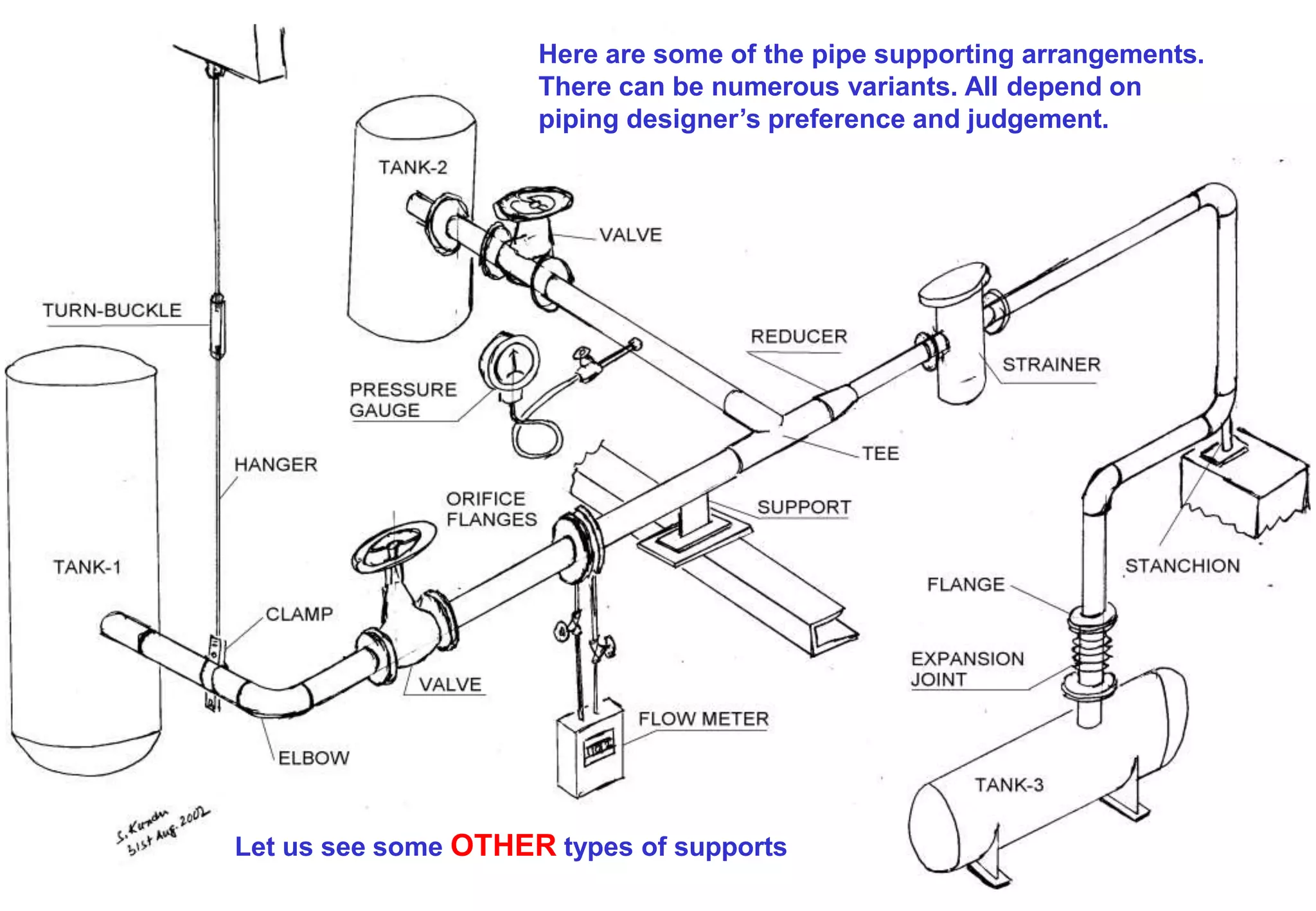

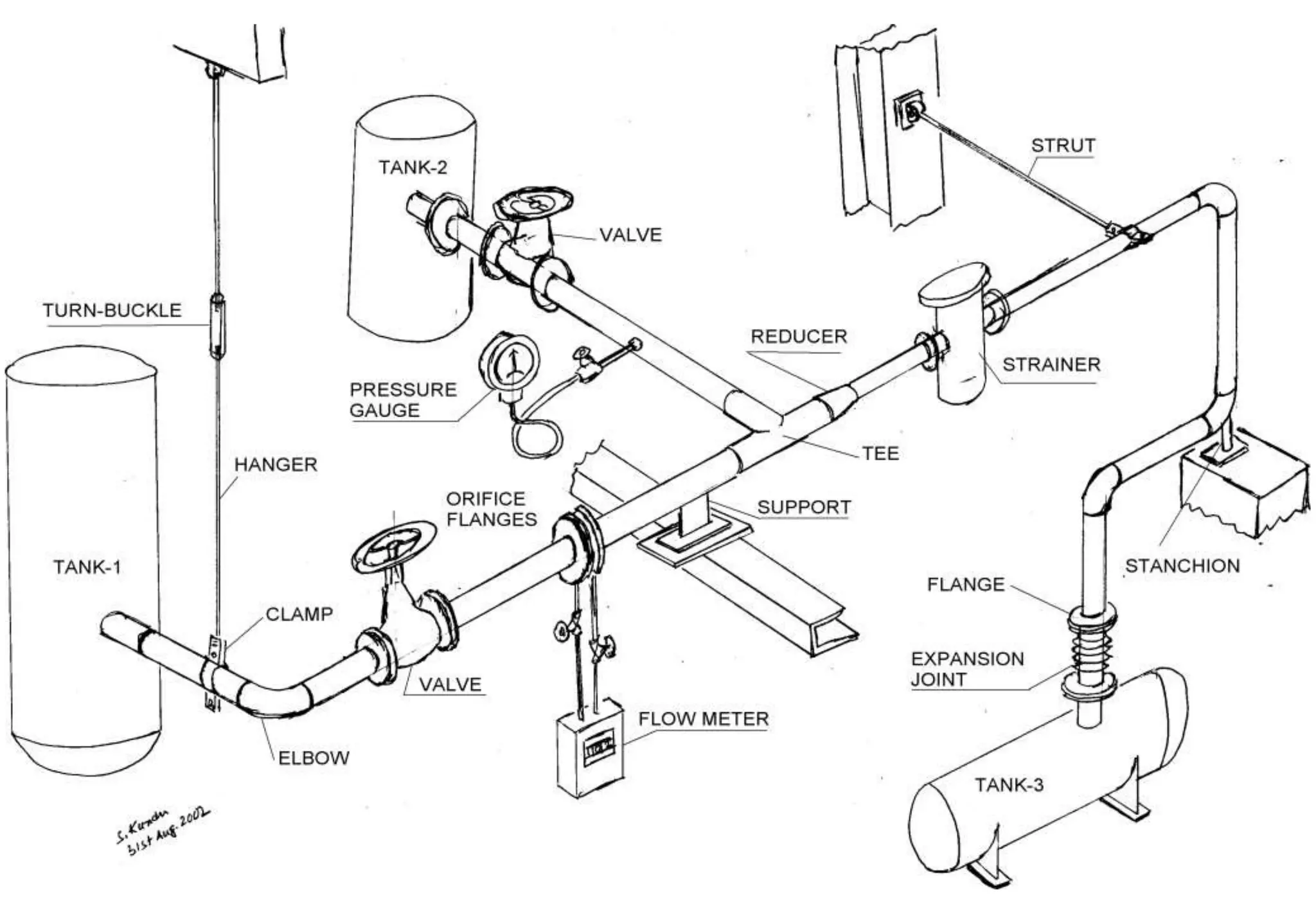

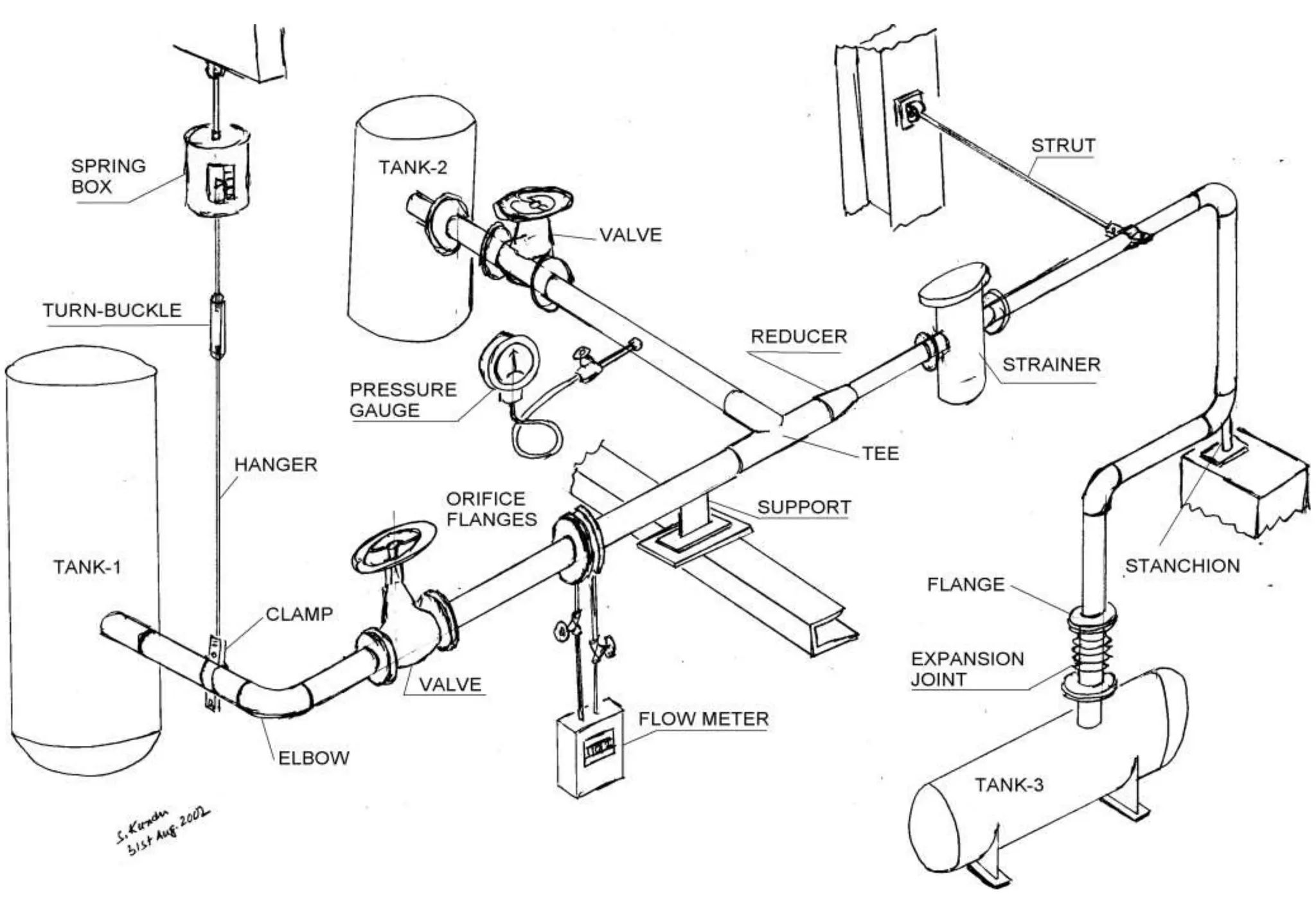

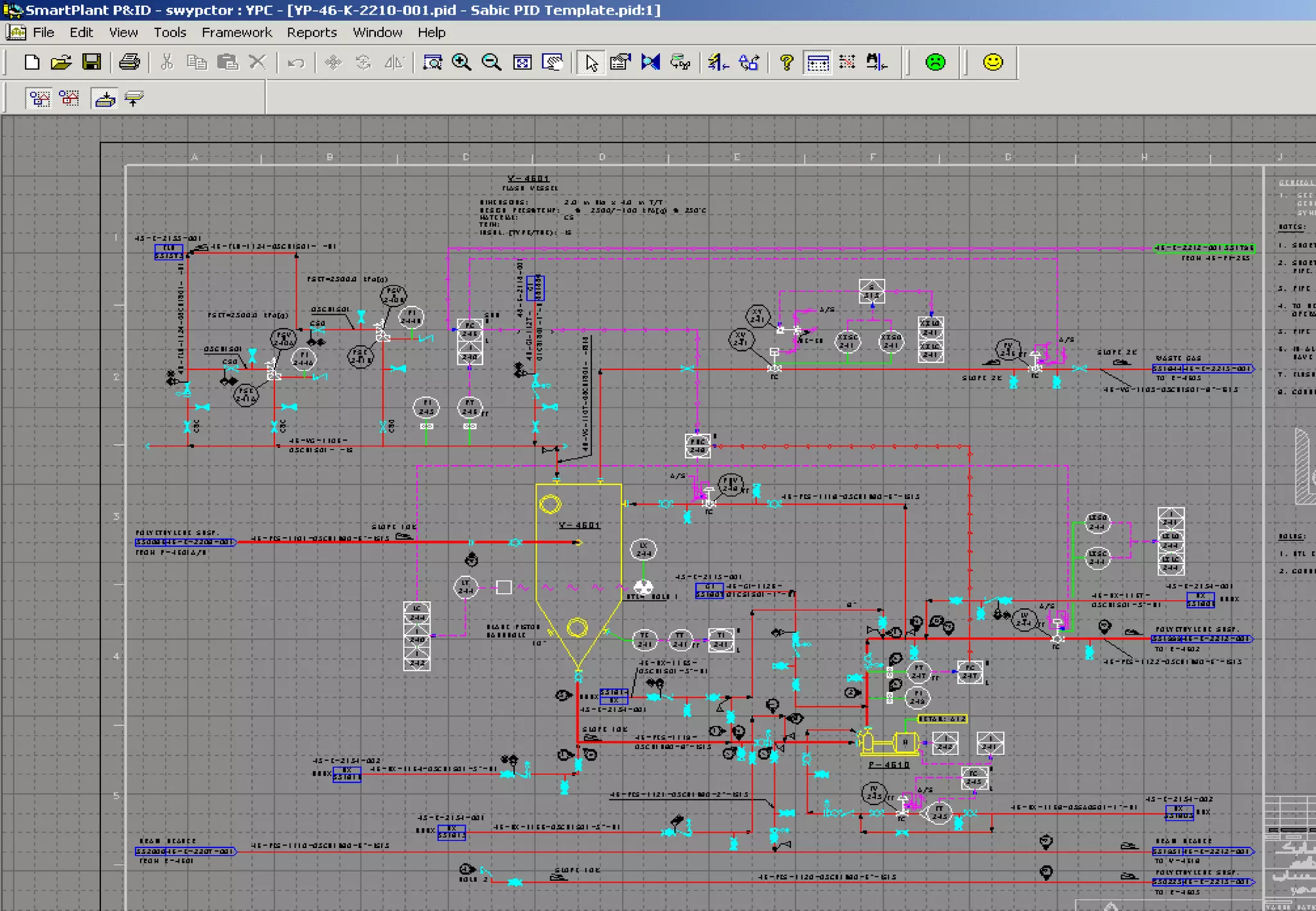

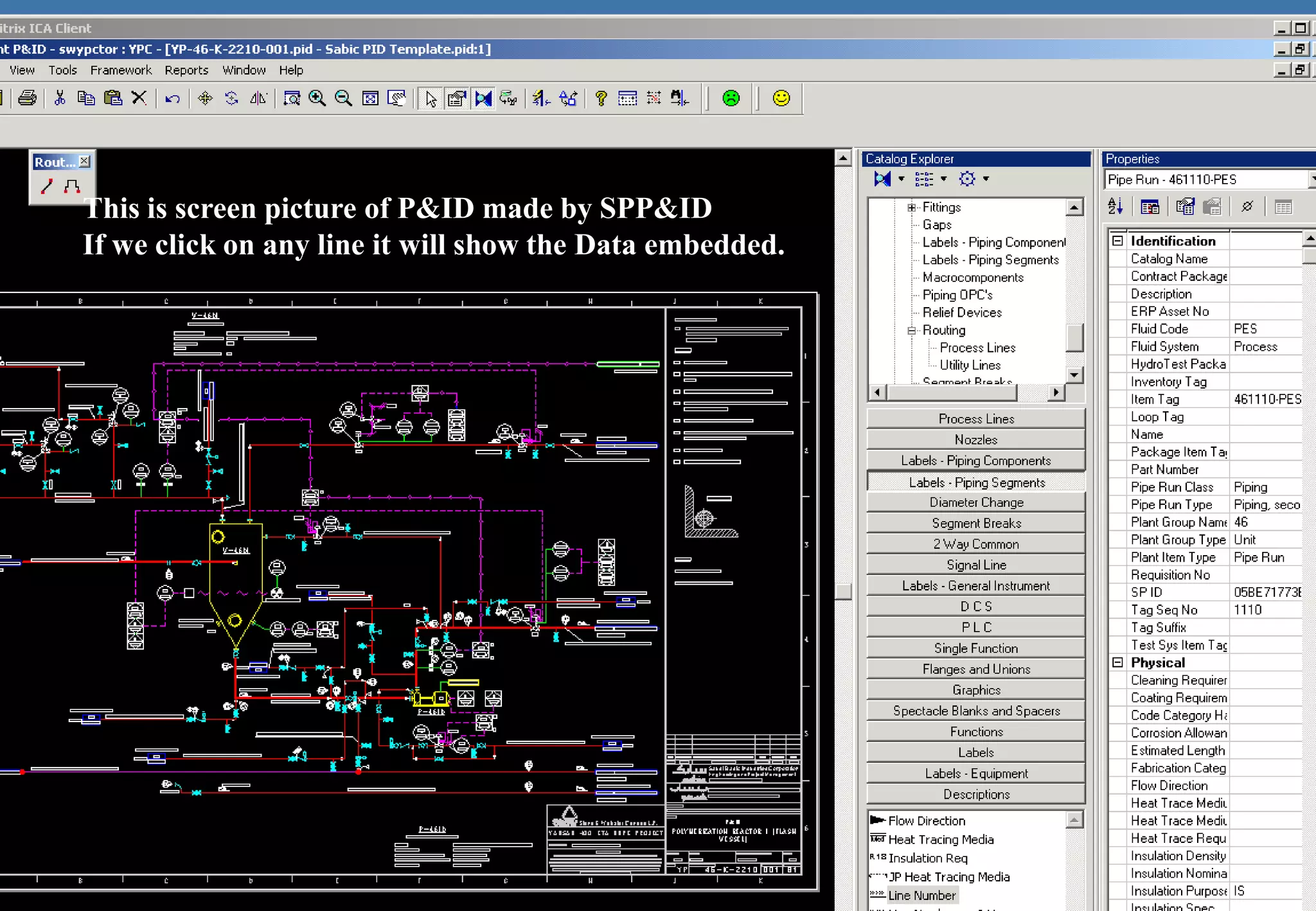

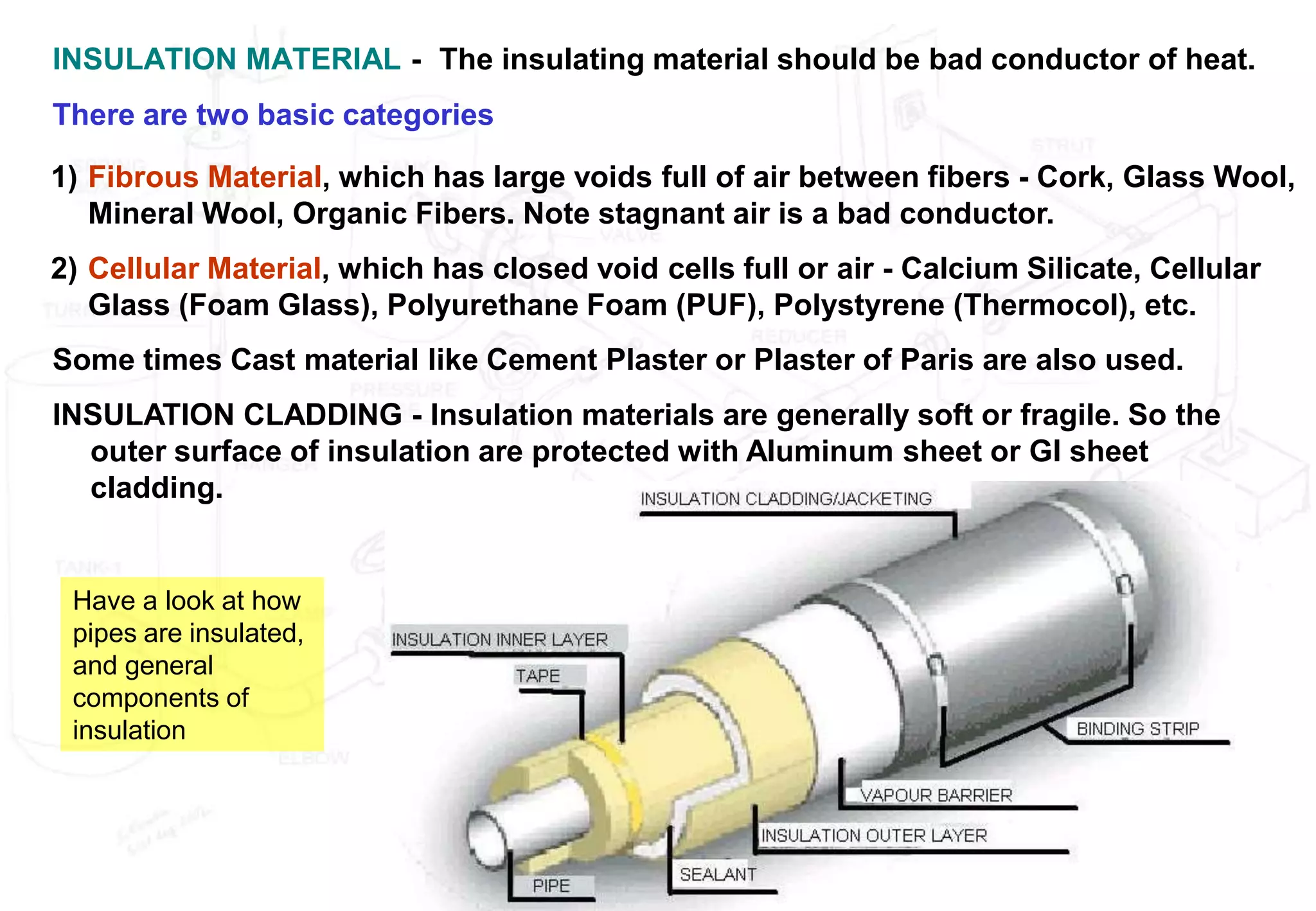

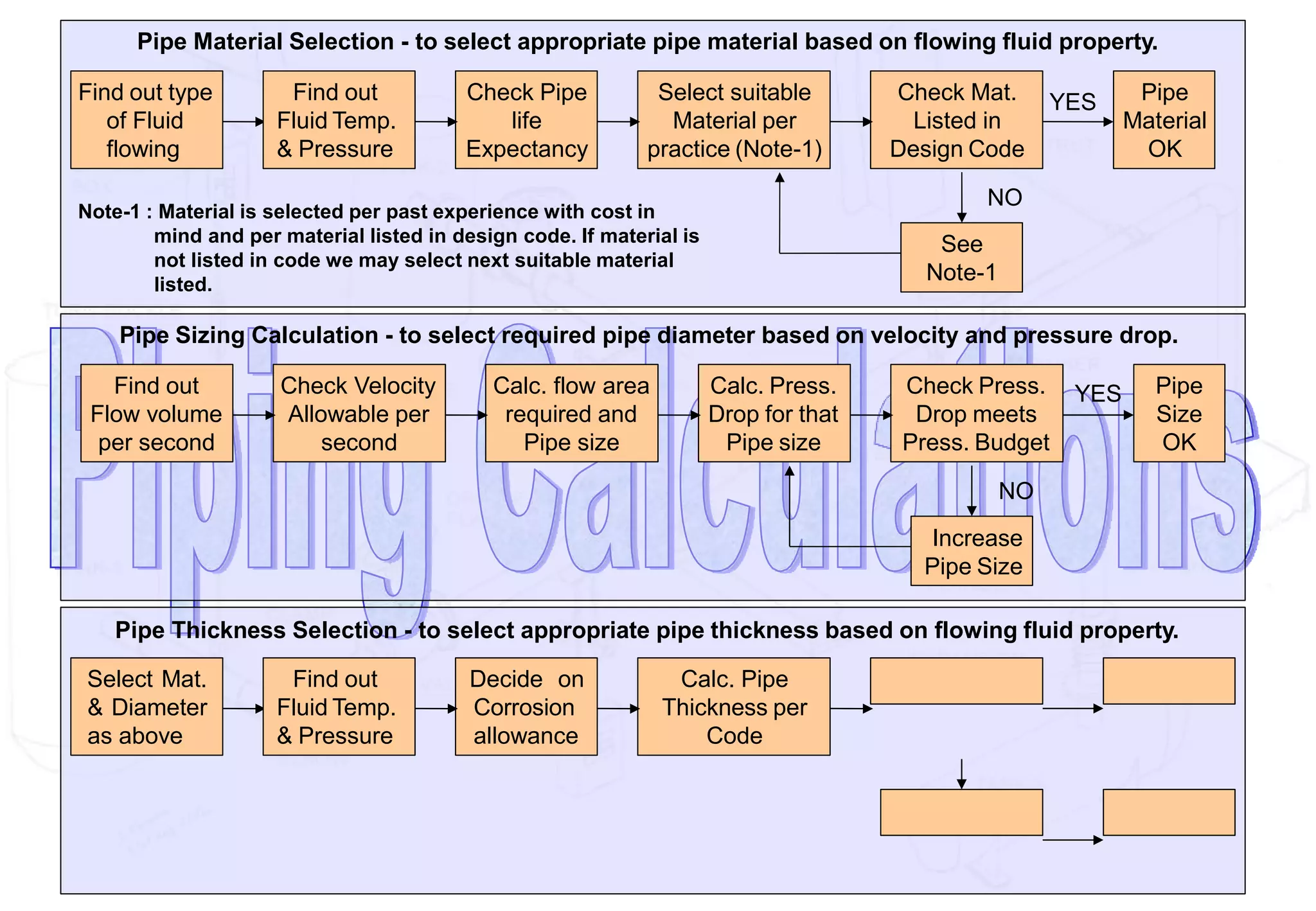

Piping is used to convey liquids, gases, or materials through a process plant. Key considerations for piping design include selecting pipe sizes and materials based on flow properties, installing necessary fittings, valves, instruments and supports, and conducting pipe stress analysis to ensure the piping can withstand pressures and temperatures. Critical high-pressure steam and water lines require special attention to flexibility and stress analysis to safely manage thermal expansion and prevent failures.