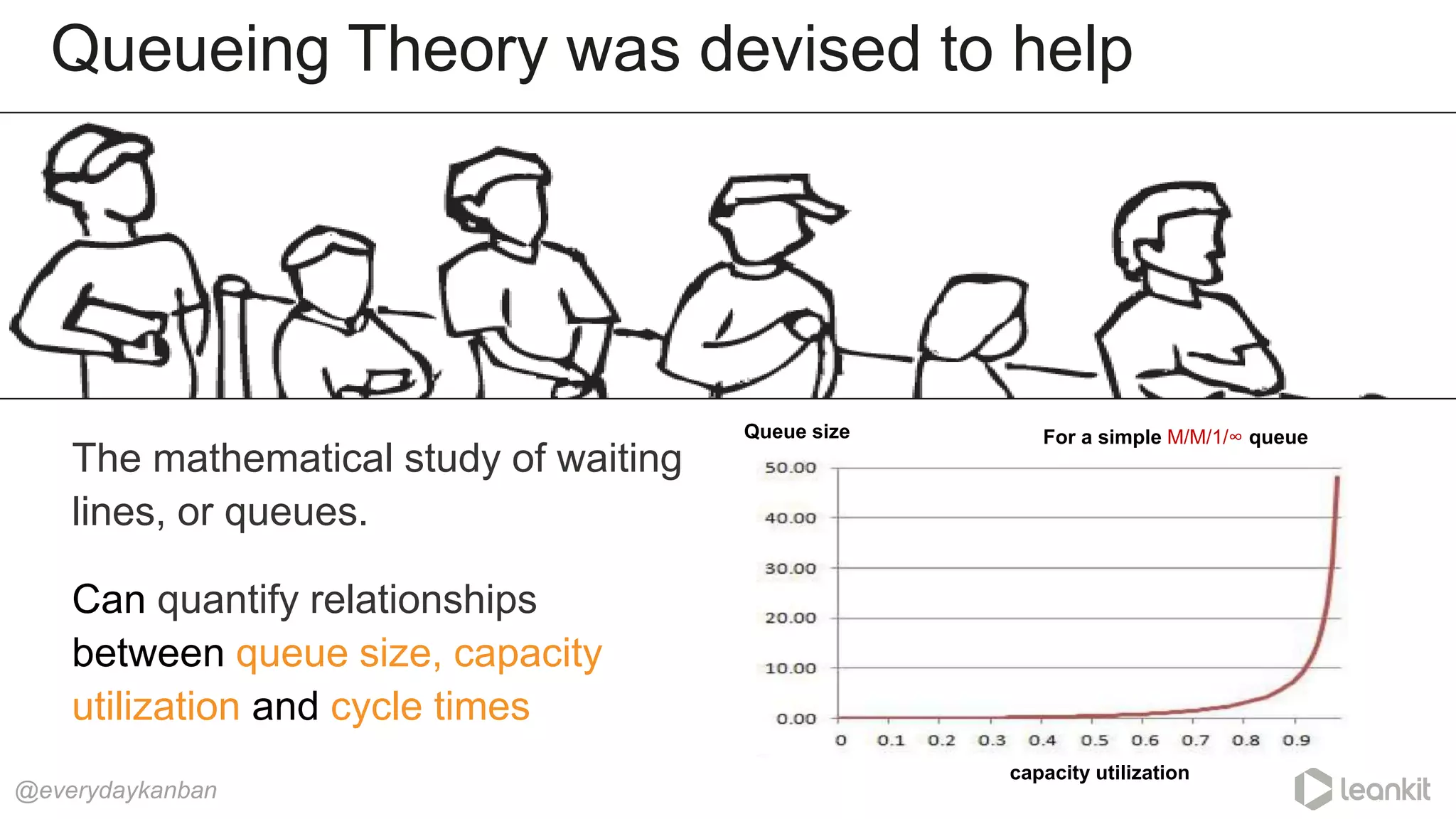

This document discusses predictability in software development and how it relates to managing work queues and flow. It provides several key points:

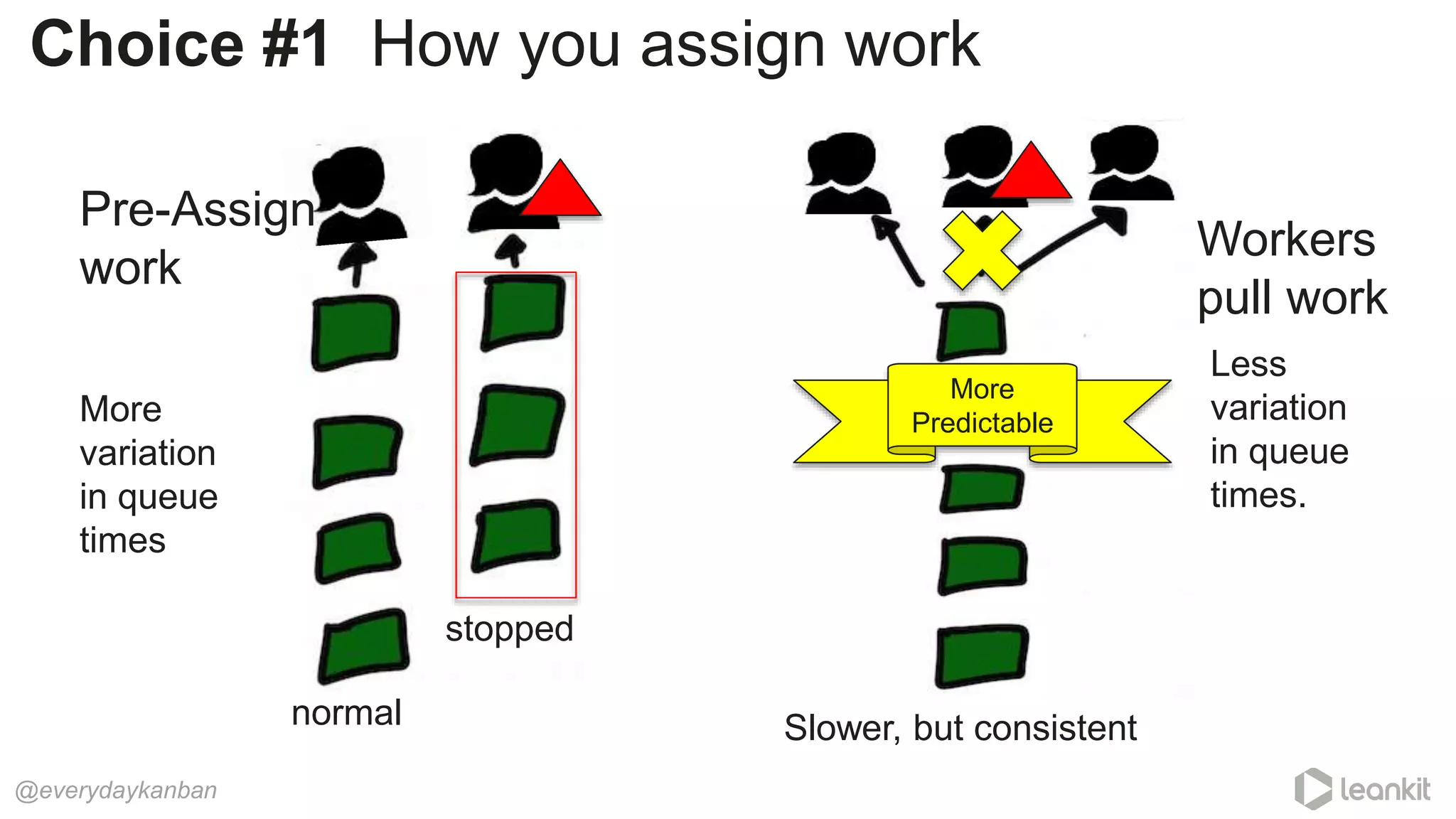

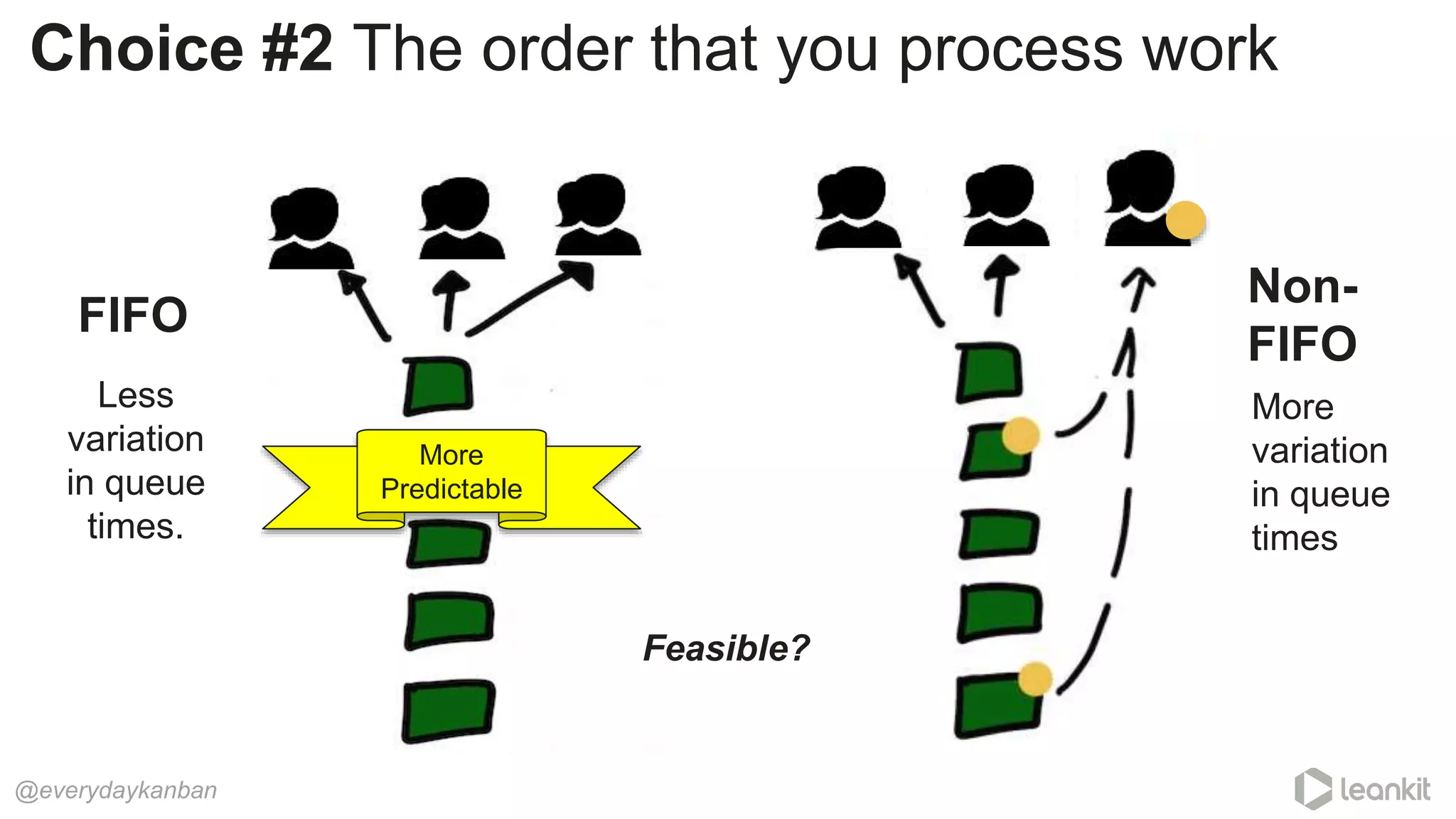

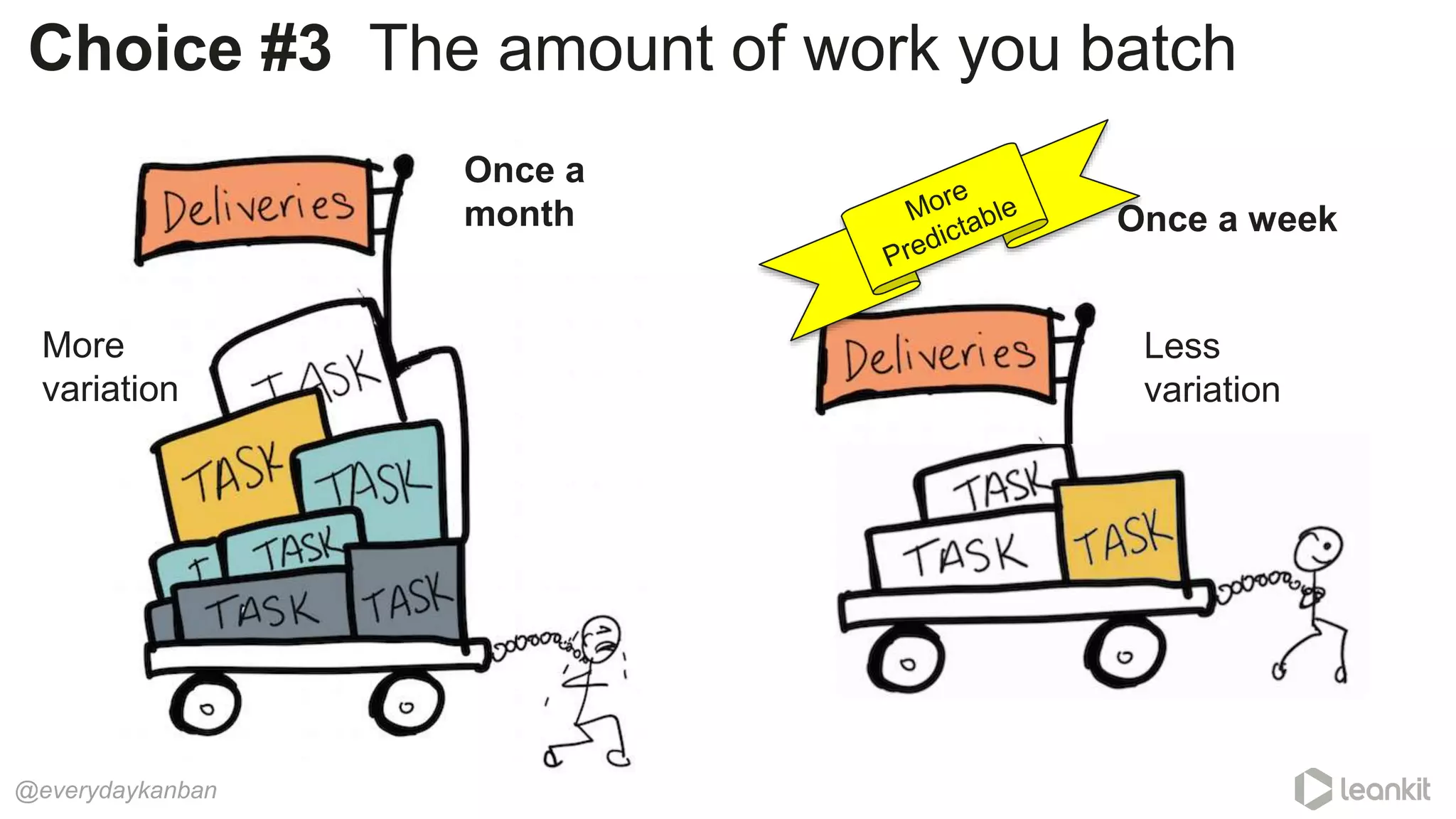

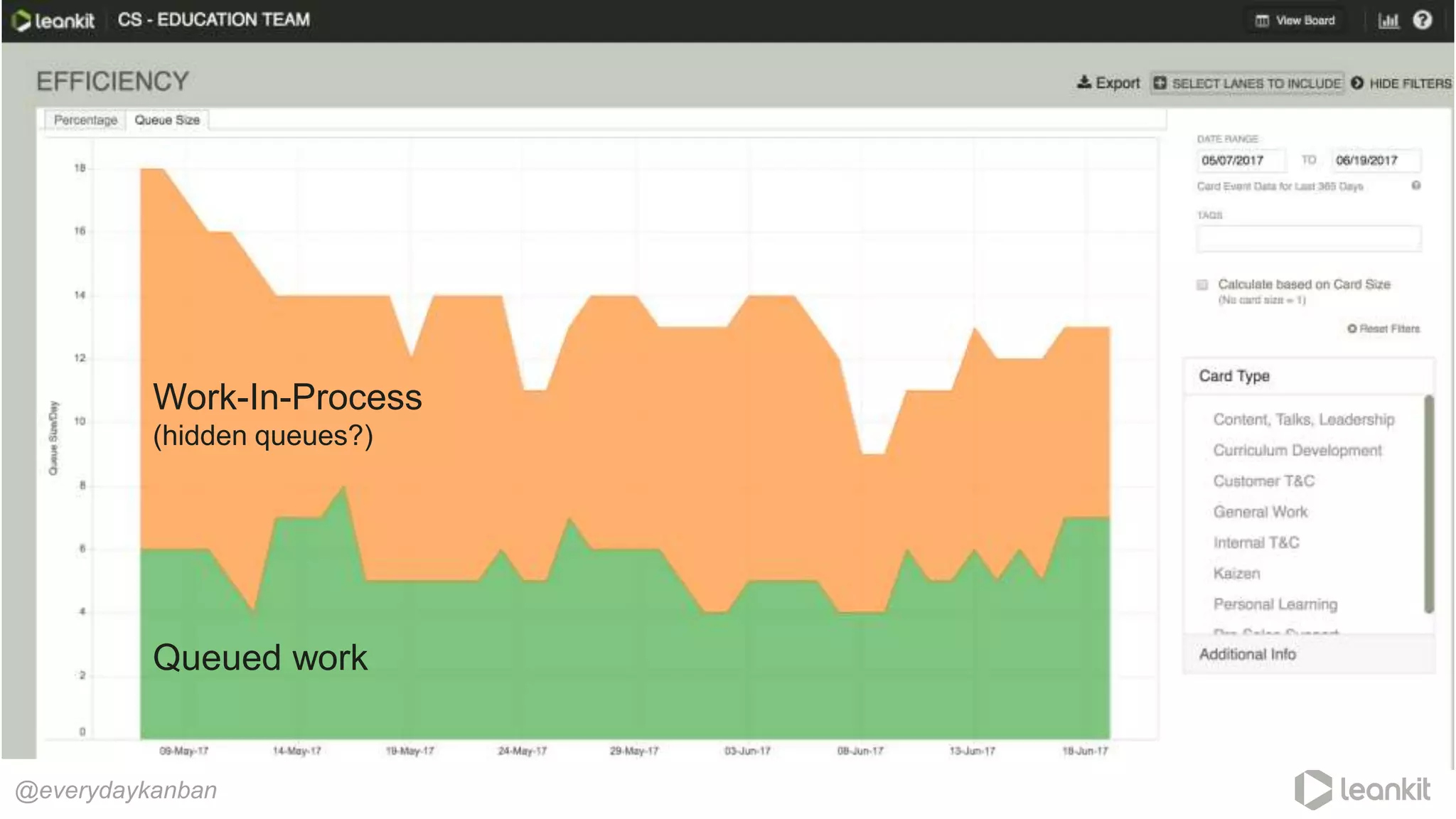

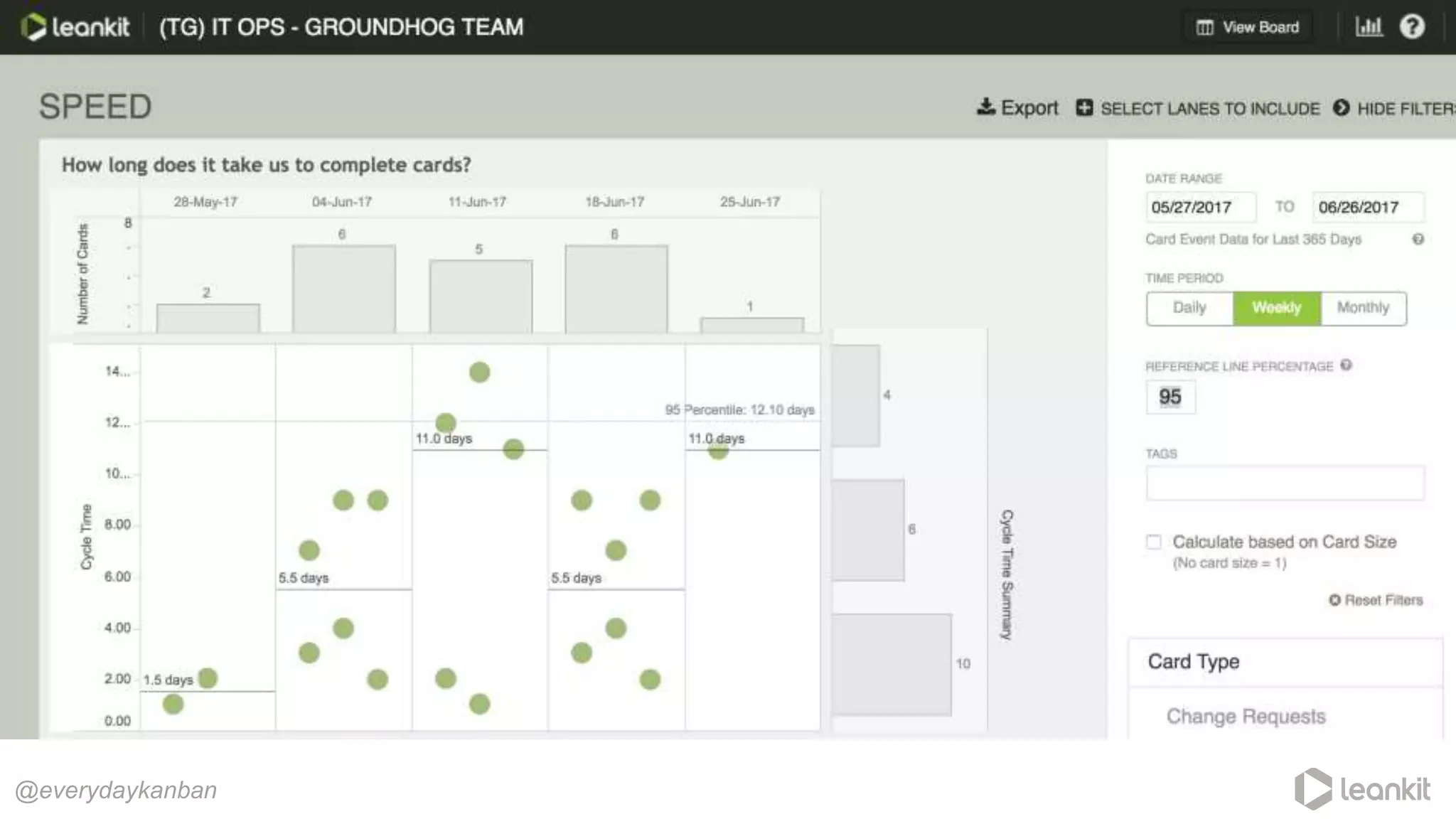

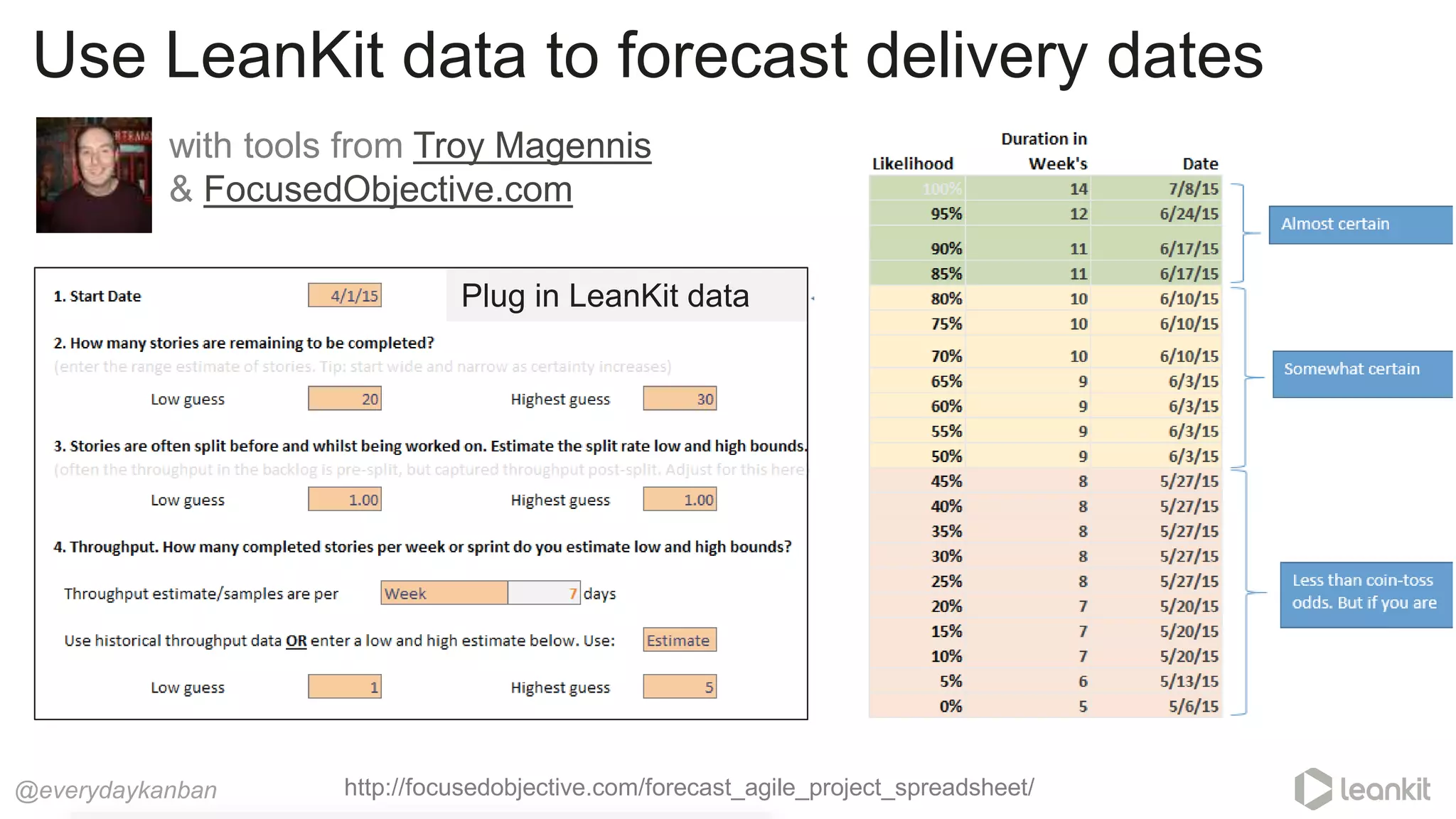

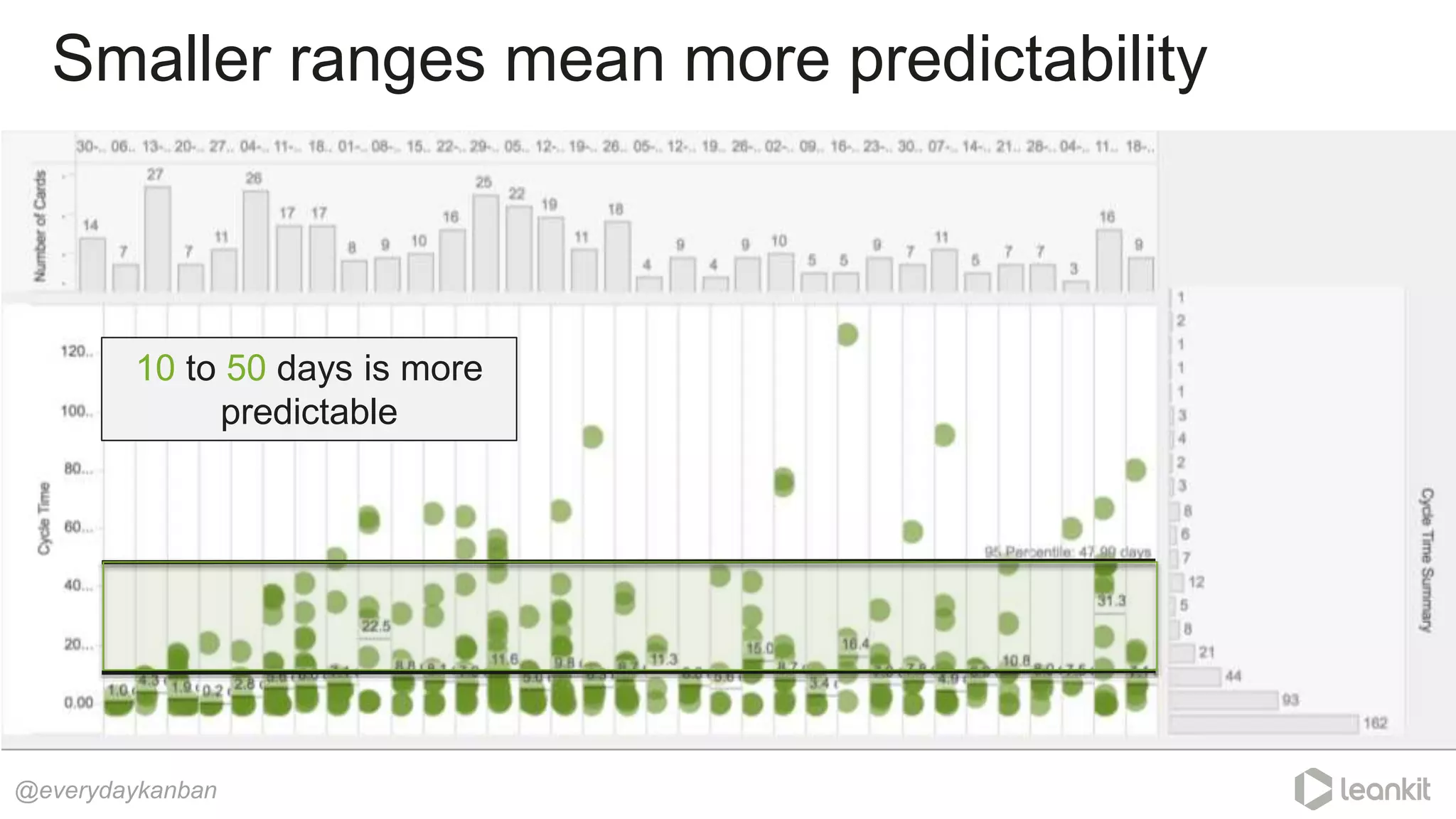

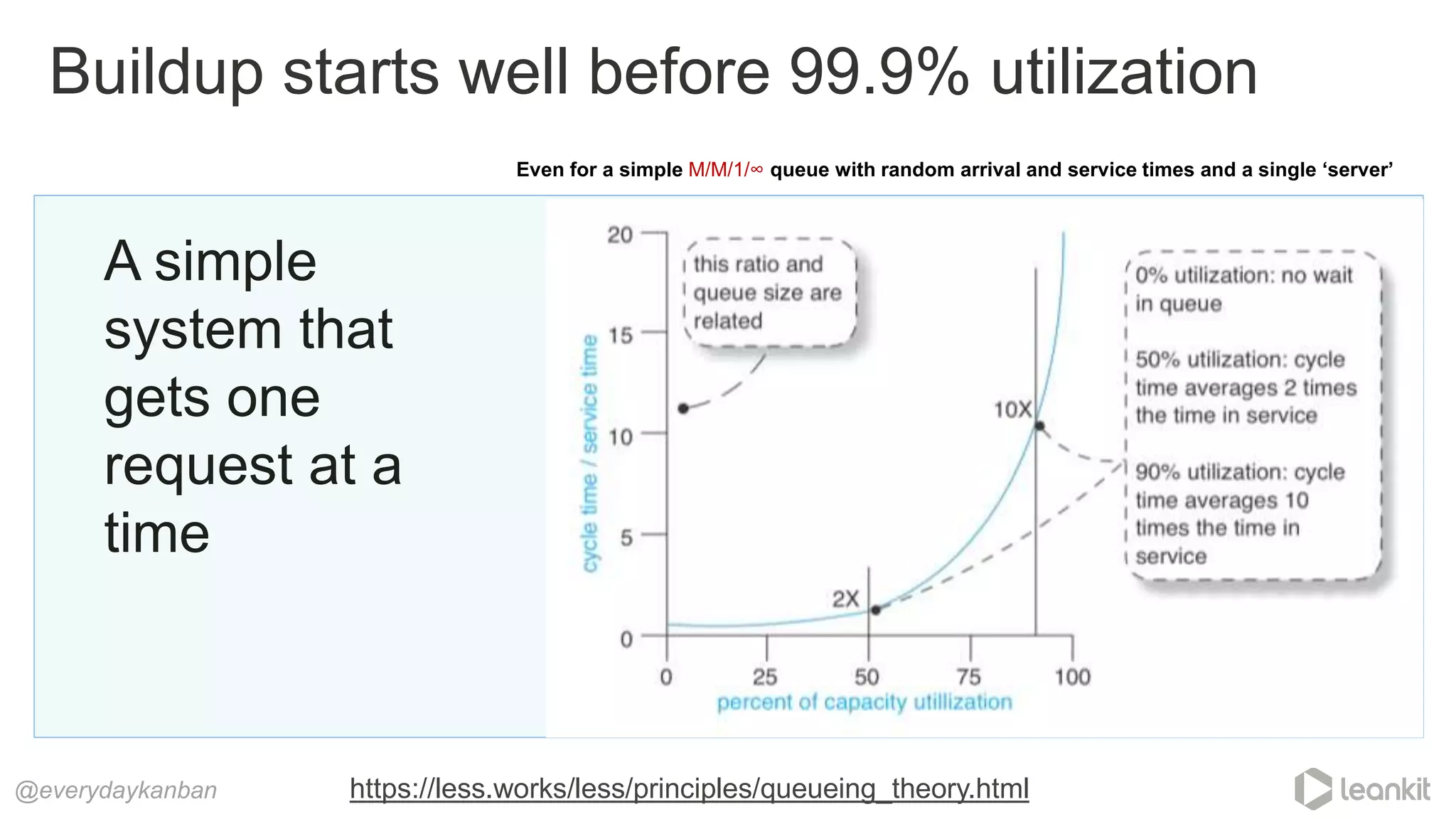

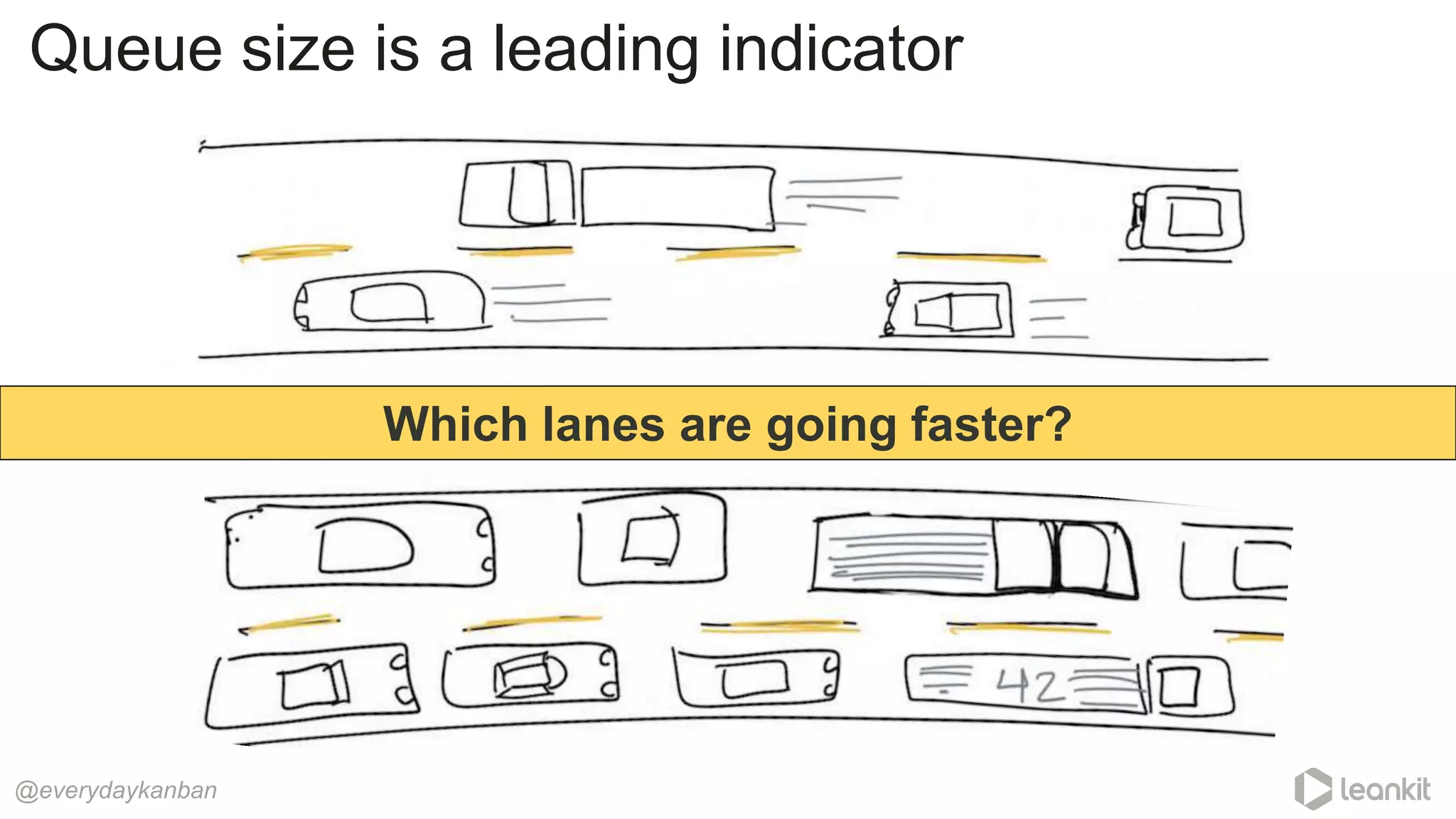

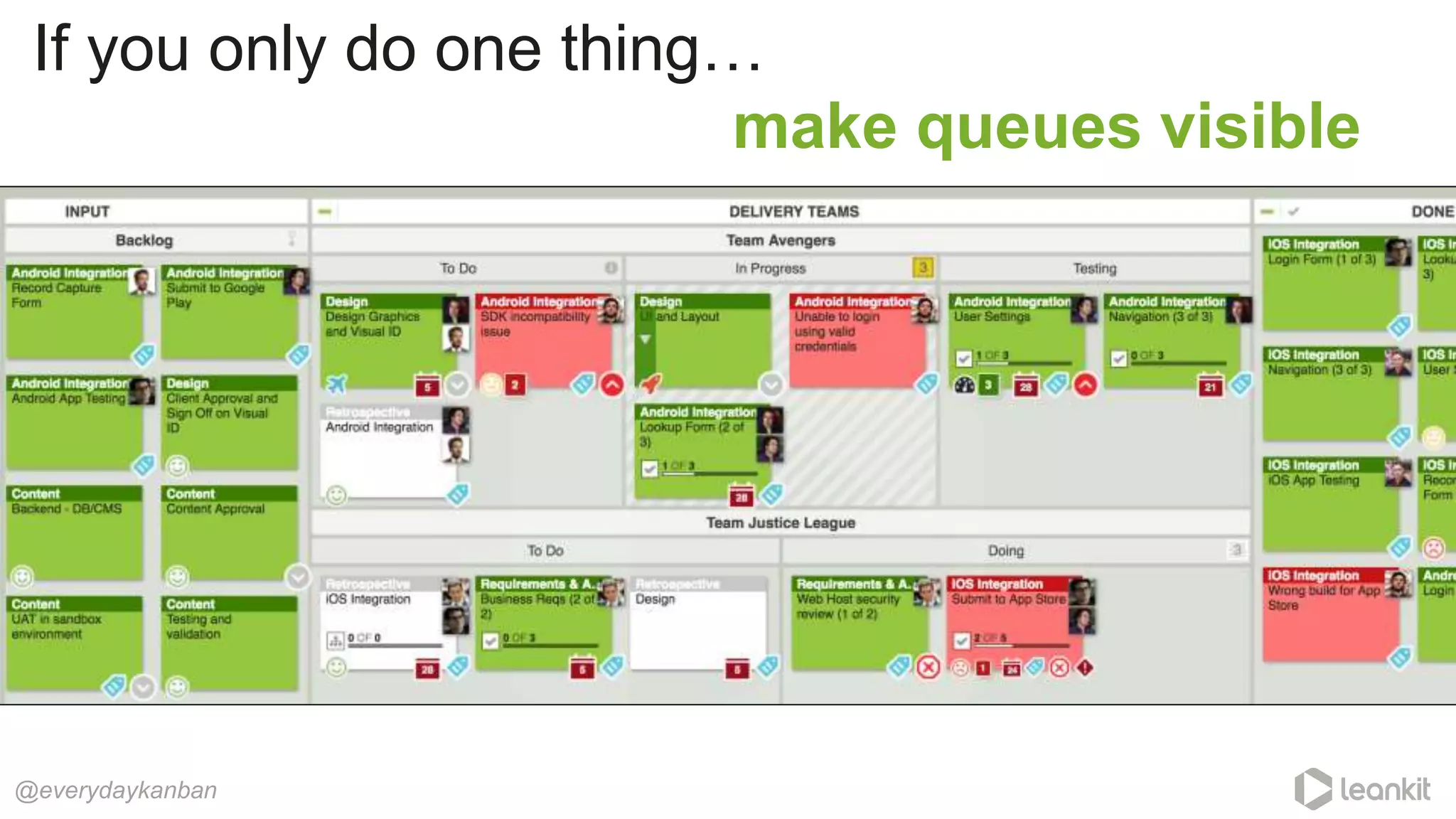

1. Predictability is driven by the range of outcomes, with smaller ranges meaning more predictability. Queue size and utilization also impact predictability.

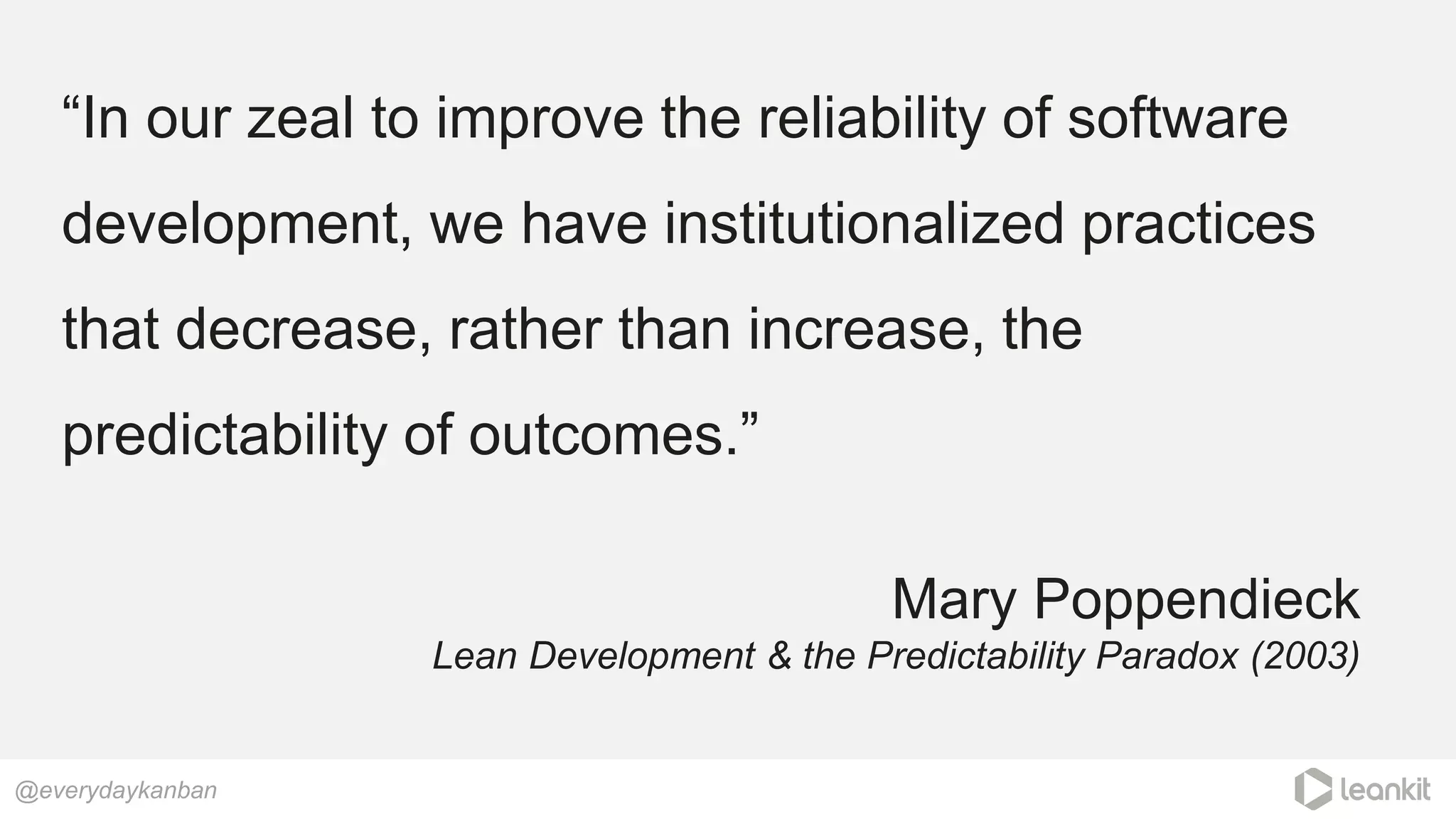

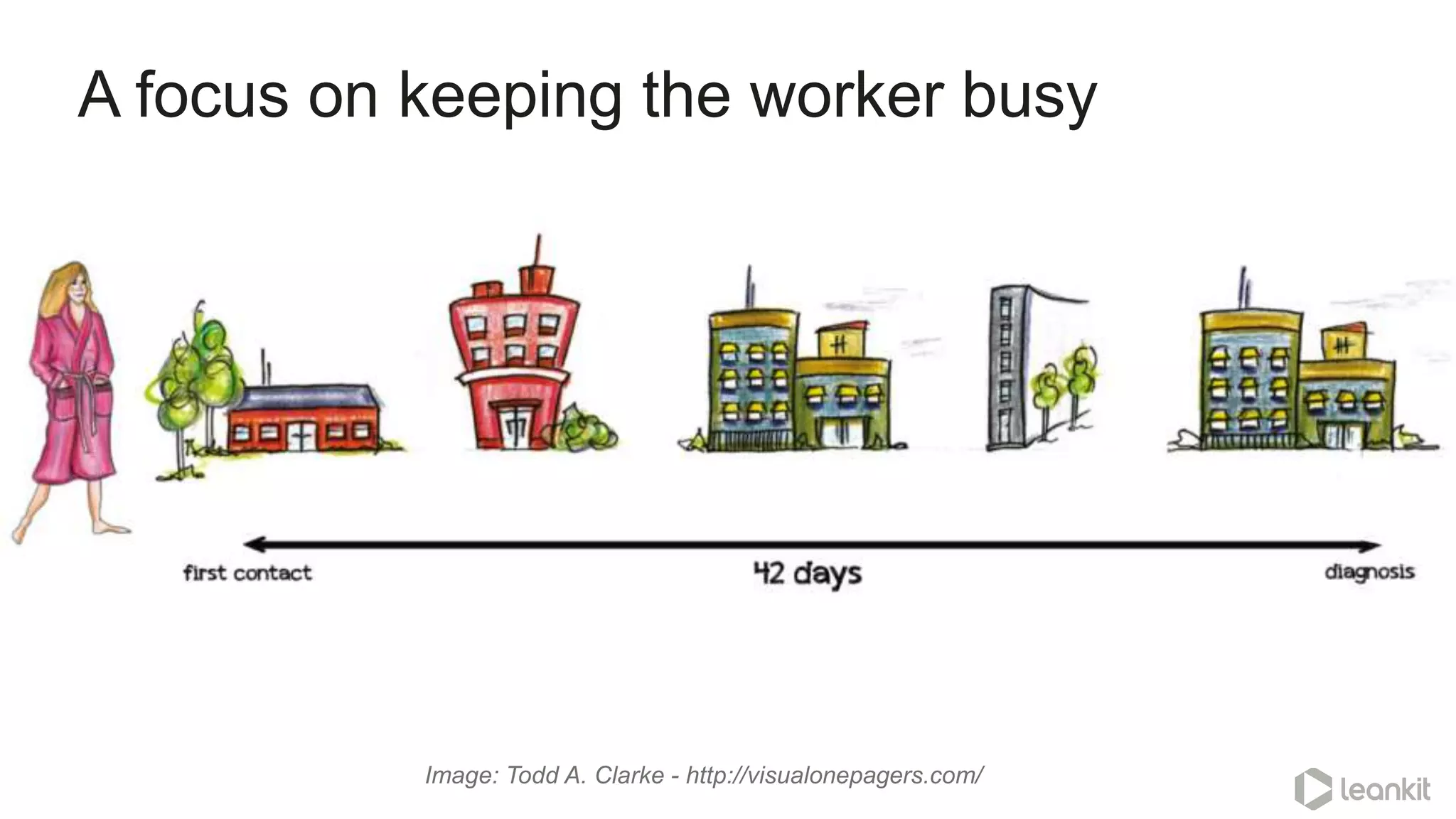

2. Common practices aimed at improving reliability can actually decrease predictability by increasing variation in work and queues.

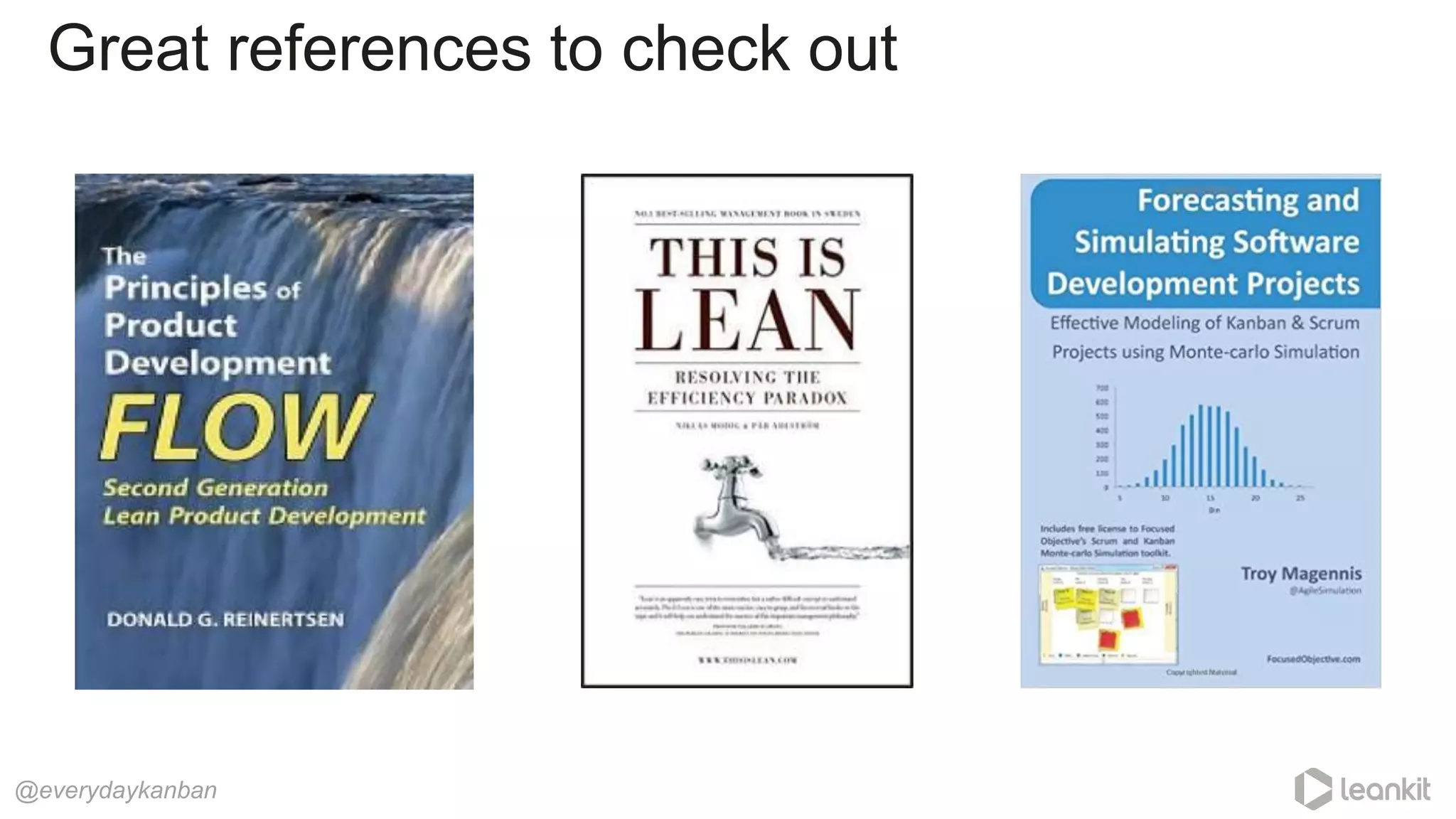

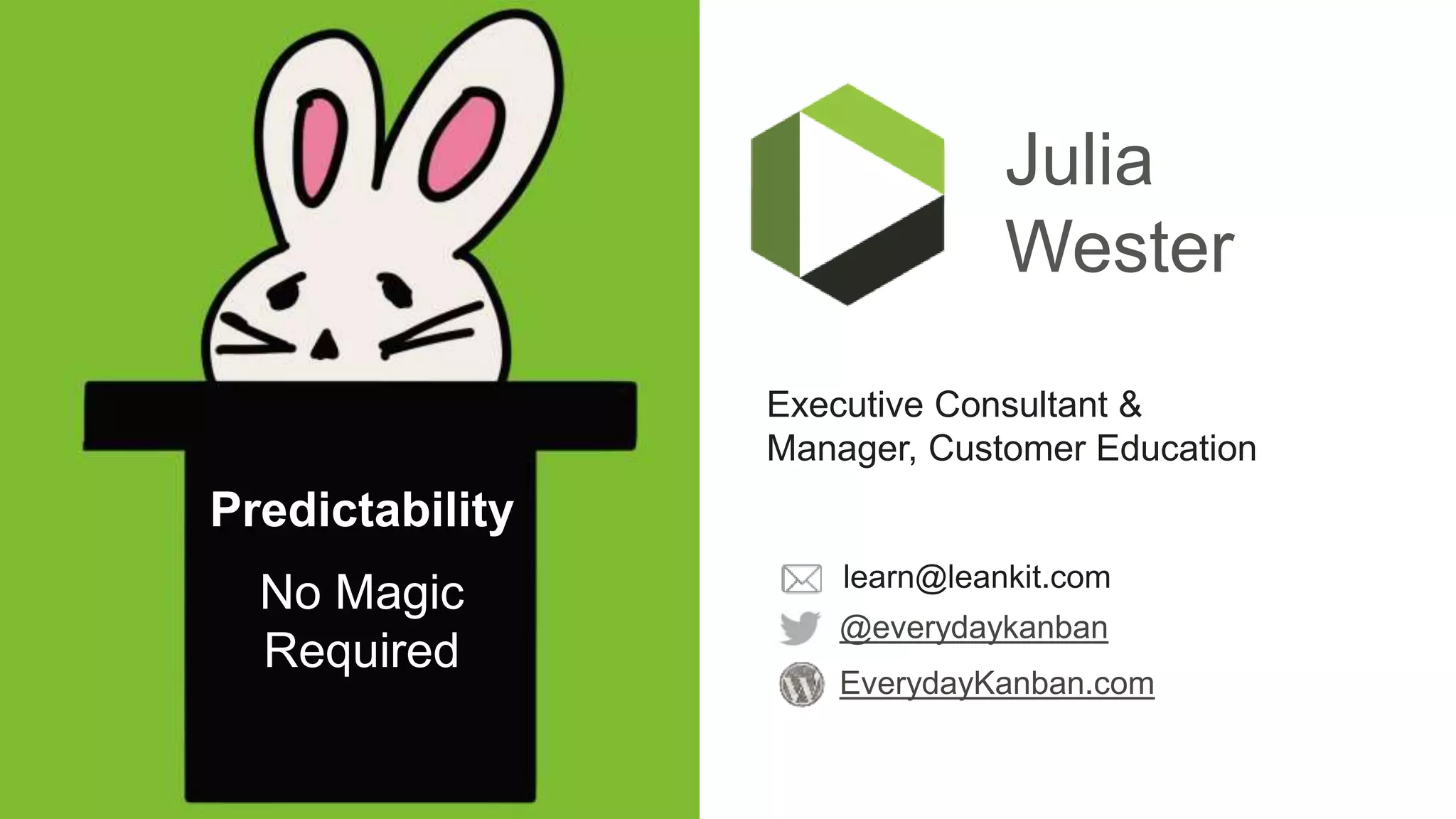

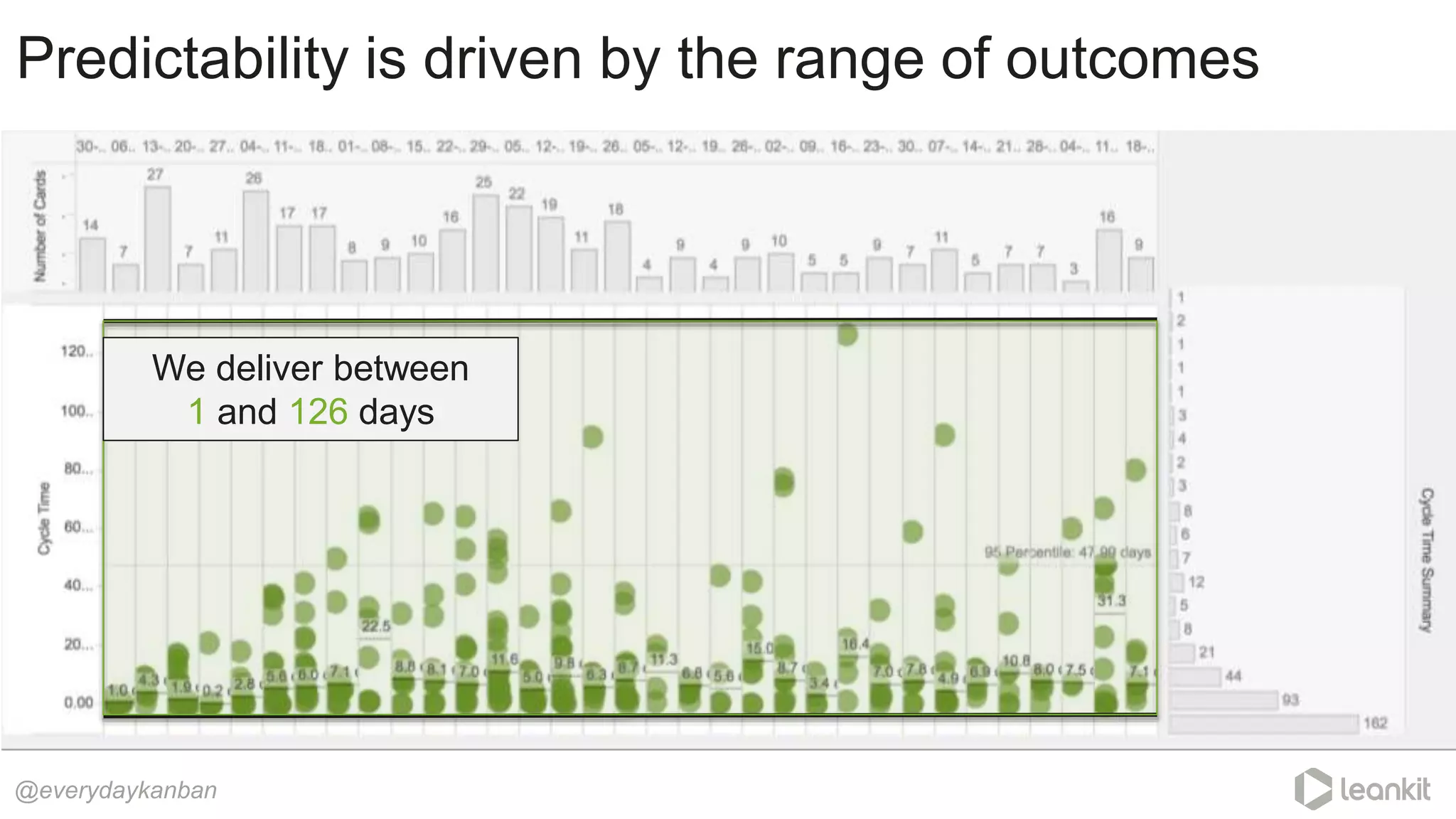

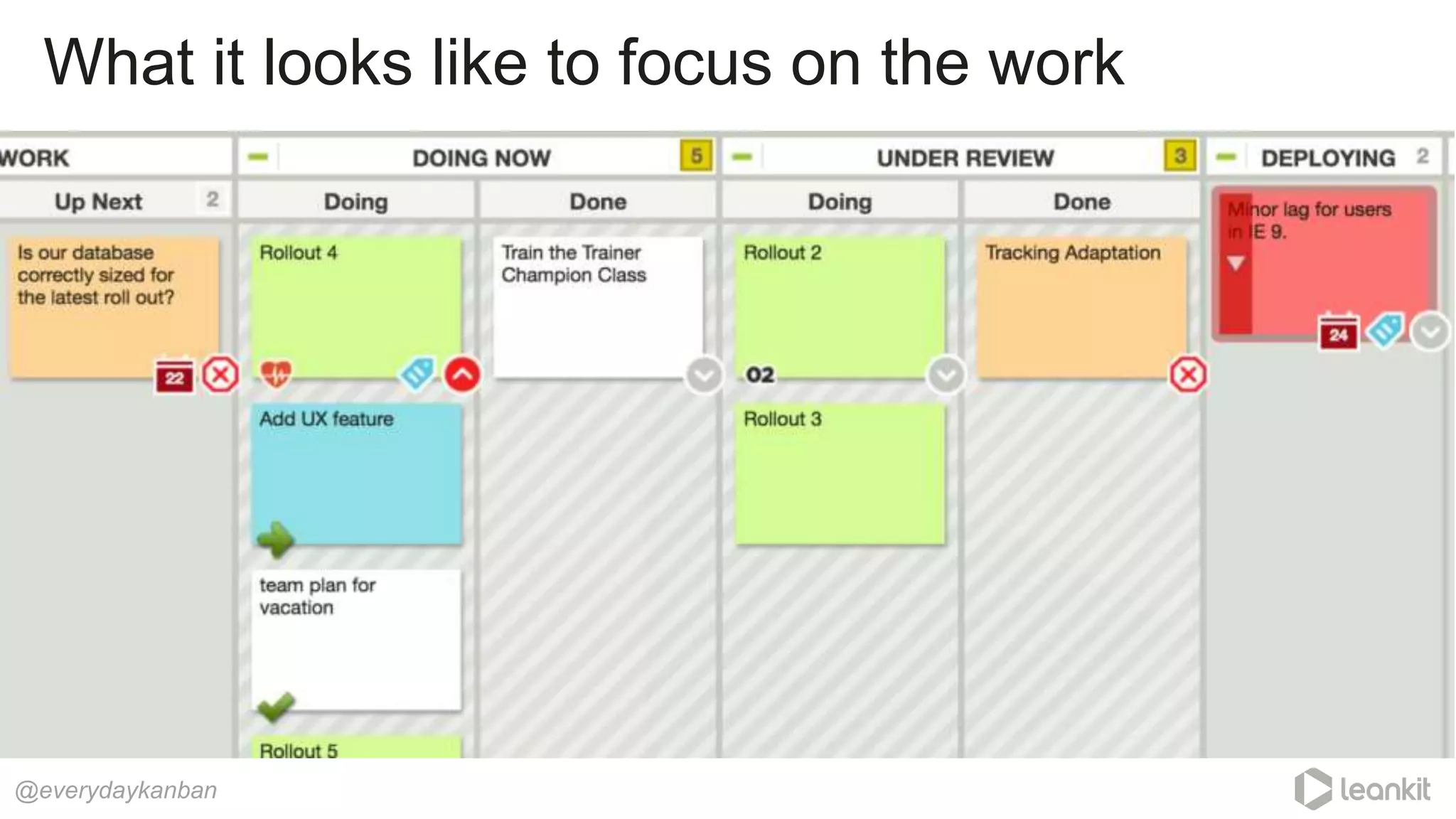

3. Queueing theory can help quantify relationships between queue size, utilization, and cycle times. Managing queues and smoothing flow is important for predictability.

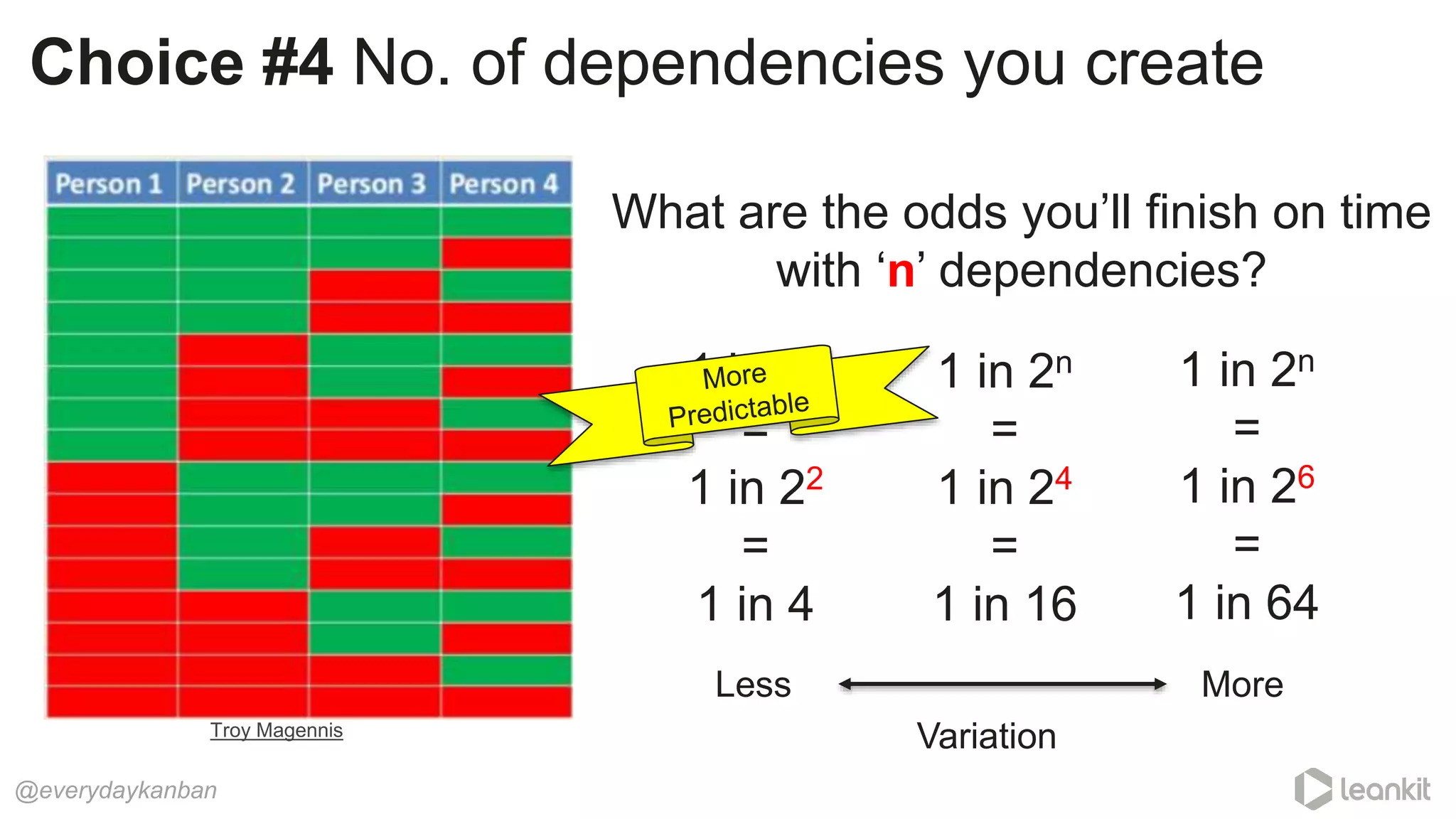

4. Choices around work assignment, processing order, batching, and dependencies all impact variation in queues and predictability. Monitoring work-in-process, queued work

![Adjective

Expected, especially on the basis

of previous or known behavior

Predictable

[pri-dik-tuh-buh l]

@everydaykanban

USUALLY

________!](https://image.slidesharecdn.com/predictability-webinar-170629155922/75/Predictability-No-Magic-Required-LeanKit-Webinar-June-2017-2-2048.jpg)

![Request size Utilization Cycle Time

Single item

requests

50% 2x Time in service

90% 10x Time in service

Big Batch

requests

50% 5x Time in Service

90% 22x Time in Service

What about queues that aren’t so simple?

@everydaykanban https://less.works/less/principles/queueing_theory.html

Big Batches with random arrivals and service times: M[x]/M/1/∞ queue](https://image.slidesharecdn.com/predictability-webinar-170629155922/75/Predictability-No-Magic-Required-LeanKit-Webinar-June-2017-13-2048.jpg)

![“100% of developers

[that I surveyed] measured

cycle time.

2% measured queues.”

@everydaykanban

Donald Reinertsen

The Principles of Product Development Flow (2009)](https://image.slidesharecdn.com/predictability-webinar-170629155922/75/Predictability-No-Magic-Required-LeanKit-Webinar-June-2017-16-2048.jpg)

![“Business units that embraced

[process/queue management] reduced their

average [product] development times by 30%

to 50%.”

@everydaykanban

OnPoint - HBR.org

Getting the most out of your product development process (2003)](https://image.slidesharecdn.com/predictability-webinar-170629155922/75/Predictability-No-Magic-Required-LeanKit-Webinar-June-2017-24-2048.jpg)