Development Of A Particle Sampling Roller

•

0 likes•507 views

This material is presented as an example of work I\'ve done. The information has been previously published and is presented here in a low detail format.

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (19)

Plasticizers (solid content, expose chloride, etc.)

Plasticizers (solid content, expose chloride, etc.)

Environmental Factors Affecting Drying Time on Plastic and Potential Issues A...

Environmental Factors Affecting Drying Time on Plastic and Potential Issues A...

Lab 3 measurement of the viscosity of drilling mud using marsh funnel.

Lab 3 measurement of the viscosity of drilling mud using marsh funnel.

Optimization MRR Of Stainless Steel 403 In Abrasive Water Jet Machining Using...

Optimization MRR Of Stainless Steel 403 In Abrasive Water Jet Machining Using...

Lab 10 measurement of the oil, water and solid contents of drilling mud samp...

Lab 10 measurement of the oil, water and solid contents of drilling mud samp...

Item 7 :Comparación de los *SOPs entre LATSOLAN y **SEALNET

Item 7 :Comparación de los *SOPs entre LATSOLAN y **SEALNET

Viewers also liked

Viewers also liked (7)

Similar to Development Of A Particle Sampling Roller

Similar to Development Of A Particle Sampling Roller (20)

Testing equipments used in thermal spraying aluminium coating

Testing equipments used in thermal spraying aluminium coating

Analysis for predicting the Input Interactions of HBF Performance at -10 μm P...

Analysis for predicting the Input Interactions of HBF Performance at -10 μm P...

Technology reqmts-hvac-design-ses-2-aseptic-wkshp-pune-f

Technology reqmts-hvac-design-ses-2-aseptic-wkshp-pune-f

Development Of A Particle Sampling Roller

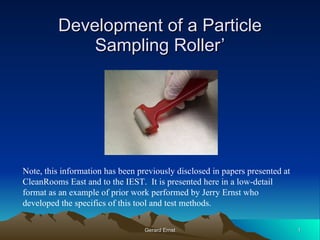

- 1. Development of a Particle Sampling Roller’ Note, this information has been previously disclosed in papers presented at CleanRooms East and to the IEST. It is presented here in a low-detail format as an example of prior work performed by Jerry Ernst who developed the specifics of this tool and test methods.