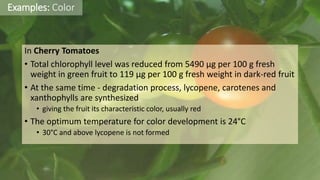

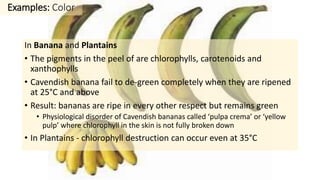

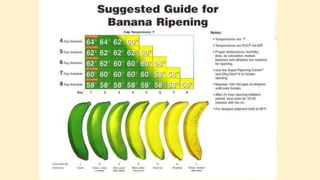

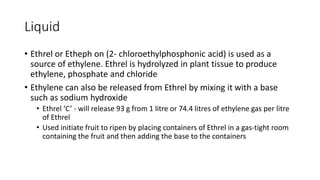

This document discusses fruit ripening conditions and factors that influence the ripening process. It describes how climacteric and non-climacteric fruits differ in their respiration rates during ripening. Ripening involves physical and chemical changes in the fruit brought about by ethylene exposure and environmental conditions like temperature and humidity. Key changes during ripening include softening of texture, changes in color, sugar content, acidity, and the development of flavor and aroma compounds. The role of ethylene and controlled atmosphere storage conditions in modulating the ripening process is also covered.