The Basics Of Heat Treatment.pdf

•

0 likes•3 views

Heat treatment is a process used to alter the physical, mechanical, and metallurgical properties of a material by heating and cooling it in a controlled manner. The goal of heat treatment is to improve the material's properties such as strength, toughness, and wear resistance. There are several different heat treatment techniques, including annealing, normalizing, hardening, tempering, carburizing, nitriding, and induction hardening, each with its own unique set of benefits and applications. Understanding the basics of heat treatment is essential for those working in industries such as aerospace, automotive, and medical devices, where high-performance materials are critical.

Report

Share

Report

Share

Download to read offline

Recommended

More Related Content

Similar to The Basics Of Heat Treatment.pdf

Similar to The Basics Of Heat Treatment.pdf (20)

Induction Heating – Operation, Applications and Case Studies

Induction Heating – Operation, Applications and Case Studies

Induction Heating – Operation, Applications and Case Studies - Presentation S...

Induction Heating – Operation, Applications and Case Studies - Presentation S...

Induction Heating – Operation, Applications and Case Studies

Induction Heating – Operation, Applications and Case Studies

Influence of various parameters of cryogenic treatment on performance of tun...

Influence of various parameters of cryogenic treatment on performance of tun...

The International Journal of Engineering and Science (IJES)

The International Journal of Engineering and Science (IJES)

Recently uploaded

Recently uploaded (20)

Unit 4_Part 1 CSE2001 Exception Handling and Function Template and Class Temp...

Unit 4_Part 1 CSE2001 Exception Handling and Function Template and Class Temp...

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Standard vs Custom Battery Packs - Decoding the Power Play

Standard vs Custom Battery Packs - Decoding the Power Play

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

"Lesotho Leaps Forward: A Chronicle of Transformative Developments"

"Lesotho Leaps Forward: A Chronicle of Transformative Developments"

NO1 Top No1 Amil Baba In Azad Kashmir, Kashmir Black Magic Specialist Expert ...

NO1 Top No1 Amil Baba In Azad Kashmir, Kashmir Black Magic Specialist Expert ...

Block diagram reduction techniques in control systems.ppt

Block diagram reduction techniques in control systems.ppt

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

DC MACHINE-Motoring and generation, Armature circuit equation

DC MACHINE-Motoring and generation, Armature circuit equation

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

The Basics Of Heat Treatment.pdf

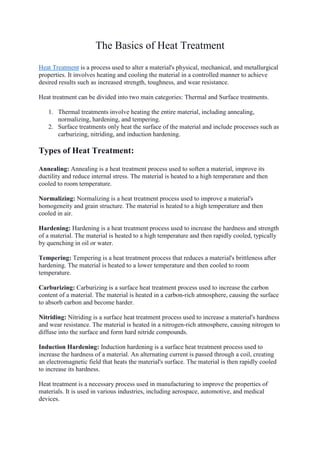

- 1. The Basics of Heat Treatment Heat Treatment is a process used to alter a material's physical, mechanical, and metallurgical properties. It involves heating and cooling the material in a controlled manner to achieve desired results such as increased strength, toughness, and wear resistance. Heat treatment can be divided into two main categories: Thermal and Surface treatments. 1. Thermal treatments involve heating the entire material, including annealing, normalizing, hardening, and tempering. 2. Surface treatments only heat the surface of the material and include processes such as carburizing, nitriding, and induction hardening. Types of Heat Treatment: Annealing: Annealing is a heat treatment process used to soften a material, improve its ductility and reduce internal stress. The material is heated to a high temperature and then cooled to room temperature. Normalizing: Normalizing is a heat treatment process used to improve a material's homogeneity and grain structure. The material is heated to a high temperature and then cooled in air. Hardening: Hardening is a heat treatment process used to increase the hardness and strength of a material. The material is heated to a high temperature and then rapidly cooled, typically by quenching in oil or water. Tempering: Tempering is a heat treatment process that reduces a material's brittleness after hardening. The material is heated to a lower temperature and then cooled to room temperature. Carburizing: Carburizing is a surface heat treatment process used to increase the carbon content of a material. The material is heated in a carbon-rich atmosphere, causing the surface to absorb carbon and become harder. Nitriding: Nitriding is a surface heat treatment process used to increase a material's hardness and wear resistance. The material is heated in a nitrogen-rich atmosphere, causing nitrogen to diffuse into the surface and form hard nitride compounds. Induction Hardening: Induction hardening is a surface heat treatment process used to increase the hardness of a material. An alternating current is passed through a coil, creating an electromagnetic field that heats the material's surface. The material is then rapidly cooled to increase its hardness. Heat treatment is a necessary process used in manufacturing to improve the properties of materials. It is used in various industries, including aerospace, automotive, and medical devices.

- 2. Conclusion: In conclusion, heat treatment is a critical process in manufacturing that is used to improve materials' physical, mechanical, and metallurgical properties. The process involves heating and cooling the material in a controlled manner to achieve desired results such as increased strength, toughness, and wear resistance. There are several different heat treatment techniques, including annealing, normalizing, hardening, tempering, carburizing, nitriding, and induction hardening, each with unique benefits and applications. Heat treatment is widely used in industries such as aerospace, automotive, and medical devices to improve the performance and reliability of materials. Whether you are an engineer, manufacturer, or simply interested in materials science, understanding the basics of heat treatment is essential for success.