ENGINEERING TECHNOLOGY RESUME

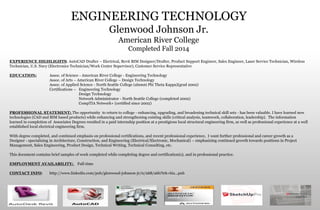

- 1. ENGINEERING TECHNOLOGY Glenwood Johnson Jr. American River College Completed Fall 2014 EXPERIENCE HIGHLIGHTS: AutoCAD Drafter – Electrical, Revit BIM Designer/Drafter, Product Support Engineer, Sales Engineer, Laser Service Technician, Wireless Technician, U.S. Navy (Electronics Technician/Work Center Supervisor), Customer Service Representative EDUCATION: Assoc. of Science - American River College - Engineering Technology Assoc. of Arts – American River College – Design Technology Assoc. of Applied Science - North Seattle College (alumni Phi Theta Kappa)(grad 2002) Certifications – Engineering Technology Design Technology Network Administrator - North Seattle College (completed 2002) CompTIA Network+ (certified since 2002) PROFESSIONAL STATEMENT: The opportunity to return to college - enhancing, upgrading, and broadening technical skill sets - has been valuable. I have learned new technologies (CAD and BIM based products) while enhancing and strengthening existing skills (critical analysis, teamwork, collaboration, leadership). The information learned in completion of Associates Degrees resulted in a paid internship position at a prestigious local structural engineering firm, as well as professional experience at a well established local electrical engineering firm. With degree completed, and continued emphasis on professional certifications, and recent professional experience, I want further professional and career growth as a Designer - specializing in Architecture, Construction, and Engineering (Electrical/Electronic, Mechanical) – emphasizing continued growth towards positions in Project Management, Sales Engineering, Product Design, Technical Writing, Technical Consulting, etc. This document contains brief samples of work completed while completing degree and certification(s), and in professional practice. EMPLOYMENT AVAILABILITY: Full-time CONTACT INFO: http://www.linkedin.com/pub/glenwood-johnson-jr/0/268/a6b?trk=biz...pub

- 8. Section3 AutoCAD Modeling Creating models based on provided specifications AutoCADModeling 1 Solid Models EngineeringModeling 3-D wireframe view of AMES 6”2000SS Backflow Preventer, using AutoCAD. Solid model view of AMES 6” 2000 Backflow Preventer, using AutoCAD. AMES 6’ 2000SS Backflow Preventer design specifications provided per PDF.

- 9. AutoCAD Modeling Creating models based on provided specifications AutoCADModeling 3 Visualizations and Renderings EngineeringModeling MATerials browser, via AUTOCAD 2013, utilized to apply selected material to designed model. Visualization of AMES 2000SS Backflow Preventer, with materials applied using MATerials brower in AUTOCAD 2013.

- 10. AutoCAD Modeling Creating models based on provided specifications AutoCADModeling 4 Animations EngineeringModeling Animation path of WATTS 12” ACV, modeled per provided specifications

- 11. Sketch-Up Modeling 1 Mechanical Models Sketch-UpModelingEngineeringModeling Photo of Baldor Electrical Motor, courtesy of Google Images. 3D Model created with SketchUp, v8, per provided specifications. File: Motor Template 256T Frame. Design sketches used to create solid model of BALDOR Electric Motor, specs downloaded from d2L. Animation created within SketchUpv8. Located on K:EDUCATIONDESIGN AND ENGINEERING TECHNOLOGYDESIGNDESIGN328U nit 3.

- 12. Mechanical Room Plan MechanicalRoom addition 3D overall site view Level 1 Level 3 Level 2 GlenwoodJohnson EngineeringSystemsandDesign Initial client provided information prior to additions, modifications, and technical data inclusion. Data provided via REVIT .project file, saved to external USB.

- 13. Mechanical Room Plan MechanicalRoom addition GlenwoodJohnson EngineeringSystemsandDesign 3D view - NE exterior, post Mechanical room addition 3D view - SE exterior, including addition of double flush door, per client. Level 1 view, including mechanical room addition, room labels, door labels, door locations, and selected door type information. Annotated Level 1 and 3D views, post Mechanical room addition. Spaces modified and labeled using the WALL and DOOR commands within REVIT 2013, saved to external USB. Views include: - Level 1 layout NE external - 3D SE exterior - 3D NE exterior

- 14. Mechanical Room Plan MechanicalRoom Addition GlenwoodJohnson EngineeringSystemsandDesign Sheet A100 - includes - Space plan including additions - Master Format Spec - Room Schedules - Door schedules

- 15. HVAC System GlenwoodJohnson EngineeringSystemsandDesign HVACSystem Snips of Mechanical Equipment Schedule, created in Revit 2013 (below with gray shading). Schedule included within CEC- HYBRID-MEP.rvt, saved externally. (above) - Revit version; (below) technical version Level 1 Schematic view, including annotated Supply and Return Air systems, terminals, section view callous, and equipment tags. Saved externally to CEC-HYBRID-MEP.rvt. Rendered view of Mechanical Room addition, medium quality, with artificial and natural lighting. Image externally saved as a .PNG fine. Created with Revit 2013. 3D visualization of Return and Supply system ducting and terminals, HVAC system, Mech Room access, and Repair Bay doors.

- 16. HVAC System HVACSystemGlenwoodJohnson EngineeringSystemsandDesign 3D view of Mech Room, including Spot Elevations, Supply and Return Air systems, terminals, and HVAC unit. Created with Revit 2013, saved externally. 3D Plan view(s) (above) Supply lines from Mech Room (not shown) thru Repair Bays to Access area. (below) North view, 3D, indicating return lines to Mech Room, HVAC unit, and Supply Air lines out to Repair Bays

- 17. HVAC System GlenwoodJohnson EngineeringSystemsandDesign HVACSystem Sheet M100 - Schedules, Calculations, Visualizations - Mechanical Room requirements - Space plan including additions - 3D internal view from repair bay to mechanical room - 3D exterior view including entry - Rendered internal view of Access entry to Repair Bays

- 18. HVAC System HVACSystemGlenwoodJohnson EngineeringSystemsandDesign Sheet M110 - includes - Level 1 Schematic Section views: - Mechanical Room , incl 3D visuals with HVAC unit and elevations - Section view of Supply Air system, incl 3D visuals - Section view of Return Air system, incl. 3D visuals

- 19. Electrical System ElectricalSystemDesignGlenwoodJohnson EngineeringSystemsandDesign Place and Set Up Power Distribution Panels Place and set up junction boxes Place and set up receptacles Connect power circuits Create circuit schedules Analyze Circuits and Select Wire Sizes Analyze Power Density Analyze Building Power Feed Requirements System browser snapshot (above) showing system name, name of PDU (power distribution unit), and type of load (duplex GFCI receptacle, junction box, etc). Snapshot of circuit P2-120-12, illustrating connected GFCI duplex outlet to PDU Level 1 floor plan, with installed power distribution units, junction boxes, GFCI duplexes, and light gage structural steel running columns. Snapshot of PDU circuit P1-480-3, showing connections for Junction Boxes 1,3, and 5.

- 20. Electrical System ElectricalSystemDesignGlenwoodJohnson EngineeringSystemsandDesign 3D, perspective view of repair bay leading to Mechanical Room, with added cable runner beams (light gage steel), junction boxes, and lighting fixtures. Master Format Specifications calling out lighting control panels, lighting panels, wiring devices, wiring methods. (Above) - Section 26 24 16:01 and Section 26 09 23 (Below) - Section 16 10 00 and Section 16 14 00 Plan view of Lighting circuit P3-120-18, including connected lighting devices, circuit designation, wires, and connections to specified 120V panel. Snip of Revit 2013 System Browser, indicating circuit P3- 120-18, volts, distribution system, amperage rating, #of poles.

- 21. Plumbing System PlumbingSystemDesignGlenwoodJohnson EngineeringSystemsandDesign Plan view of plumbing layout - section view callouts included - including plumbing fixtures (toilets/urinals, sinks, tankless heater, valve stops), pipe layout, and shading showing domestic cold and hot water lines. Visual saved externally as a project as CEC-HYBRID-PLUMBING.rvt System browser snip, illustrating piping systems (Domestic Cold Water, Domestic Hot Water), flow rate, pipe size. Saved within CEC-HYBRID- PLUMBING.rvt 3D view - with realistic shading and fine detail level - of connected fixtures (urinal, toilets, sinks, tankless water heater) to piping systems (Domestic Cold Water, Domestic Hot Water). Result of embedded Pipe Analysis Report, showing Total Pressure Loss Data needed to calculate Critical Path Analysis

- 22. Plumbing System PlumbingSystemDesignGlenwoodJohnson EngineeringSystemsandDesign Sheet P100 - CALCS, SCHEDULES, VISUALS - Plumbing Fixture Schedule - Pipe Fitting Schedule - Drafting view of Residual Pressure Calculation (calculation performed in Excel), with data extracted from Pipe Pressure Loss Report (Analyze tab) within Revit - 3D visuals of Mens and Womens Restrooms, including Domestic Cold Water and Sanitary Drain systems

- 23. Facility Workplace Design - Collaboration FacilityWorkplace- DesignCollaborationGlenwoodJohnson EngineeringSystemsandDesign 3 2 Results of CEC-HYBRID Building Collaboration testing, performed with NavisWorks Manage 2014 Clash Detection test, using .DWF files imported from Revit 2014 BIM model files (HVAC, Plumbing, and Electrical. Bubble callouts indicate the following: 1) Initial 3D graphic, .DWF files appended into NavisWorks, 2) results of Clash Detection test, indicating status (active or resolved), 3) 3D graphic showing location of clash between HVAC, Plumbing, and Electric systems, 4) successful resolution of clash between lighting fixture and electrical cable tray runner, and 5) assignment of clash report to appropriate section (Electrical) for resolution. 5 4 1

- 24. Facility Workplace Design FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Sheet W100 - VISUALS - Created in Revit 2014, models imported from RevitCity.com - Additional models imported from AutoCAD - Photos courtesy of ARC Auto Tech Department - Models rendered in Realistic and Consistent Color style - Saved externally to USB in .PDF format - Scale ⅛” - 1’0”

- 25. Facility Workplace Design FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Sheet W110 - SAFETY - Created in Revit 2014, models imported from RevitCity.com - Safety and Vision boxes imported from AutoCAD 2014 file - Annotations ¼” text size - Saved externally to USB in .PDF format - Scale ⅛” - 1’0”

- 26. Facility Workplace Design FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Sheet W120 - SANITARY/WASTE - Created in Revit 2014, models imported from RevitCity.com - Safety and Vision boxes imported from 2014 model file - Annotations ¼” text size - Sanitary/Waste Disposal schedule imported as drafting view from excel spreadsheet - Saved externally to USB in .PDF format - Scale ⅛” - 1’0”

- 27. Facility Workplace Design FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Sheet W130 - OPERATIONS - Created in Revit 2014, models imported from RevitCity.com - Annotations ¼” text size - Operational Equipment Schedule imported as Drafting View, created via Excel spreadsheet - Saved externally to USB in .PDF format - Scale ⅛” - 1’0”

- 28. Component Layout and Modeling FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Excel generated spreadsheet indicating o-ring sizing, including: - thread sizes - inner and outer diameters - thresholds indicating appropriate fitting sizes - Oring identification O-ring sizes based on information contained in the Parker 5700 O-Ring handbook, Design chart 4-1. Pre-DESIGN NOTES: - location of desired thread - location of seal - thread size - inner and outer diameters - plug diameter

- 29. Component Layout and Modeling FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Excel generated BOM (Bill of Materials) spreadsheet indicating: - Quantity - Units - Descriptions - Material composition - File names indicating machining and casting drawings Engineers Sketch of Model 330g-M Inlet Port AutoCAD 2014 generated title block. Including: - part and model number - drawing scale - tolerancing - Bill of Materials

- 30. Component Layout and Modeling FacilityWorkplaceDesign -LayoutGlenwoodJohnson EngineeringSystemsandDesign Model 330g-M INLET PORT Machining Drawing - Created in AutoCAD 2014, file saved as 330g-M P-Inlet valve.dwg - Saved to USB in .PDF format - Dimensioning per MMC tolerancing standards

- 31. Design Skill Projects DesignSkillProjectsGlenwoodJohnson EngineeringSystemsandDesign HVAC Design Skill Sheet. Includes - Level 1 Schematic View of HVAC AHU, ducting measured in CFM, ducting terminals and terminal sizes, duct locations - Schedules, including Mechanical Equipment and Air Terminal Sizes 3D Views of site and Air Handler Unit

- 32. Design Skill Projects DesignSkillProjectsGlenwoodJohnson EngineeringSystemsandDesign Electrical Design Skill Sheet. Includes - Level 1 Schematic View of HVAC AHU, ducting measured in CFM, ducting terminals and terminal sizes, duct locations - Schedules, including Mechanical Equipment and Air Terminal Sizes 3D Views of site and Air Handler Unit

- 33. Design Skill Projects DesignSkillProjectsGlenwoodJohnson EngineeringSystemsandDesign Electrical and Lighting Design Skill Sheet. Includes - Level 1 Schematic View of HVAC AHU, ducting measured in CFM, ducting terminals and terminal sizes, duct locations - Schedules, including Mechanical Equipment and Air Terminal Sizes 3D Views of site and Air Handler Unit