Dhruva Kumar Mishra's Resume - An Experienced Instrumentation Engineer Seeking Senior Roles

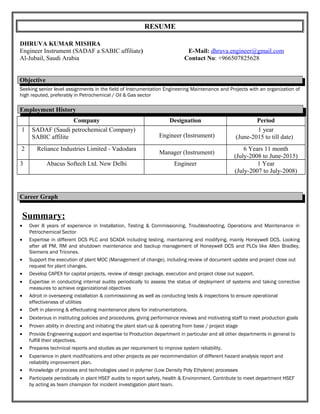

- 1. RESUME DHRUVA KUMAR MISHRA Engineer Instrument (SADAF a SABIC affiliate) E-Mail: dhruva.engineer@gmail.com Al-Jubail, Saudi Arabia Contact No: +966507825628 Objective Seeking senior level assignments in the field of Instrumentation Engineering Maintenance and Projects with an organization of high reputed, preferably in Petrochemical / Oil & Gas sector Employment History Company Designation Period 1 SADAF (Saudi petrochemical Company) SABIC affilite Engineer (Instrument) 1 year (June-2015 to till date) 2 Reliance Industries Limited - Vadodara Manager (Instrument) 6 Years 11 month (July-2008 to June-2015) 3 Abacus Softech Ltd. New Delhi Engineer 1 Year (July-2007 to July-2008) Career Graph Summary: • Over 8 years of experience in Installation, Testing & Commissioning, Troubleshooting, Operations and Maintenance in Petrochemical Sector • Expertise in different DCS PLC and SCADA including testing, maintaining and modifying, mainly Honeywell DCS. Looking after all PM, RM and shutdown maintenance and backup management of Honeywell DCS and PLCs like Allen Bradley, Siemens and Triconex. • Support the execution of plant MOC (Management of change), including review of document update and project close out request for plant changes. • Develop CAPEX for capital projects, review of design package, execution and project close out support. • Expertise in conducting internal audits periodically to assess the status of deployment of systems and taking corrective measures to achieve organizational objectives • Adroit in overseeing installation & commissioning as well as conducting tests & inspections to ensure operational effectiveness of utilities • Deft in planning & effectuating maintenance plans for instrumentations. • Dexterous in instituting policies and procedures, giving performance reviews and motivating staff to meet production goals • Proven ability in directing and initiating the plant start-up & operating from base / project stage • Provide Engineering support and expertise to Production department in particular and all other departments in general to fulfill their objectives. • Prepares technical reports and studies as per requirement to improve system reliability. • Experience in plant modifications and other projects as per recommendation of different hazard analysis report and reliability improvement plan. • Knowledge of process and technologies used in polymer (Low Density Poly Ethylene) processes • Participate periodically in plant HSEF audits to report safety, health & Environment. Contribute to meet department HSEF by acting as team champion for incident investigation plant team.

- 2. • Experience in Participating as team member and chairman for conducting scheduled activities such as RCA, PHA, PSSR and Reliability improvement plan. Core Competency: • Formulating and implementing strategies for achieving annual business goals for the division • Implementing various techniques for cycle time reduction and managing identification of opportunities • Planning and effectuating predictive & preventive maintenance schedules for various equipment / lines • Increasing system up time & equipment reliability and implementing maintenance schedules • Carrying out periodic checks to ensure performance of equipment and maintaining requisite documents • Identifying areas of obstruction & taking steps to rectify the equipment by the help of troubleshooting tools • Managing installation & commissioning of various instrumentations. • Anchoring erection & commissioning of instruments like DCS, PLC and SCADA with field hardware and ensuring completion of project in minimum turnaround time effective resource utilization to maximize the output ORGANIZATIONAL EXPERIENCE Currently working with SADAF (Saudi petrochemical Company) a SABIC affiliate Company, KSA as Maintenance Engineer in Styrene Plant • Looking after all DCS, PLC and Field Instrumentation maintenance in styrene plant. Same responsibility as it was in Reliance Industries Ltd. Worked with Reliance Industries Ltd. (RIL), Vadodara, Gujarat as Maintenance Engineer in Low Density Polyethylene Plant (LDPE) since July 2008 • Accountable for working as Sectional Head – Instrumentation Maintenance and Reliability Engineer in Low Density Poly- Ethylene Plant (LDPE) • Handling installation, testing & maintenance of various field instrument equipment like Pressure, Temperature, Level and flow transmitters, DCS and PLC system. • Managing procurement of various instrumentation equipment & their critical spares • Carrying out cable integrity survey, earthing & bonding survey, other internal audits, thermography of critical equipment like SOV, DCS and PLC Barriers, Panels and electronics card. • Performed root cause analysis for different failures of DCS, PLCs and field instruments. • Served as Team Leader of Dept. and British Safety Council (BSC) Lead Trainer • Functioned as Integrated Management System (IMS) Team Lead and Quality Circle Head of dept. • Functioning as MOC coordinator of LDPE plant for all major/minor projects ensuring compliance of design basis, PO terms, project schedules, cost estimates etc • Exposure in Supply chain management in handling vendor bills and payments, compliance and closure of contracts for all AMC, ARC and OTCs • Managing a group of 8 technicians with proper job allocation on daily basis • Planning lead of Instrument department ensuring compliance of all PdM, PM and corrective maintenance jobs on weekly and monthly basis. • Generation of MIS reports for deviation in project implementation schedules, Daily PM job compliance • Tracking of contractor job performance on daily basis and generating compliance report based on job performance and safety compliance • Implementation of approved MOCs with participation in engineering pre bid, vendor selection • Provided technical support to maintenance and operations department. • Investigate incidents and failure of field instruments and recommend changes. • Process Safety Management (PSM) activities like Process Hazard Analysis (PHA), Plant Startup Safety

- 3. • Review (PSSR), Mechanical Integrity & Quality Assurance (MIQA), Management of Change (MOC), Field Change Over (FCO), Incident Investigation (II), Process Technology (PT), Contractor Safety Management in coordination DUPONT • Calibration and trouble shooting of all type of field instruments, analyzers and lab instruments. • DCS and PLC and F&G System modification and up gradation jobs along with scheduled PM jobs • Checking of Loops, Alarm & Interlock systems • Creating new loops in DCSs as well as in fields as required. • Maintenance of Instruments such as Control Valves, RTD, Thermocouple, Level Transmitter, Pressure Transmitter, various types of Flow meters etc. • Daily Job Planning and working with the SAP for issuing work permit. • Working on bagging control system, Bagging PM & other maintenance jobs. • Working on AMS system for Honeywell DCS, Triconex and Allen Bradley PLC. July’ 07 – July’08 with ABACUS SOFTECH Ltd New Delhi Role: • Maintenance and servicing of smart Card Readers and different security Products. • Worked on designing of Token Management System based on 89C51 microcontroller. • Worked on designing and Programming of Digital Time Clock based on 89C52 microcontroller. • Worked on designing and Programming of Smart Card readers Based on AT89C52 IC having Mother Board RF Module. KNOWLEDGE PURVIEW • Gained exposure to: o Various IS, IEEE, IEC, NEMA, ASTM, hazardous area classification (both European & American), other is codes, standards & practices pertaining to petrochemical, oil & gas/hydrocarbon industries o World class engineering proactive & preventive maintenance activities like PM and PDM scheduling. o World class safety practices, ISO9000/9001, ISO14001, TQM, TPM & various other quality & HSEF standards o Process Safety Management (PSM) activities like Process Hazard Analysis (PHA), Plant Startup Safety Review (PSSR), Mechanical Integrity & Quality Assurance (MIQA), Management of Change (MOC), Field Change Over (FCO), Incident Investigation (II), Process Technology (PT), Contractor Safety Management in coordination DUPONT MAJOR PROJECTS Have experience as team member or team leader in different projects: • Honeywell DCS system up gradation in year 2012-13. Project Description: Since installed GUS (Global User Station) was declared obsolete by vendor so same was upgraded with Experion based system like EST and ESVT. This project includes installation of new Experion station, Experion Server, Domain Controller and Flex station. Hystorization also improves from 10 sec to 1 sec. • Installation of PROGNOST Vibration Monitoring system in Hyper Compressor: Project Description: Installation of two rod drop sensor and one cross head sensor per cylinder with one frame vibration and one trigger sensor in two stage six cylinder hyper compressor. Communication established for the system with DCS to transfer to and fro data required for analysis. • K-Tron system up gradation: Installation and commissioning of new additive feeder as K-Tron system. This includes engineering for loop drawing modification, system installation, dynamic and static calibration, communication with DCS. • Associated for DCS commissioning in Poly Butadiene Rubber Plant from pneumatic to Yokogawa DCS. EDUCATION • B.Tech. (Electronics & Instrumentation) from Shobhit Institue of Engineering and Technology affiliated to Uttar Pradesh Technical University Lucknow UP. in 2007 Certification:

- 4. Done 6 days certified training course on Advance course on Siemens S7 200/300/400 Done 3 days certified training course on Invensys India Ltd (Triconex System) Done 5 days certified training course on Honeywell DCS (Experion Plateform) Done 5 days certified training course on Honeywell DCS (TPS Maintenance) Done 5 days certified training course on Yokogawa DCS (CS-3000) Done 6 days training on PLC and SCADA from Automation & Control System Pune. Got PLC Overview on: Allen Bradley Siemens Mitsubishi Done 30 days Training on Embedded System from CETPA InfoTech Pvt. Ltd. Got Microcontroller Overview on: 1. AT89C2051 2. AT89C2051 IT Skills: Well versed with SAP, ERP and MS Office Suite (Word, Excel and PowerPoint) Educational Qualification Exam Institute Year of passing University/ Board Percentage B. Tech Shobhit Institute of Engineering &Technology 2007 U.P.T.U. 77.7% HSC Govt. Queens College Varanasi 2001 U. P. Board 63% SSC Govt. Queens College Varanasi 1999 U. P. Board 76.6% Extra Curricular Activity • Participated in different singing competition. • Won 2nd prize Circuit Debugging competition at college level. • Got Best Embedded System student award. • Got Pratibha Samman Award from Meerut Engineering Association • Got two times One Team recognition from current company Other Details Current CTC : 16000 SAR per month Total experience : 8.6 years Notice period : 1 month Passport No. : K8635950 Skye ID : dhruvagreat Personal Details Date of Birth : 1st Aug 1983 Father’s name : Late. Shree Karam Chand Mishra Mother’s name : Mrs. Nirmala Mishra Hobbies : Listening Music, Cooking Marital status : Married Languages known : English, Hindi Present Address : C-755, Sector-1, IPCL Township, Vadodara, Gujarat-391345 Permanent Address : 242 Mahila Silaee Kendra, PO Industrial Estate Lahartara Varanasi, Uttar Pradesh, India

- 5. Declaration I hereby declare that all the particulars stated above are true to the best of my knowledge and belief. Yours faithfully, Dhruva Kumar Mishra

- 6. Declaration I hereby declare that all the particulars stated above are true to the best of my knowledge and belief. Yours faithfully, Dhruva Kumar Mishra