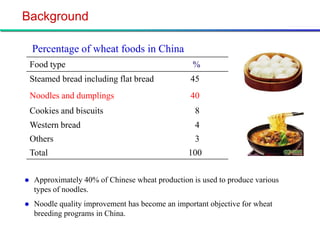

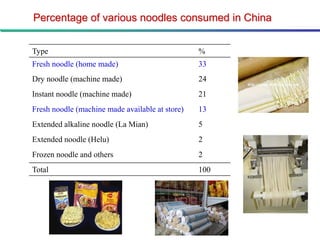

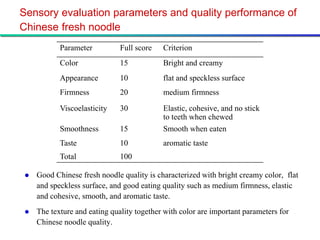

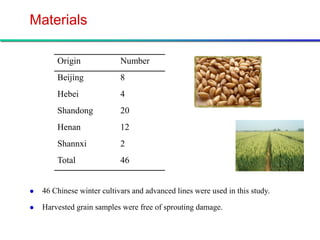

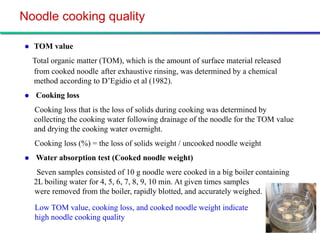

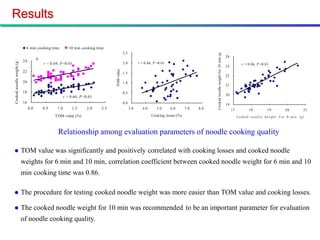

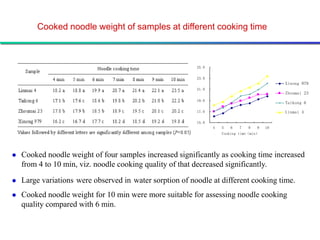

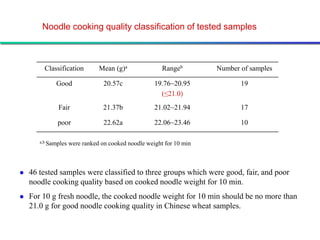

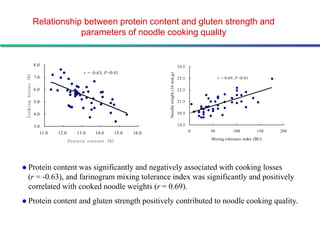

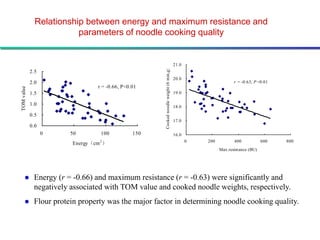

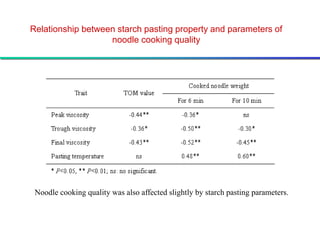

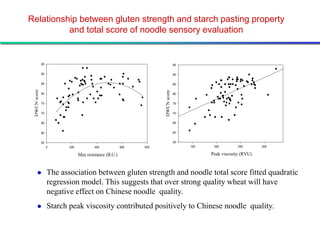

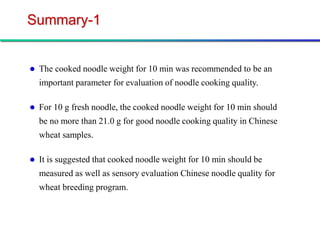

This document summarizes research on evaluating the cooking quality of Chinese fresh noodles. It finds that the cooked noodle weight after 10 minutes of cooking is a good parameter for assessment. Noodles of good quality absorbed less water, retaining a weight of 21 grams or less for 10 grams of fresh noodles. Flour protein content and gluten strength positively impacted cooking quality, while starch pasting properties had a smaller effect. Flour with medium protein, gluten strength, and starch viscosity produced the best quality noodles according to sensory tests.