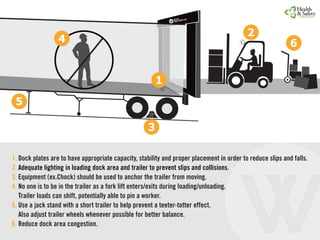

The document outlines safety precautions for loading docks, emphasizing the need for proper equipment, adequate lighting, and maintenance to prevent slips, falls, and accidents. It advises on the use of dock plates with appropriate capacity, trailer anchoring, and minimizing congestion in dock areas. Regular checks and repairs of equipment and infrastructure are essential to maintain safety standards.