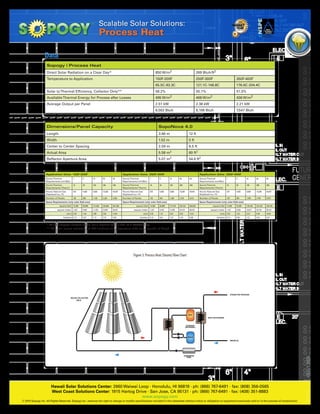

Sopogy provides concentrating solar power technologies to help customers meet renewable energy goals and reduce costs. Their MicroCSP systems can provide thermal process heat in the range of 200-400°F to supplement existing needs and reduce natural gas demand, particularly for agricultural and industrial operations. MicroCSP offers advantages over fossil fuels by offsetting gas/propane while providing emissions-free high-quality heat for applications like food preparation, industrial processes, material drying, and improving plant efficiency.