Embed presentation

Downloaded 32 times

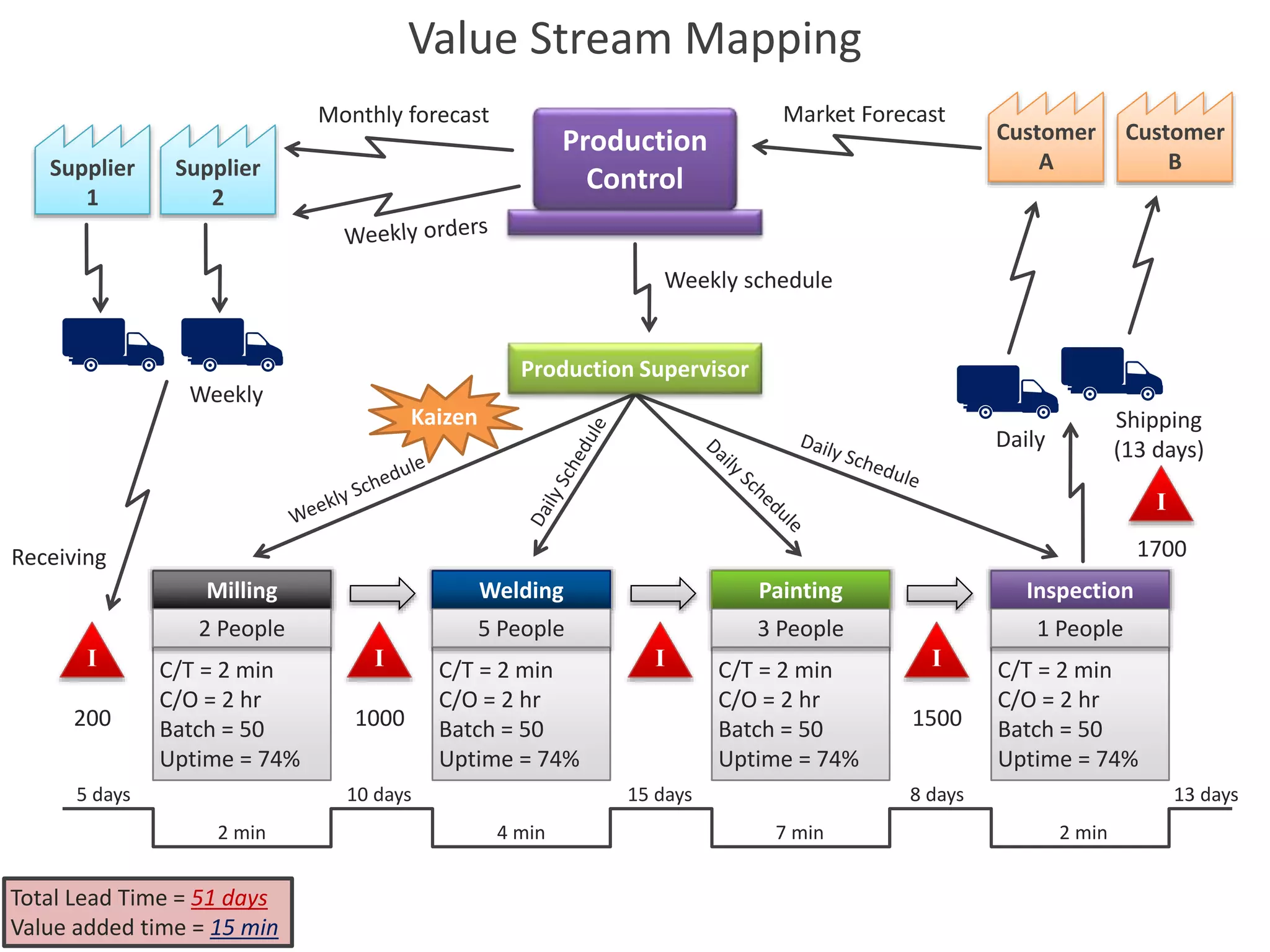

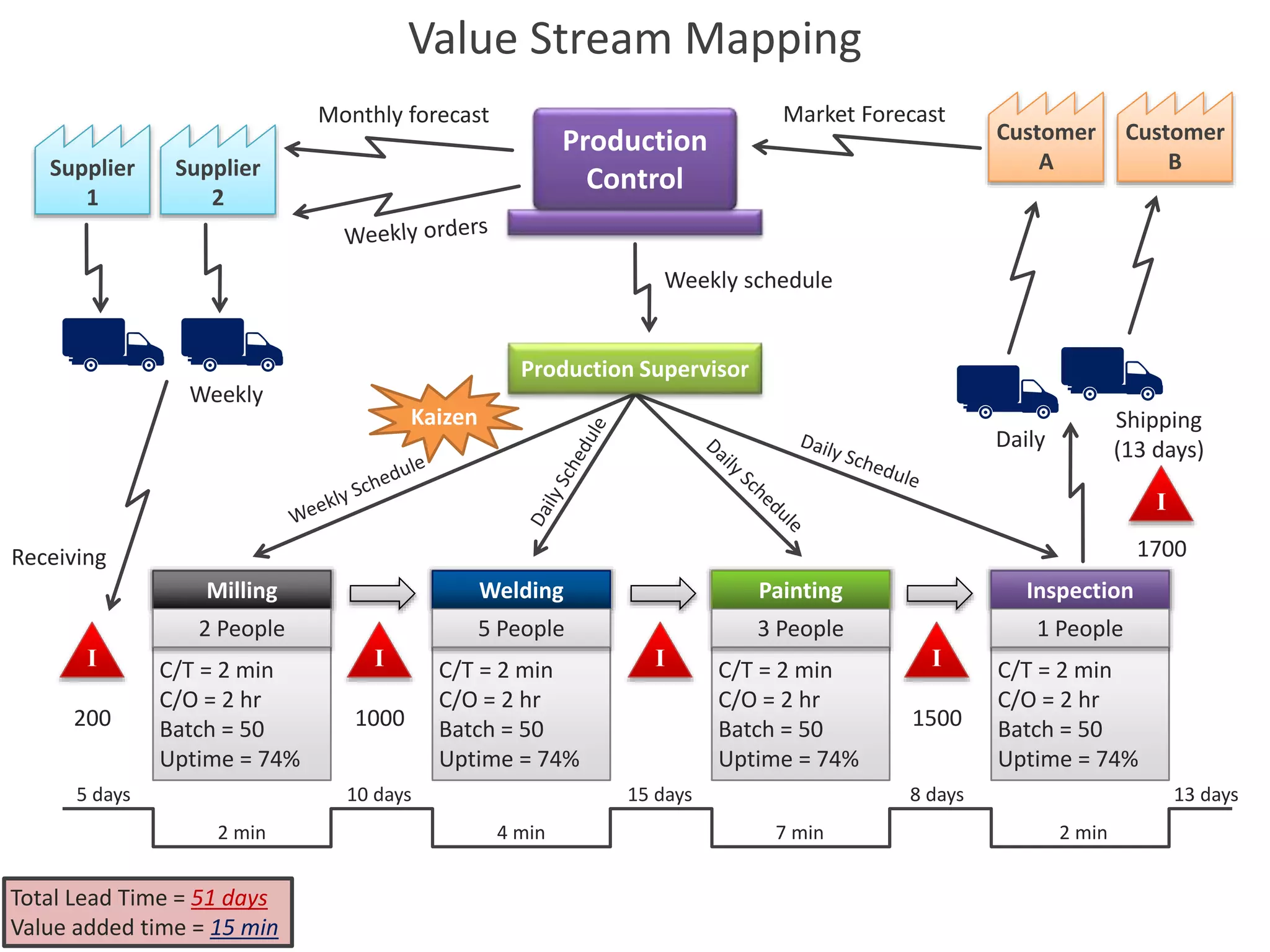

This value stream map outlines the production process for a product from two suppliers through receiving, milling, welding, painting, and inspection before being shipped to two customers. The process takes 51 days total from start to finish with only 15 minutes of value-added time and involves receiving raw materials from suppliers, batch processing through each stage, and shipping the finished goods to customers over 13 days on average.