Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

IRJET- Optimal Riser Design for Sand Casting of Drop Ball using Constraint Op...

IRJET- Optimal Riser Design for Sand Casting of Drop Ball using Constraint Op...

15665658 square-cup-deep-drawing-using-forming-limit-diagram

15665658 square-cup-deep-drawing-using-forming-limit-diagram

Dr.R.Narayanasamy - Power Point on Powder Compaction

Dr.R.Narayanasamy - Power Point on Powder Compaction

Comparison of performance of coated carbide inserts with uncoated carbide

Comparison of performance of coated carbide inserts with uncoated carbide

DESIGN & DEVELOPMENT OF CONVEYOR CHAIN OUTER LINK BY USING COMPOSITE MATERIAL

DESIGN & DEVELOPMENT OF CONVEYOR CHAIN OUTER LINK BY USING COMPOSITE MATERIAL

Dimensional Control and Formability in Impact Forming

Dimensional Control and Formability in Impact Forming

Material Selection of Smartphone Body Shell [Autosaved].ppt 2![Material Selection of Smartphone Body Shell [Autosaved].ppt 2](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Material Selection of Smartphone Body Shell [Autosaved].ppt 2](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Material Selection of Smartphone Body Shell [Autosaved].ppt 2

Lec 18 19 -flexural analysis and design of beams-2007-r

Lec 18 19 -flexural analysis and design of beams-2007-r

Study of roller burnishing process on aluminum work pieces using design of ex...

Study of roller burnishing process on aluminum work pieces using design of ex...

Design and detailing_of_retaining_walls counter fort.تصميم الجدران الاستنادية...

Design and detailing_of_retaining_walls counter fort.تصميم الجدران الاستنادية...

Viewers also liked

Viewers also liked (6)

Stress analysis of storage tank piping - Jeba Anand

Stress analysis of storage tank piping - Jeba Anand

Similar to PIPE SIMULATION AND STRESS ANALYSIS

Similar to PIPE SIMULATION AND STRESS ANALYSIS (20)

Design & Development of Rotating Work-piece Holding Mechanism for EDM Process

Design & Development of Rotating Work-piece Holding Mechanism for EDM Process

Failure analysis of the reducer nipple of a propylene gas tank in a petrochem...

Failure analysis of the reducer nipple of a propylene gas tank in a petrochem...

Design and Manufacturing of Press Tools for Compressor Shell

Design and Manufacturing of Press Tools for Compressor Shell

Optimization of MRR in EDM Process with Different Job Material i.e Stainless ...

Optimization of MRR in EDM Process with Different Job Material i.e Stainless ...

Research Inventy : International Journal of Engineering and Science

Research Inventy : International Journal of Engineering and Science

Optimization of Weld Bead Geometry in Submerged Arc Welds Deposited On En24 S...

Optimization of Weld Bead Geometry in Submerged Arc Welds Deposited On En24 S...

08-Strength of Welded Connections (Steel Structural Design & Prof. Shehab Mou...

08-Strength of Welded Connections (Steel Structural Design & Prof. Shehab Mou...

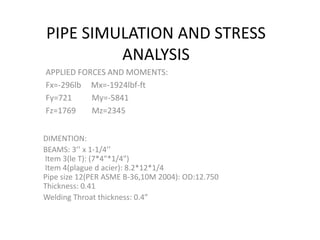

PIPE SIMULATION AND STRESS ANALYSIS

- 1. PIPE SIMULATION AND STRESS ANALYSIS APPLIED FORCES AND MOMENTS: Fx=-296lb Mx=-1924lbf-ft Fy=721 My=-5841 Fz=1769 Mz=2345 DIMENTION: BEAMS: 3’’ x 1-1/4’’ Item 3(le T): (7*4"*1/4") Item 4(plague d acier): 8.2*12*1/4 Pipe size 12(PER ASME B-36,10M 2004): OD:12.750 Thickness: 0.41 Welding Throat thickness: 0.4”

- 3. 2-D DRAWING

- 4. RED ARROWS: FORCES AND MOMEMNTS YELLOW ARROWS: SURFACE INDICATORS

- 5. MECHANICAL PROPERTIES: Sub-Category : Cast Iron60 Material Type : IsotropicMaterial Mass Density (RHO) : 7.469e-006kg/mm^3 ======== Mechanical Young's Modulus (E) : 131000000mN/mm^2(kPa) Poisson's Ratio (NU) : 0.25 ======== Strength Yield Strength : 130000mN/mm^2(kPa)

- 6. POST PROSSESING: VON-MISSES STRESS Max: 8.2 E+004 Min:1.3 E+001

- 9. AVARAGE STRESS IN CRITICAL AREA Solution Name : 15.07_sim1 : Solution 1 Load Case : Subcase - Static Loads 1 Iteration : Static Step 1 Result : Stress - Elemental, Unaveraged Units : mN/mm^2(kPa) Coordinate System : Absolute Rectangular Elem ID X Coord Y Coord Z Coord Von-Mises 17721 12.854E+0 2.405E+0 16.23314 72.168E+3 17724 12.853E+0 1.959E+0 16.23365 68.754E+3 17759 12.906E+0 2.995E+0 16.19497 58.681E+3 19192 1.332E+0 2.207E+0 16.3736 57.167E+3 19216 1.312E+0 1.918E+0 16.3202 77.818E+3 19297 12.485E+0 1.927E+0 16.35486 76.433E+3 Minimum 57.167E+3 Elem ID 19192 Maximum 77.818E+3 Elem ID 19216 Column Sum 411.021E+3 Column Avg 68.504E+3

- 10. SUMMARY: 1. MAXIMUM ELEMENT STRESS IS 8.2 E+004 Kpa WHICH IS LESS THAN THE MATERIAL YIELD STRENGTH 2. AVARAGE STRESS IN CRITICAL AREA IS 68 E+004 Kpa SO BY CAMPARING WITH THE MATERIAL YIELD STRENGTH, SYSTEM WOULD BE SAFE WITH SAFTY FACTOR 2. 3. WELDING THROAT THICKNESS MUST BE MINIMUM 0.5” OR MORE