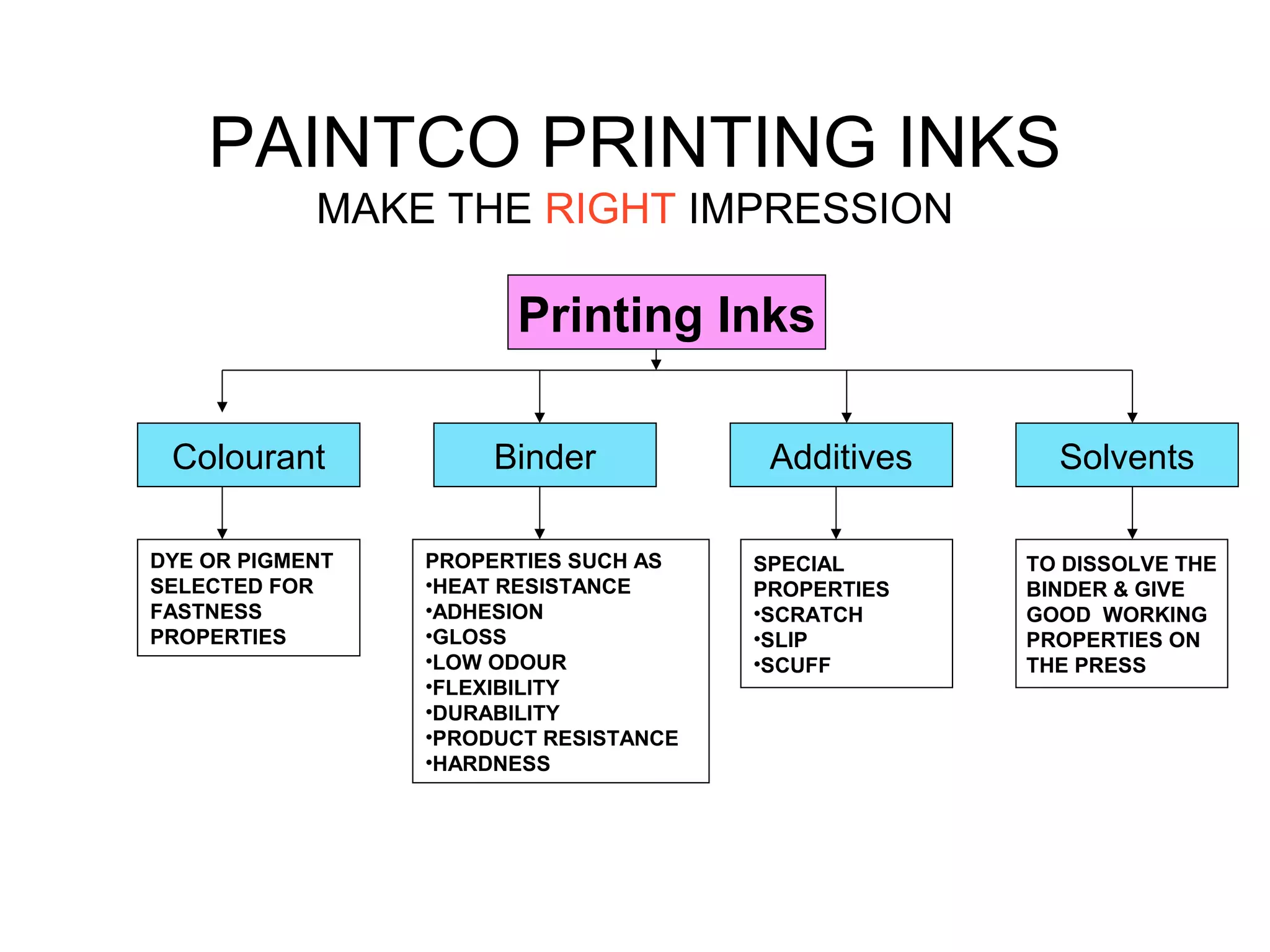

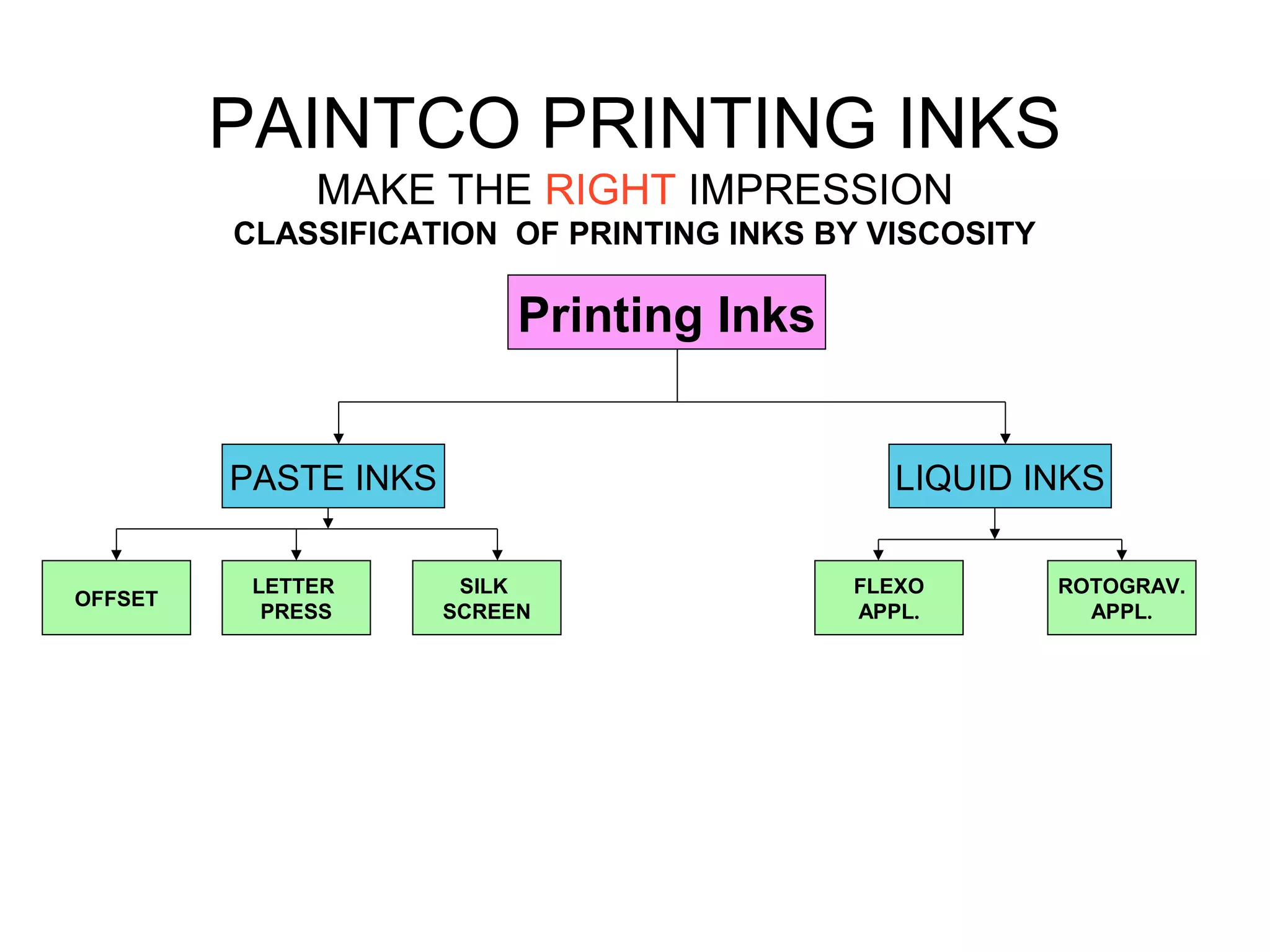

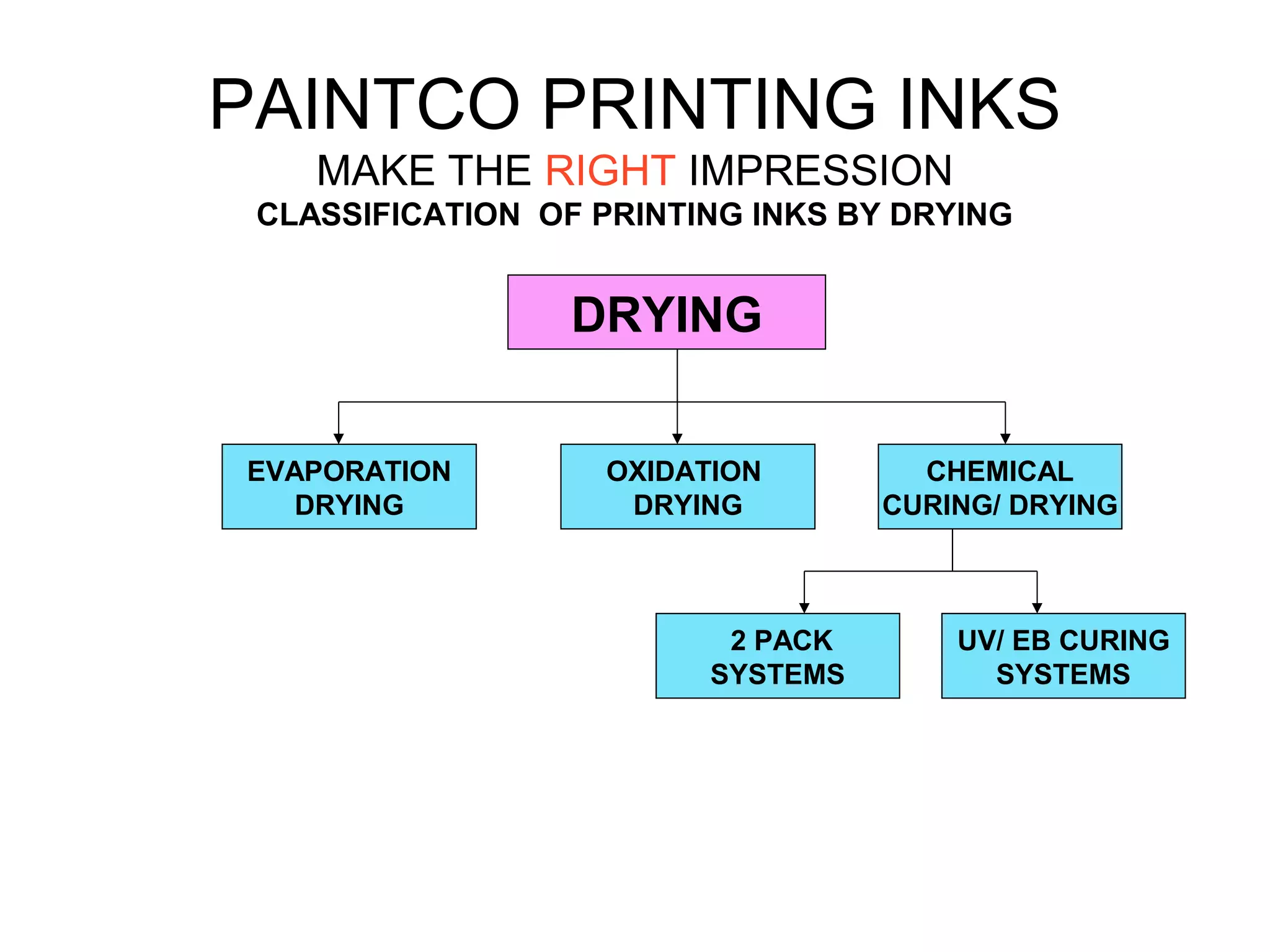

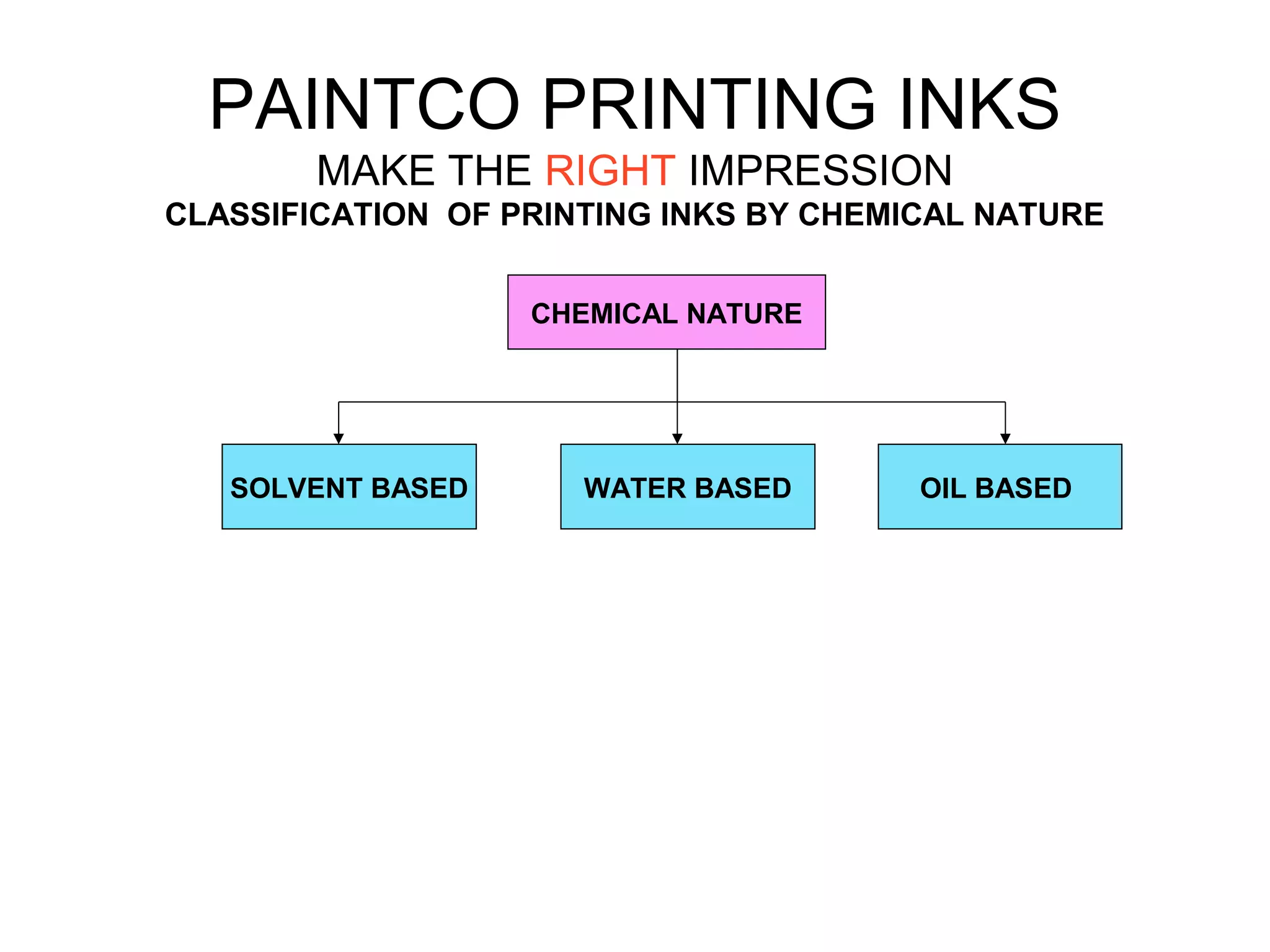

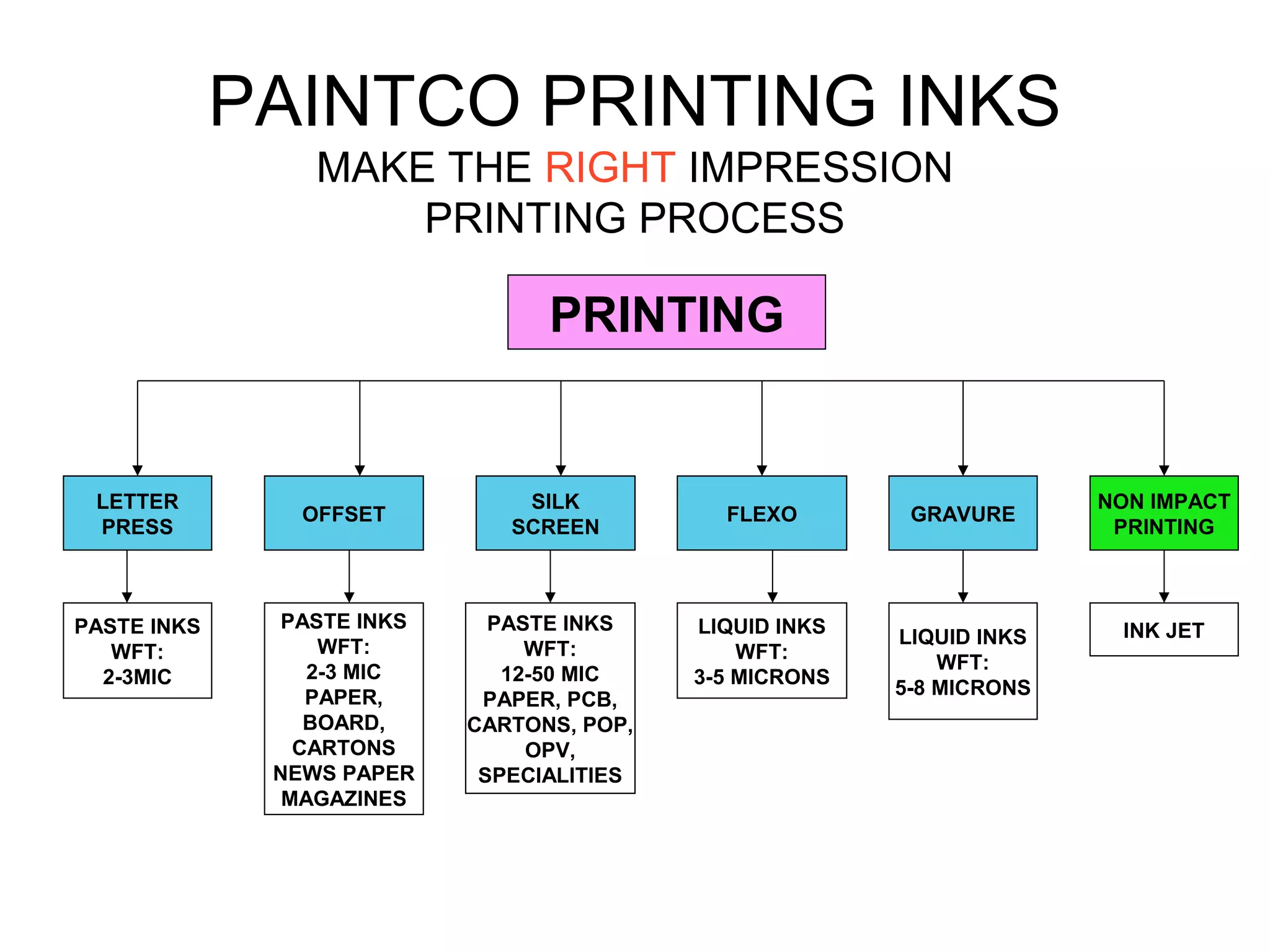

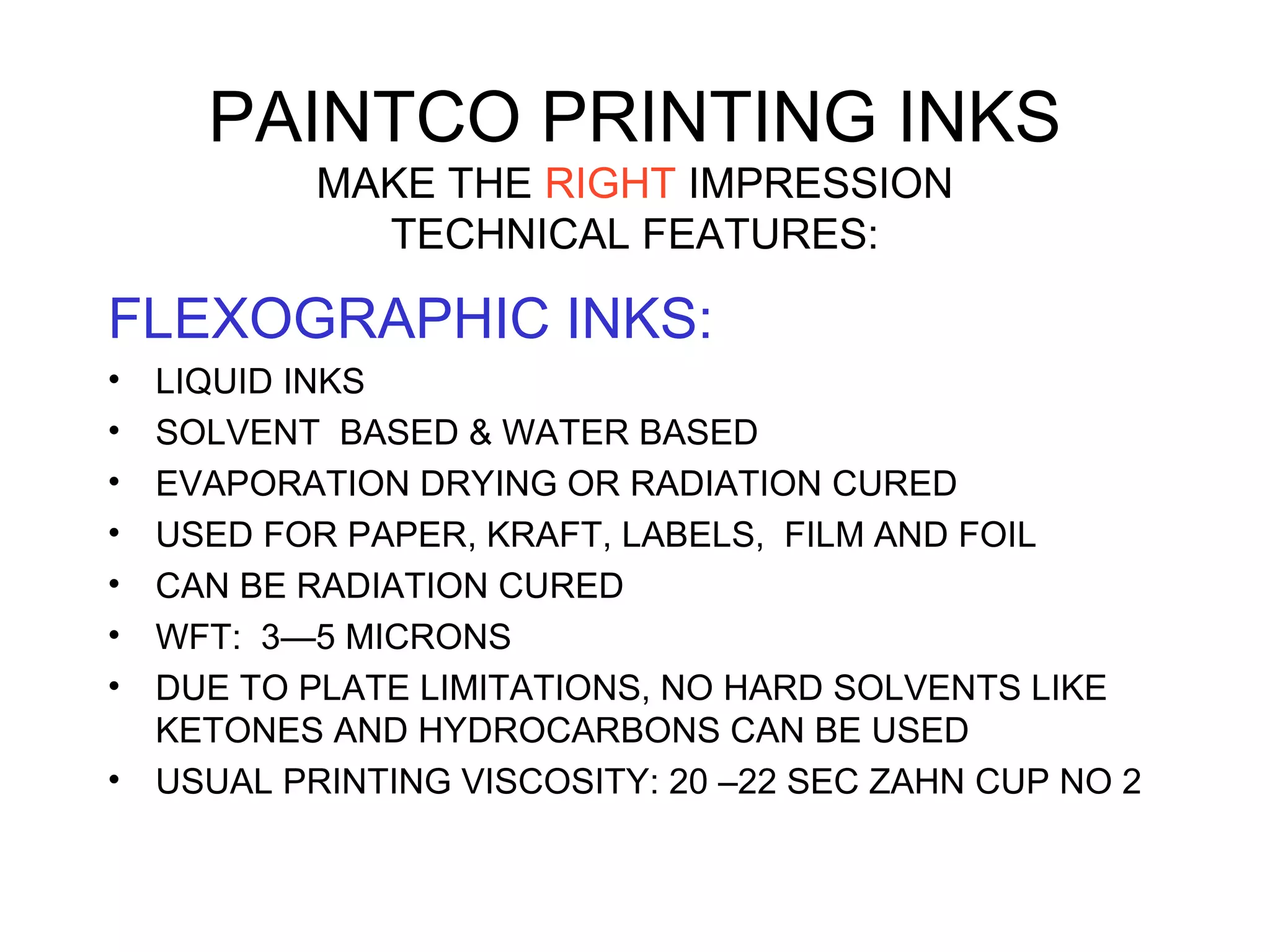

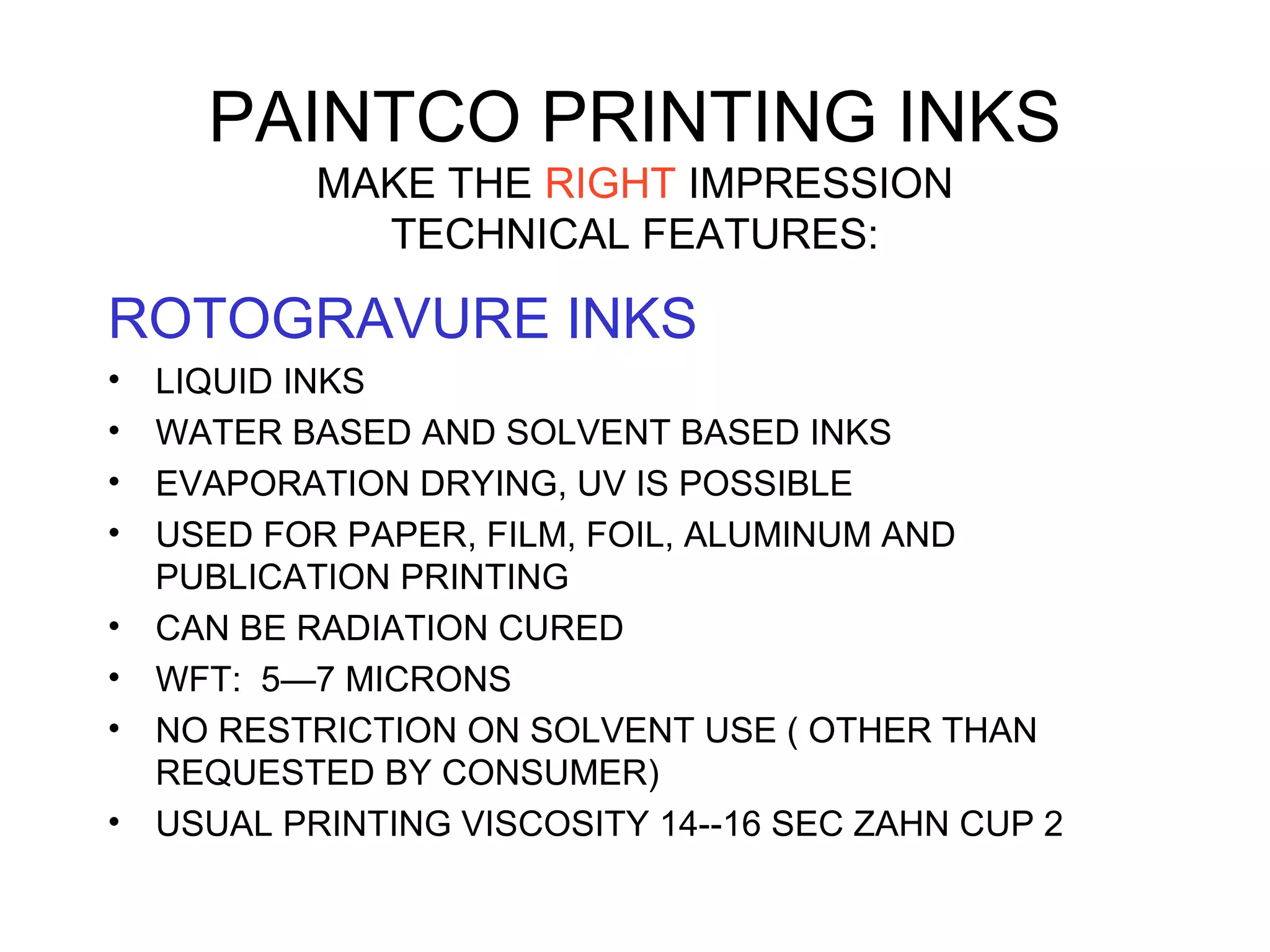

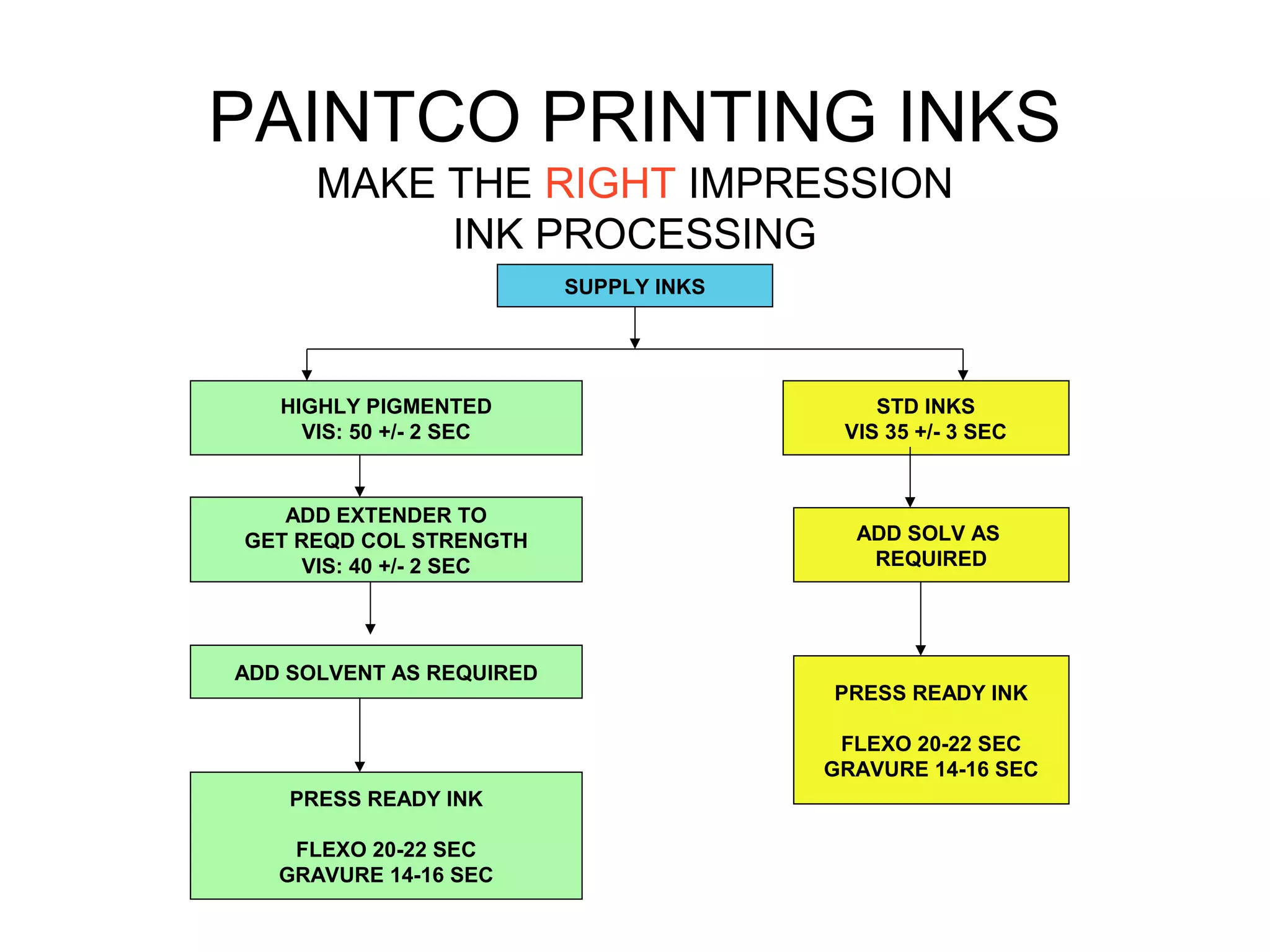

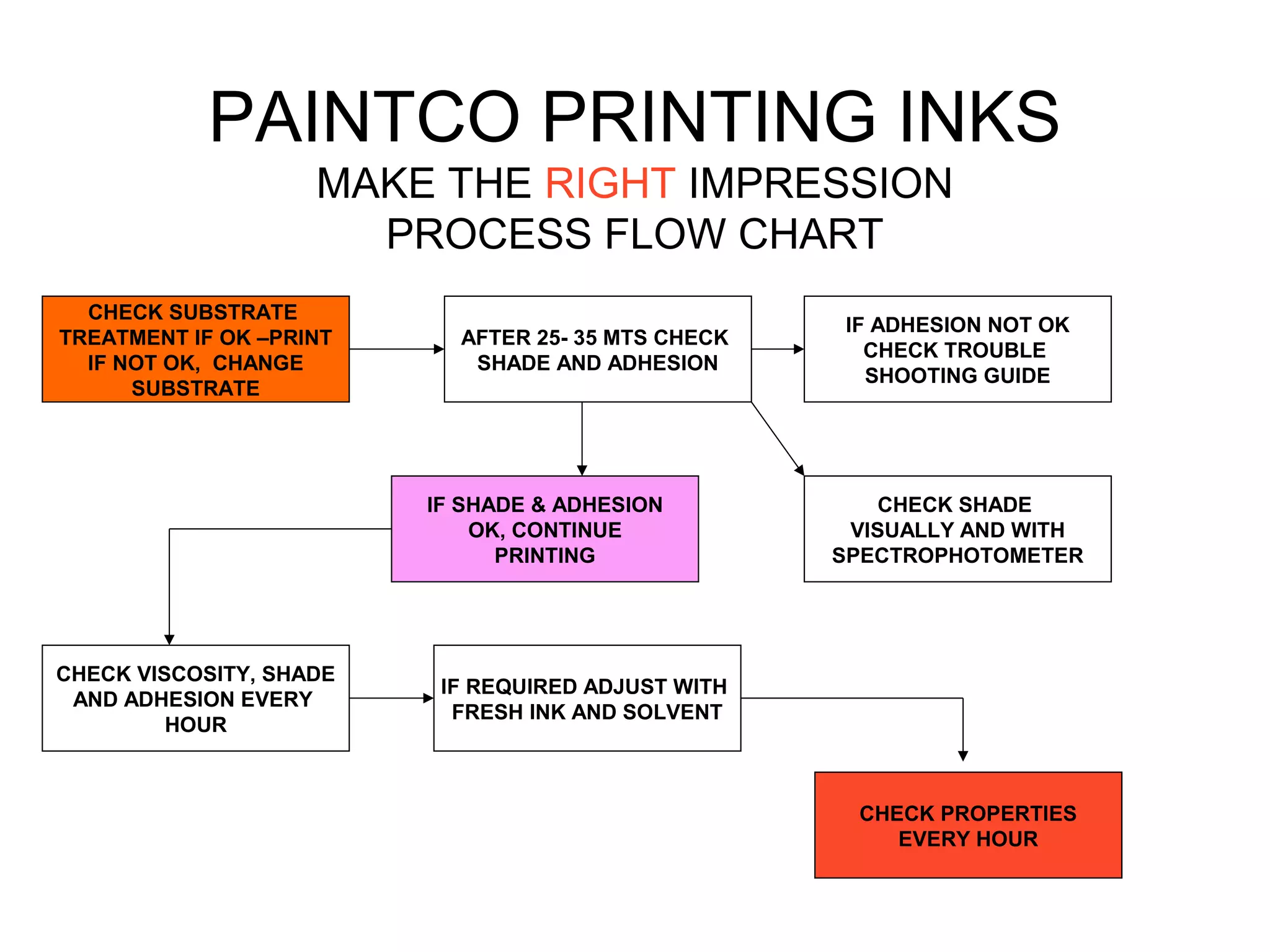

The document discusses different types of printing inks used in various printing processes. It describes the key components of printing inks including solvents, binders, colorants and additives. It then classifies printing inks based on viscosity, drying method and chemical nature. Specific details are provided about letterpress, offset, silk screen, flexographic and gravure inks as well as recommended viscosity for different processes. Processing steps like adjusting viscosity and adding solvents/extenders are also summarized.