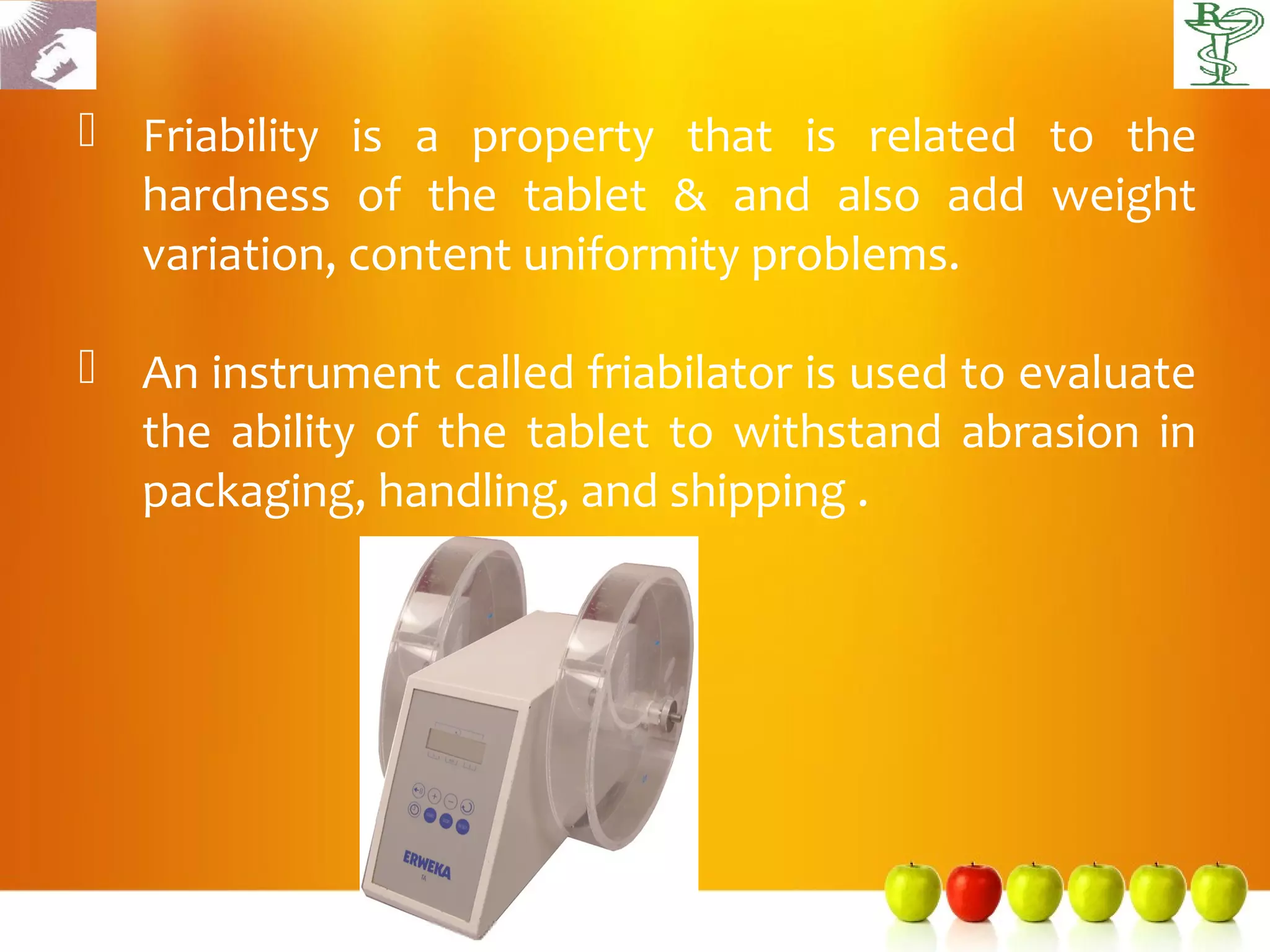

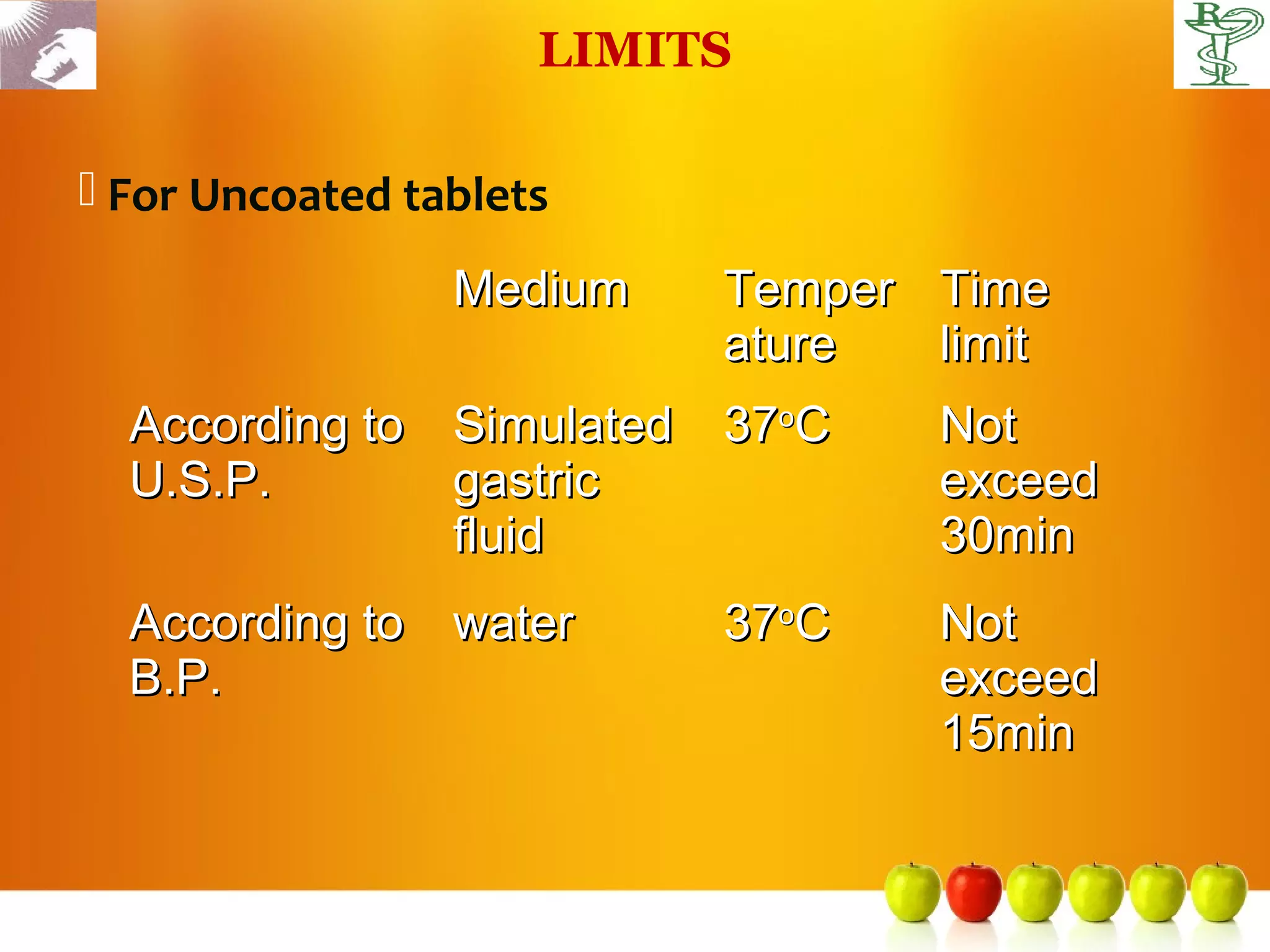

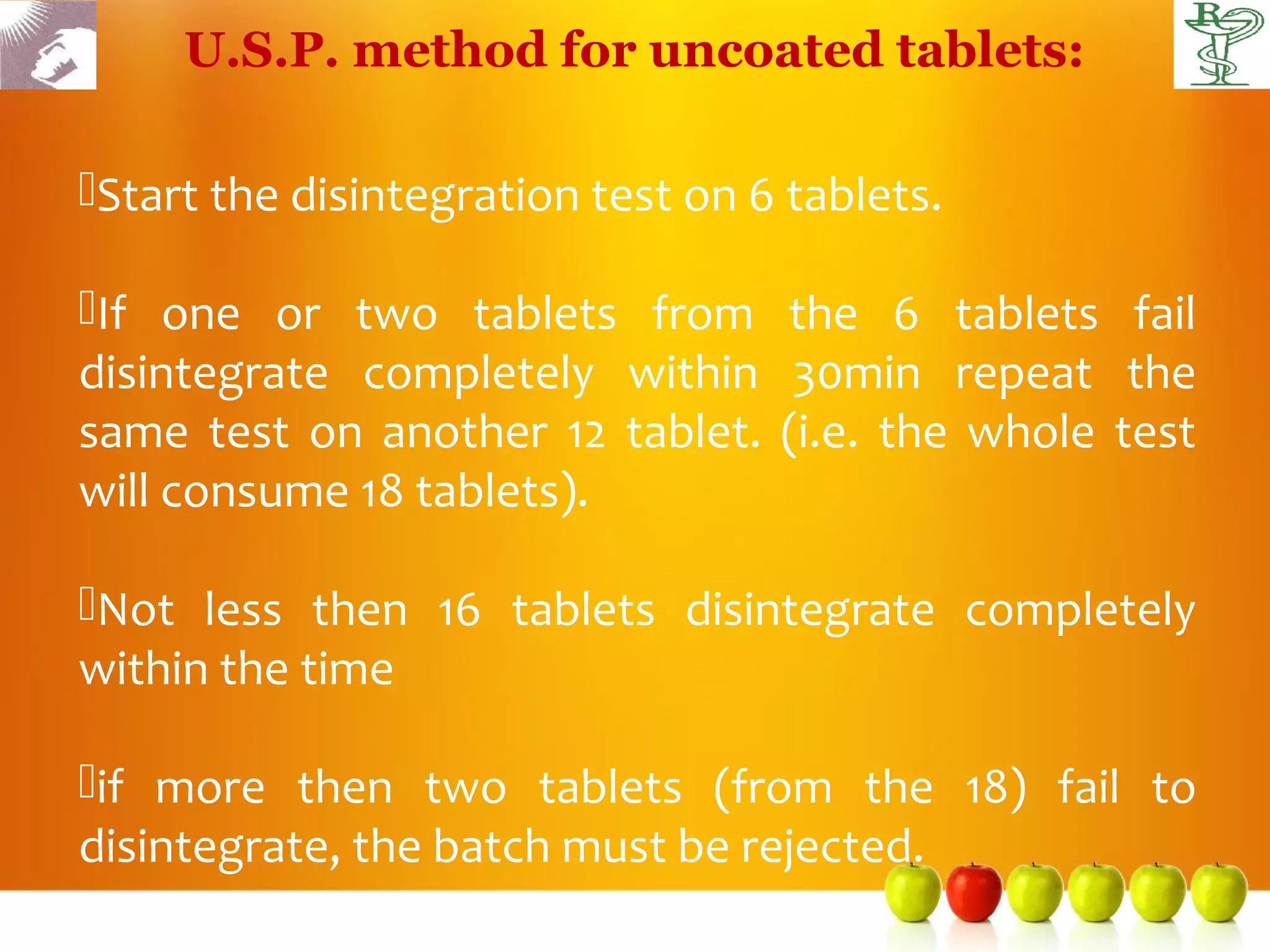

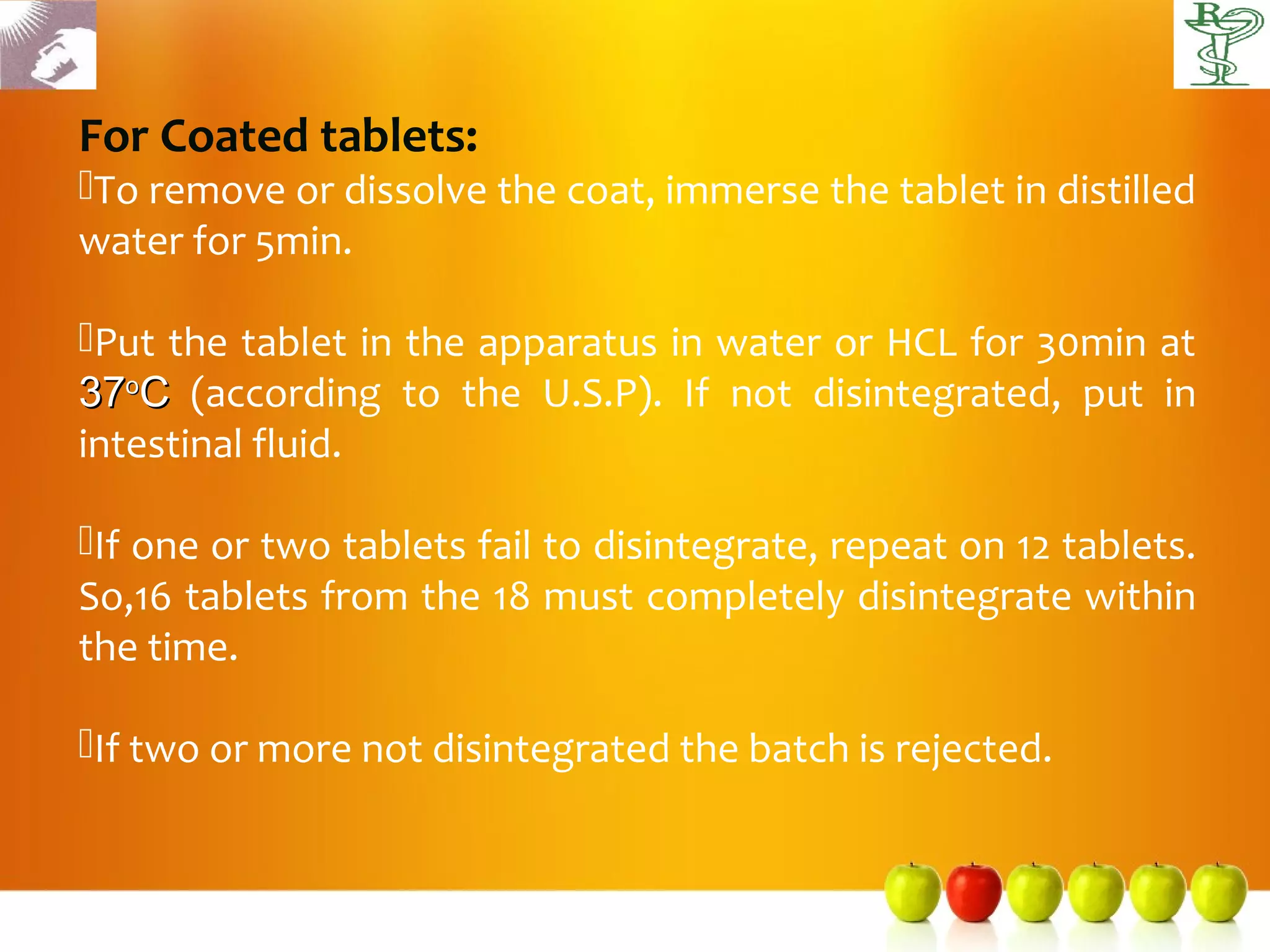

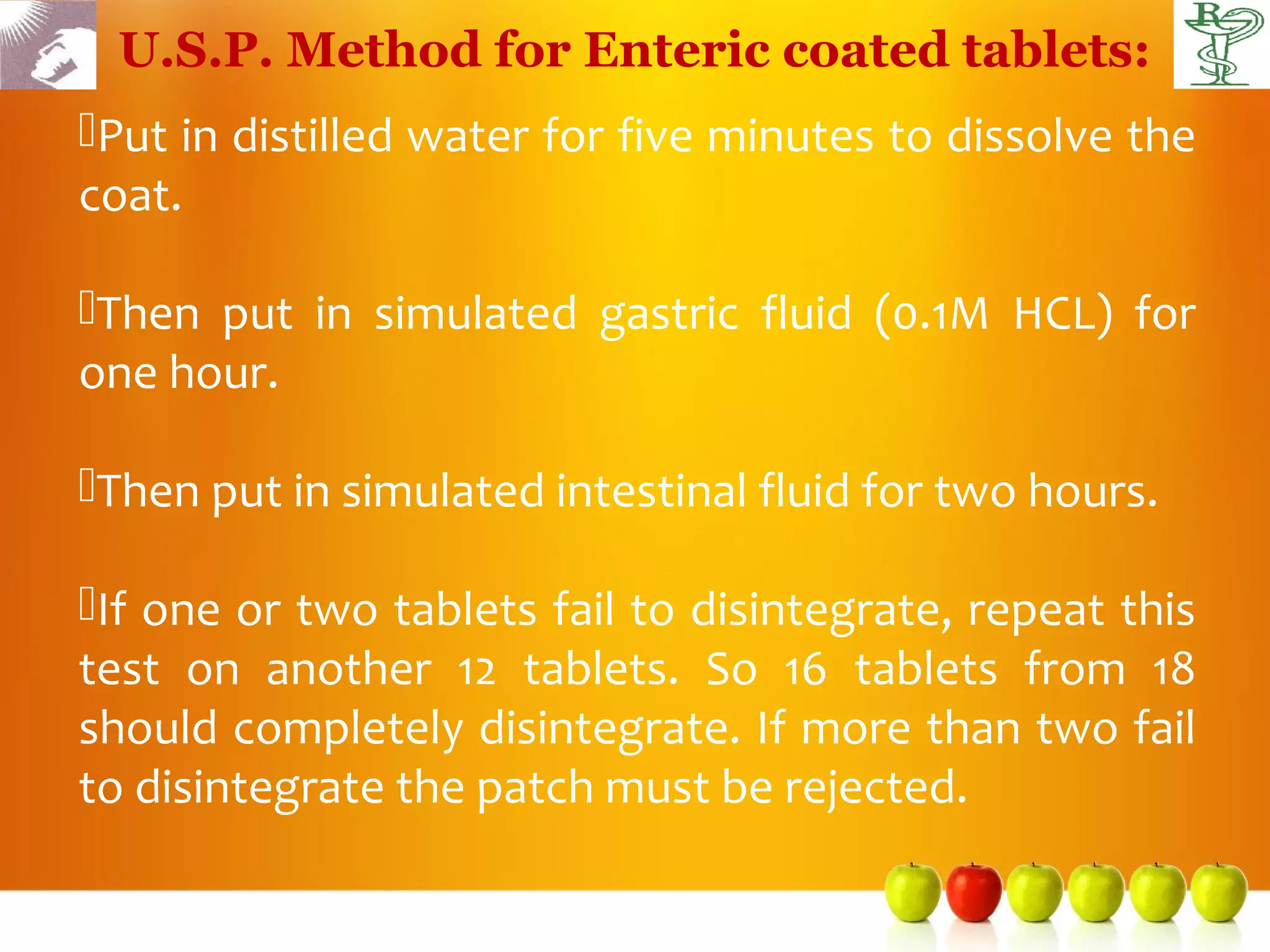

The document discusses various quality control tests that are performed on tablets during manufacturing, including tests for general appearance, hardness, friability, weight variation, content uniformity, disintegration and dissolution. It provides details on procedures and limits for these tests according to pharmacopoeial standards like the British Pharmacopoeia, Indian Pharmacopoeia and United States Pharmacopoeia. The tests are important to ensure tablets meet requirements for reproducibility, stability and accurate dosing of the active drug.